Method for preparing ion conductivity membrane for flow battery through electrostatic spinning

A technology of ion conductivity and electrospinning, which is applied in the field of electrospinning to prepare ion-conducting diaphragms for flow batteries, to achieve the effects of improving mechanical strength and swelling resistance, reducing discharge capacity attenuation, and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

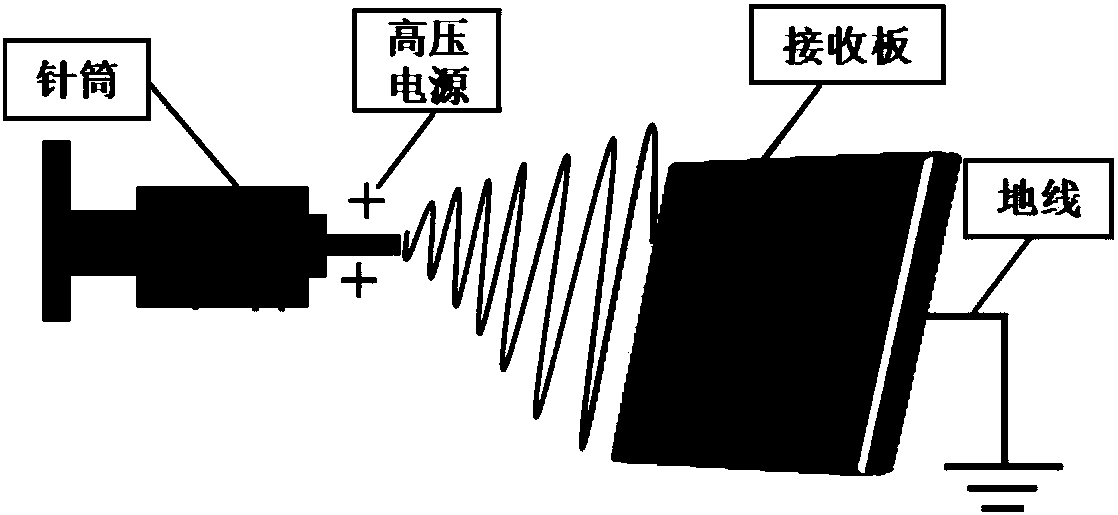

Method used

Image

Examples

Embodiment 1

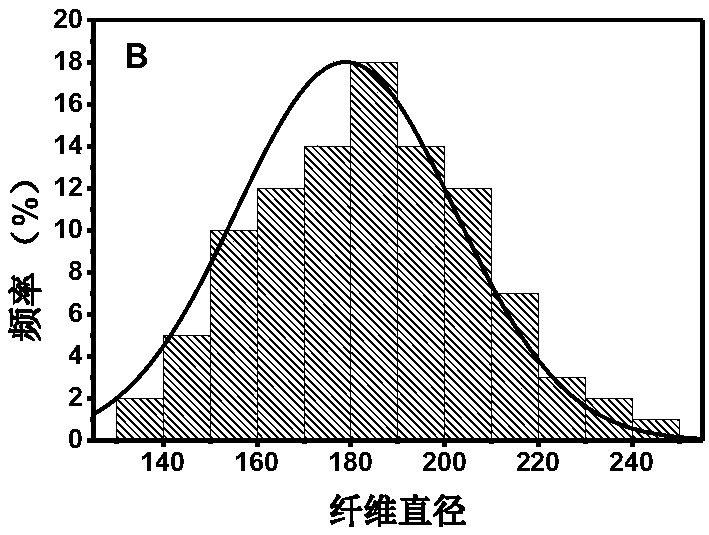

[0024] Dissolve 0.6585g of sulfonated polyetheretherketone with an ion exchange capacity of 1.62mmol / g in 3g of N,N-dimethylformamide to prepare a spinning solution with a mass fraction of 18%, and then add 3.3mg The multi-walled carbon nanotubes are made to have a mass fraction of 0.5%, and after being magnetically stirred for 6 hours, ultrasonic waves are used for 30 minutes to make them uniformly dispersed. Under the spinning conditions that the applied voltage is 18kV and the distance from the spinneret to the receiving plate is 15cm, a three-dimensional network-like electrospun nanofiber is prepared, with a fiber diameter of 80-300nm and a thickness of 130μm.

[0025] Place the above-mentioned electrospun ordered nanofibers in the saturated steam above the N,N-dimethylformamide solvent bath at normal pressure and 60°C for 15 minutes to make the fibers swell and stick to each other. Then, hot press at room temperature and 4.0 MPa for 10 min to make the fibers form a dense fi...

Embodiment 2

[0028] Dissolve 0.6585g of sulfonated polyetheretherketone with an ion exchange capacity of 2.06mmol / g in 3g of N, N-dimethylformamide to prepare a spinning solution with a mass fraction of 18%, and then add 5.3mg The mass fraction of multi-walled carbon nanotubes is 0.8%. After being stirred by magnetic force for 6 hours, it is ultrasonically dispersed for 30 minutes to make it uniformly dispersed. Under the spinning conditions that the applied voltage is 20kV and the distance from the spinneret to the receiving plate is 18cm, three-dimensional network-like electrospun nanofibers are prepared, with a fiber diameter of 100-300nm and a thickness of about 130 μm.

[0029] The above nanofibers prepared by electrospinning were placed in the upper saturated steam of the N,N-dimethylformamide solvent bath at normal pressure and 60°C for 20 minutes to make the fibers swell and stick to each other. Then, the fibers were hot-pressed at room temperature and 5.0 MPa for 20 min to form a ...

Embodiment 3

[0032] Dissolve 0.6585g of sulfonated polyetheretherketone with an ion exchange capacity of 1.62mmol / g in 3g of N,N-dimethylformamide to prepare a spinning solution with a mass fraction of 18%, and then add 3.3mg The multi-walled carbon nanotubes are made to have a mass fraction of 0.2%, and after being magnetically stirred for 6 hours, ultrasonic waves are used for 30 minutes to make them uniformly dispersed. Under the spinning conditions that the applied voltage is 22kV and the distance between the spinneret and the receiving plate is 20cm, a three-dimensional network electrospun nanofiber is prepared, with a fiber diameter of 80-300nm and a thickness of about 200 μm.

[0033] The above nanofibers prepared by electrospinning were placed in the saturated steam above the N,N-dimethylformamide solvent bath at normal pressure and 60°C for 25 minutes to make the fibers swell and stick to each other. Then, the fibers were hot-pressed at room temperature and 3.0 MPa for 40 min to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com