Cantilever supporting structure combining sheet pile and T-shaped thin-wall pile

A technology for supporting structure and sheet piles, which is applied in basic structure engineering, coastline protection, excavation, etc., can solve the problems of small deformation economy, high cost of supporting structure, poor safety, etc. Beautiful and simple, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

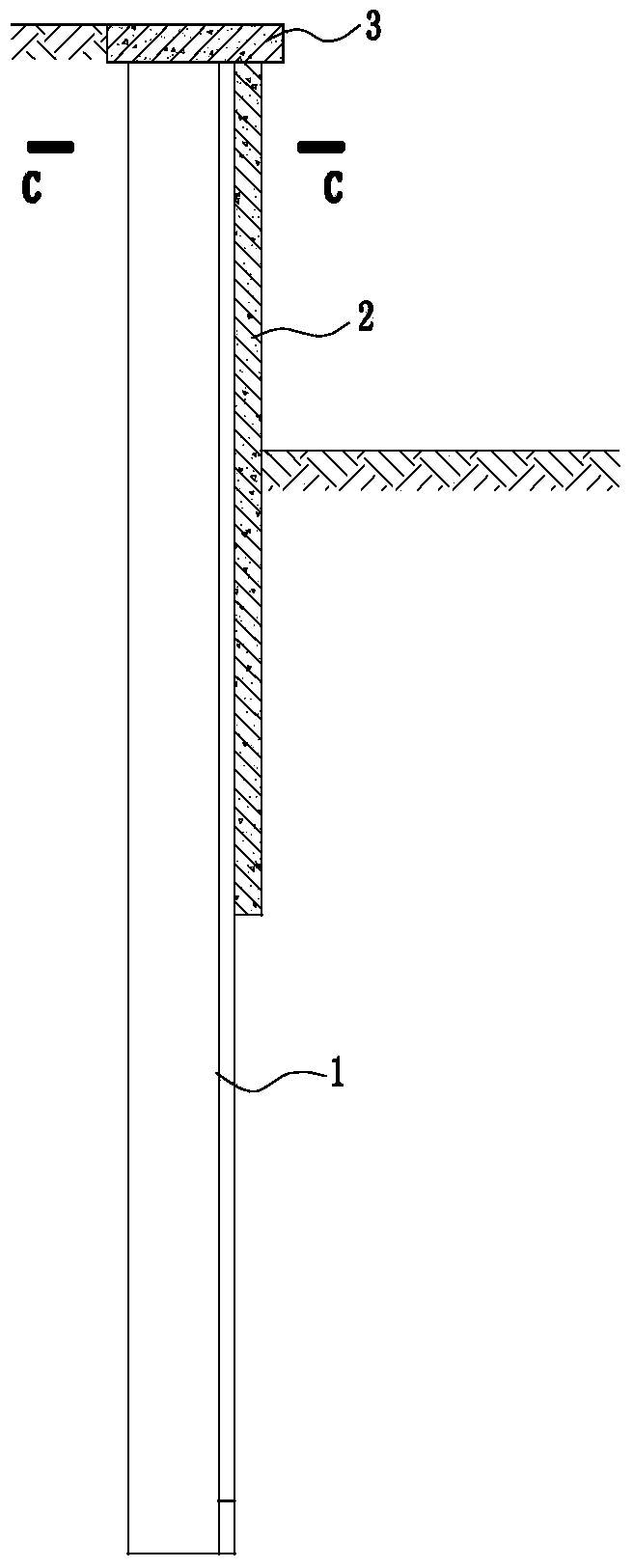

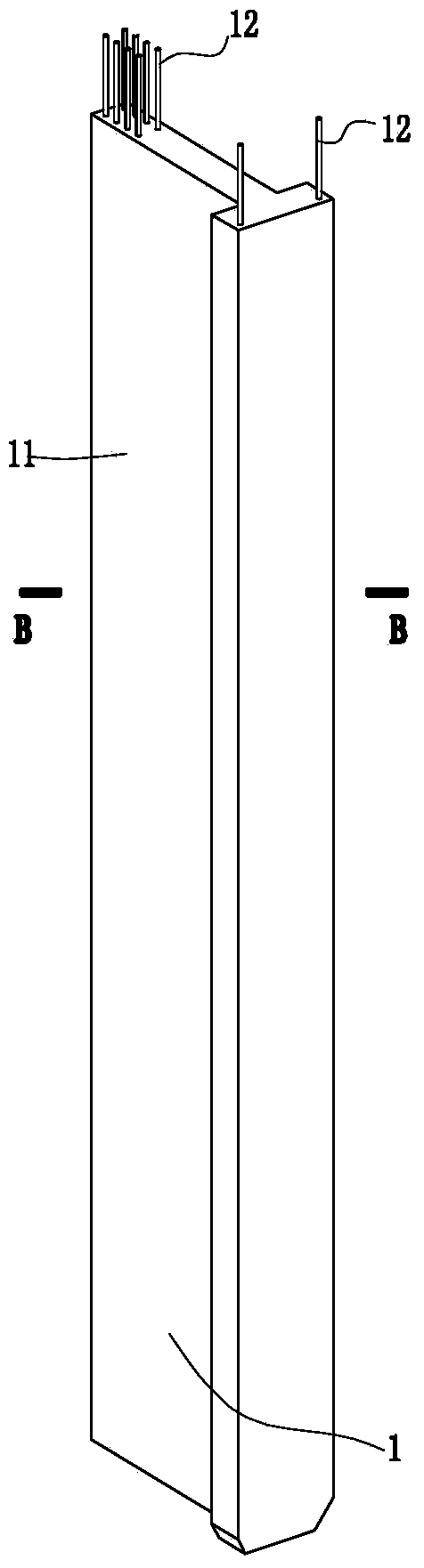

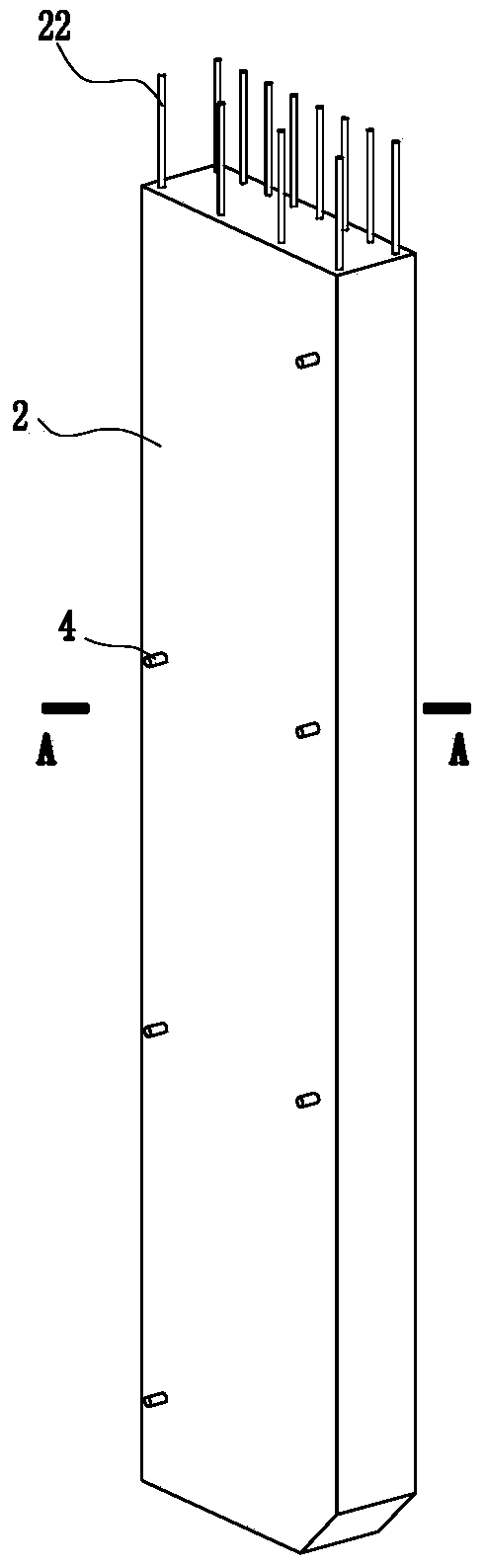

[0020] see Figure 1 to Figure 6 , a cantilever support structure combined with a sheet pile and a thin-walled T-shaped pile provided in the present invention includes a T-shaped pile 1, a sheet pile 2 and a cap beam 3, and the T-shaped pile 1 includes a T-shaped concrete body 11, Prestressed steel strand 12 and shear mesh 13. The sheet pile 2 includes a rectangular concrete body 21 and a prestressed steel strand 22, the sheet pile 2 is vertically arranged outside the flange of the T-shaped pile 1, and the cap beam 3 is arranged on the T-shaped pile 1 and the sheet pile 2 tops. The support pile adopts T-shaped cross-section, which is reasonable in force and saves the amount of concrete. The use of prestressed high-strength steel strands as the main reinforcement can save reinforcement, and the shear mesh is used to bear the shear force, which is convenient to manufacture and high in work efficiency. Usually, the support piles with small shear force do not need to use rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com