Patents

Literature

38results about How to "Easy to blow up" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

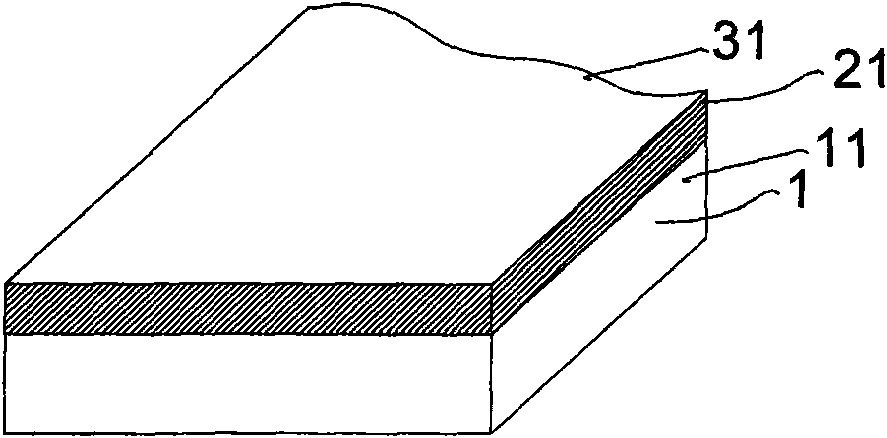

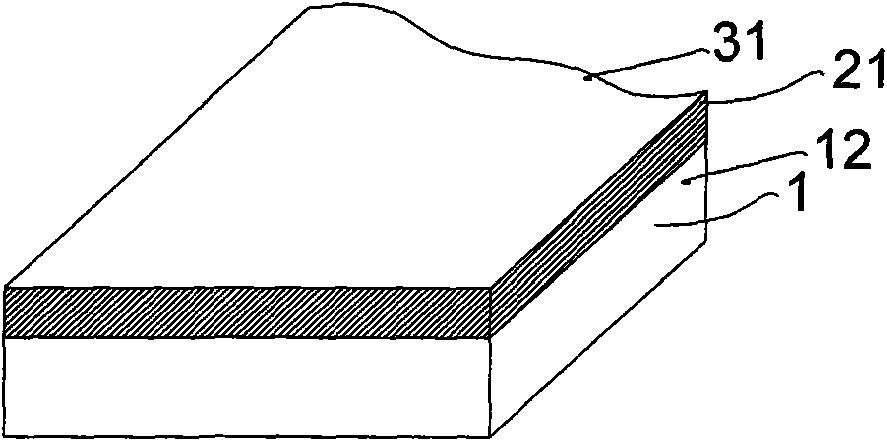

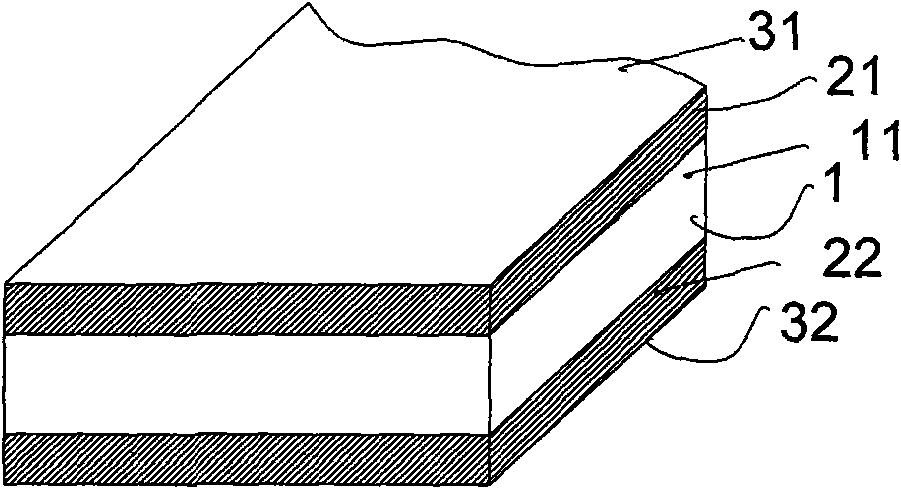

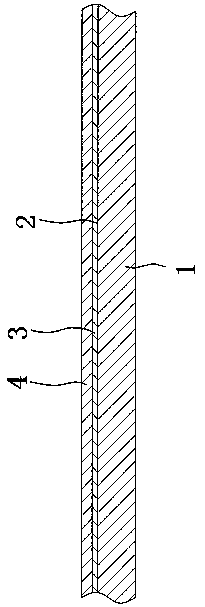

Paint-free abrasion resistant veneer and preparation technique thereof

InactiveCN101554825ALow priceEasy accessLamination ancillary operationsDecorative surface effectsSurface layerLacquer

The invention discloses a paint-free abrasion resistant veneer which comprises a base material layer; one surface of the base material layer is stuck with a first surface layer; and the first surface layer is first glue film blank paper which is coated with a first alumina layer which is dried and solidified to form first glue film paper. The paint-free abrasion resistant veneer preparation technique comprises the surface layer manufacture step, the base material selecting step, the blank-matched sticking step, the high temperature overlaying step and the deburring decoration step. The surface layer manufacture step comprises the steps of selecting the natural wood-grain colored or plain decorative paper of series designs and colors; selecting melamine-resin adhesive or melamine modified urea-formaldehyde resin as a cementing compound; forming the glue film blank paper by the decorative paper after being dipped by the cementing compound; spraying alumina on the outer surface of the glue film blank paper to form a surface layer so as to form the glue film paper; the base material selecting step comprises the steps of selecting veneers or blockboards; and the blank-matched sticking step comprises the steps of butting the inner surface of the glue film paper and sticking one surface of the selected veneer or respectively butting the inner surfaces of two pieces of glue film paper and sticking the two surface of the selected veneer to form a blank-matched decorative veneer. The paint-free abrasion resistant veneer and preparation technique thereof have the advantages of convenient processing, beauty and practicability, high strength, long service life and good environmental protection property.

Owner:张良明

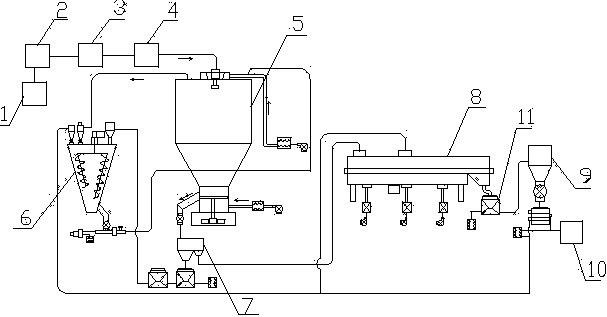

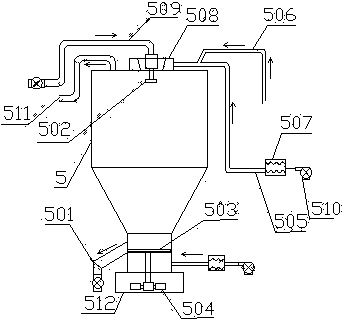

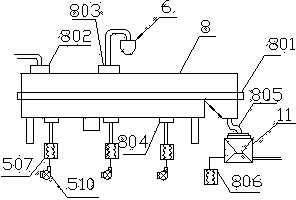

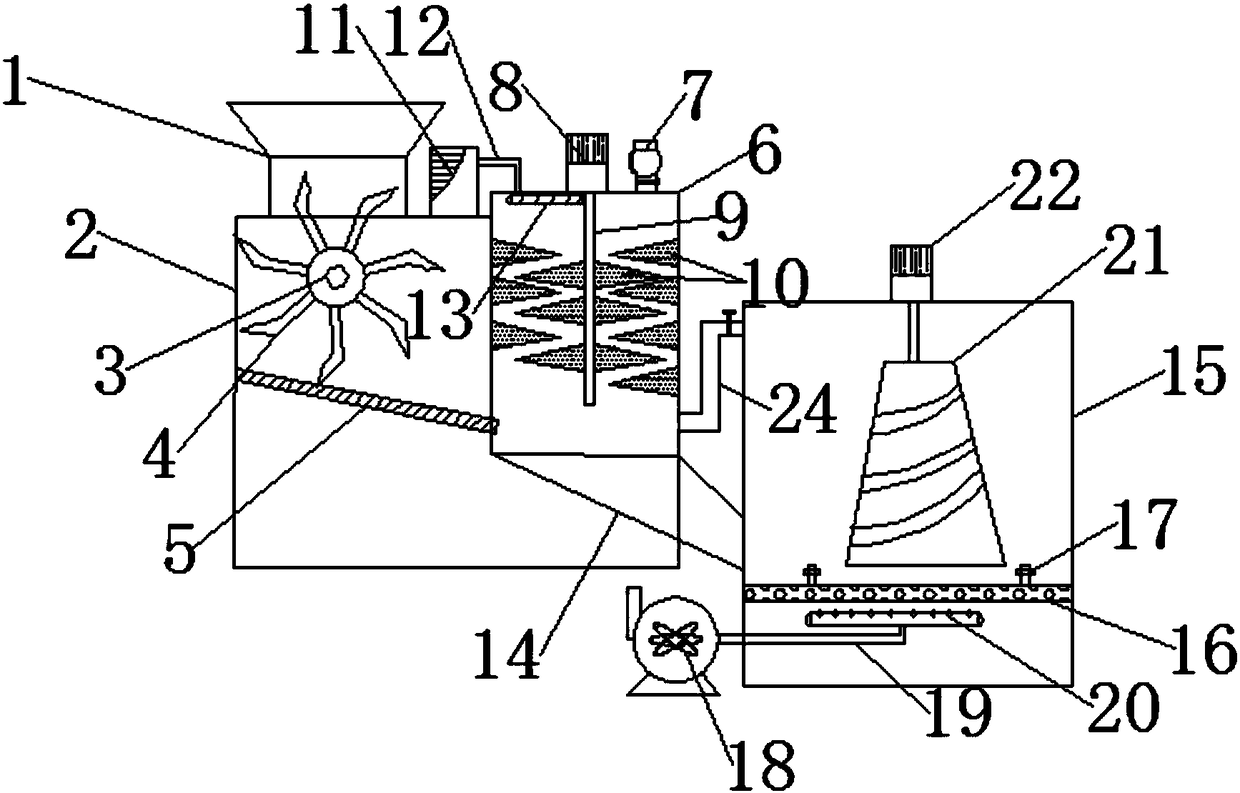

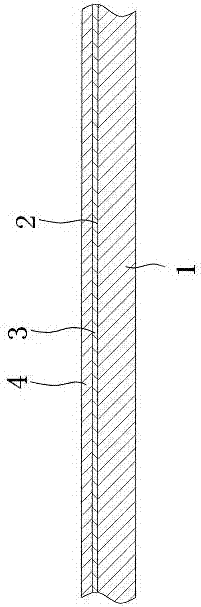

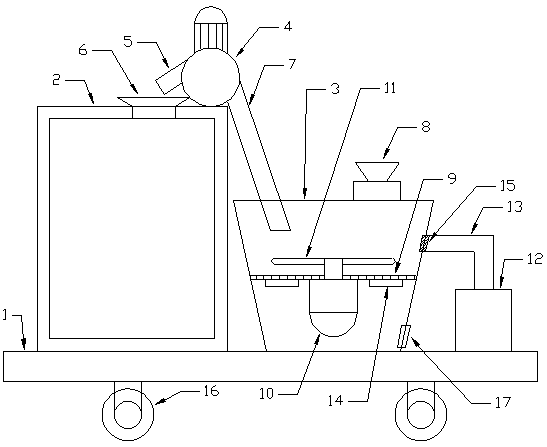

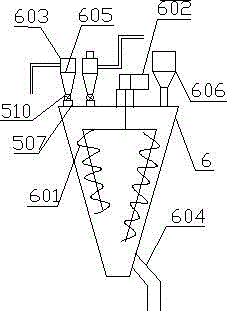

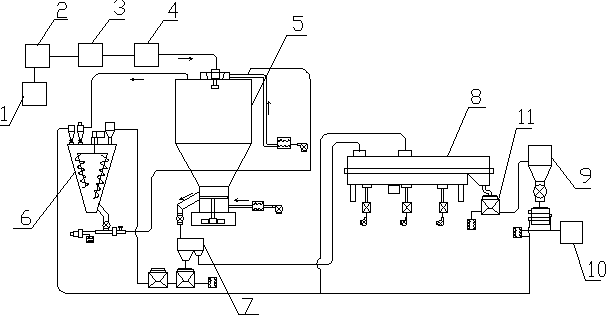

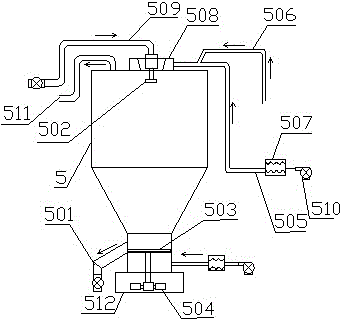

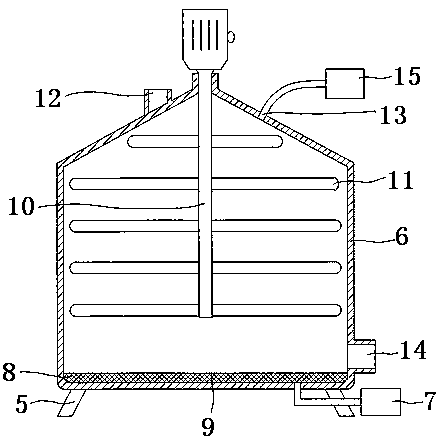

Preparation process and device of vitamin D3 microcapsule powder

ActiveCN104306353AImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processCalcium biphosphateSolubility

