Three-dimensional cone interpolation method for electric sparkle forming processing

A forming and EDM technology, which is applied in the field of EDM CNC machine tool processing, can solve problems such as inapplicability to EDM machining, and achieve the effects of improving accuracy, facilitating discharge and avoiding interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

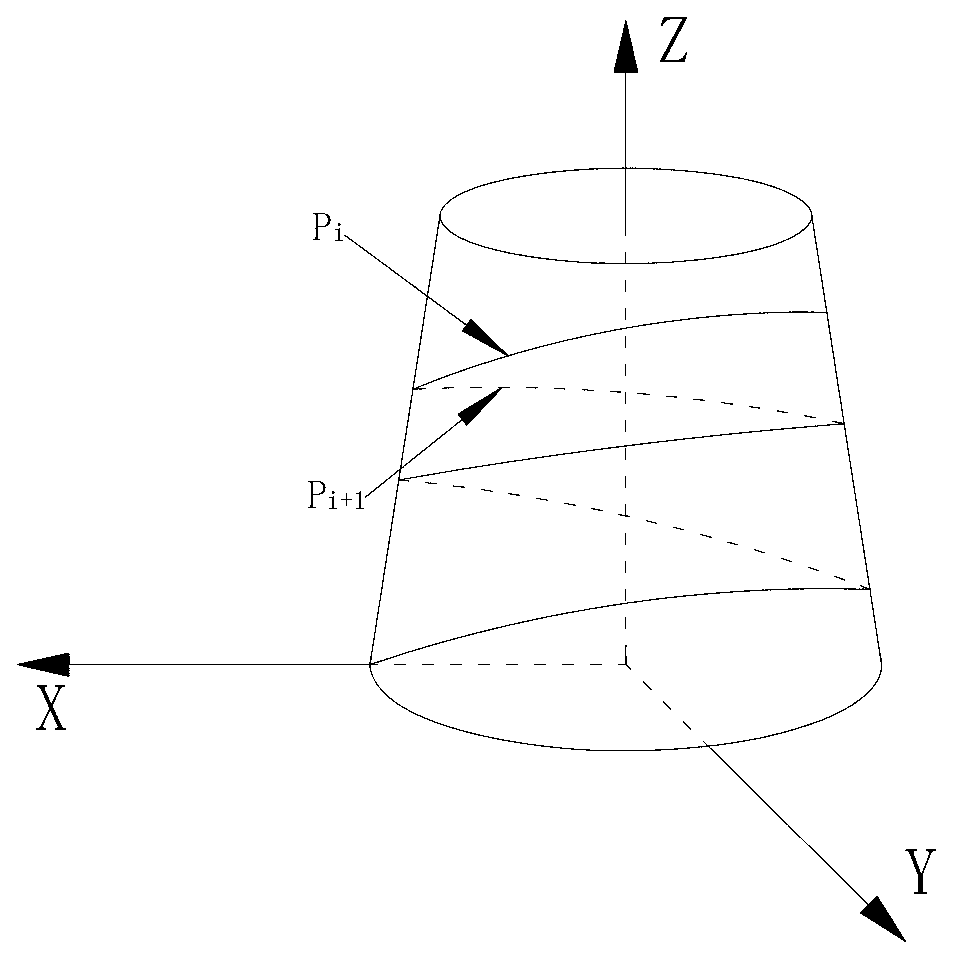

[0028] The invention realizes the space reversible interpolation of electric discharge forming processing through the three-dimensional conical reversible interpolation technology. The three-dimensional conical interpolation method for EDM processing of the present invention comprises the following implementation steps:

