Underwater integrated electric motor thruster

A propeller and armature winding technology, which is applied to propulsion components, ship propulsion, propulsion device engines, etc., can solve the problems of long axial dimension of motor propeller, damage of motor propeller, poor sealing effect, etc., and achieve simple structure, The effect of reducing weight and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

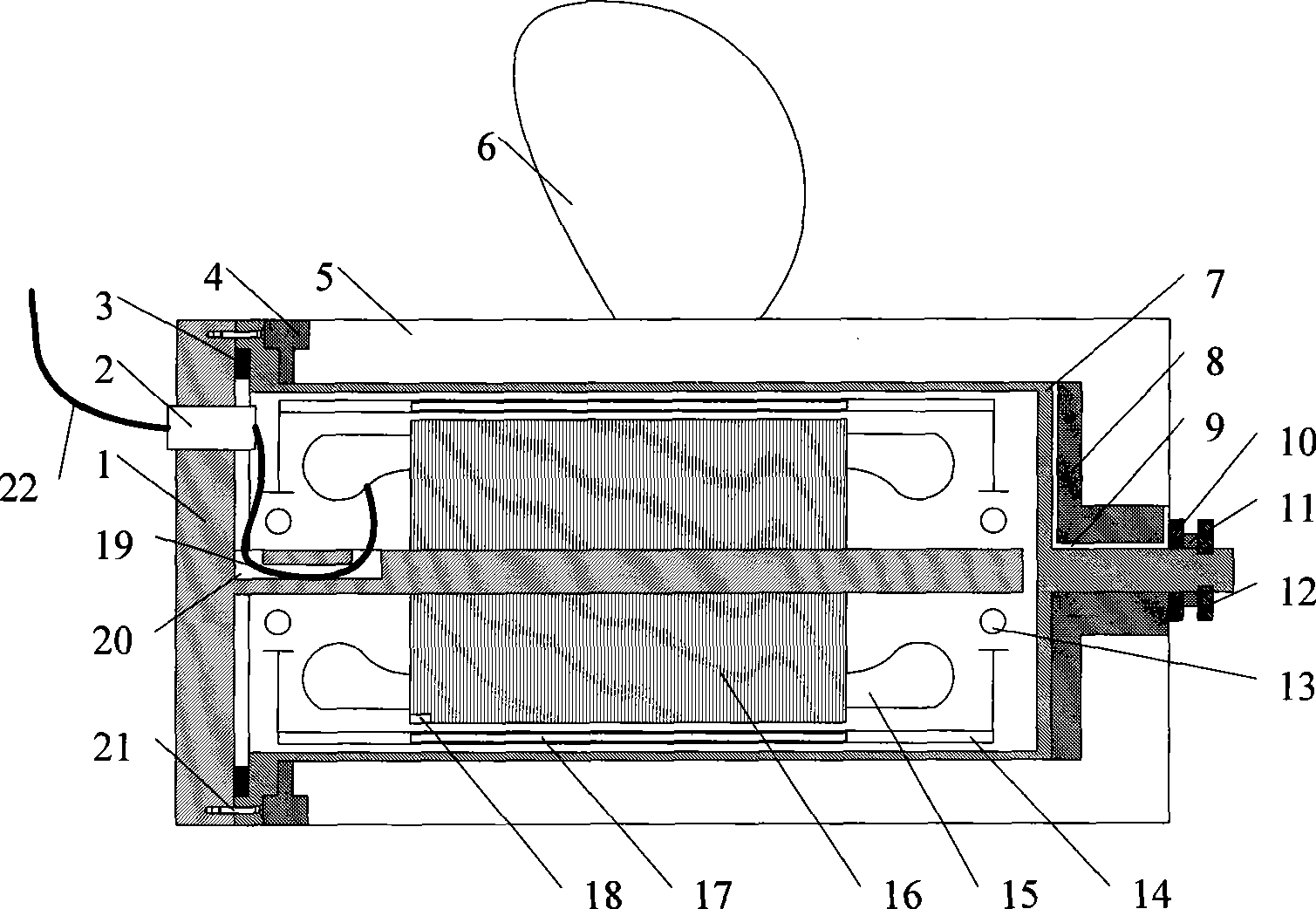

[0020] Specific implementation mode one: combine figure 1 , the external controller obtains the output signal of the rotor position sensor 18 through the external cable 22, the underwater sealing plug 2 and the cable 19, and then controls each phase winding of the armature winding 15 to be energized in sequence, and the armature magnetic field and the permanent magnet on the rotor The magnetic poles 17 interact to make the rotor continue to rotate. The rotating magnetic field of the rotor penetrates the non-magnetic sealing shell 7 and enters the magnetically conductive sleeve 5. Since there is relative motion between the magnetic field and the sleeve 5, the An induced current, namely eddy current, is generated inside to form an electromagnetic torque. Under the action of the electromagnetic torque, the sleeve 5 rotates with the rotor, and then drives the propeller blade 6 to rotate to realize underwater propulsion. During the working process, external water enters the gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com