Disk birotor dual veer DC brushless motor

A DC brushless, double-steering technology, applied in the field of motors, can solve the problems of wasting electric energy, small torque, and high energy consumption, and achieve the effects of expanding the scope of promotion and use, reducing manufacturing difficulty, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

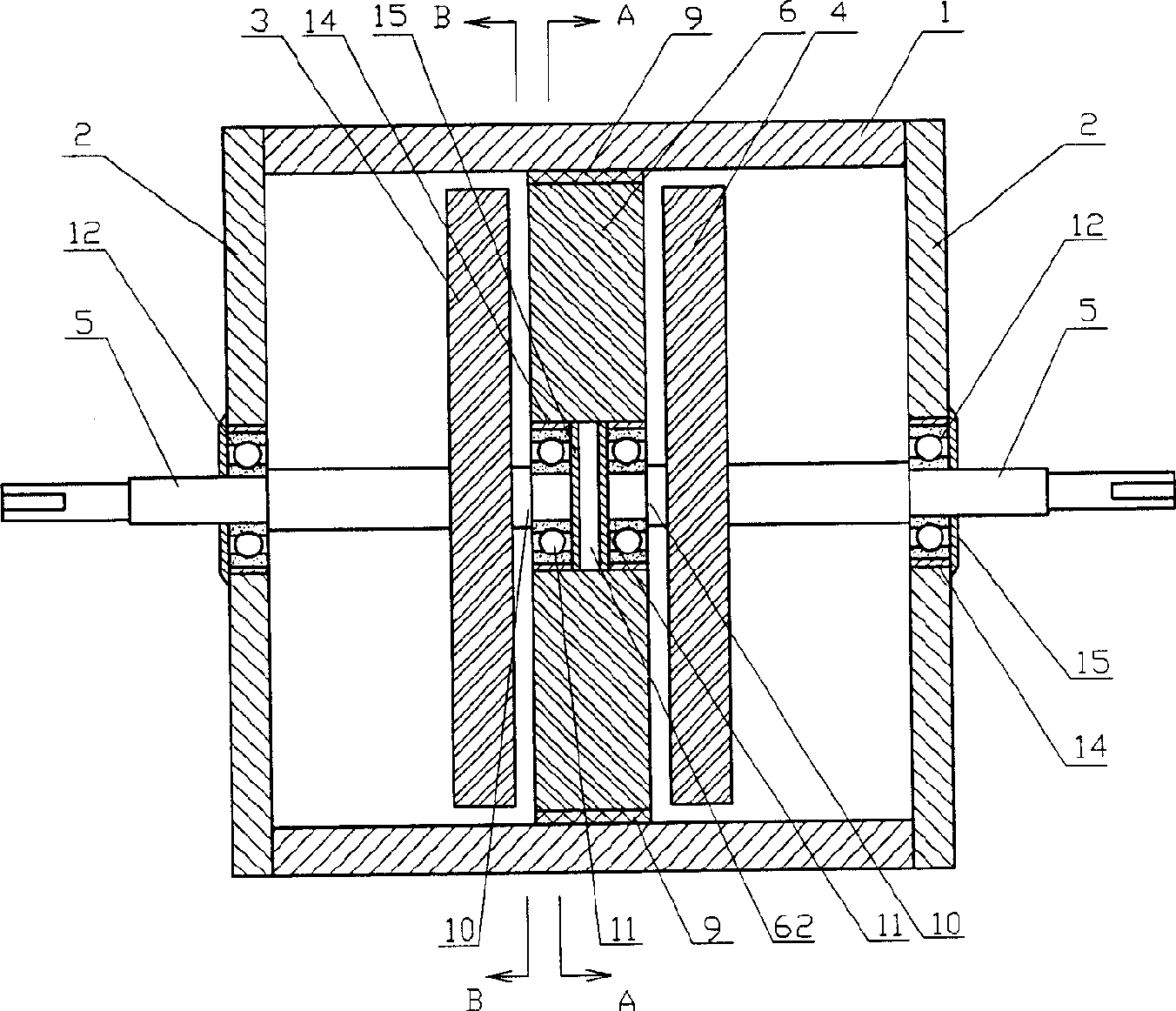

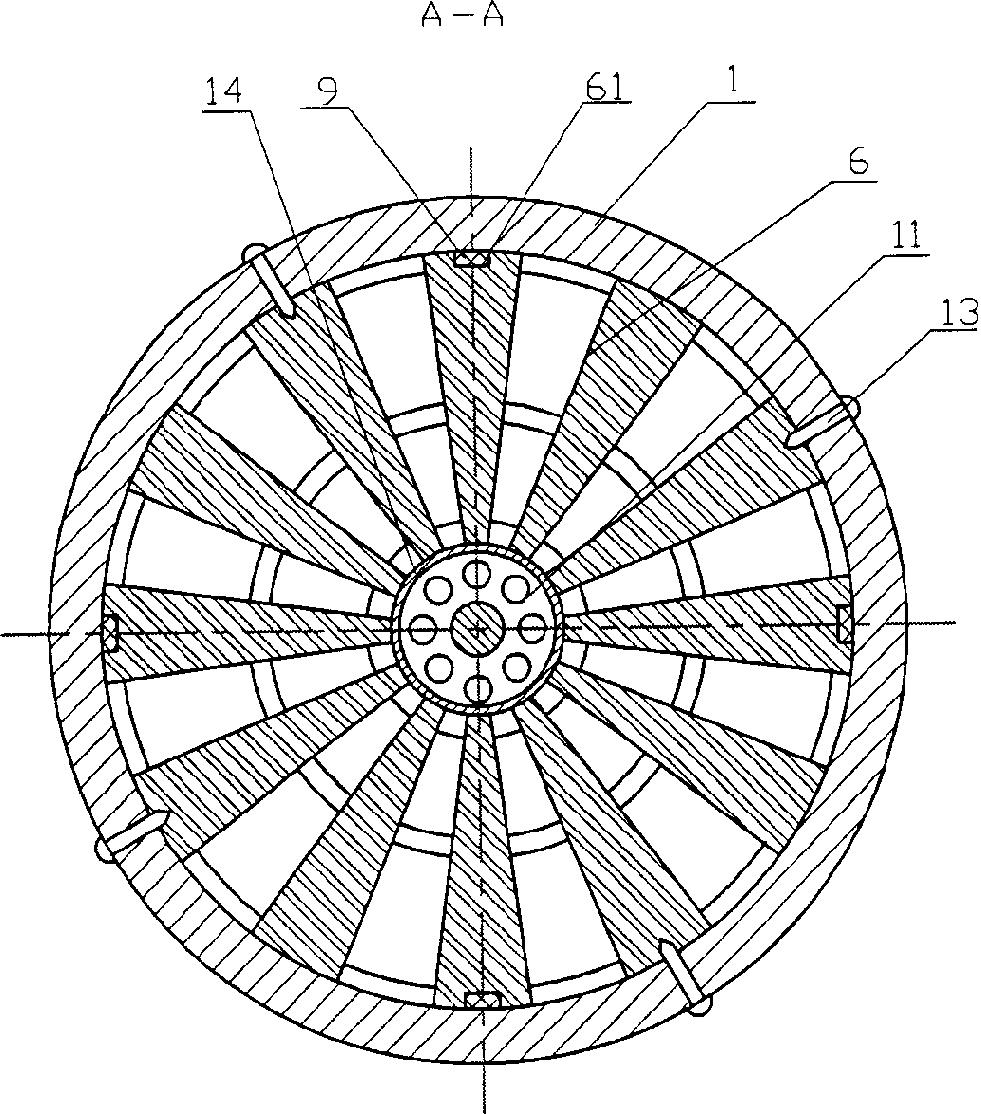

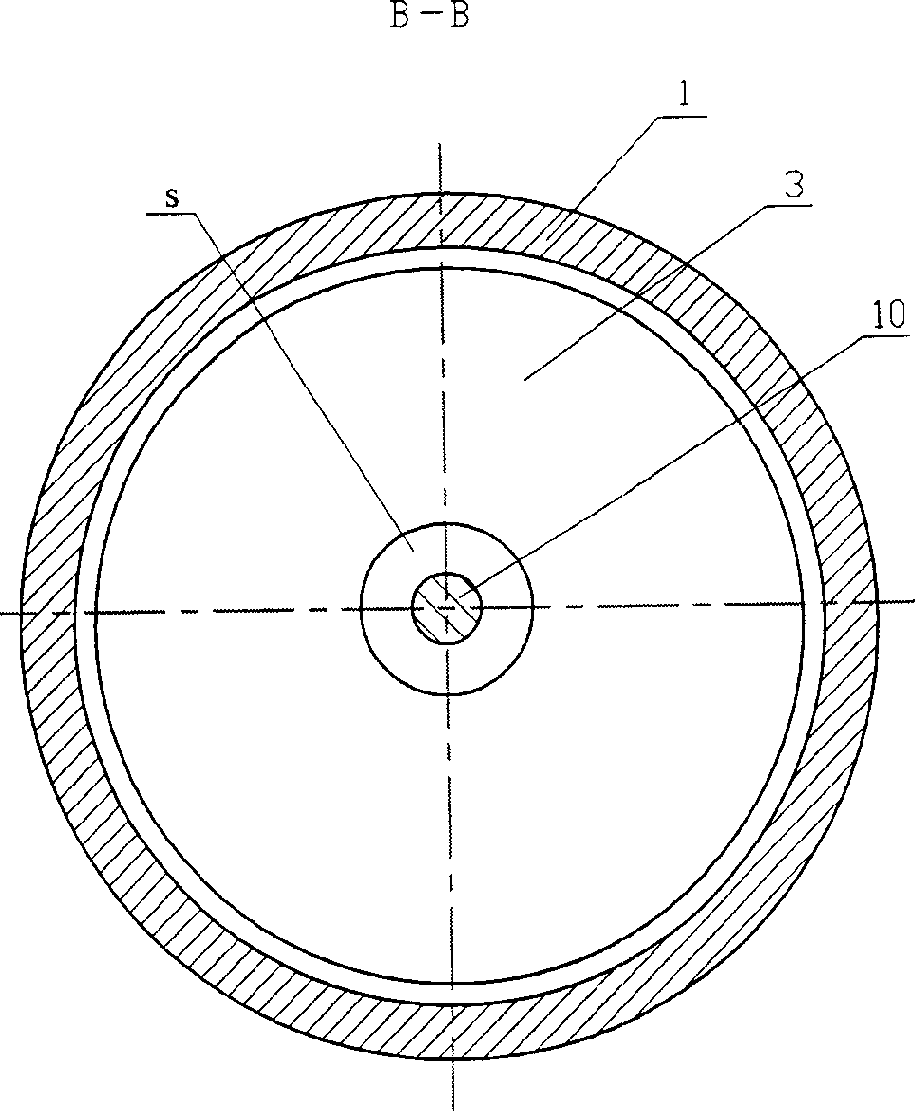

[0029] Figure 1 to Figure 9 Shown is an embodiment of the present invention, including a frame 1, an end cover 2, a stator, rotors 3 and 4, an output shaft 5, and the stator includes a stator core 6 and a stator winding. Such as figure 1 As shown, the end cover 2 is arranged at both ends of the frame 1, and the stator core 6 and the rotors 3 and 4 are all disc-shaped (see figure 2 and image 3 ), wherein the rotors are two permanent magnets, namely the N-pole rotor 3 and the S-pole rotor 4. In order to avoid the magnetic force between the rotor and the machine base and the end cover, the two rotors can also have N poles and S poles on the inner side only. The two rotors are vertically arranged in the machine base 1 respectively, and the inner surfaces thereof are corresponding to each other. One stator core 6 is vertically fixed between the two rotors, and its left and right sides correspond to the inner surfaces of the two rotors respectively. Such as figure 1 and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com