Artificial turf infill

a technology of artificial turf and playing surface, applied in the field of artificial turf playing surface, can solve the problems of lead, zinc and cadmium, and could be harmful to the environment, and achieve the effects of increasing water absorption and retention capacity, and reducing the risk of silicosis and other respiratory harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

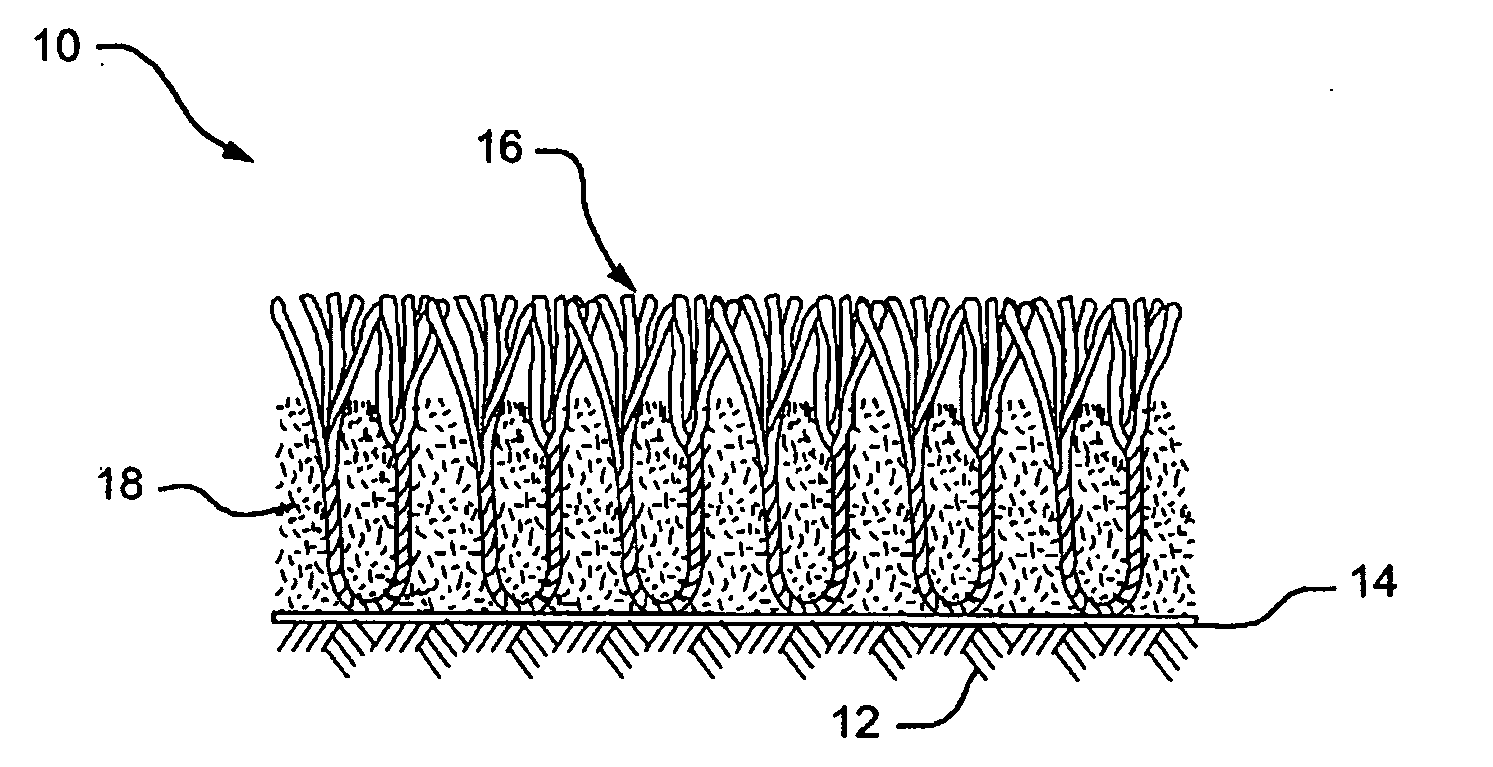

[0026]Referring to FIG. 1, a cross-sectional view of an artificial turf system 10 comprising an aggregate turf base 12, a backing 14 made of woven or non-woven material, a pile fabric 16 tufted in the backing 14 and an infill 18 in the space around the filaments of the pile fabric 16 according to the present invention.

