Water-flushing sinking-assisting system and construction technical method thereof

A construction technology, water flushing technology, which is applied in the direction of foundation structure engineering, building, sheet pile wall, etc., can solve the problems of short construction period, high cost, complicated process, etc., and achieve the goal of improving pile sinking efficiency, saving cost, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

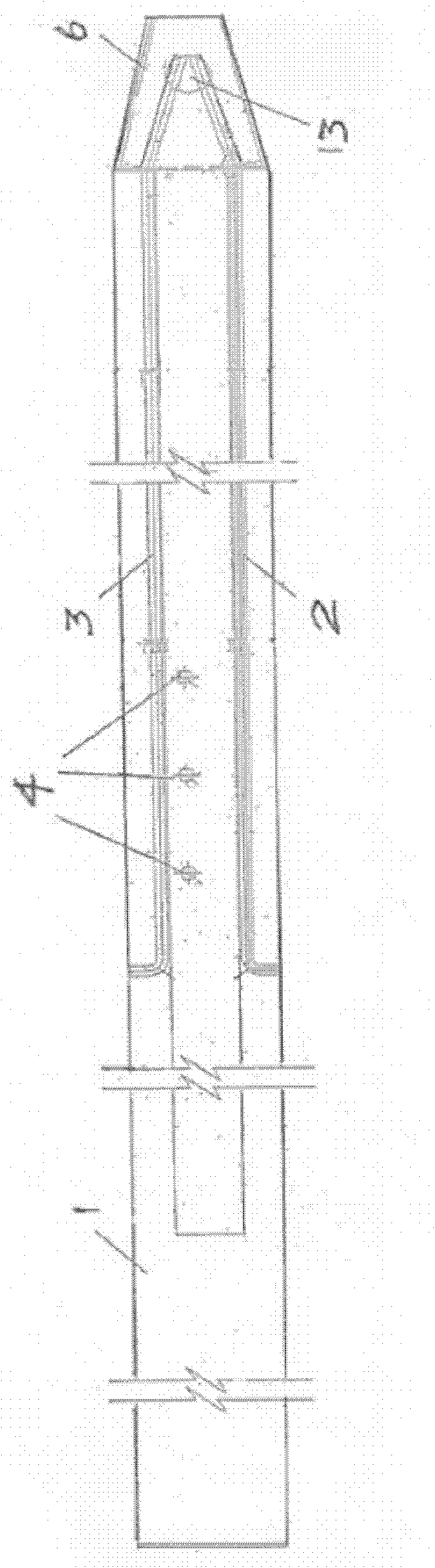

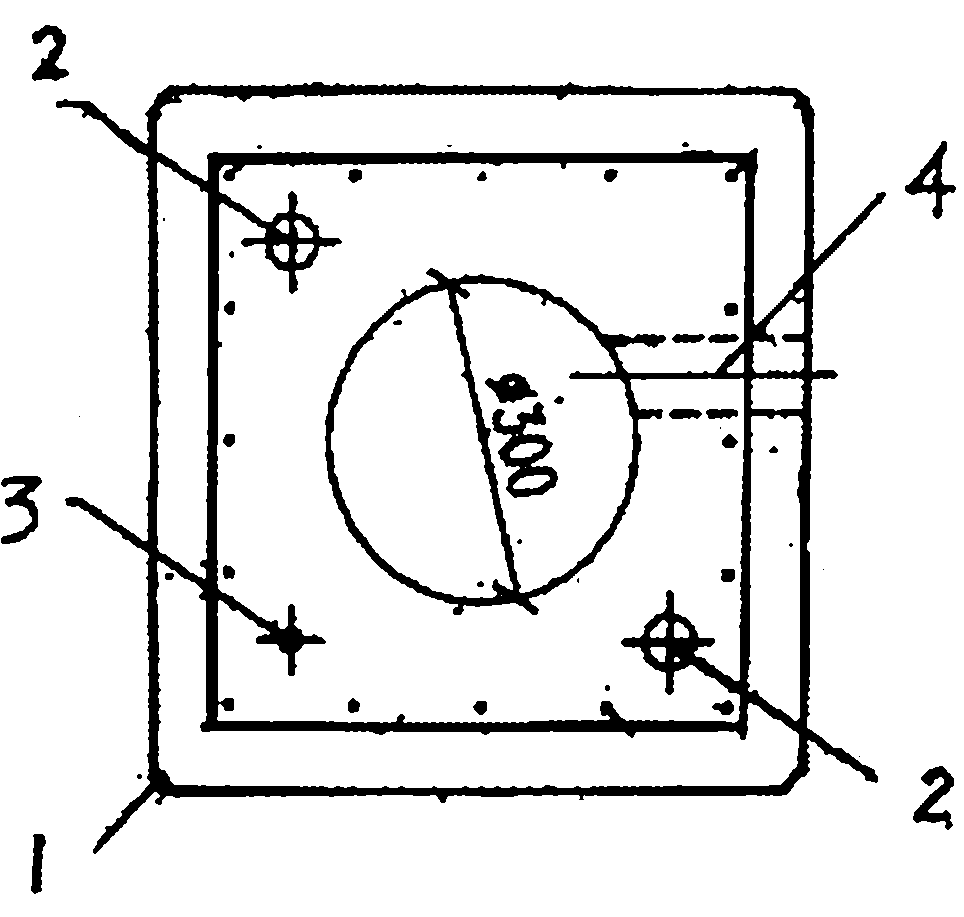

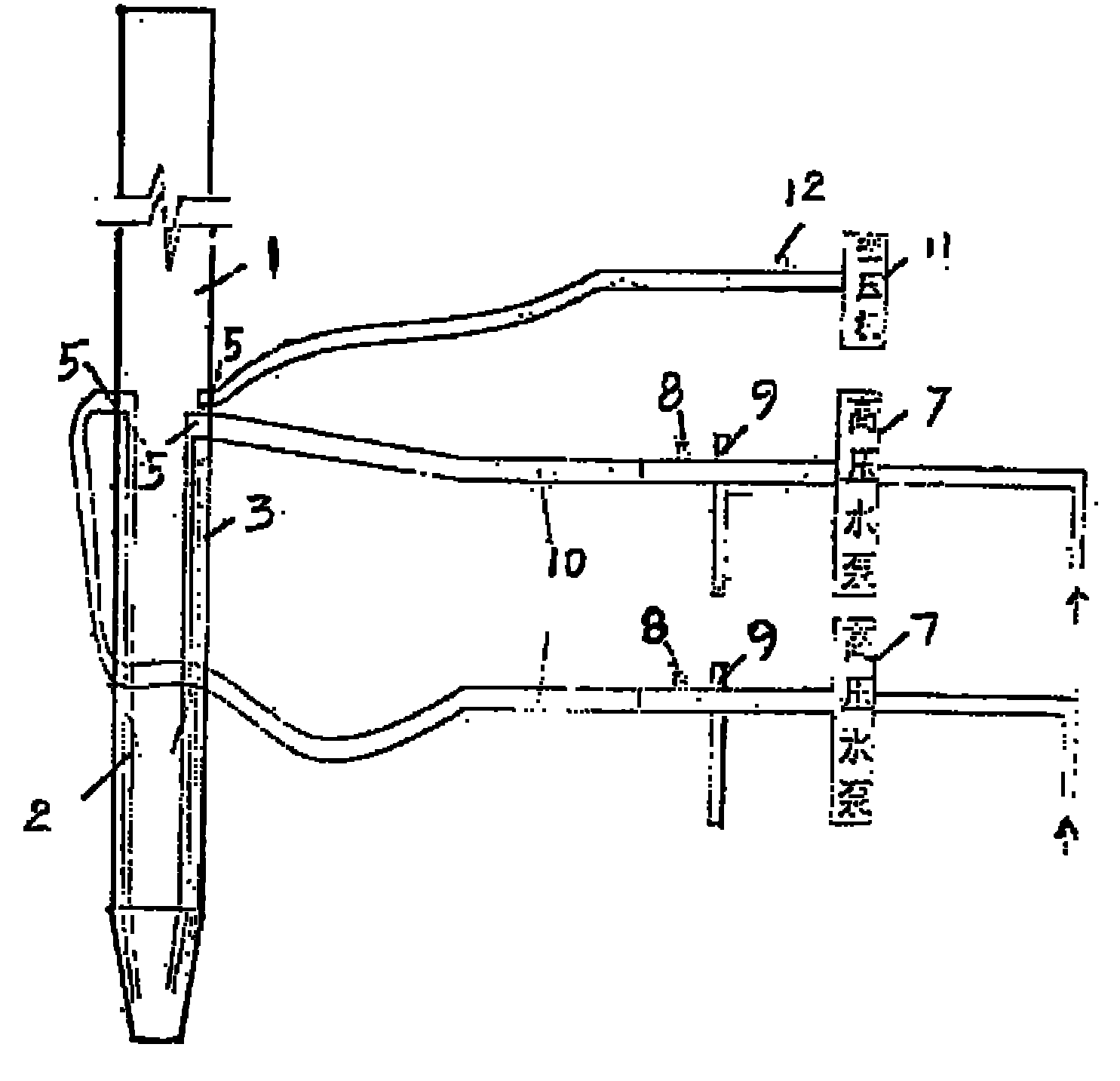

[0037] Such as figure 1 , 2 , 3 shows a new type of water flushing aided sinking construction technology device, compared with the traditional water flushing aided sinking process device, its characteristic is that during the prefabrication process of the pile, two water jet pipes 2 are pre-buried in the pile body 1 (see Figure 6 ), an air supply tube 3 (see Figure 7 ), reserve three outer drainage holes 4 with a diameter of 70 mm on the side wall of the pile body; use a quick connector 5 when connecting the water pipe and air pipe (see Figure 4.1 , 4.2 ) connection; the pile point is a funnel-shaped steel pile point 6 (see Figure 5.1 , 5.2 ), welded with steel plates; the direction of the two water pipes at the tip of the pile is hedged; the double water pumps 7 supplying the two water jets are respectively equipped with pressure gauges 8 and regulating valves 9, and the double water pumps adjust the water pressure at the same time.

[0038] Further specific explanat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com