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

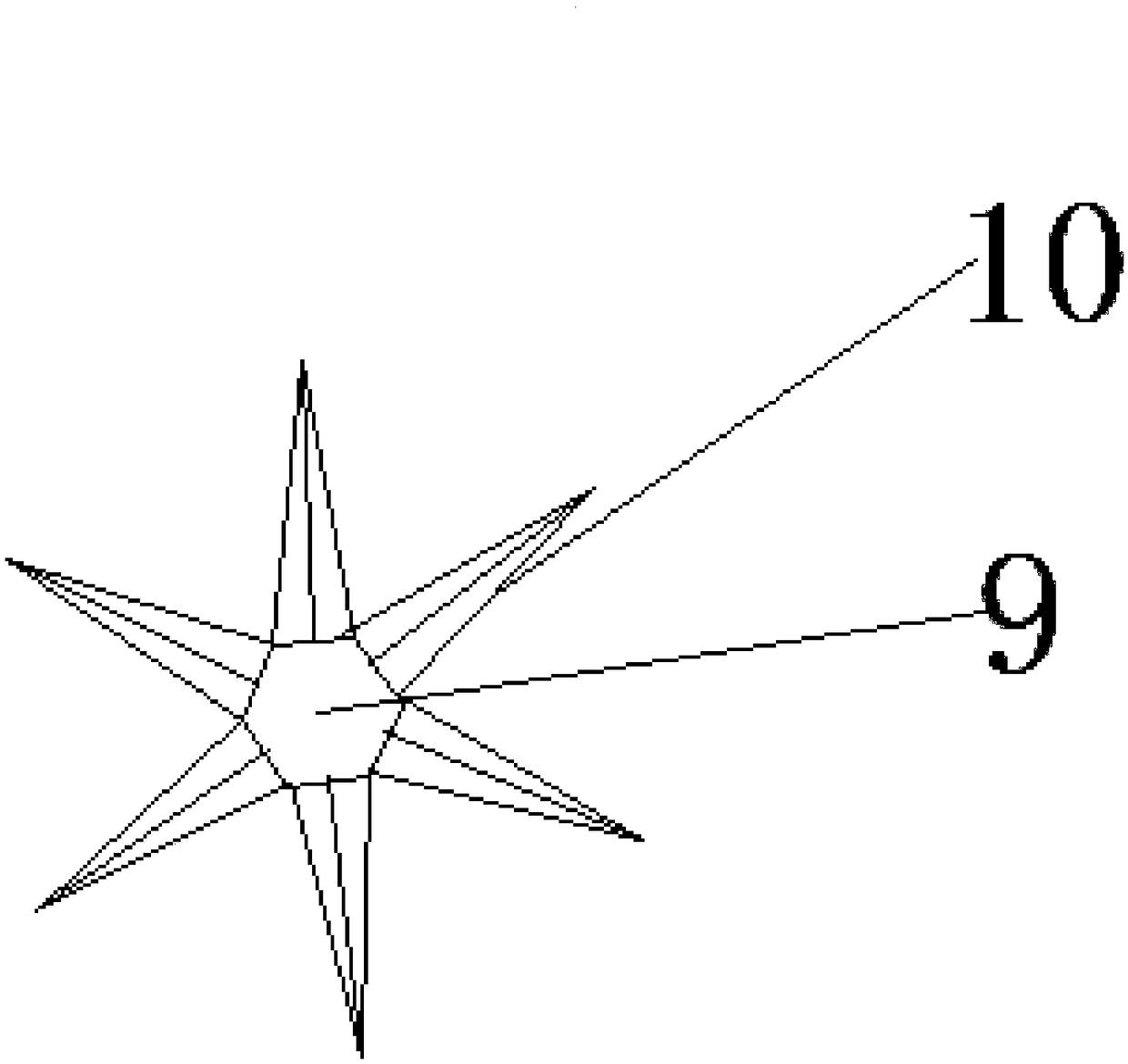

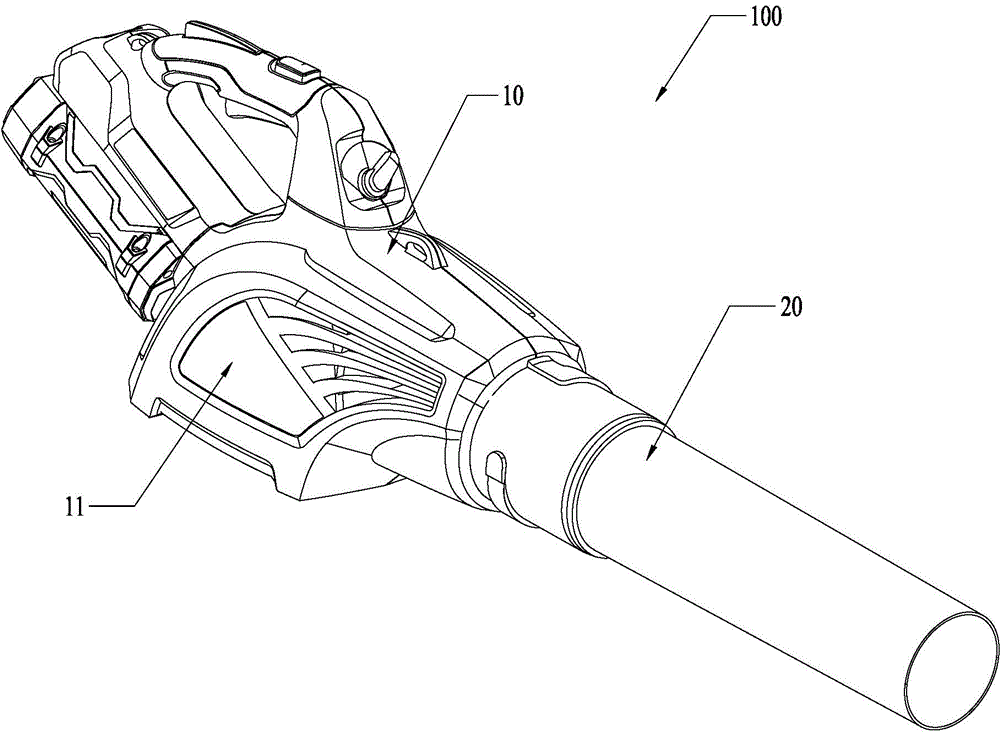

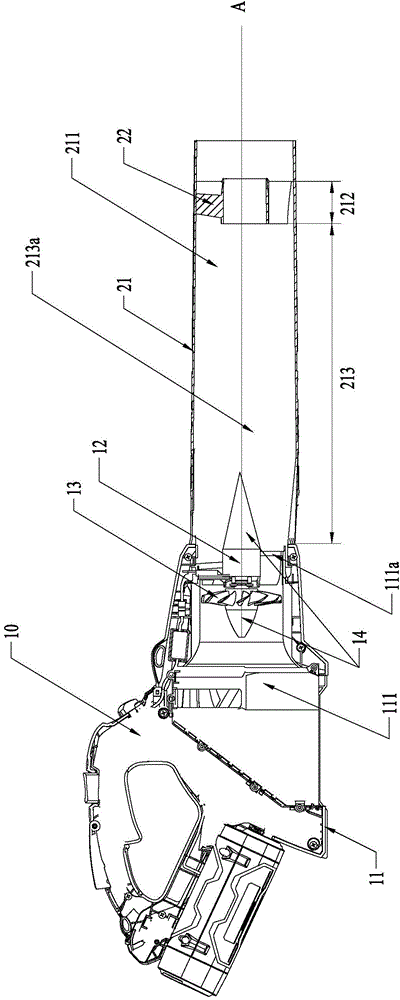

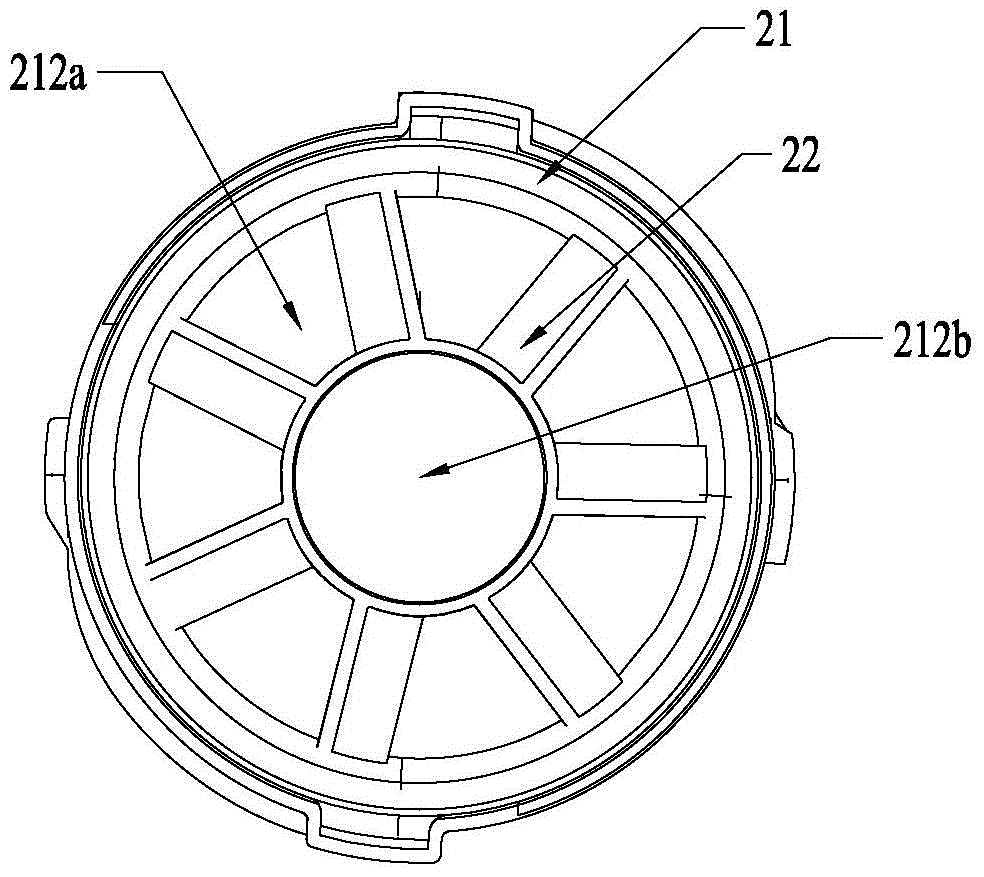

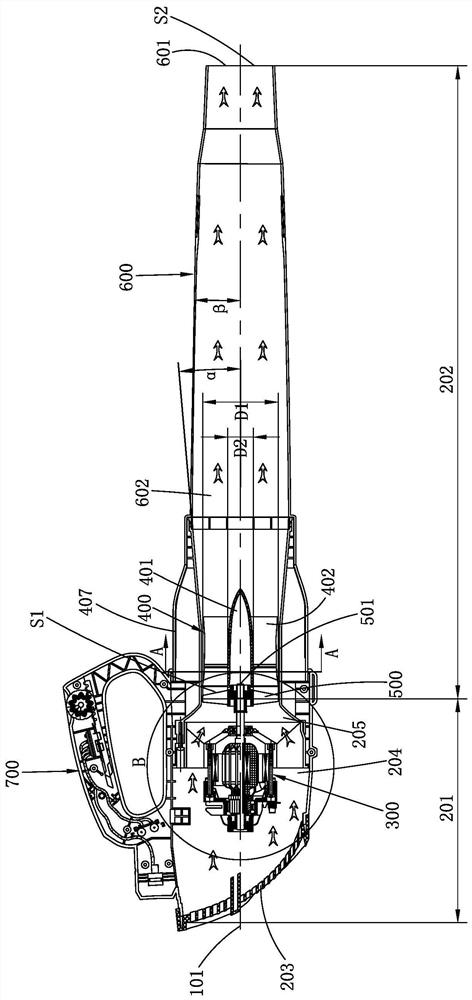

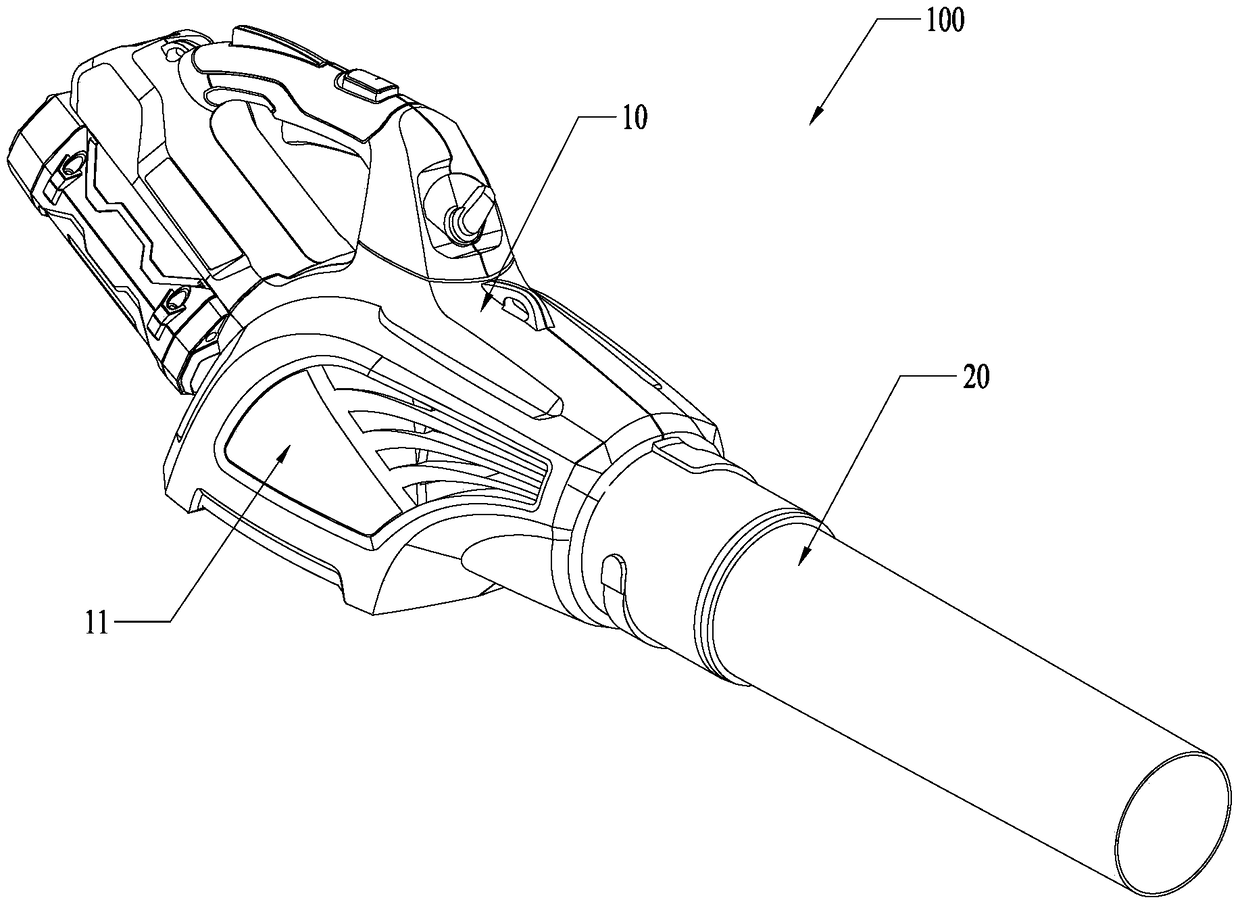

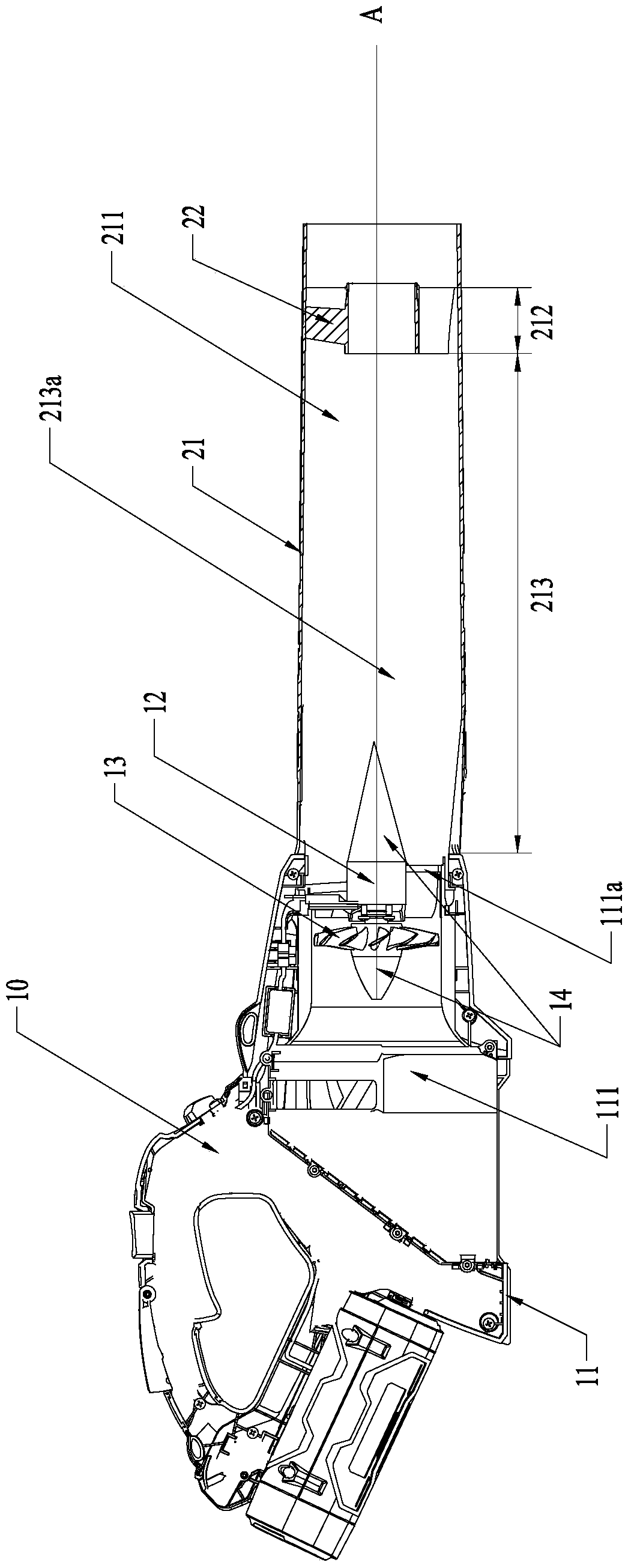

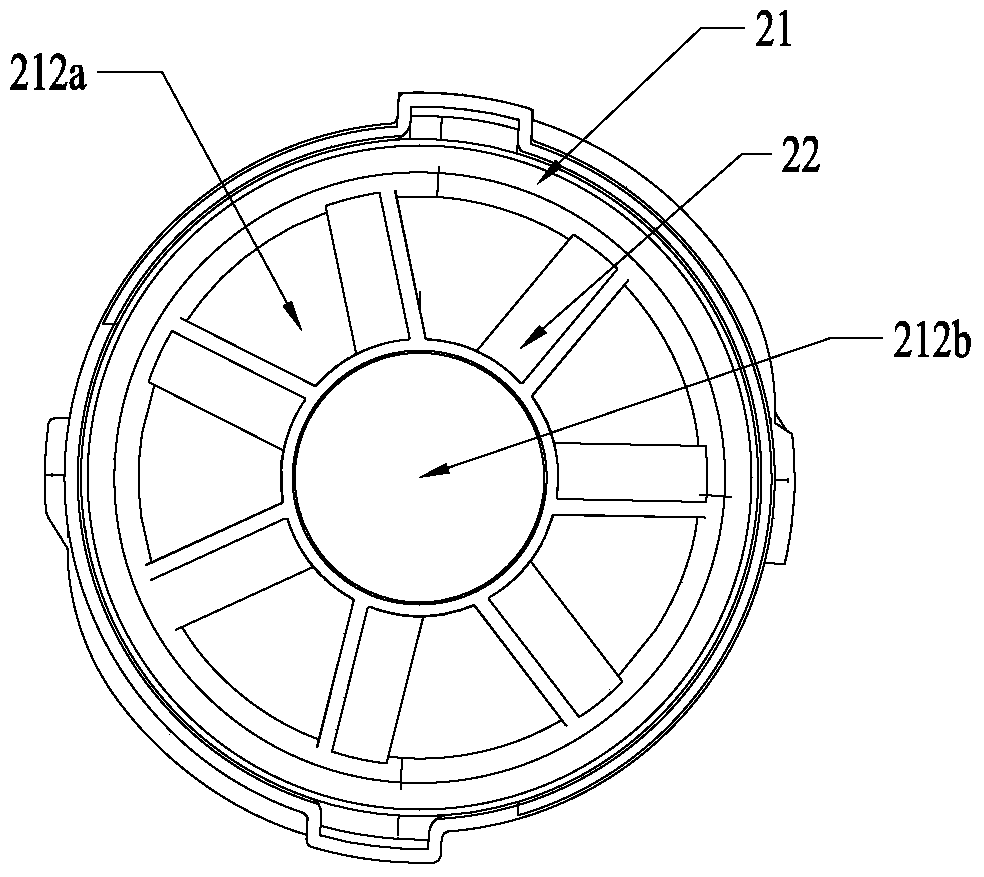

Air blower

The invention provides an air blower which comprises a shell, a motor, an axial fan, an air blowing pipe and a duct, wherein an air inlet is formed in the shell; air enters from the air inlet; the motor is located in the shell; the axial fan is driven by the motor to rotate to generate an air flow; the axial fan comprises matched and connected with the motor and a plurality of blades mounted on the hub; the air blowing pipe is connected with the shell and is provided with an air outlet; the air flow is blown out of the air outlet; the duct is used for guiding the air flow to move toward the air outlet; the diameter of the axial fan is less than 88mm; the rotating speed of the motor is more than 21000rpm. Compared with the prior art, the air blower provided by the invention has the advantages that the small-diameter fan is driven at a high rotating speed, the power consumption is low, the higher air-blowing efficiency is acquired, the heavier leaves on the lawn and the leaves located in the gaps can be conveniently blown.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

