Modeling method for kinetic mass transfer model of CO2 electrochemical hydrogenation reactor

A hydrogenation reactor and kinetic model technology, applied in the field of electrochemical engineering, can solve the problems of not considering the dissolution and transfer process, difficult reactor model integration process design and parameter optimization, and high computing resource requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]The present invention will be further described below with reference to the accompanying drawings, and the following examples are used only to more clearly illustrate the technical solutions of the present invention without limiting the scope of the invention.

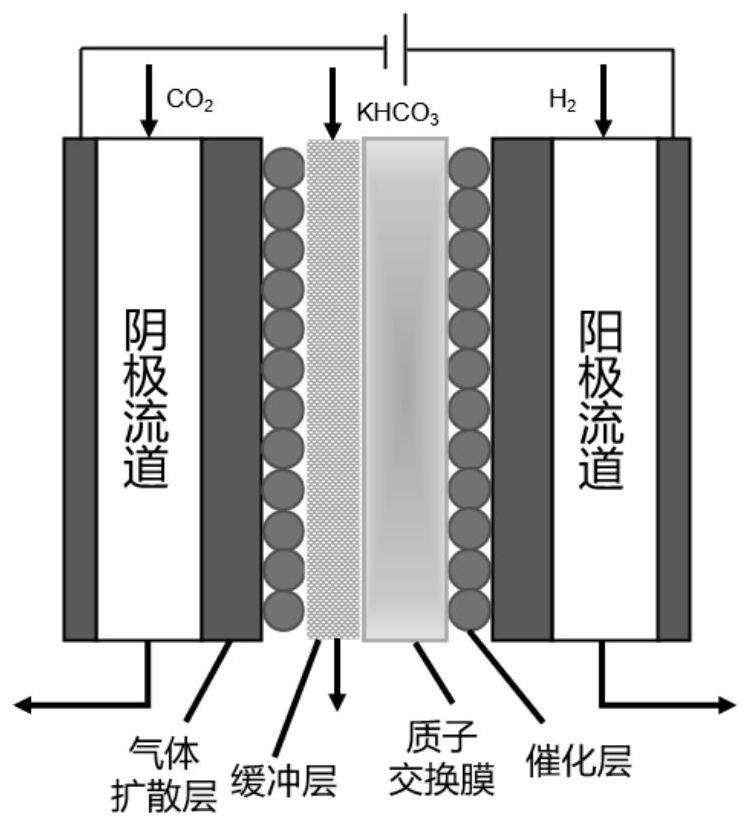

[0051]CO2infigure 1 Electrochemical hydrogenation in a fuel cell device having a buffer layer is carried out, and the cathode catalyst uses SN, the carrier is 2.0 mg cm.2, The anode catalyst uses PT / C with 0.5 mg of CM.2, Buffer uses 0.5m khco3Solution.

[0052]Hydrogen is reached by the proton of the anodic displacement electron dissociation, through the proton exchange membrane and buffer to the cathode, and CO2Hydrogenation reaction occurs, produces product formic acid and CO while accompanied by hydrogenation side effects.

