Device and method for preparing biogas by anaerobic fermentation of high-solid-content organic solid waste

A technology for organic solid waste and anaerobic fermentation, applied in solid-phase fermentation bioreactors, biochemical cleaning devices, biochemical equipment and methods, etc., can solve low heat and mass transfer efficiency, difficult material mixing, and easy acid accumulation and other problems, to achieve the effect of high heat and mass transfer efficiency, short start-up period, and high start-up success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

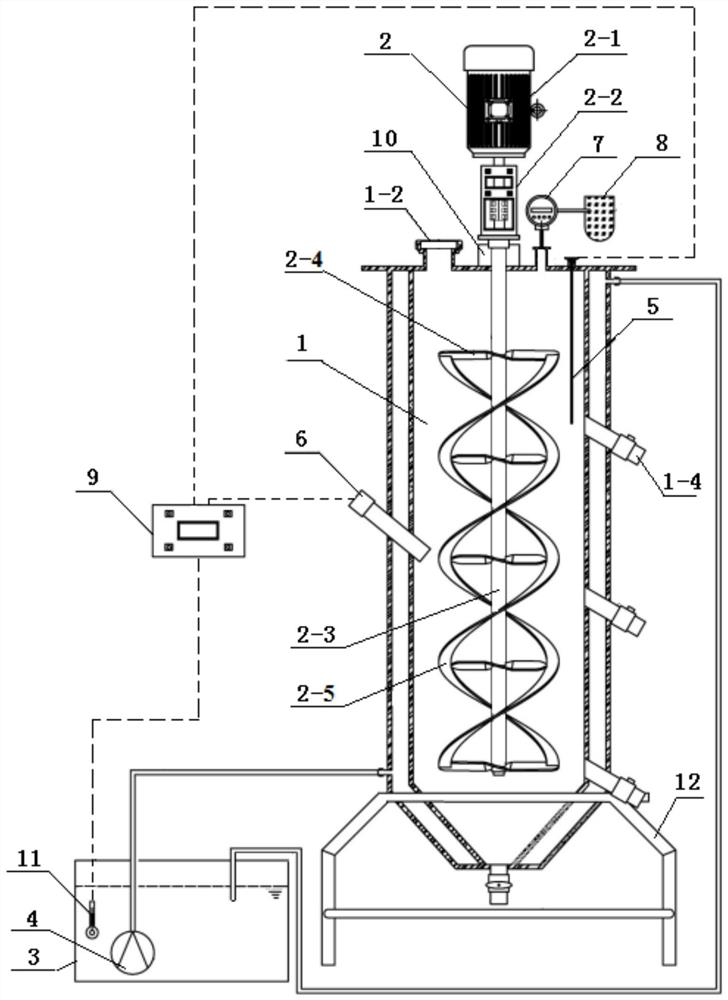

[0041] Embodiment 1: The device for preparing biogas by anaerobic fermentation of high-solid organic solid waste in this embodiment consists of a main reaction tank 1, a stirring power device 2, a constant temperature water tank 3, a submersible pump 4, a thermometer 5, a pH / ORP electrode 6, The gas flow meter 7, the gas collection bag 8 and the digital display control box 9 also include a liquid seal device 10, a temperature probe 11 and a bracket 12;