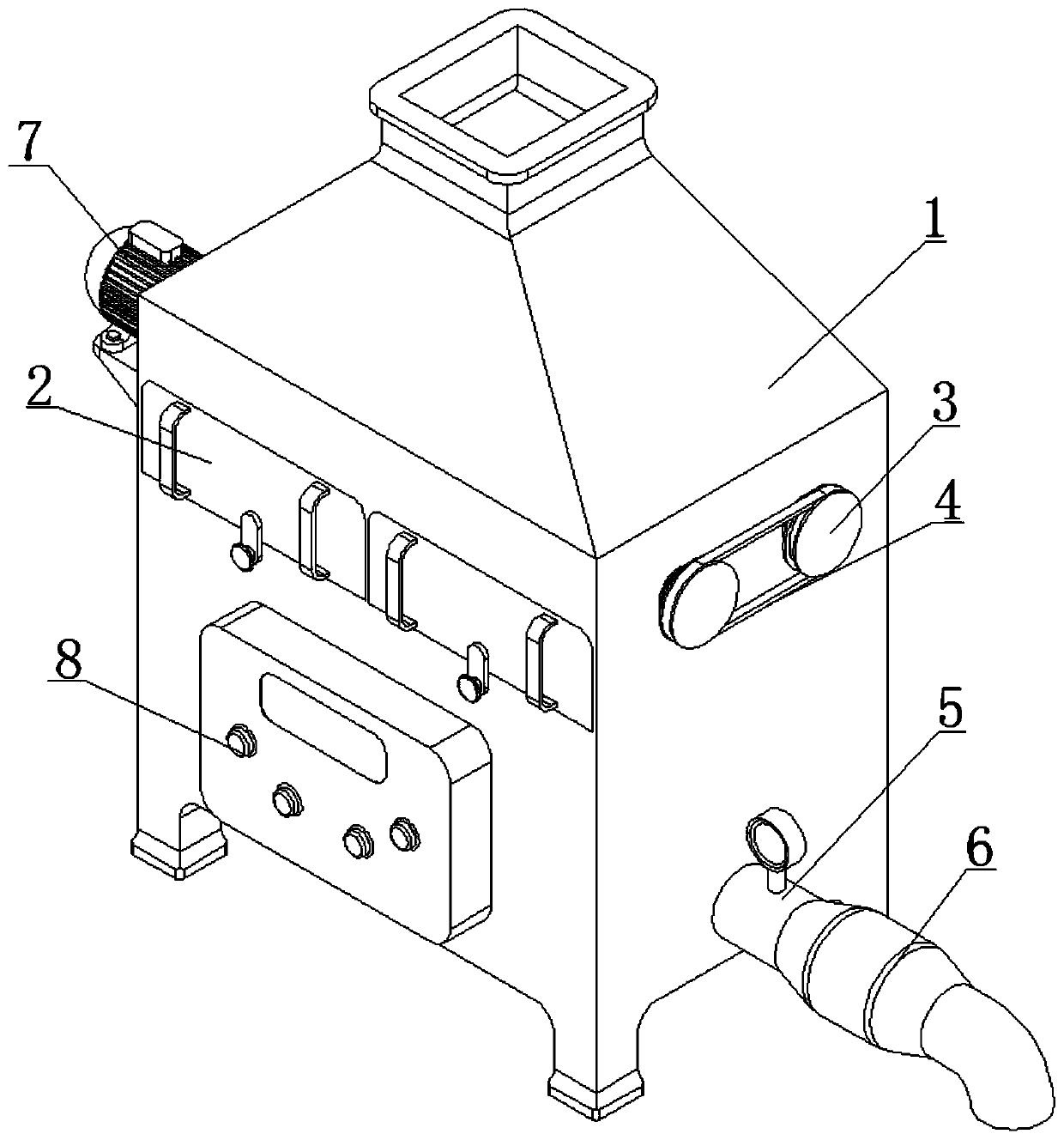

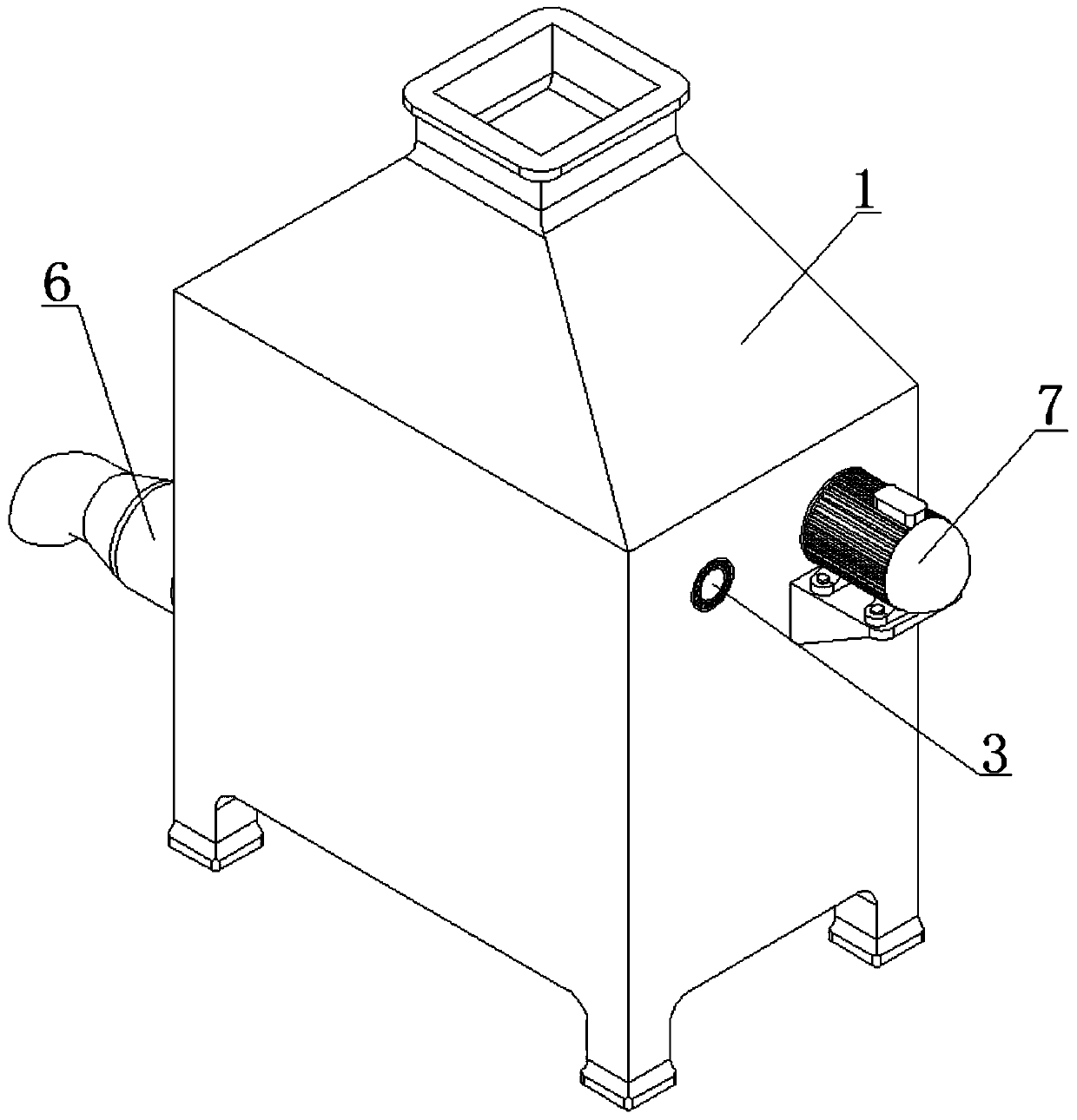

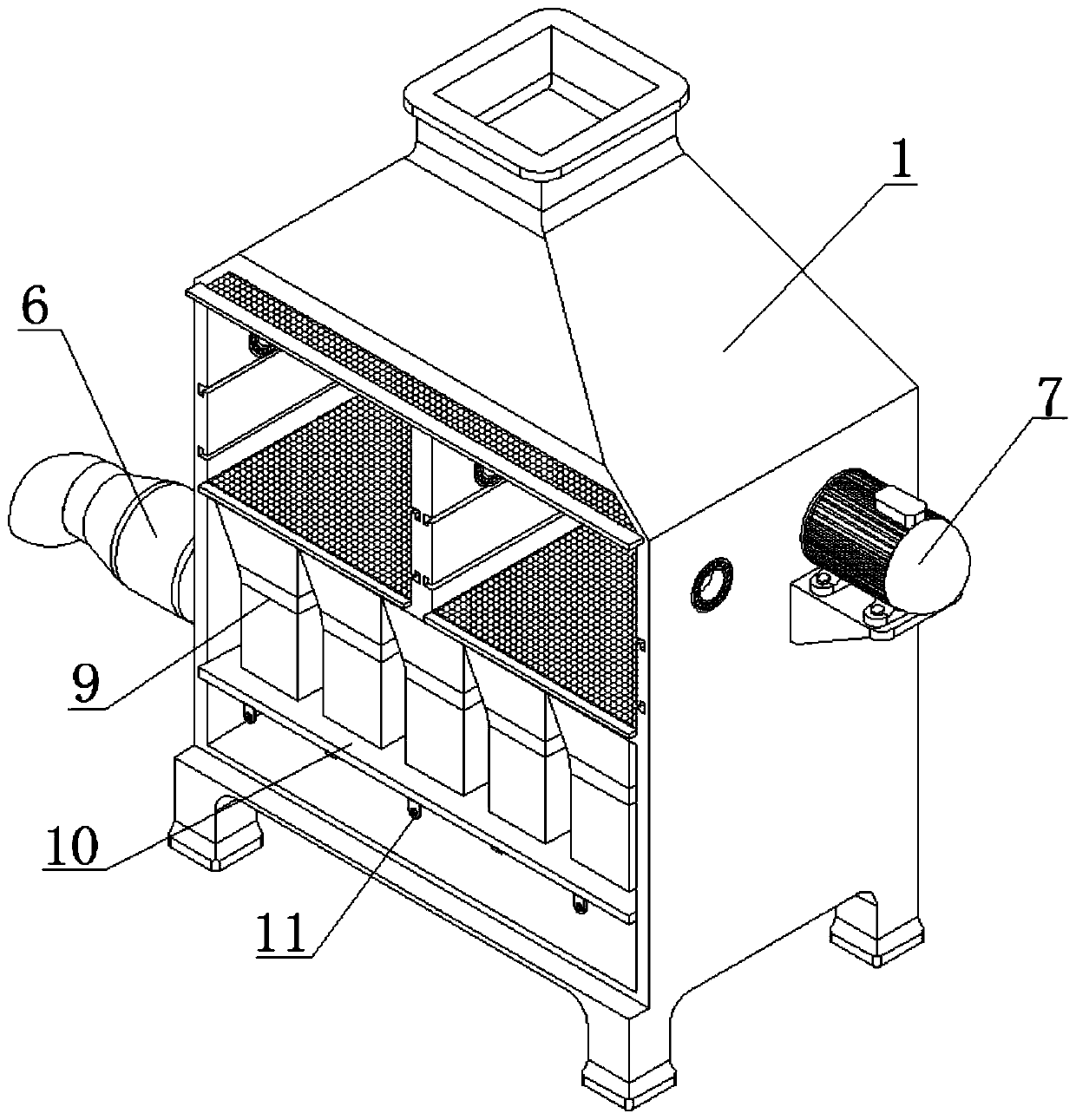

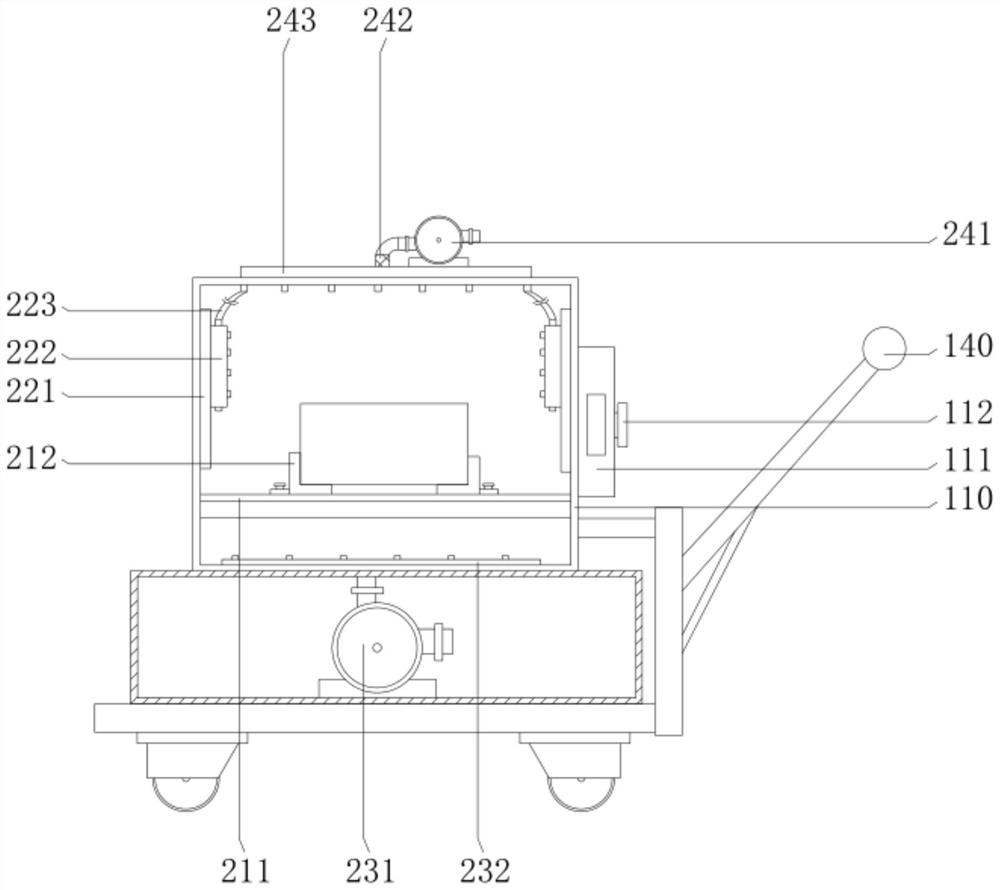

Safe and efficient medical waste disposal incinerator

InactiveCN108397778AEasy to put inCheck it offAir/fuel supply for combustionIncinerator apparatusCombustionMedical waste

The invention discloses a safe and efficient medical waste disposal incinerator which comprises a feeding pipe, a housing, a rotary roller, a drawing rake, a sliding plate, a cutting box, cutting blades, a gas collecting tank, a combustion box, a combustion plate, an air blower, a rotary drum and a rotary motor, wherein the feeding pipe is arranged at the top end of the housing; the lowest end ofthe sliding plate is connected with the cutting box; a stirring motor is mounted at the top end of the cutting box; an output shaft of the stirring motor is connected with a stirring shaft; the cutting blades are arranged on the stirring shaft and on the inner wall of the cutting box; the top end of the cutting box is connected with the gas collecting tank through a breather pipe; the bottom end of the cutting box is connected with the combustion box through a conveying pipe; the combustion plate is arranged in the combustion box; a spraying grate is arranged below the combustion plate and communicates with the air blower through a vent pipe; and the side wall of the top end of the combustion box communicates with the cutting box through a hot-gas feeding pipe. The safe and efficient medical waste disposal incinerator avoids breeding and spread of harmful germs to improve security, prevents medical waste from polluting the external ambient air and being stacked, facilitates combustionof waste, is simple in structure and convenient to use and facilitates popularization.

