A kind of copolymer composite material and composite electrode material and preparation method thereof

A composite material and composite electrode technology, used in hybrid capacitor electrodes, battery electrodes, circuits, etc., can solve the problems of weak adhesion between the coating and the current collector interface, cumbersome molding process, and small capacitance of electrode materials. Defects, high mechanical properties, improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 prepares pure ethylene-vinyl acetate copolymer

[0045] After 100 grams of ethylene-vinyl acetate copolymer (vinyl acetate content is 32%, the product model is MA10, produced by Singapore Polyolefin Company) is dissolved in 250 milliliters of benzene solvent, cast in the cellulose hydrogel mould, wait two The toluene solvent evaporates completely, and the ethylene-vinyl acetate copolymer of a specific shape is obtained.

[0046] In addition to using benzene solvent in this embodiment, it can also be replaced by xylene solvent or tetrahydrofuran solvent.

Embodiment 2

[0047] Embodiment 2 prepares 20% carbon nanotube / ethylene-vinyl acetate copolymer composite material

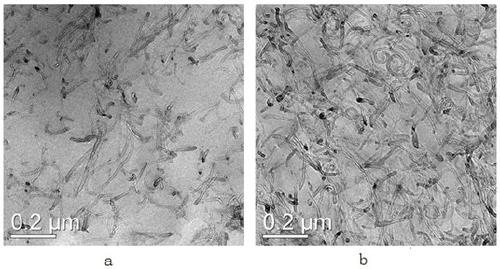

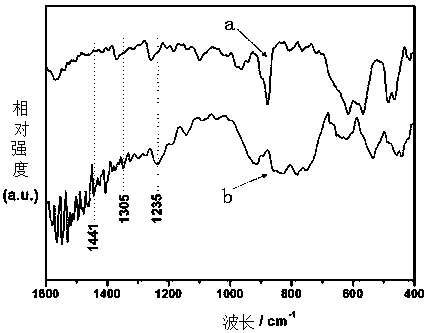

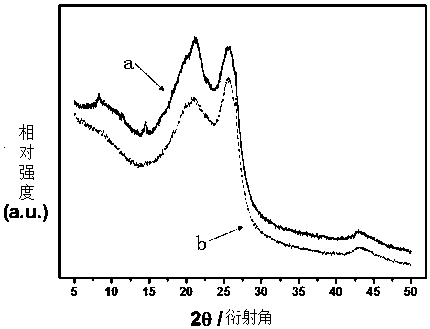

[0048] After dissolving 8 grams of ethylene-vinyl acetate copolymer in 250 ml of xylene solvent, the weight ratio of ethylene-vinyl acetate copolymer to xylene solvent should not be higher than 20:80, preferably 10:80 in this embodiment, Add 2 grams of carbon nanotubes (the model is NC7000, produced by Nanocyl S.A.) under the condition of ultrasonic stirring, disperse the carbon nanotubes with ethylene-vinyl acetate copolymer solution, mix well, and cast in the cellulose hydrogel mold , until the xylene solvent is completely volatilized, a 20% carbon nanotube / ethylene-vinyl acetate copolymer composite material with a specific shape is obtained, and the carbon nanotubes and ethylene-vinyl acetate copolymer in the composite material form a three-dimensional co-continuous phase structure.

Embodiment 3

[0049] Embodiment 3 prepares 40% carbon nanotube / ethylene-vinyl acetate copolymer composite material

[0050] After dissolving 6 grams of ethylene-vinyl acetate copolymer in 250 milliliters of benzene solvent, add 4 grams of carbon nanotubes under the condition of ultrasonic stirring, mix evenly, cast it in a cellulose hydrogel mold, and wait for the xylene solvent to volatilize completely , 40% carbon nanotube / ethylene-vinyl acetate copolymer composite material was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com