[0053]Anode: h2→ 2h++ 2E-

[0054]Cathode: Co2+ 2E-+ H2O → HCOO-+ OH-

[0055]CO2+ 2E-+ H2O → Co + 2OH-

[0056]2h2O + 2E-→ h2+ 2OH-

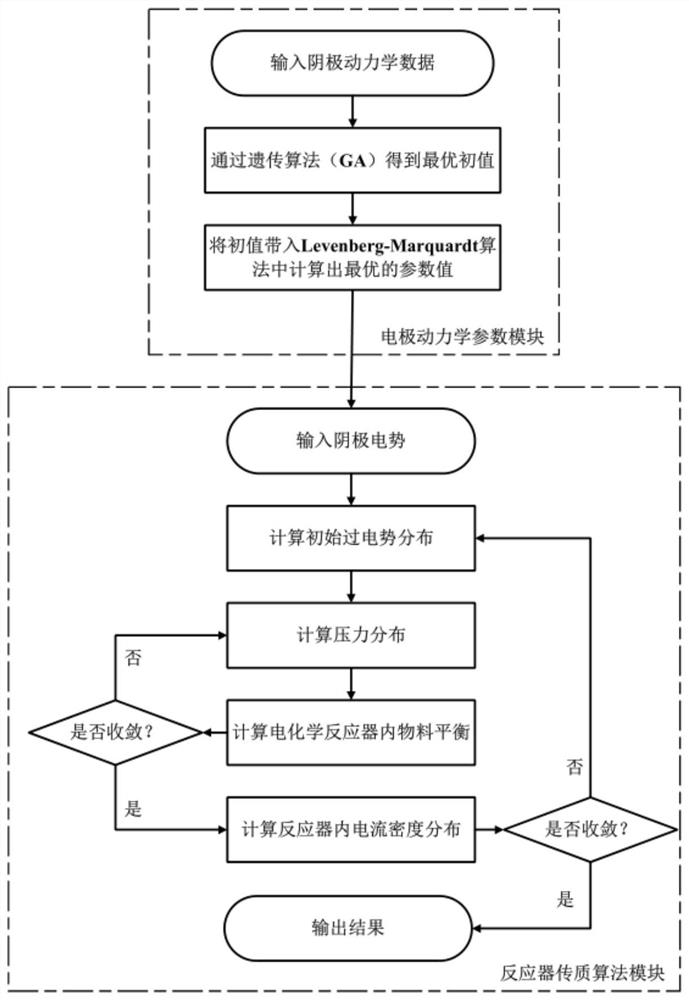

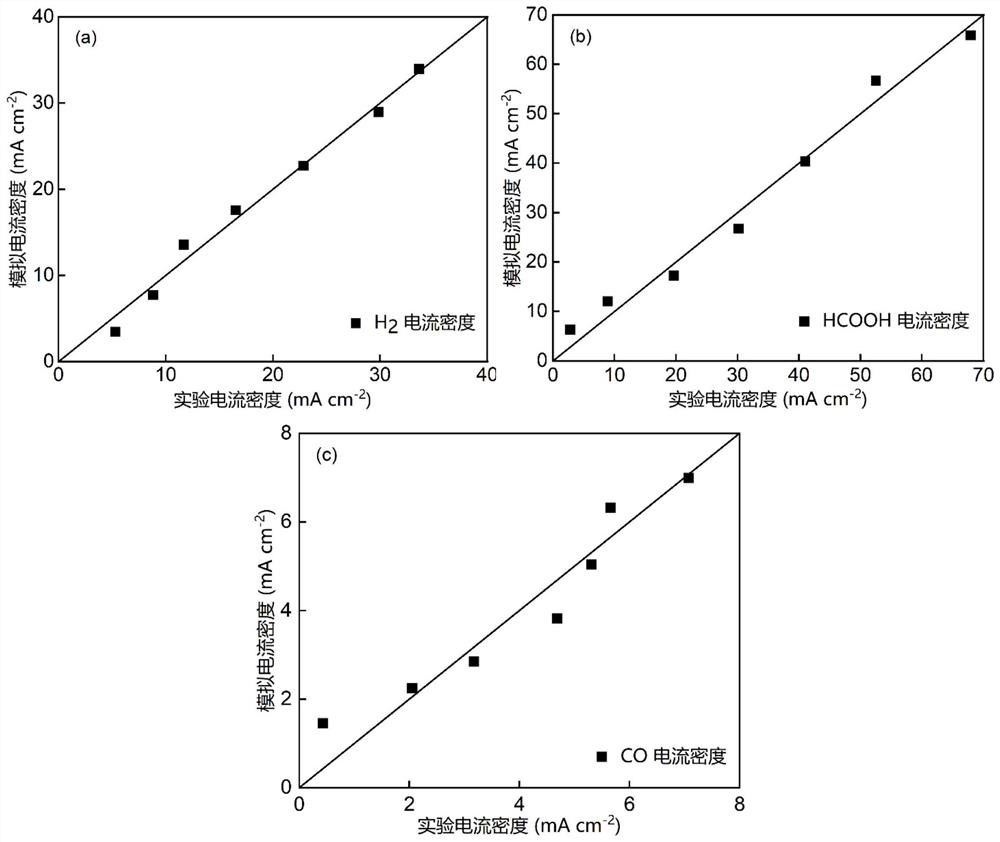

[0057]According to the CO of the present invention2Hydrogenation reaction kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com