Owner:合肥龙之韵医药技术有限公司

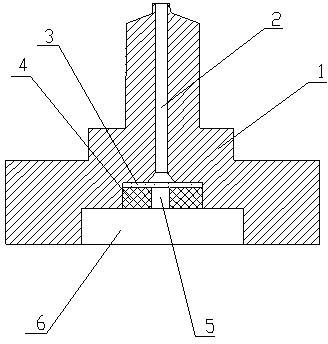

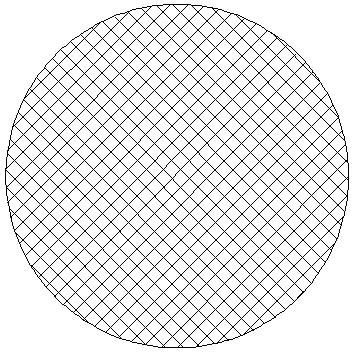

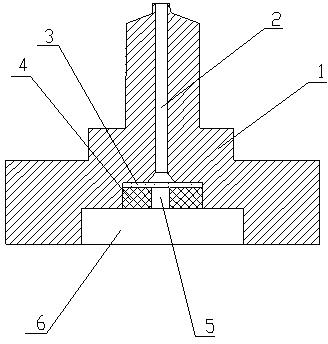

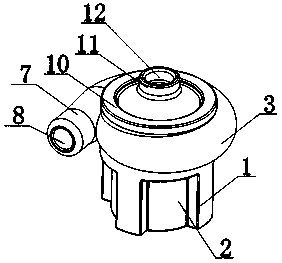

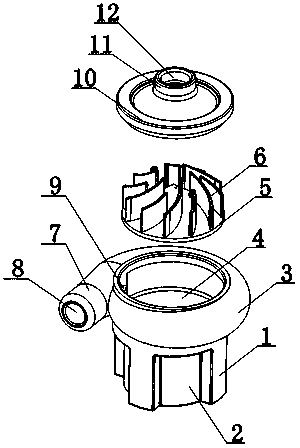

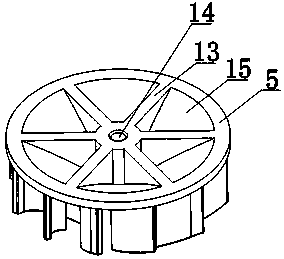

Bobbin tray

The invention provides a bobbin tray. The bobbin tray comprises a tray body, wherein a central hole is formed in the upper part of the tray body; a bottom hole is formed in the middle of the bottom surface of the tray body; the aperture of the bottom hole is greater than that of the central hole; and the bottom hole is communicated with the central hole. The bobbin tray is characterized in that a circular filtering screen of which the diameter is consistent with the aperture of the bottom hole is arranged at the end in the bottom hole, which is combined with the central hole; and a circular jacket is mounted below the circular filtering screen. The bottom hole on the bottom surface of the tray body is a stepped hole; and the aperture of one section of stepped hole, which is close to the bottom surface of the tray body, is greater than the aperture of one section, close to the lower end of the central hole, of the stepped hole. Tail yarns sucked into the central hole of a bobbin are long enough and are prevented from being wound; and meanwhile, the influence on the flowing of negative-pressure air current is avoided and the success rate of a tube exchange repiece is increased. In addition, the bobbin tray has the advantages of low cost and convenience and reliability in use.

