Modification method for adjusting pressure of single-hole carbonization chamber in existing coke oven

A chamber pressure, single-hole carbon technology, used in coke ovens, furnace safety devices, petroleum industry, etc. Control and adjustment means and other problems, to achieve the effect of simple and easy structure and method, few devices and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

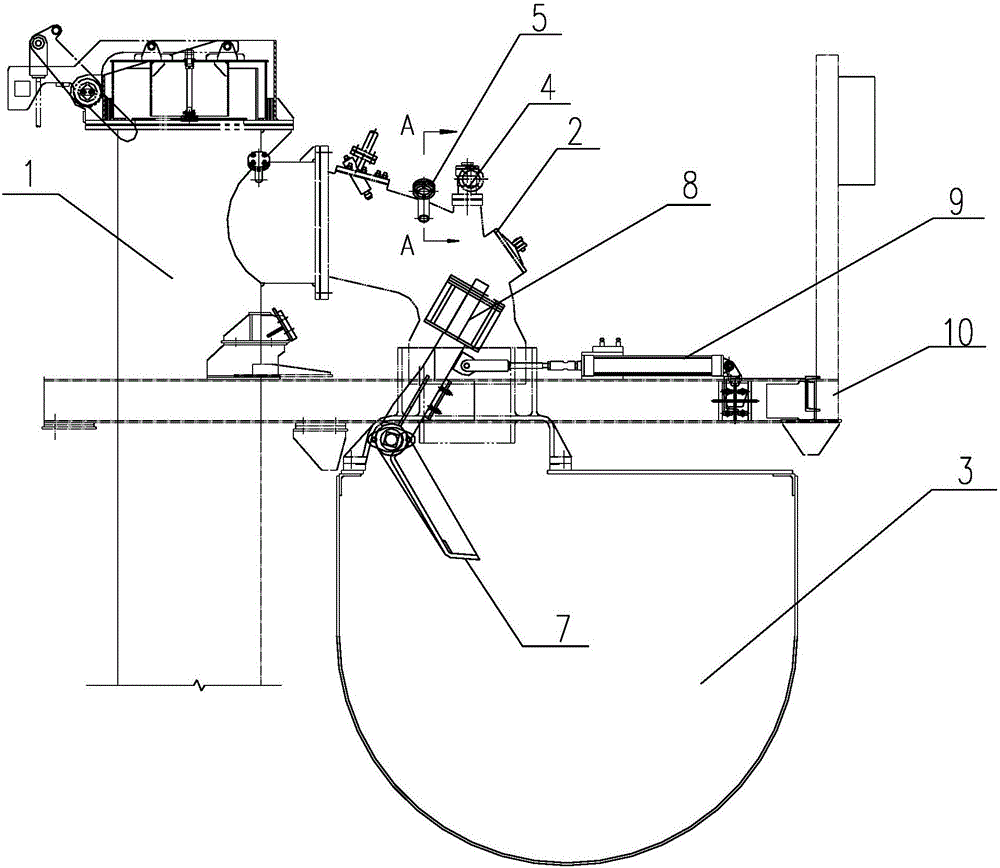

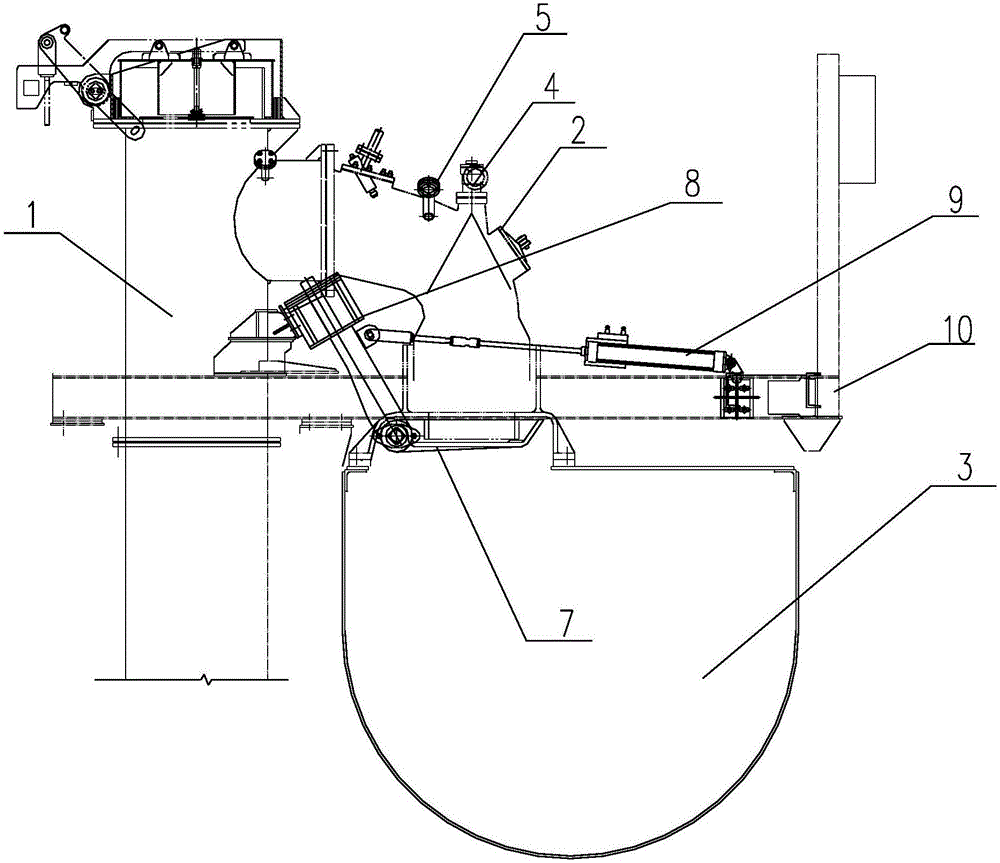

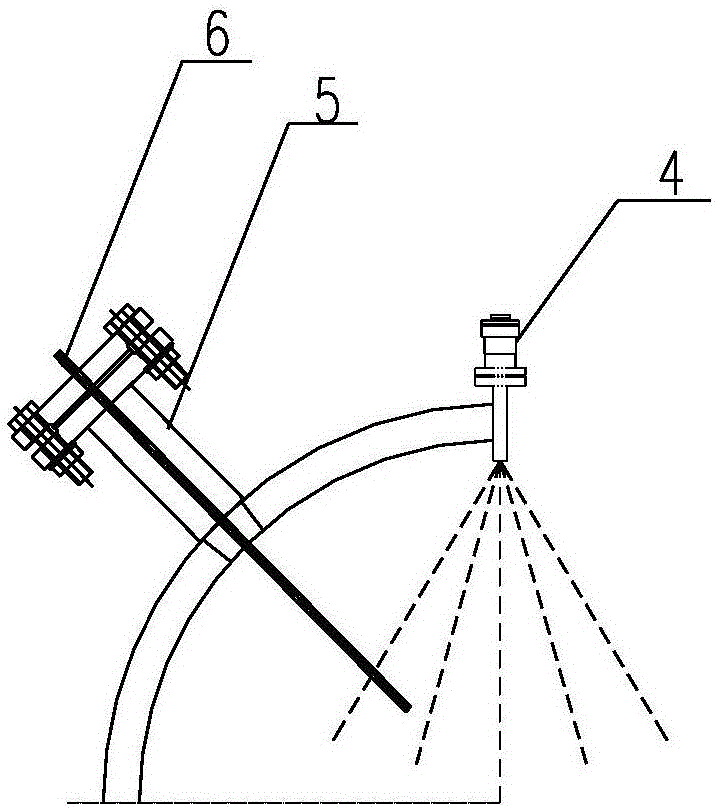

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] Such as Figure 1-Figure 3 As shown, a kind of existing coke oven of the present invention realizes the modification method of single-hole carbonization chamber pressure regulation, comprises the following steps:

[0025] 1) Install the piezometric tube guide sleeve 5 on the bridge tube 2, the piezometric tube 6 passes through the piezometric tube guide sleeve 5 and extends into the bridge tube 2, and the protruding end is within the spraying range of the ammonia water nozzle 4; An actuator 9 is installed on the console 10, and the power output end of the actuator 9 is connected to the moving rod 8 of the water-sealed valve disc; the pressure measuring tube 6 and the actuator 9 are both connected to the computer control system;

[0026] 2) According to the different amount of raw gas produced in different working hours of the coke oven, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com