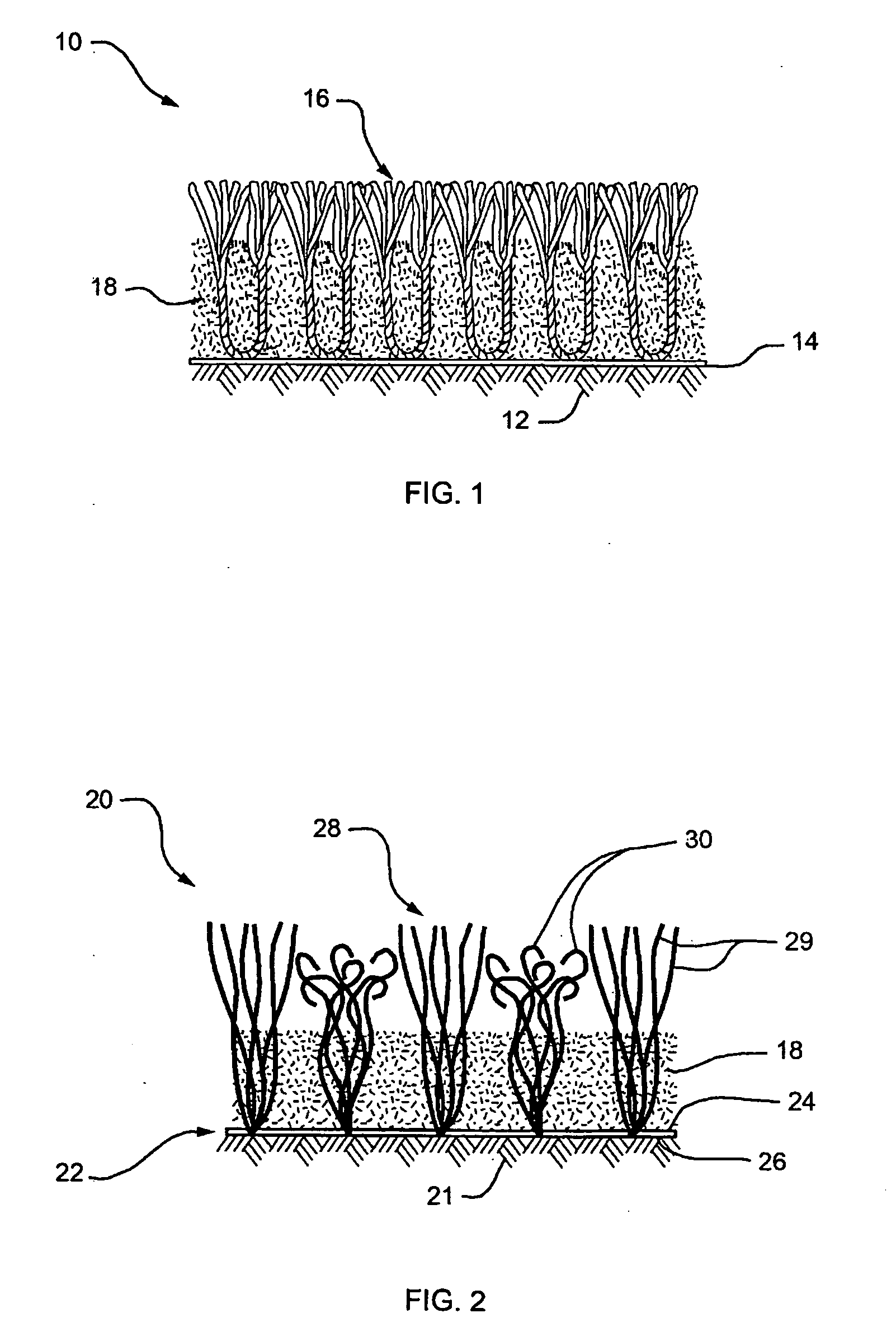

[0027]Referring to FIG. 2, a cross-sectional view of another artificial turf system 20 comprising of a aggregate turf base 21, a backing 22 made of woven or non-woven sheet material, a pile fabric 28 tufted in the backing 22, and the infill 18 in the space around the filaments of the pile fabric 28 which is a resilient granular material. The pile fabric 28 comprises a straight yarns 29 and curled yarns 30 tufted in the backing 22 in alternating stitch lines.

[0028]The backing 22 of the artificial turf system 20 comprises a primary backing 24 and a secondary backing 26 and it is sufficiently permeable. If the secondary backing 26 is impermeable, it should have plural hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com