Sensor-less three-stage type starting method for deep well piston pump and application thereof

A piston pump and sensor technology, applied in the direction of electronic commutator, starting device, etc., can solve the problems of inaccurate control switching, high requirements for motor and controller starting and low-speed running characteristics, and limited electric energy, so as to improve the success of starting. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] The position sensorless three-stage start-up method of the deep well piston pump of the present invention is carried out in three stages, which will be described separately below.

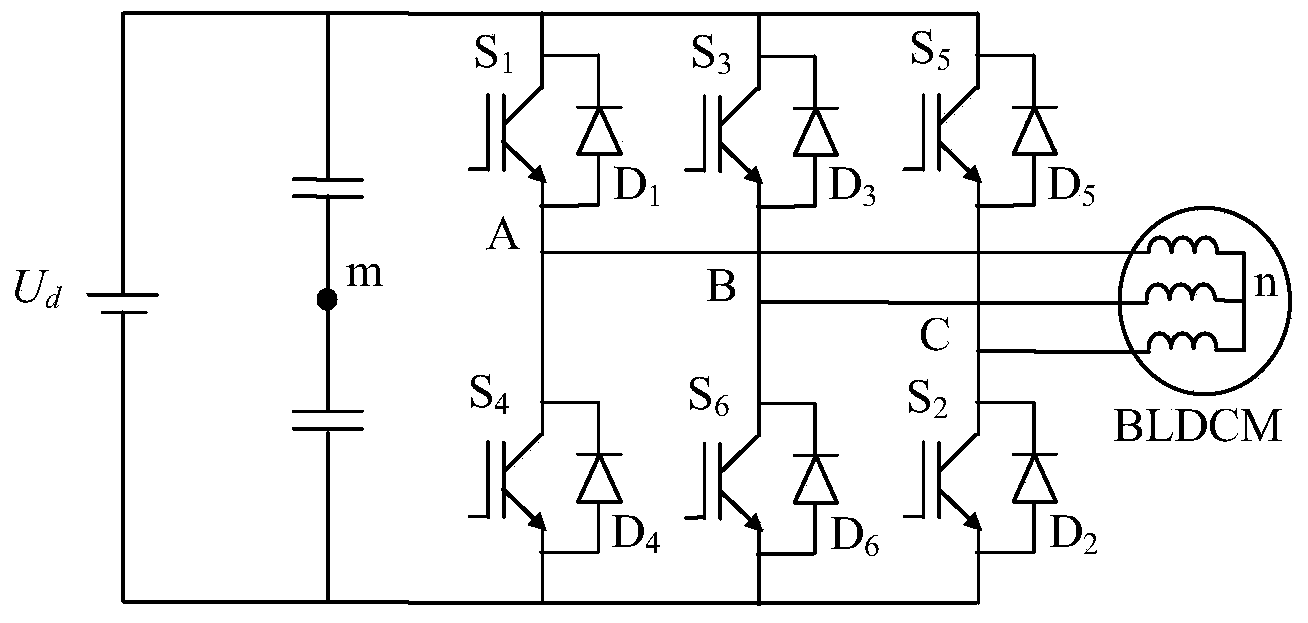

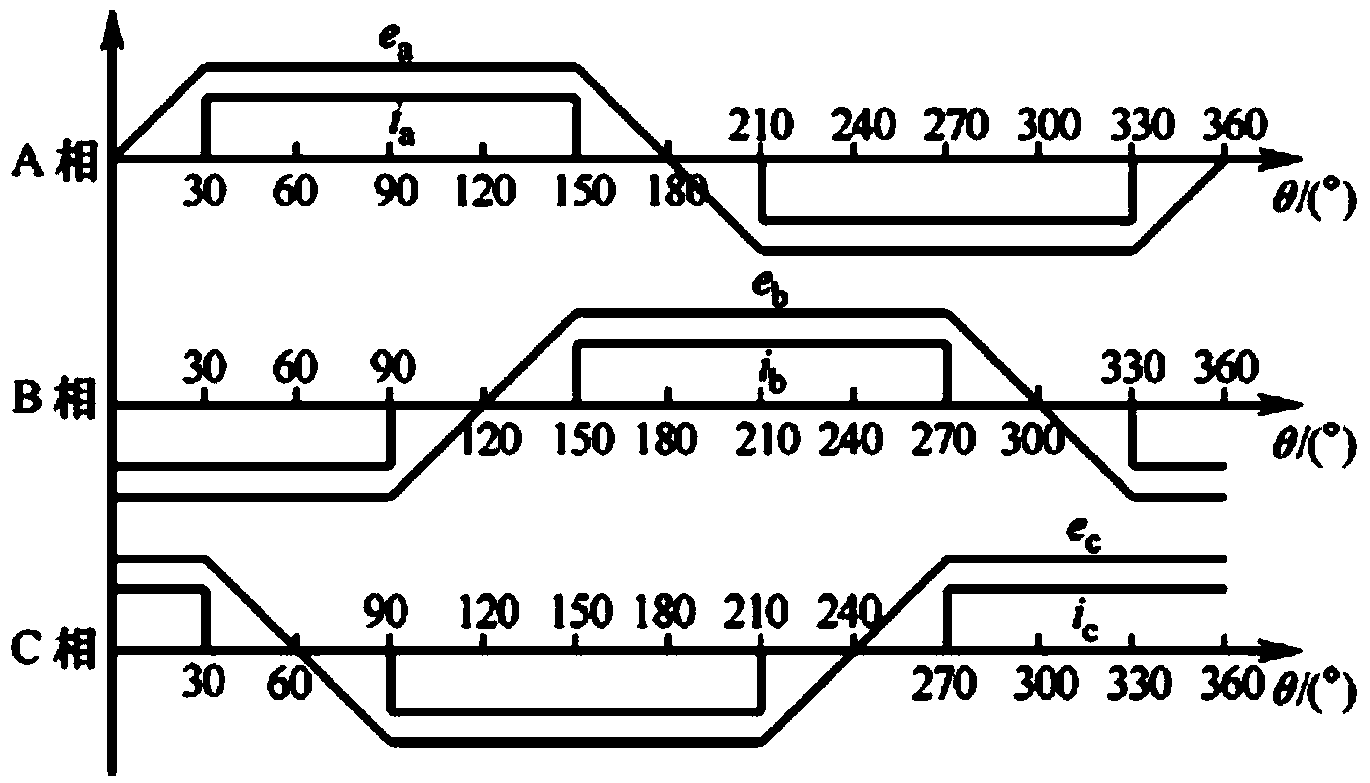

[0036] The first stage: adaptive drive based on short-term pulse detection and positioning. In this stage, the rotor position is detected by first applying a short-time pulse, and then gradually increasing the voltage vector corresponding to the optimal direction, so that the motor starts and accelerates from a standstill.

[0037] The first stage includes: step S1, determining the current position of the rotor based on short-time pulse detection and positioning, and controlling the inverter according to the control strategy corresponding to the position. Step S2, repeating step S1 until the rotational speed reaches the first threshold.

[0038] For step S1, due to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com