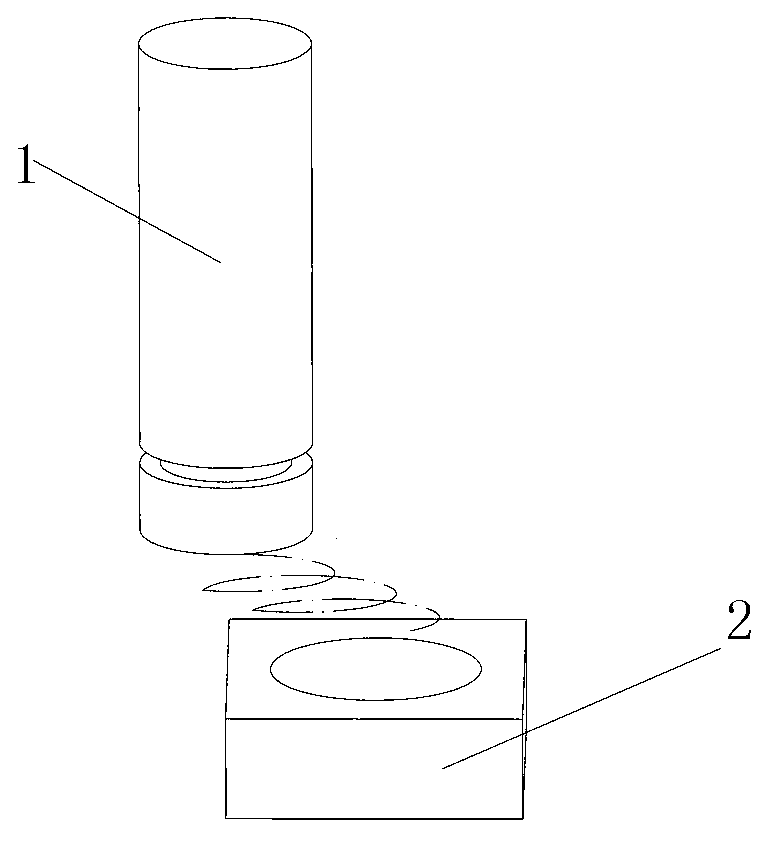

[0029] 1. The controller sends a pulse command to make the spindle respond quickly and move to the specified position at a certain speed.

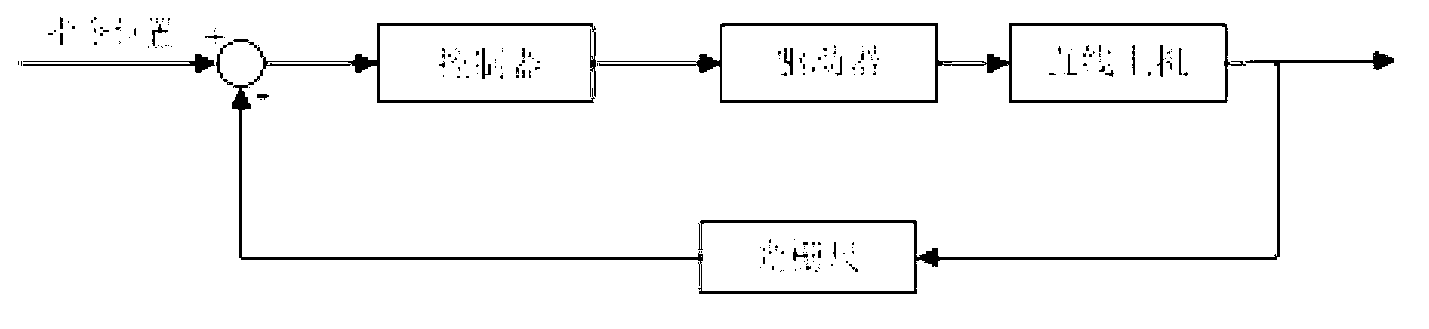

[0030] Such as figure 1 As shown, the controller, the driver and the linear motor are connected in sequence, the linear motor is fixedly connected to the main shaft, and the grating scale is fixed on the linear motor and connected to the controller. The controller can be realized by DSP, and the controller sends corresponding pulse instructions to make the moving parts of the system run according to the instructions. The upper controller sends the pulse command to the driver, and then the motor realizes quick response a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com