A recycling process of polyimide film waste

A polyimide film and polyimide technology, which is applied in the field of polyimide film waste recycling process, can solve the problems of long processing cycle, multi-stage process, environmental pollution, etc., and achieve short processing cycle and crushing Short time and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of recovery process of polyimide film waste, it comprises the steps:

[0029] 1) Weigh 10 parts of polyimide film waste powder and 90 parts of phenolic resin respectively, and dry them at 80°C for 4 hours;

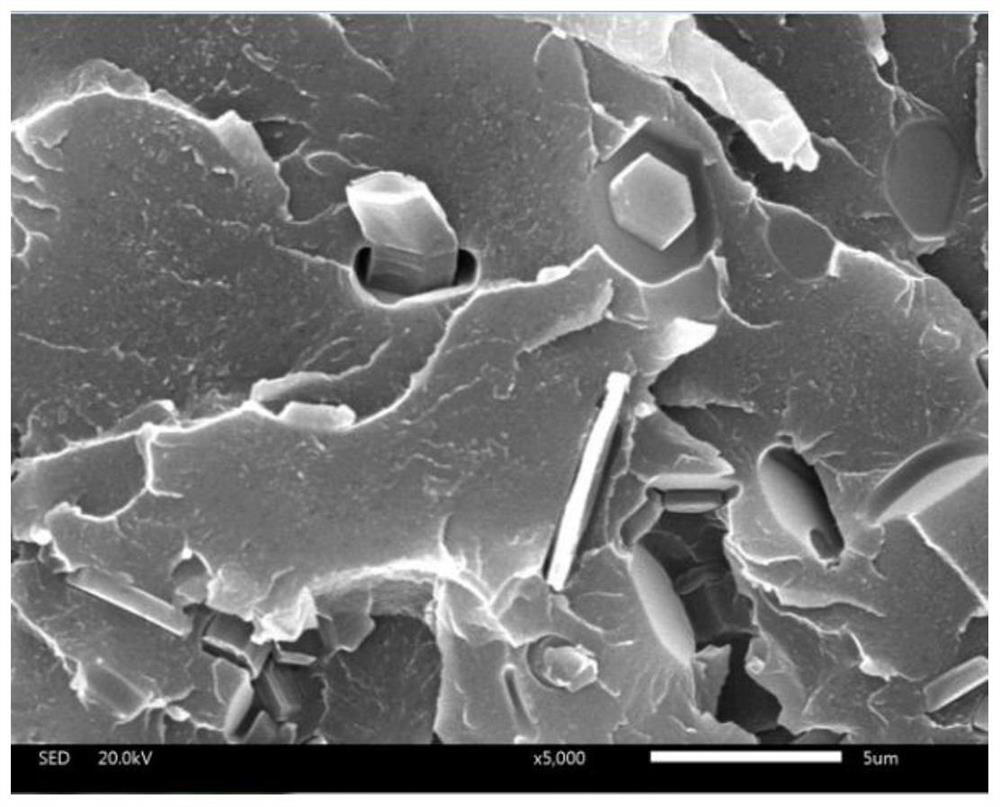

[0030] 2) Then ball mill at a high speed for 30 minutes in a high-energy planetary ball mill at a speed of 400r / min, mix evenly and improve the interface between the two phases; put the material obtained by ball milling into the cavity of the forming mold, then put it into a plate press, and heat it to 120°C for preheating 0.5h, then continue to heat up to 150°C for 0.5h, and start to apply pressure, control the pressure to 10MPa; continue to heat up to 180°C for 2h, and then maintain the temperature and pressure at 200°C for 1h; cool down to 140°C before unloading Press, open the mold and take out the test piece to obtain the polyimide / phenolic resin composite material.

Embodiment 2

[0032] A kind of recovery process of polyimide film waste, it comprises the steps:

[0033] 1) Weigh 15 parts of polyimide film waste powder and 85 parts of phenolic resin respectively, and dry them at 80°C for 4 hours;

[0034] 2) Then ball mill at a high speed for 30 minutes in a high-energy planetary ball mill at a speed of 400r / min; put the material obtained from the ball mill into the cavity of a forming mold, then put it into a flat press, heat it to 120°C for 0.5h, and then raise the temperature to 150°C for heat preservation 0.5h, and start to apply pressure, control the pressure at 10MPa; continue to heat up to 180°C for 2h, and then maintain the temperature and pressure at 200°C for 1h; wait until the temperature is cooled to 140°C to release the pressure, open the mold and take out the test piece; that is Polyimide / phenolic resin composite.

Embodiment 3

[0036] A kind of recovery process of polyimide film waste, it comprises the steps:

[0037] 1) Weigh 10 parts of polyimide film waste powder, 85 parts of phenolic resin and 5 parts of amino-terminated polysiloxane, and dry them at 80°C for 4 hours;

[0038] 2) Then ball mill at a high speed for 30 minutes in a high-energy planetary ball mill at a speed of 400r / min; put the material obtained from the ball mill into the cavity of a forming mold, then put it into a plate press, heat it to 120°C for 0.5h, and then continue to heat up to 150°C Keep warm for 0.5h, and start to apply pressure, and control the pressure to 10MPa; continue to heat up to 180°C for 2h, and then maintain the temperature and pressure at 200°C for 1h; wait until the temperature drops to 140°C to release the pressure, open the mold and take out the test piece; that is A polyimide / phenolic resin composite was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

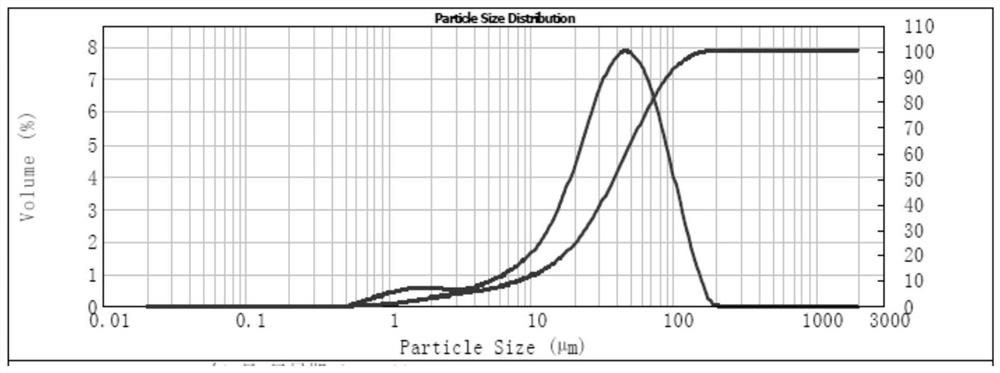

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com