Novel composite floor system for super high-rise building

A composite floor and multi-storey building technology, which is applied in the direction of load-bearing elongated structural components, buildings, building components, etc., to achieve the effect of saving building space loss, reducing the amount of reinforcement and concrete, and improving comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

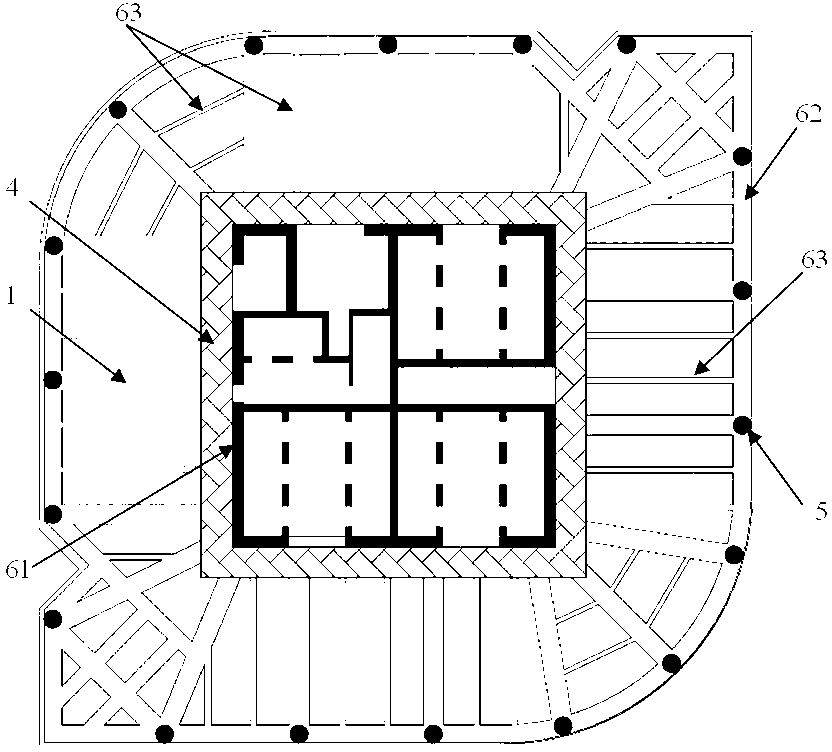

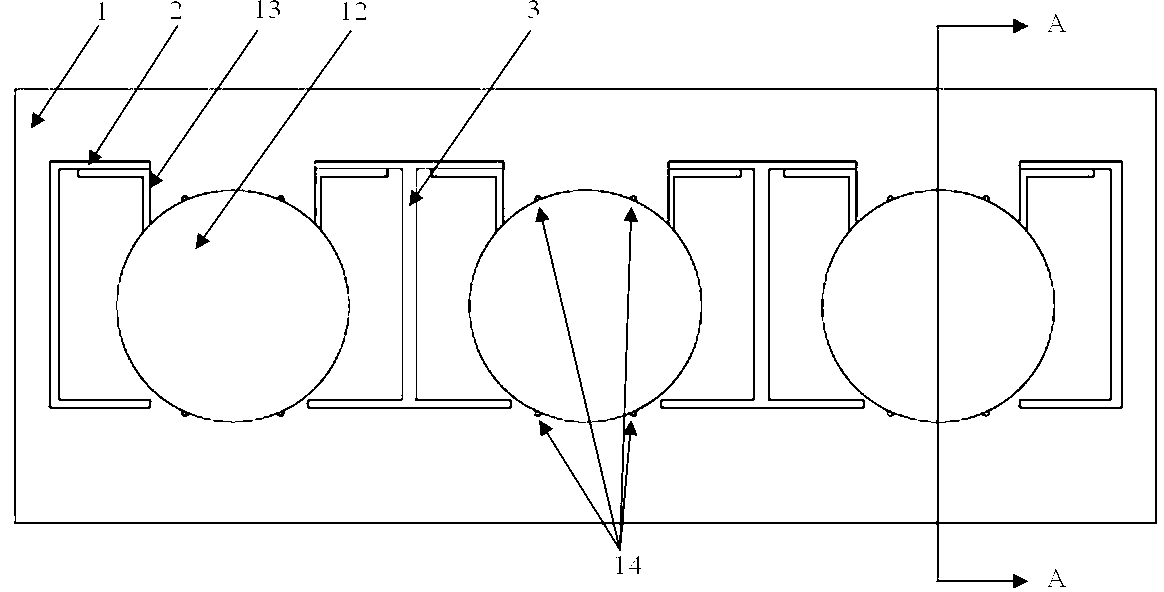

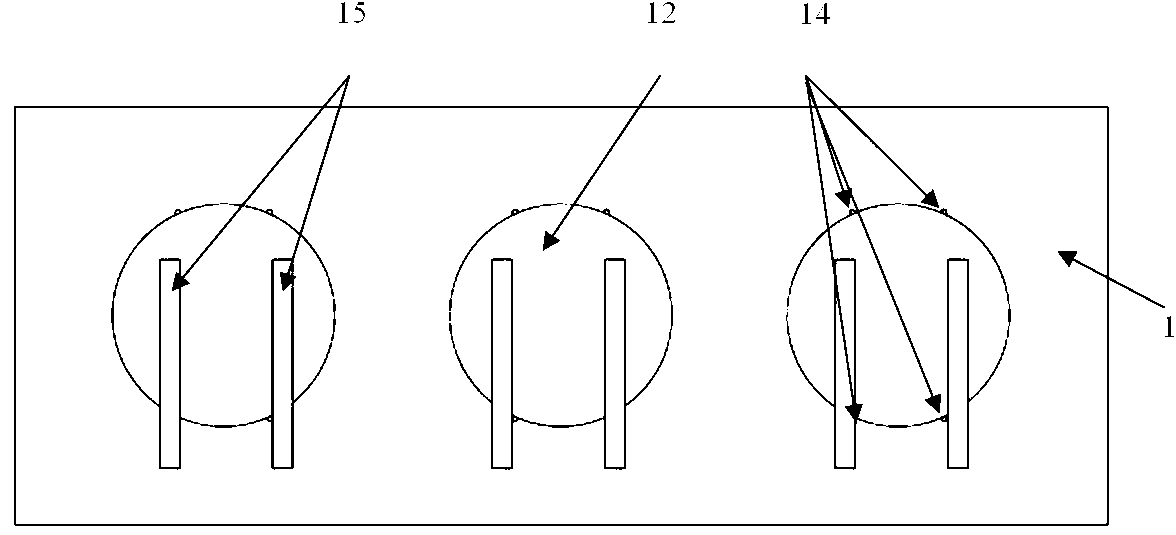

[0028] see figure 1 , a new type of composite floor system for super high-rise buildings, including an inner support wall 61, an outer support wall 62 and floor slabs, and steel tube concrete columns 5 are evenly distributed in the outer support wall 62, and each part of the surface of the super high-rise building The top of the storey is provided with an inter-story composite floor assembly; the inter-story composite floor assembly is composed of core tube wall cap 4 and beams, see Figure 8 and Figure 9 ,in,

[0029] The core tube wall cap 4 is a closed annular frame body, the thickness of the core tube wall cap 4 is between 450~300mm, the width of the core tube wall cap 4 is between 2000~3000mm, and the perimeter profile of the core tube wall cap 4 Match the outline of the supporting wall 61 in the building; the core tube wall cap 4 is constructed by steel bars; the top surface of the core tube wall cap 4 is connected with the ceiling of the floor, that is, the floor sl...

Embodiment 2

[0040] see figure 1 , a new type of composite floor system for super high-rise buildings, including an inner support wall 61 and an outer support wall 62, inside the outer support wall 62 there are uniformly distributed steel tube concrete columns 5, and on each floor of the super high-rise building surface There is an inter-story composite floor assembly on the top; the inter-story composite floor assembly is composed of core tube wall cap 4 and beams, see Figure 8 and Figure 9 ,in,

[0041] The core tube wall cap 4 is a closed annular frame body, the thickness of the core tube wall cap 4 is between 450~300mm, the width of the core tube wall cap 4 is between 2000~3000mm, and the perimeter profile of the core tube wall cap 4 Match the profile of the supporting wall 61 in the building; the top surface of the core tube wall cap 4 is connected with the ceiling of the floor, and the inner side of the core tube wall cap 4 is closely connected with the outer wall of the inner s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com