Owner:QINGDAO HONGDA TEXTILE MACHINERY

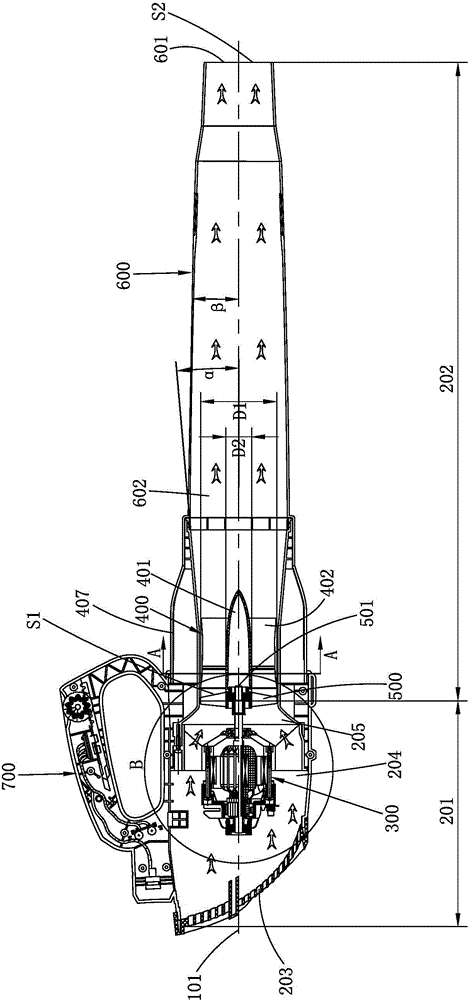

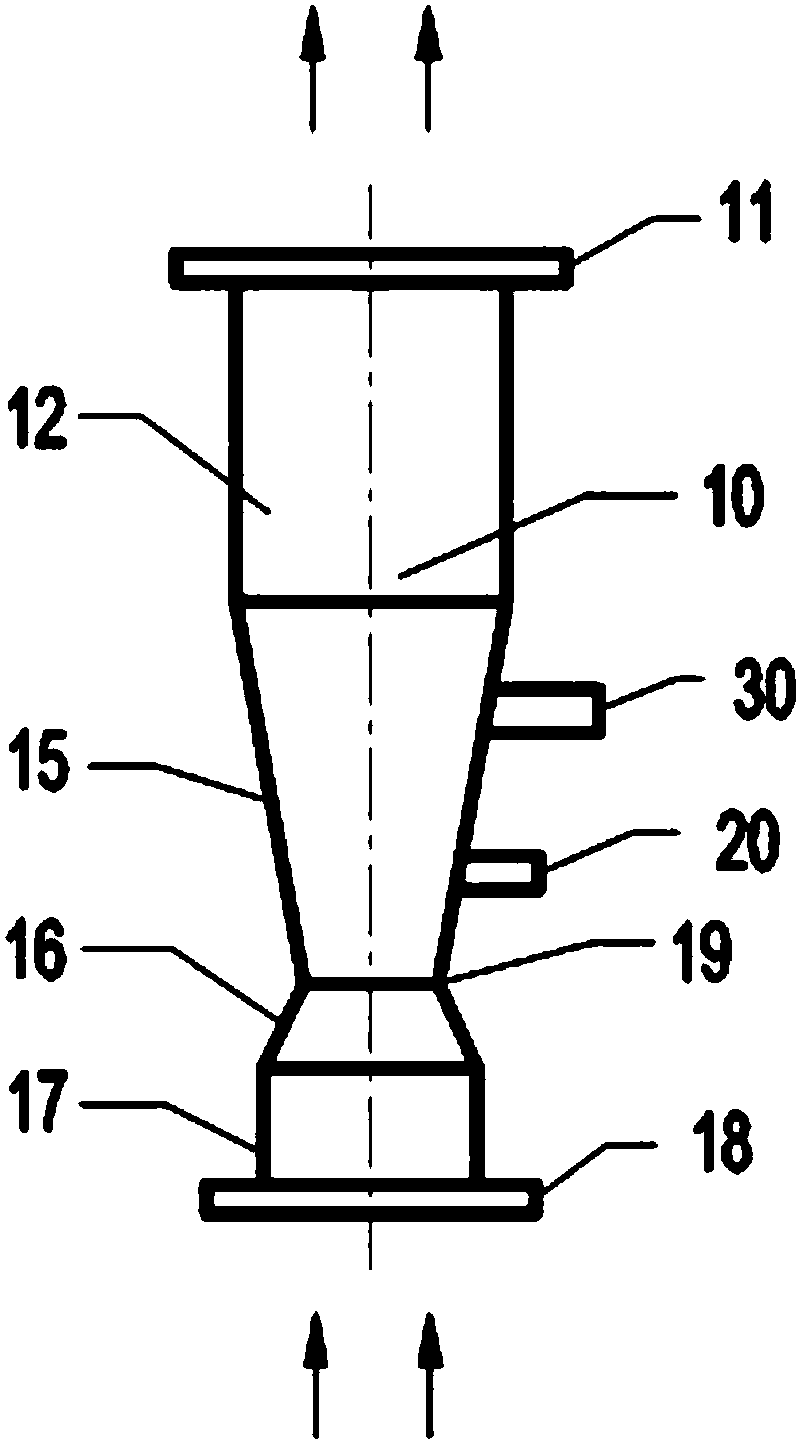

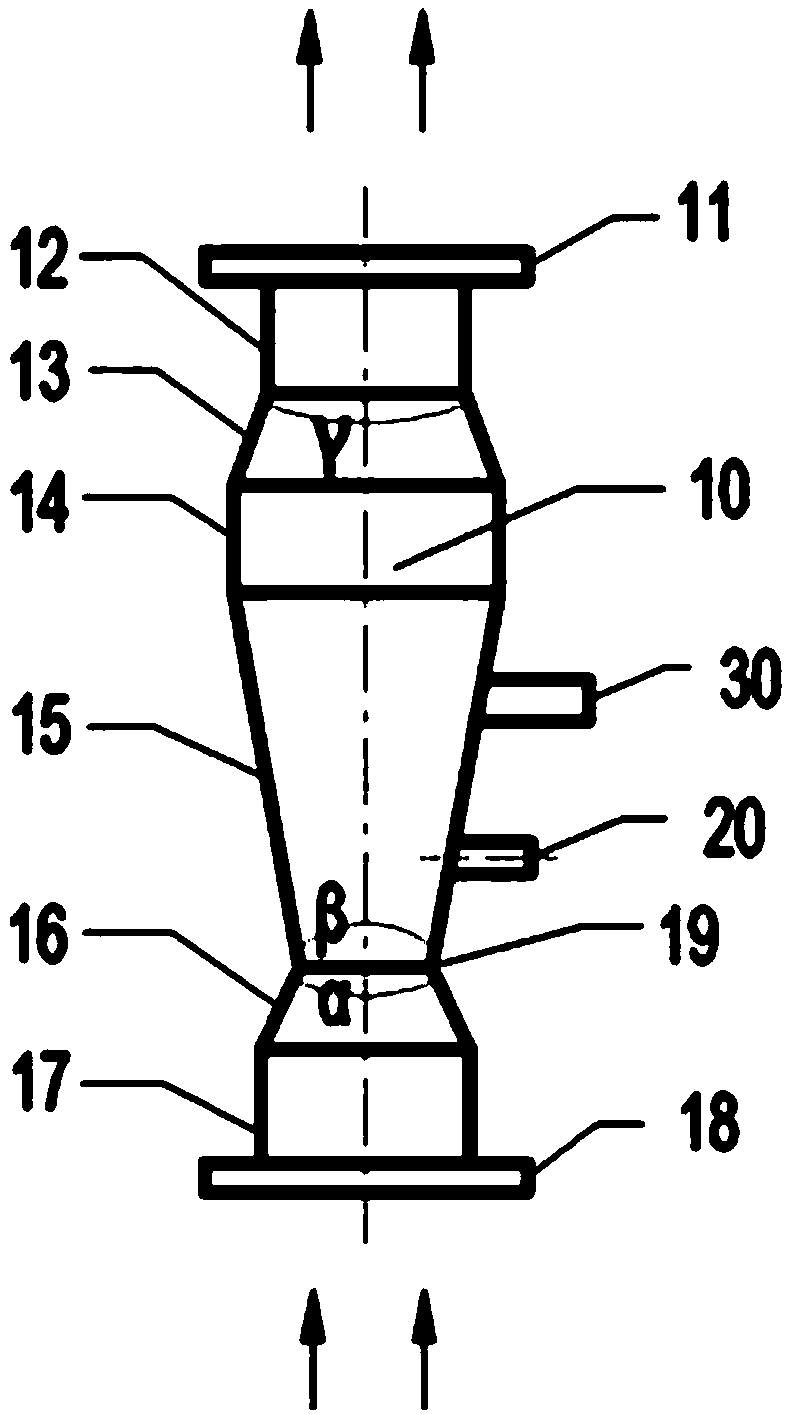

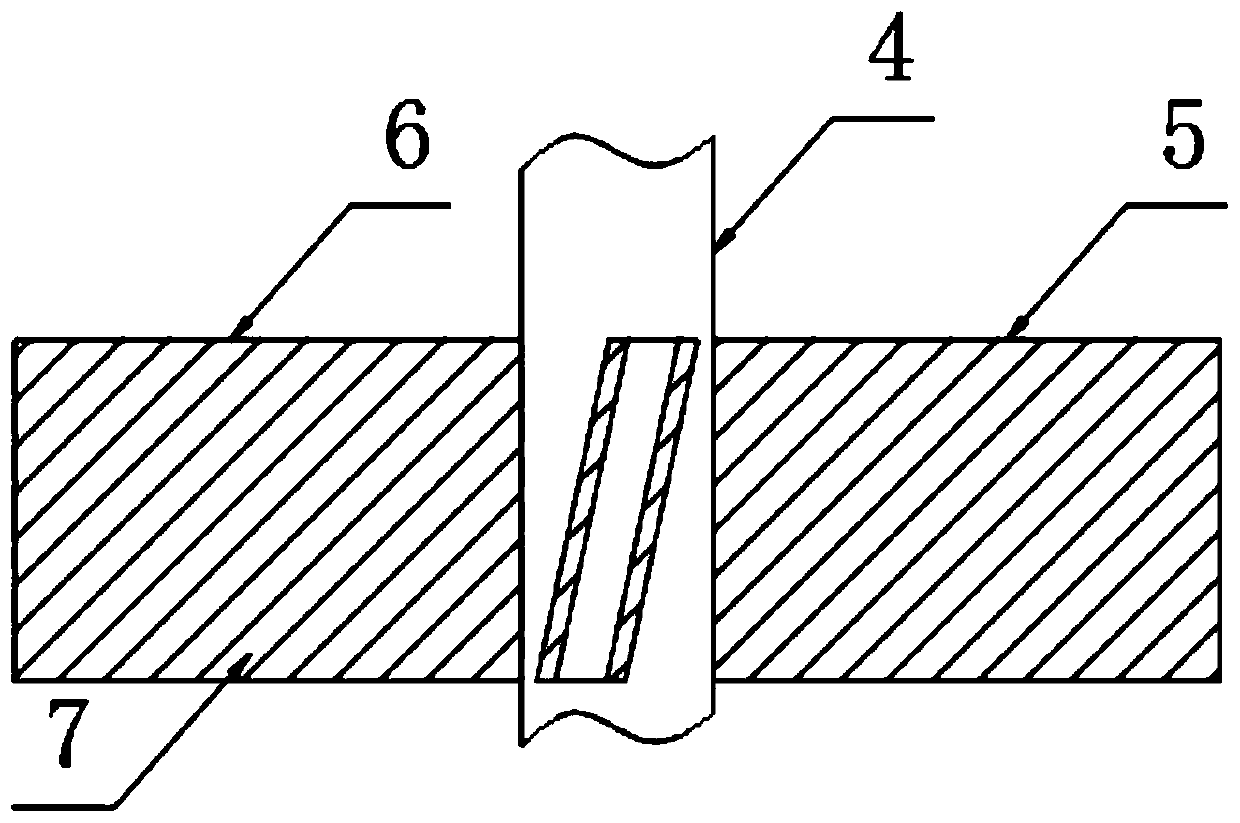

Powder conveying device and application thereof

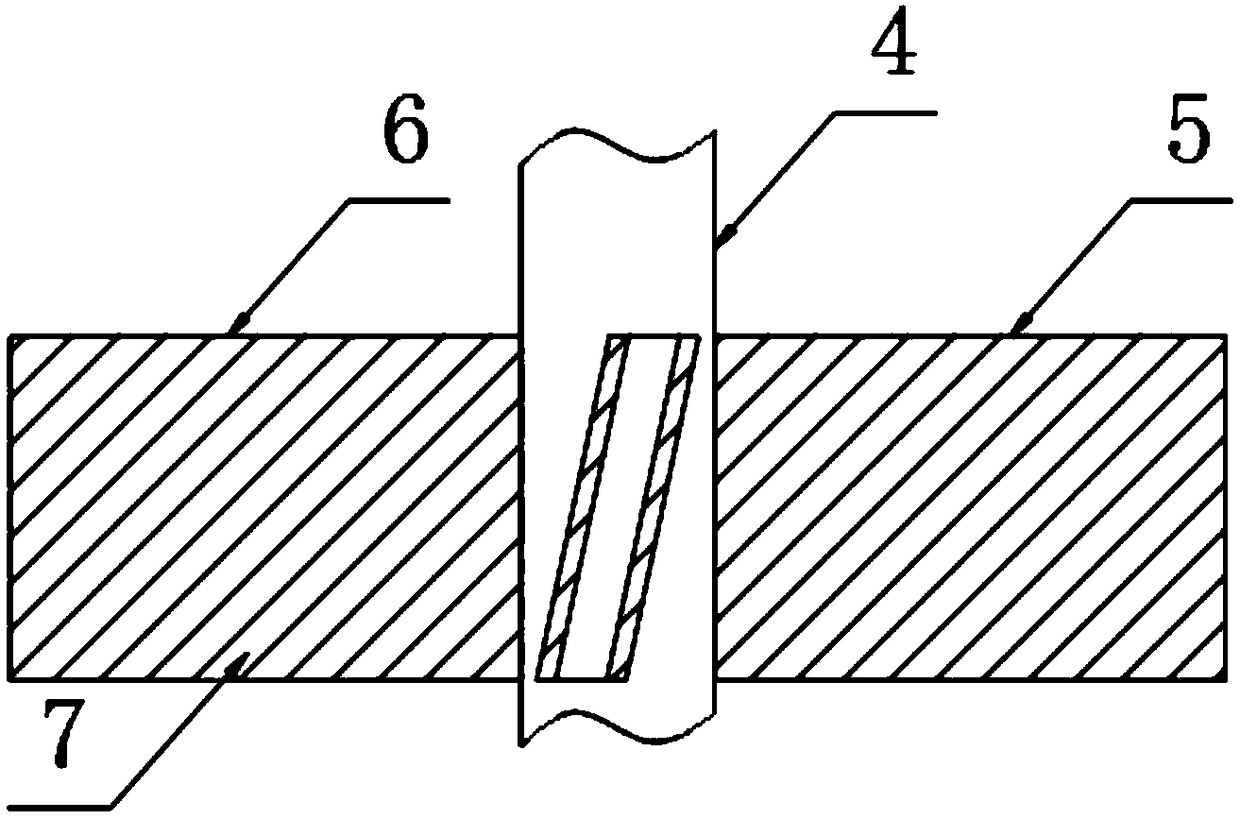

PendingCN107555178AThere will be no falling phenomenonSmall pressure dropBulk conveyorsFlangeEngineering

The invention discloses a powder conveying device and an application thereof, belonging to the field of pneumatic conveying. The powder conveying device comprises a lifting pipeline, a feeding pipeline and a purging pipeline, wherein the lifting pipeline sequentially comprises a lower flange, a lower straight section, a lower contraction section, an expansion section, a middle straight section, anupper contraction section, an upper straight section and an upper flange from bottom to top; the feeding pipeline is arranged on the expansion section and is connected to the lifting pipeline; the axis of the feeding pipeline is perpendicular to the axis of the lifting pipeline; the purging pipeline is arranged on the expansion pipeline and is connected to the lifting pipeline; and the purging pipeline is located right above the feeding pipeline. The powder conveying device solves the technical problems of the powder conveying device in the prior art that a material dropping phenomenon easilyoccurs, and the pressure drop is large. The powder conveying device is capable of fully mixing powder and gas, has small pressure drop in a conveying process, is simple and operates stably and reliably.

