Hybrid drive train having intermediate gear

A powertrain, hybrid technology, applied in hybrid vehicles, power units, transmissions, etc., can solve problems such as large structural space, and achieve the effect of large structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Features of various embodiments can also be implemented in other embodiments. So they are interchangeable.

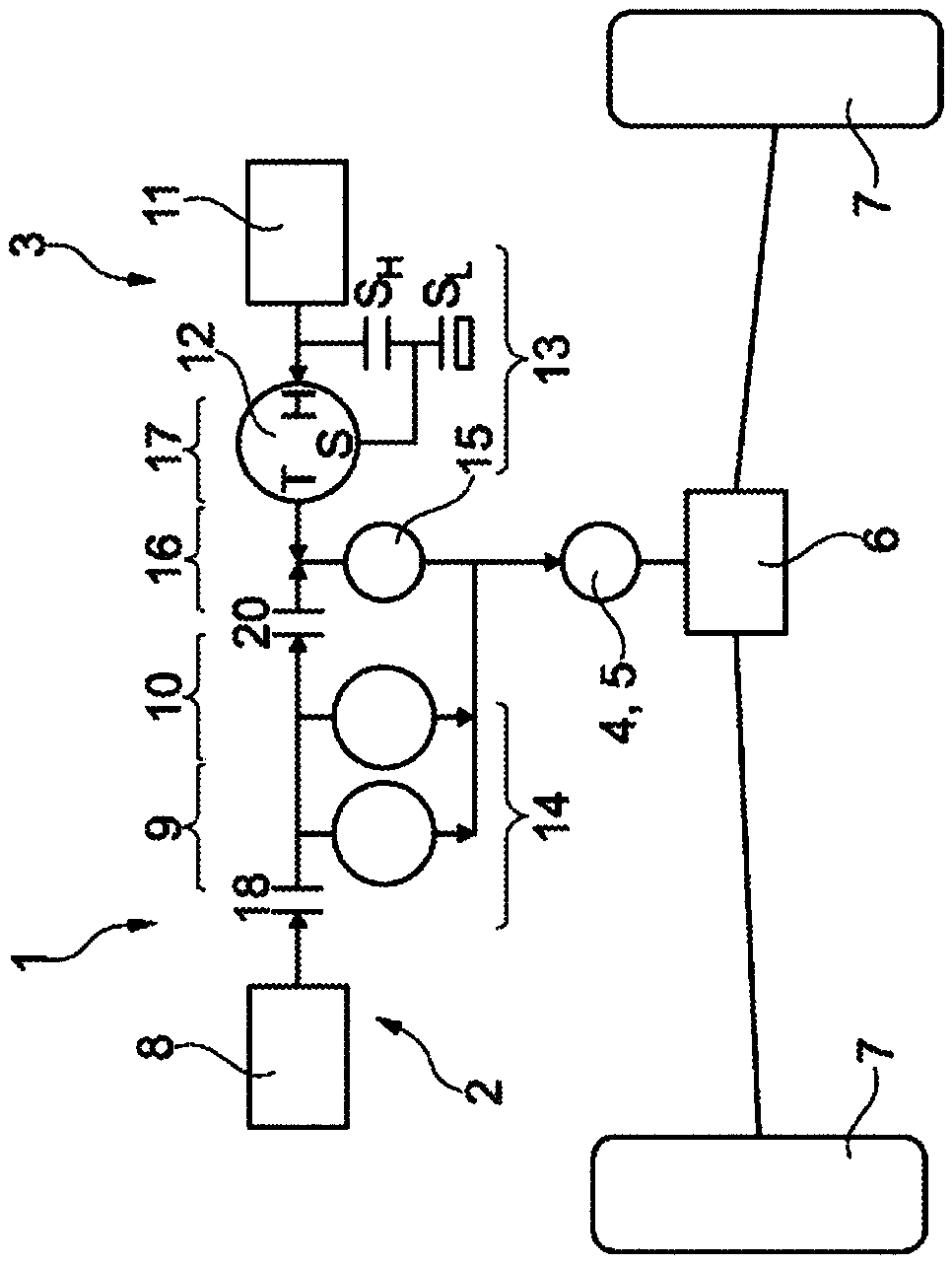

[0050] figure 1 Schematic diagram showing the logical design of a hybrid drive train 1 consisting of two drive train sub-trains 2 , 3 which can each be connected in a torque-transmitting manner with an output shaft gear 4 . In the exemplary embodiment shown here, the output shaft gear 4 is in the form of a so-called final drive wheel 5 , which is fastened to a differential 6 . Via the differential 6 , the torque arriving there is distributed and transmitted to the wheels 7 . Power train sub 2 may also be referred to as a first power train sub 2, and in figure 1 In the exemplary embodiment shown it is driven by an internal combustion engine 8 .

[0051] This first powertrain sub-train 2 is arranged as a very short transmission on one side of a final drive plane defined by the positioning of the final drive wheels and has a number of gears (see description bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com