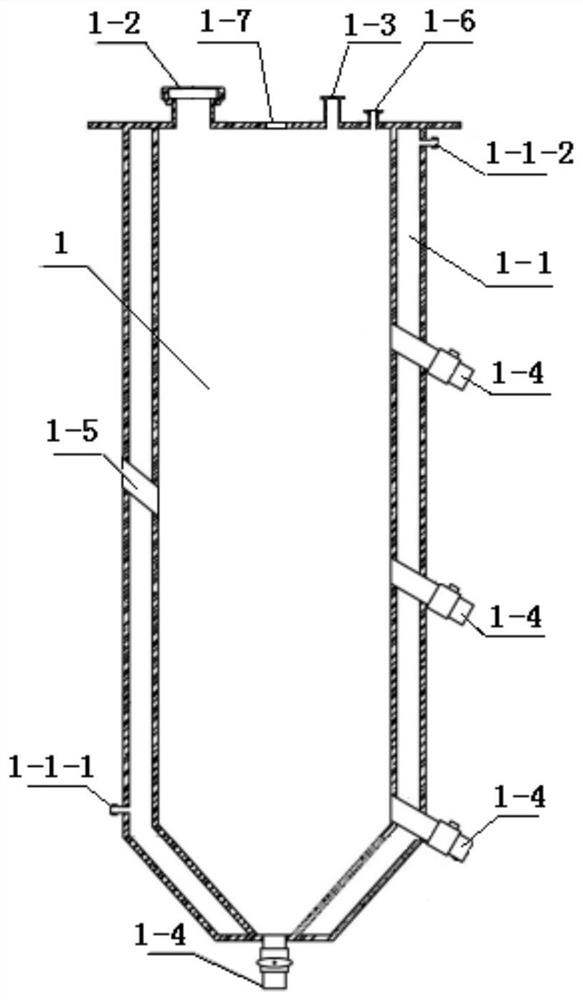

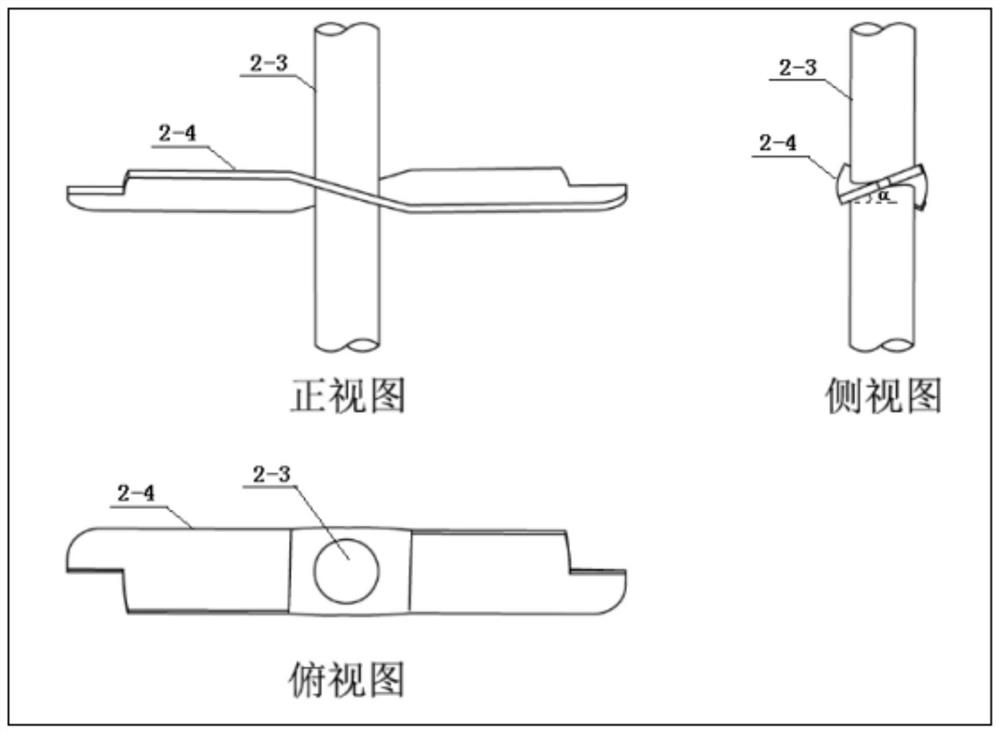

[0042] A water bath jacket 1-1 is set on the outer wall of the main reaction tank 1, an inlet 1-2 and an air outlet 1-3 are arranged on the top of the main reaction tank 1, and the side wall and the bottom of the main reaction tank 1 are arranged from top to bottom A plurality of discharge valves 1-4 are set; an electrode inlet 1-5 is also arranged on the side wall of the main reaction tank 1; a thermometer inlet 1-6 and a stirring installation hole 1-6 are also arranged on the top of the main reaction tank 1 7. The total volu...

Embodiment 2

[0055] Embodiment 2: Utilize the method for preparing biogas by anaerobic fermentation of high solid-containing organic solid waste of embodiment 1, carry out according to the following steps:

[0056] 1. Fill the anaerobic granular sludge into the reactor and fill it into the main reaction tank 1 from the feed port 1-2; mix it with domestic garbage, urban sludge and livestock and poultry manure to obtain a substrate with a TS of 30%, C / N ratio of 25:1 high solid organic solid waste organic substrate, according to the initial load of 1.5kgVS / (m 3 .d) Enter the high-solid organic solid waste substrate into the main reaction tank 1 through the feed port 1-2; the initial filling and feeding account for 60% of the volume of the main reaction tank 1, and the high-solid organic solid waste organic bottom The mass ratio of the wet body to the anaerobic granular sludge is 1:1; the submersible pump 4 is started to input the hot water in the constant temperature water tank 3 to the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com