Owner:KEDA MAS CLEAN ENERGY +1

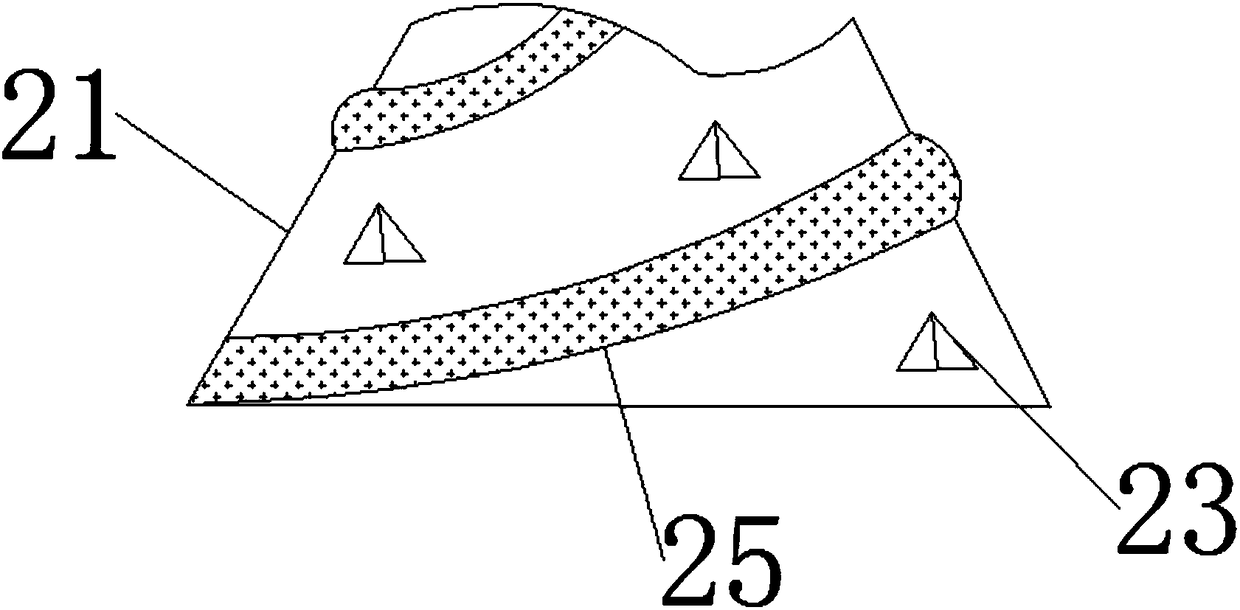

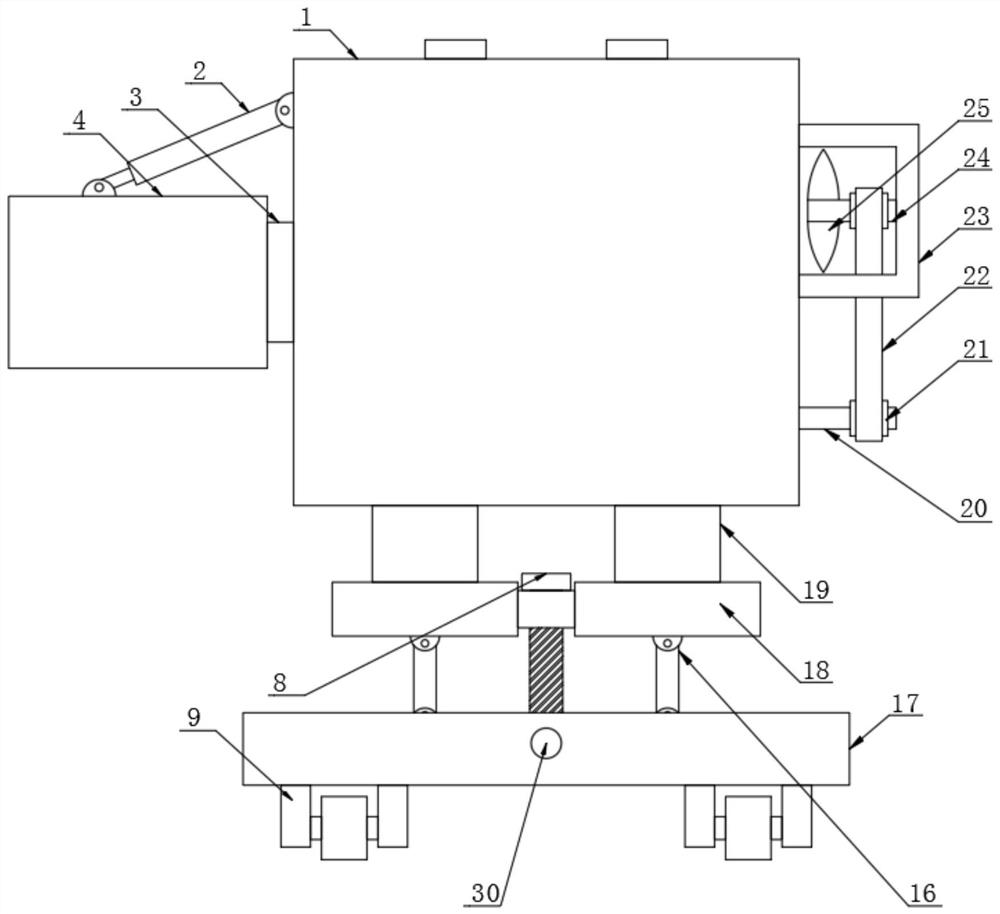

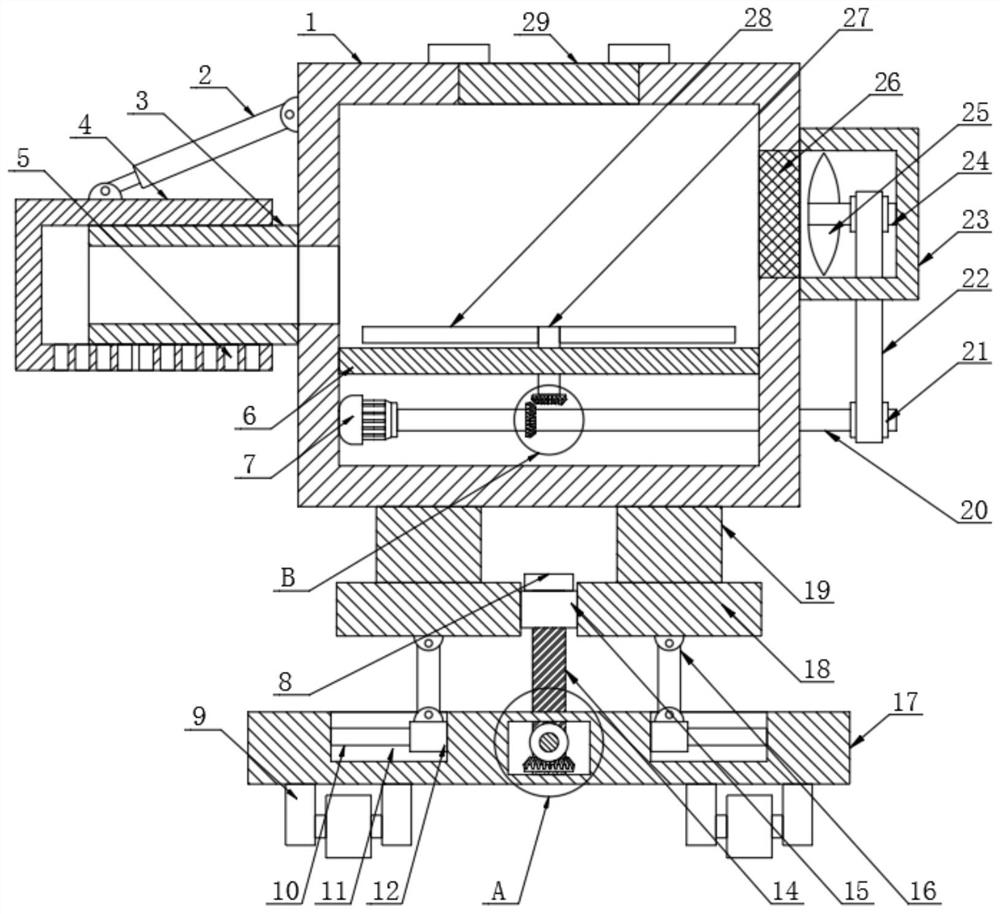

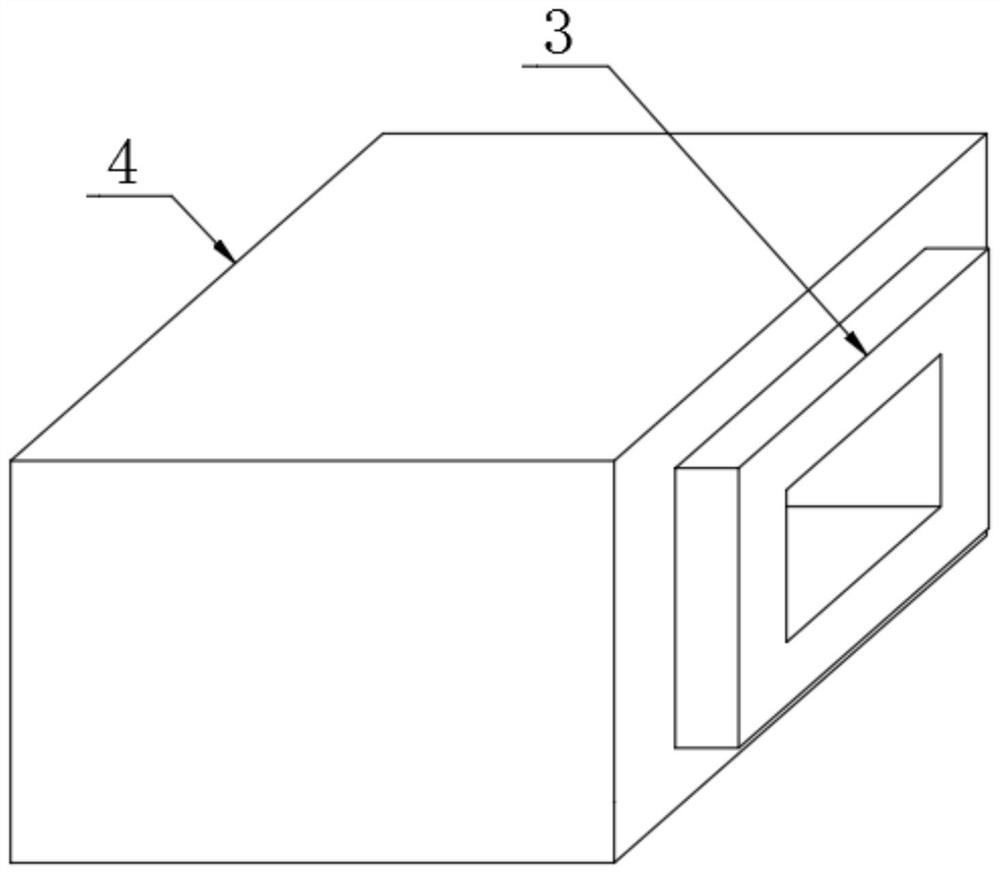

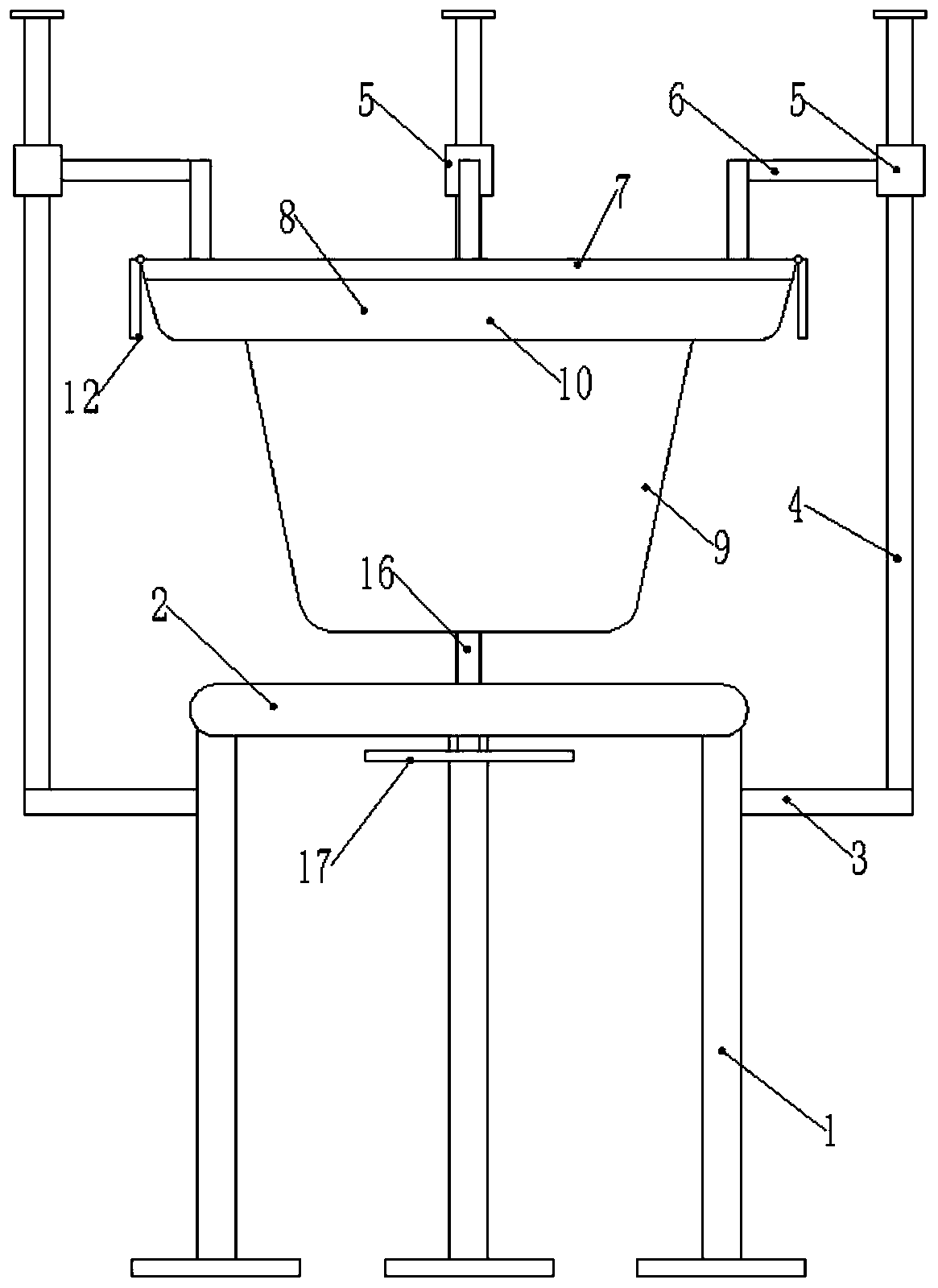

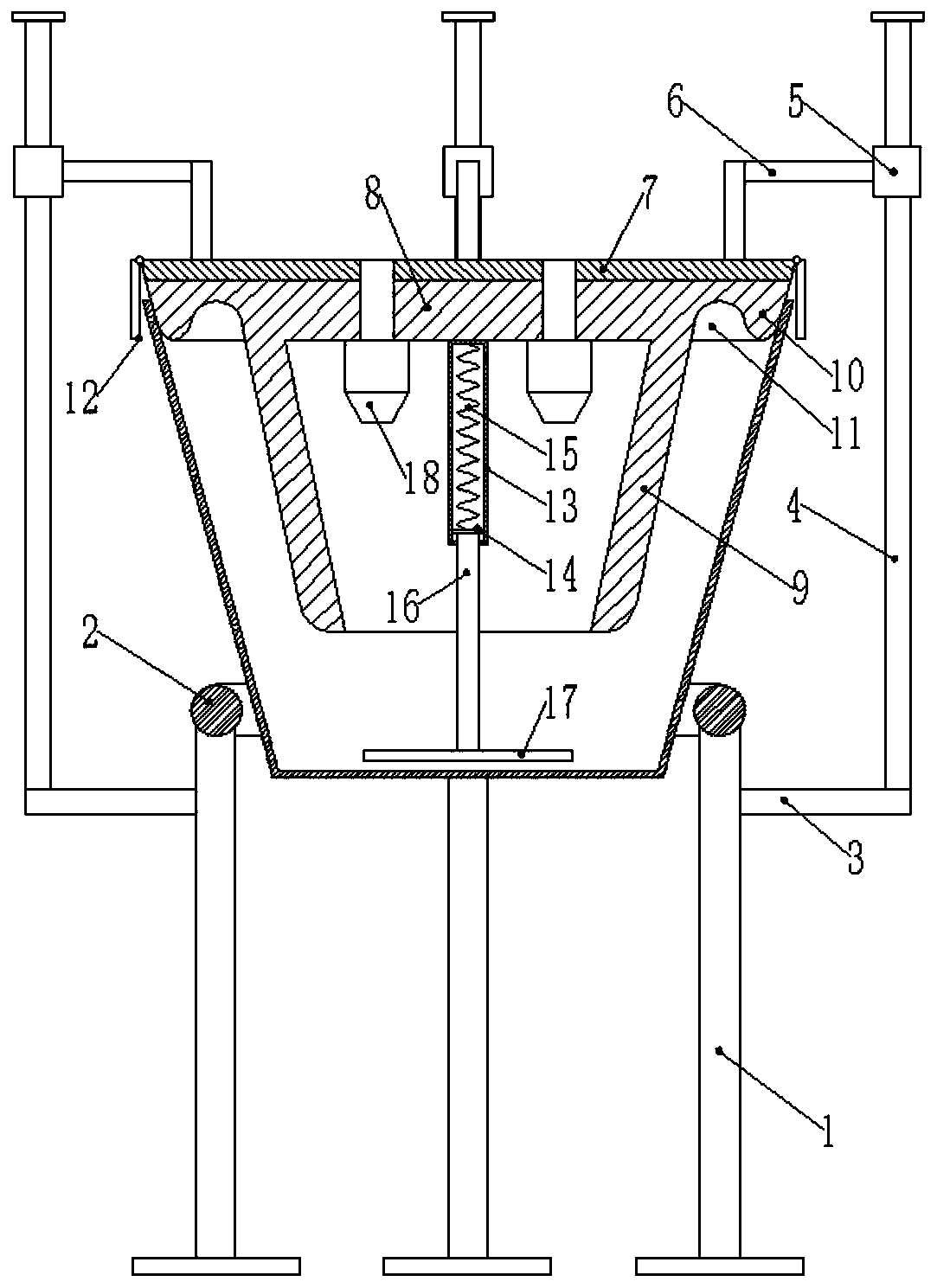

Composite sintered wear-resistant plate, preparation method and special stirring-mixing device

ActiveCN107020382AReduce coefficient of frictionIncrease contentRotary stirring mixersTransportation and packagingRough surfaceWear resistant

The invention belongs to the technical field of composite sintered wear-resistant plates and preparation methods, and discloses a composite sintered wear-resistant plate, a preparation method and a special stirring-mixing device. The composite sintered wear-resistant plate is mainly technically characterized by comprising a base plate, wherein a rough surface is formed at one side of the base plate; a copper powder layer is arranged at the outer side of the rough surface; a graphene powder-copper powder mixing layer is arranged on the outer side surface of the copper powder layer; and the weight ratio of graphene powder to copper powder is (1-2): 100; and the particle sizes of the graphene powder and the copper powder are 200-300 meshes. In this way, the graphene powder-copper powder mixing layer and the base plate are firmer in bonding, graphene is high in content and good in lubrication effect, prepared bearings and other products are low in friction coefficient, and the service lives are greatly prolonged; and during mixing for the graphene powder and the copper powder, a mixing tank is vacuumized at first, and then high-pressure gas is blown into the bottom of the mixing tank, and a stirring mechanism is started up, and in this way, more uniform mixing is achieved, the content of the graphene powder can be effectively increased, and the wear resistance of the composite sintered wear-resistant plate is improved.

