Precast reinforced concrete hollow lateral-force resisting pile and pile embedding method

A technology of anti-lateral force and reinforced concrete, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc., can solve the problems of low cost, low bending resistance, insufficient rigidity, etc., and achieve low cost and strong bending and shearing resistance , The effect of increasing the overall bending and shearing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

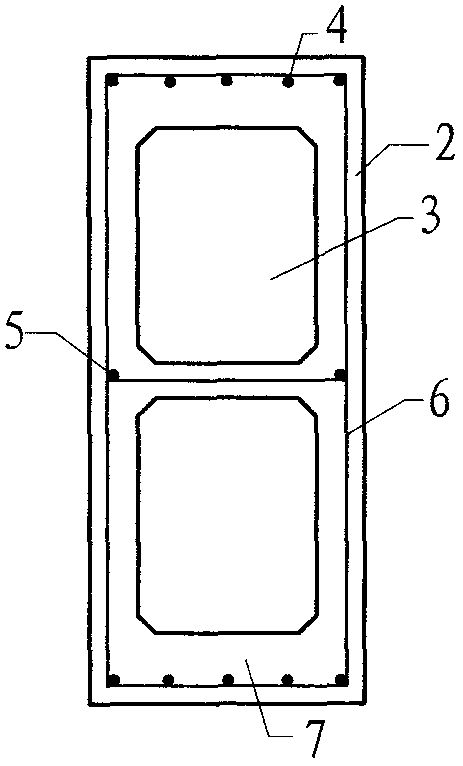

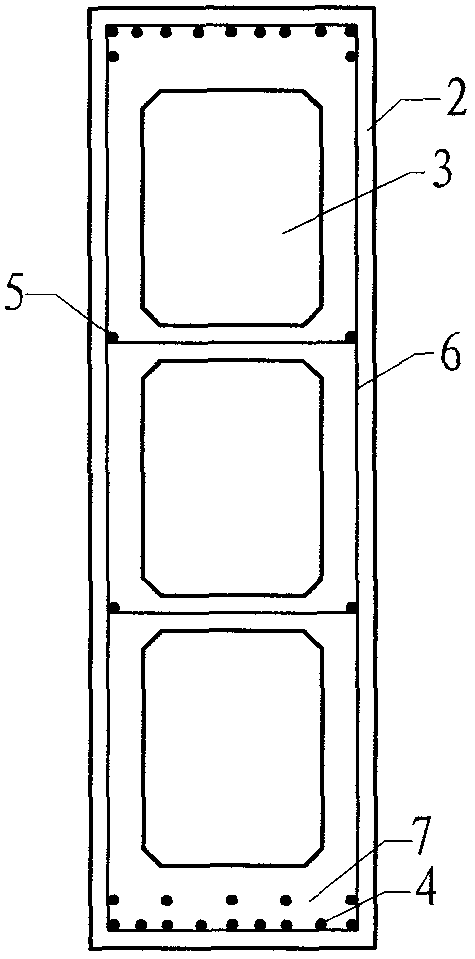

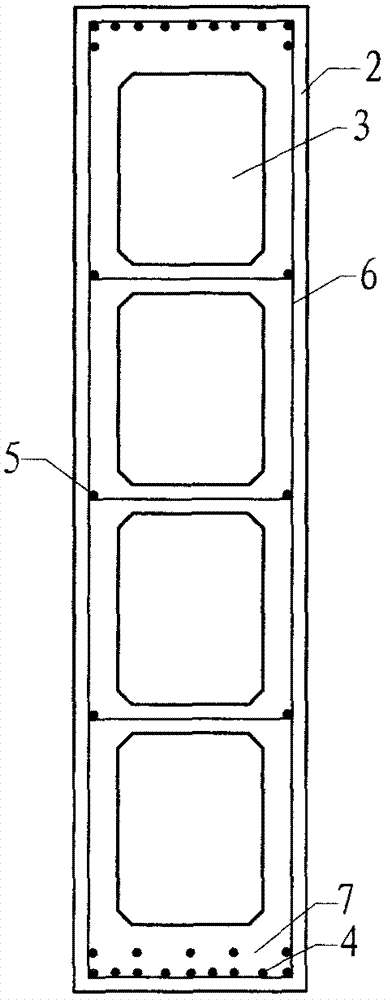

[0058] Such as figure 1 As shown, a prefabricated reinforced concrete hollow anti-lateral force pile includes a pile body 2 with a rectangular cross section, the pile body 2 has a steel cage, and an empty stomach area 3 that runs through the entire pile body is provided along the longitudinal axis of the pile body 2; The reinforcement cage includes a plurality of prestressed main reinforcements 4 , abdominal reinforcements 5 and stirrups 6 .

[0059] The two ends of the long sides of the rectangular section of the pile body 2 are thickened areas 7, which are concrete thickened areas, and the main reinforcements 4 that are mainly stressed are arranged in the thickened areas 7 at both ends. Since the main stress tendons are located at both ends of the rectangular section of the pile body 2, the effective height of the section against bending can be greatly increased, thereby greatly increasing the bending strength and rigidity of the pile body 2. The main reinforcement 4 genera...

Embodiment approach 1

[0070] Implementation scheme 1: direct pile-planting method with loose soil at the pile tip.

[0071] This implementation method utilizes a special pile machine, uses multi-axis rotary spraying to loosen the soil and multi-axis vibrating to loosen the soil to introduce holes at the front of the pile, and directly implants the prefabricated reinforced concrete hollow anti-lateral force pile. The specific instructions are as follows:

[0072] 1. Multi-axis rotary grouting to loosen the soil and directly plant piles

[0073] Such as Figure 21 As shown, the pile planting method is to use the specially developed multi-axis rotary nozzle 9 drill pipe 8 to insert and pass through the fasting area 3 of the prefabricated reinforced concrete hollow anti-lateral force pile, and start the multi-axis rotary jet drill pipe 8 after positioning. The soil at the pile end is cut with high-pressure grout to destroy the soil at the pile end. Under the action of the gravity of the pile body (w...

Embodiment approach 2

[0076] Implementation plan two: preformed hole pile planting method

[0077] This implementation method is to use a specially developed pile planting machine, which can be specifically punching and grabbing hole pile planting method and rotary digging hole hole pile planting method. The specific instructions are as follows:

[0078] 1. Punching and grabbing hole-forming pile planting method

[0079] Such as Figure 24-25 As shown, this pile planting method is to grab the hole head 12 with special punching first, and this hole head can be a common punching head similar to the underground diaphragm wall, and make appropriate improvements on the hole size (enlarge or reduce the punching head). Grab head size), so that the size of the hole is consistent with the size of the implanted prefabricated reinforced concrete fasting anti-lateral force pile, and each side is about 5 to 10 cm more. The hole forming process should be divided into dry operation and wet operation according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com