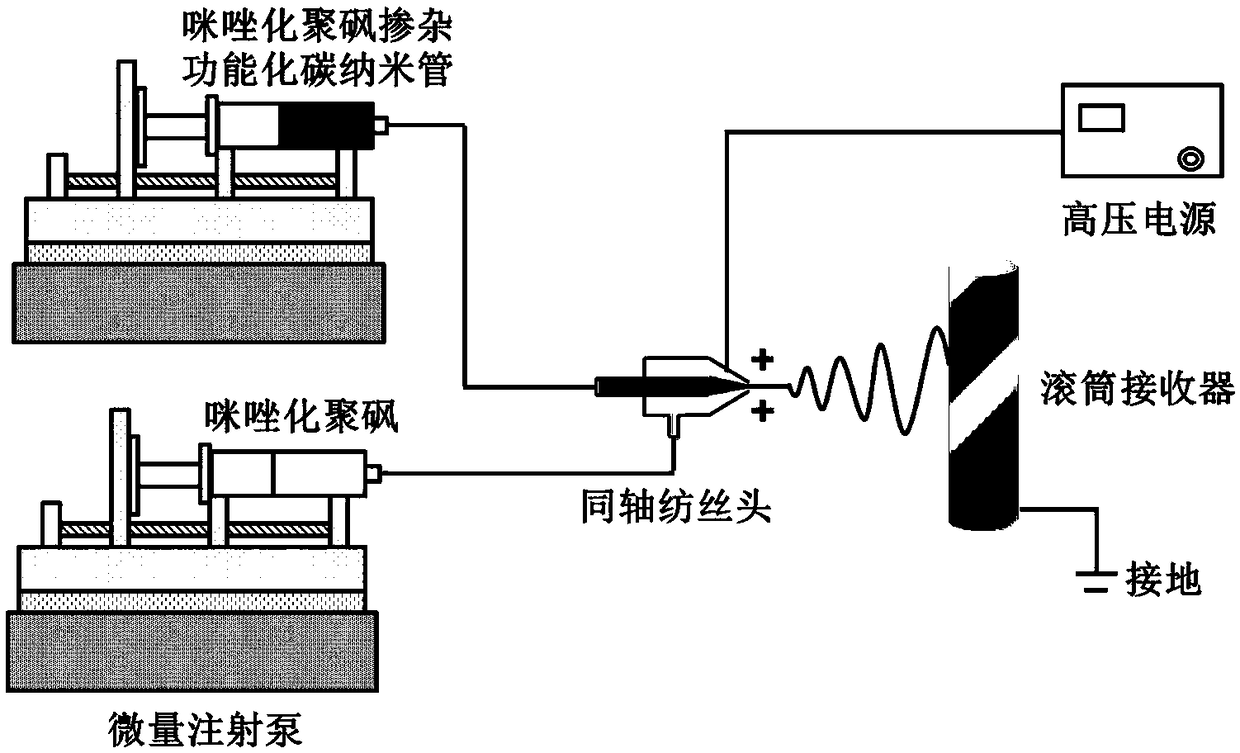

Method for preparing carbon nanotube reinforced anion exchange membrane through coaxial electrostatic spinning

A technology of coaxial electrospinning and anion exchange membrane, which is applied in the field of electrochemical engineering, can solve problems such as difficulty in improving compatibility, and achieve the effects of improving compatibility, increasing ion conductivity, and increasing doping amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

