DC brushless motor system for drainage motor, and DC brushless motor control method and control apparatus for drainage motor

A brushless DC, control method technology, applied in the direction of speed/torque control of a single motor, can solve the problems of half-water and half-air noise, increased cost, and the inability of the drainage pump to meet the increasingly high requirements of living environment comfort. , to achieve the effect of reducing half water and half air noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Various embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted.

[0037] Brushless DC motors have been widely used in various fields due to their small size, good dynamic response characteristics, large starting torque, and strong overload capacity. The DC brushless motor has an incomparable advantage over the single-phase AC permanent magnet synchronous motor in terms of starting. In addition to not requiring a starting device, it can also provide a large starting torque. Therefore, in the present invention, the DC brushless motor is applied to the field of drain pumps of household appliances such as dishwashers and washing machines.

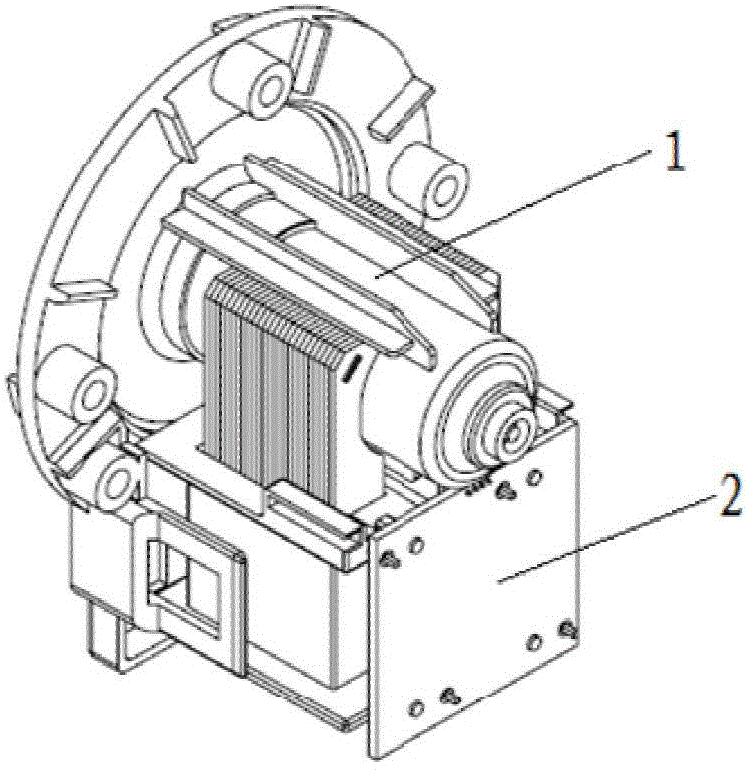

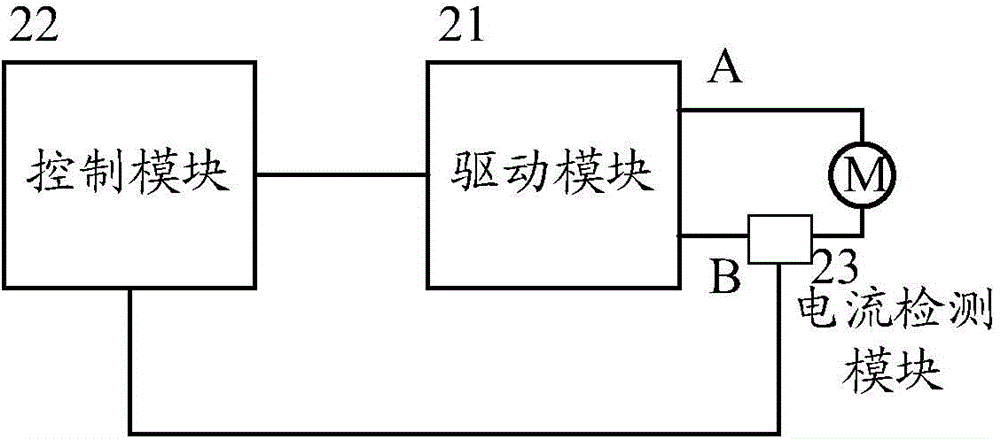

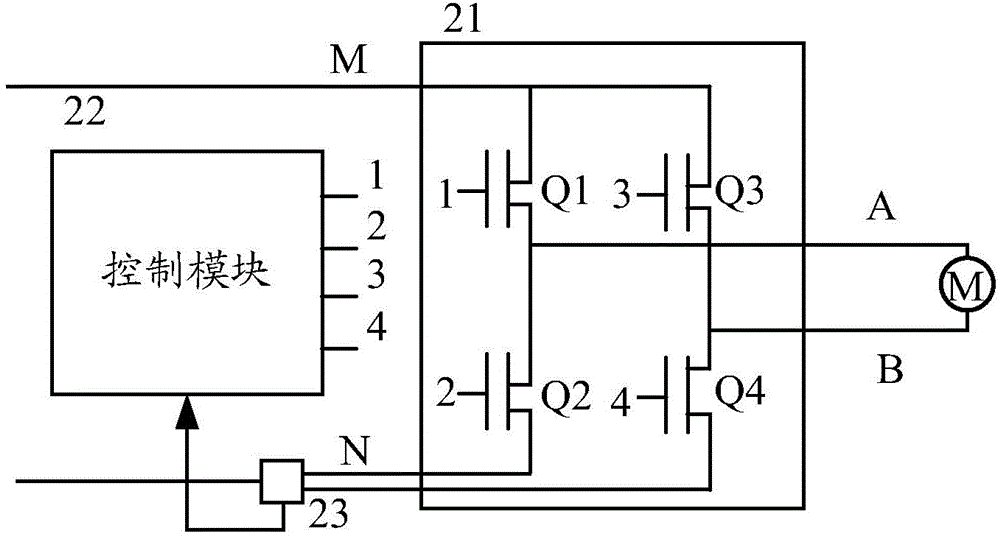

[0038] figure 1 A schematic diagram of the overall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com