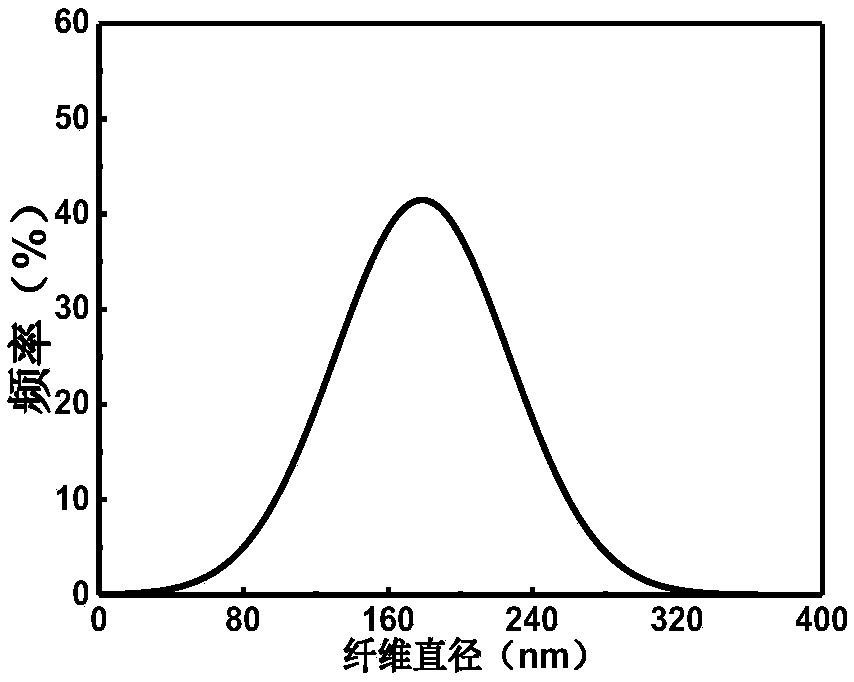

[0025] Dissolving 1.5g of imidazolized polysulfone with an ion exchange capacity of 1.61mmol / g in 6.0g of N,N-dimethylformamide is prepared into a solution with a mass fraction of 20% as a shell spinning solution; Add 9.0 mg of functionalized carbon nanotubes to the shell spinning solution to make the mass fraction 0.6%, and disperse evenly after magnetic stirring for 12 hours and ultrasonic dispersion for 30 minutes to serve as the core spinning solution. When the applied voltage is 24kV, the distance between the coaxial spinneret and the receiving drum is 15cm, the diameter of the core layer of the coaxial spinneret is 500μm, the diameter of the shell layer is 1500μm, and the pushing speed of the core layer and the shell layer injection pump is 0.06ml / h, under the spinning condition that the rotating speed of the drum is 1500rpm, the coaxial electrospun nanofibers arranged in a three-dimensional network are prepared, and the fiber diameter is 100-300nm.

[0026] Place the c...

Embodiment 2

[0029] 1.0g ion exchange capacity is 1.5mmol / g imidazole polysulfone is dissolved in 4.56g of N, N-dimethylformamide, the solution that is mixed with mass fraction is 18%, as shell spinning liquid; Add 4.0 mg of functionalized carbon nanotubes to the shell spinning solution to make the mass fraction 0.4%, and disperse evenly after magnetic stirring for 12 hours and ultrasonic dispersion for 30 minutes to serve as the core spinning solution. When the applied voltage is 27kV, the distance between the coaxial spinneret and the receiving drum is 15cm, the diameter of the core layer of the coaxial spinneret is 500μm, and the diameter of the shell layer of the coaxial spinneret is 1500μm. Under the spinning conditions of 0.09ml / h and drum rotation speed of 1500rpm, coaxial electrospun nanofibers arranged in a three-dimensional network were prepared, and the fiber diameter was 50-350nm.

[0030] Place the coaxial electrospun fibers in the saturated steam above the N,N-dimethylformami...

Embodiment 3

[0033] 0.5g ion exchange capacity is 1.65mmol / g imidazole polysulfone dissolved in 1.77g of N, N-dimethylformamide, the solution that the mass fraction is 22% is formulated, as shell spinning liquid; 4.0 mg of functionalized carbon nanotubes were added to the shell spinning solution to make the mass fraction 0.8%, and after magnetic stirring for 12 hours and ultrasonic dispersion for 30 minutes, they were uniformly dispersed as the core spinning solution. When the applied voltage is 30kV, the distance between the coaxial spinneret and the receiving drum is 15cm, the diameter of the core layer of the coaxial spinneret is 500μm, the diameter of the shell layer of the coaxial spinneret is 1500μm, and the pushing speed of the inner and outer axis injection pumps is equal. Under the spinning conditions of 0.12ml / h and drum speed of 1500rpm, coaxial electrospun nanofibers arranged in a three-dimensional network are prepared, and the fiber diameter is 100-400nm.

[0034] Place the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com