Owner:SHENZHEN YUANZHENG POLYMER COMPOSITE MATERIAL

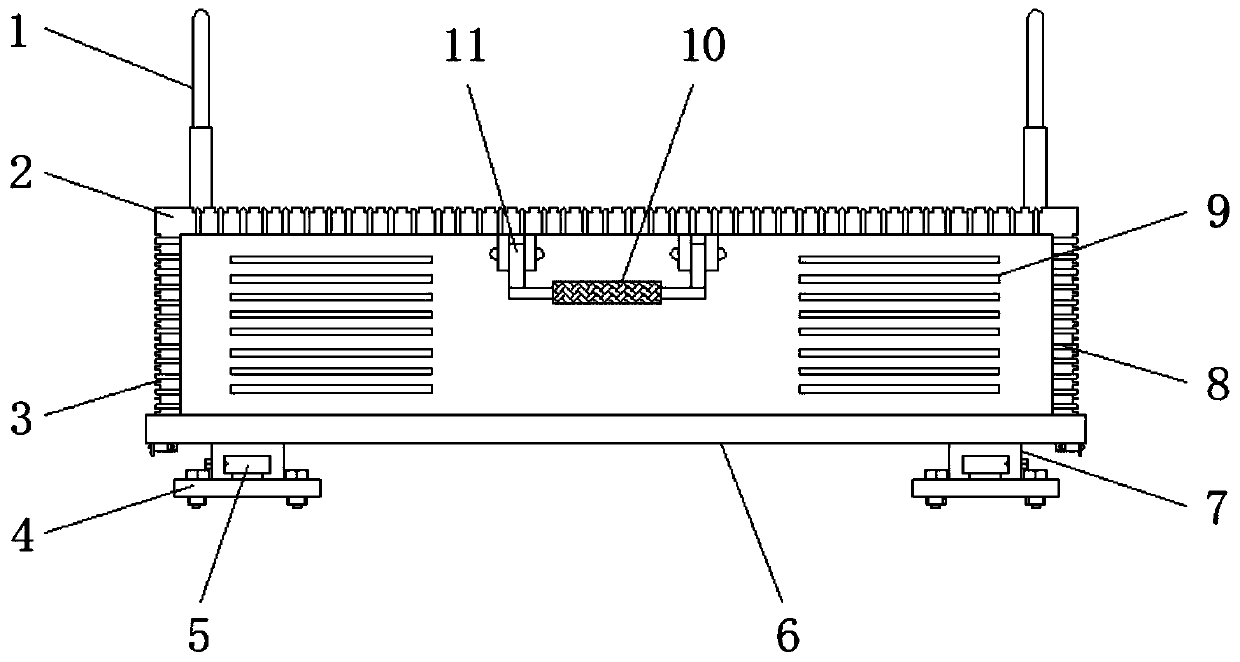

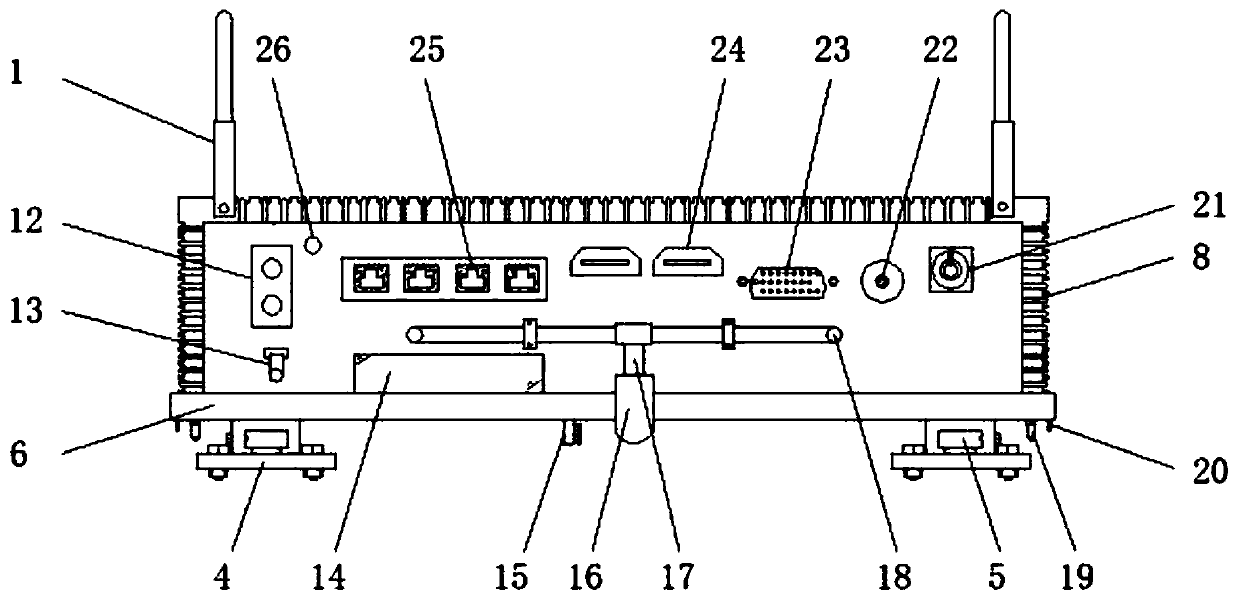

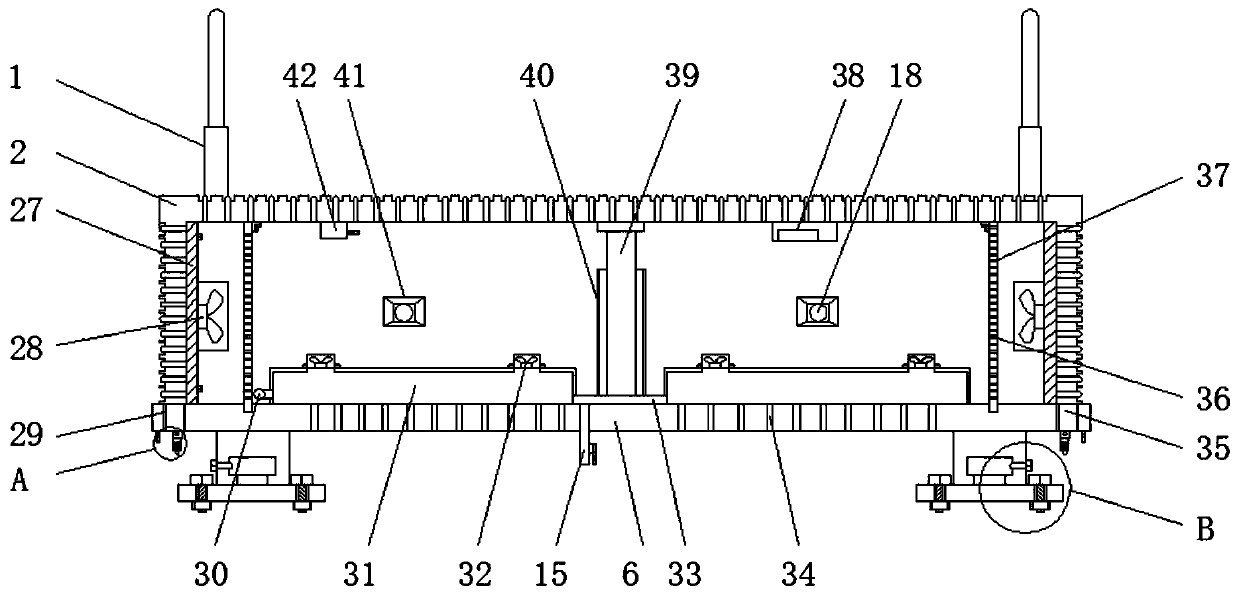

Portable on-line education terminal of artificial intelligence

InactiveCN109887355AEasy to dissipate heatEasy to blow upElectrical appliancesCooling/ventilation/heating modificationsSoftware engineeringComputer terminal

The invention discloses a portable on-line education terminal for artificial intelligence, which comprises a protective shell, a base, a fixing plate and a heat absorption fan, wherein the fixing plate is provided with fixing holes close to four corners, two ends of the bottom of the fixing plate are provided with sliding chutes, a limiting bolt is arranged on an outer side wall of the sliding chutes, and the top of the fixing plate is provided with the protective shell. By the adoption of the portable on-line education terminal for artificial intelligence, convex blocks are arranged at outersides of the bottom of the fixing plate close to the fixing holes; the convex blocks are provided with limiting holes; positions of the bottom of the protective shell close to the fixing holes are provided with limiting blocks; one end of the limiting block far away from the protective shell penetrates through the fixing holes and is provided with a fixing block; one end of the fixing block far away from a hinge shaft is provided with a second through hole; fixing cavities are internally provided with springs; and one end of the springs is provided with bulges matched with the limiting holes through limiting plates, so that the terminal is conveniently disassembled and assembled when the terminal is required to be maintained, thereby saving time, improving the assembling efficiency and reducing the labor intensity of maintenance workers.

Owner:甘肃蒲公英信息技术有限公司

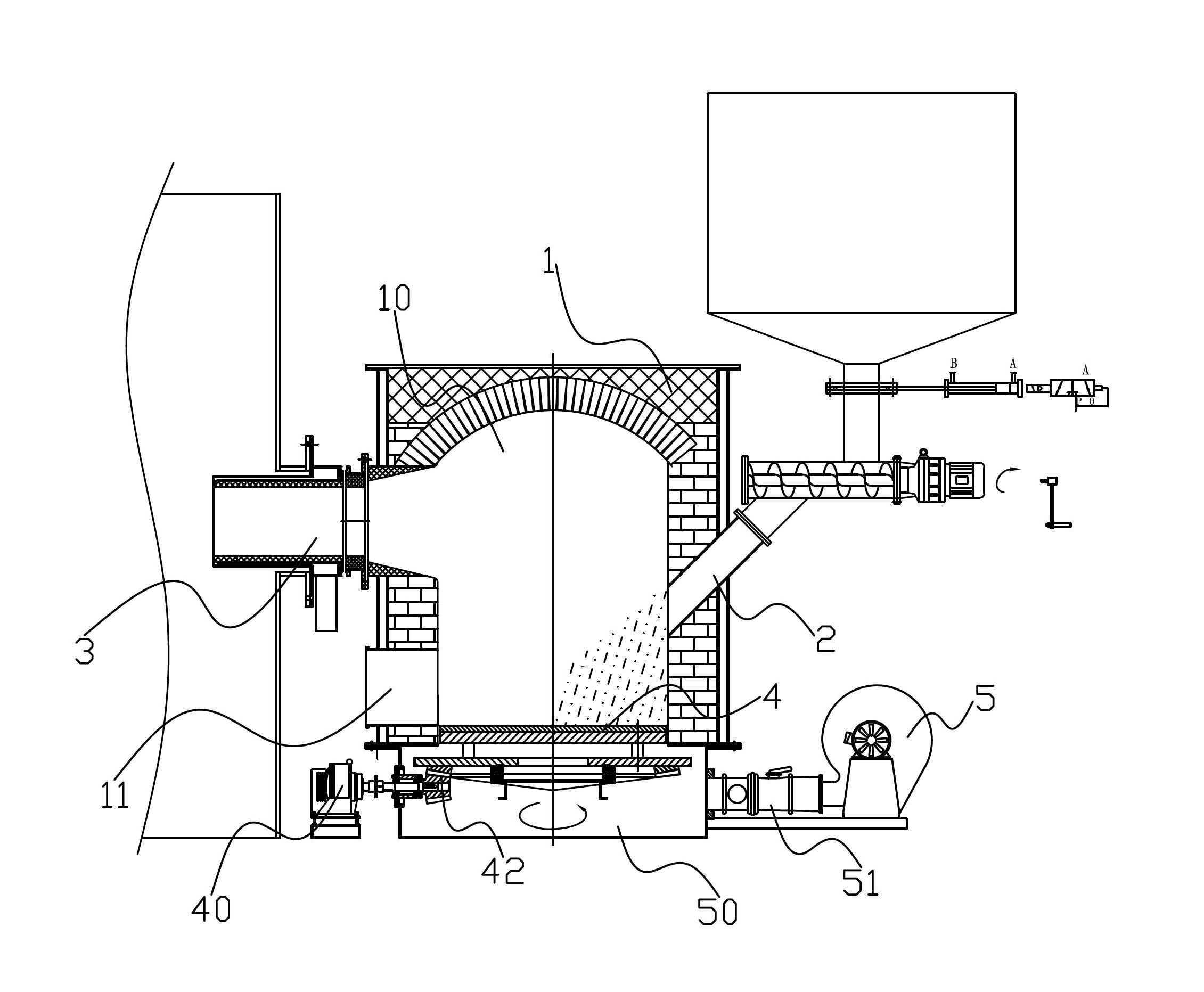

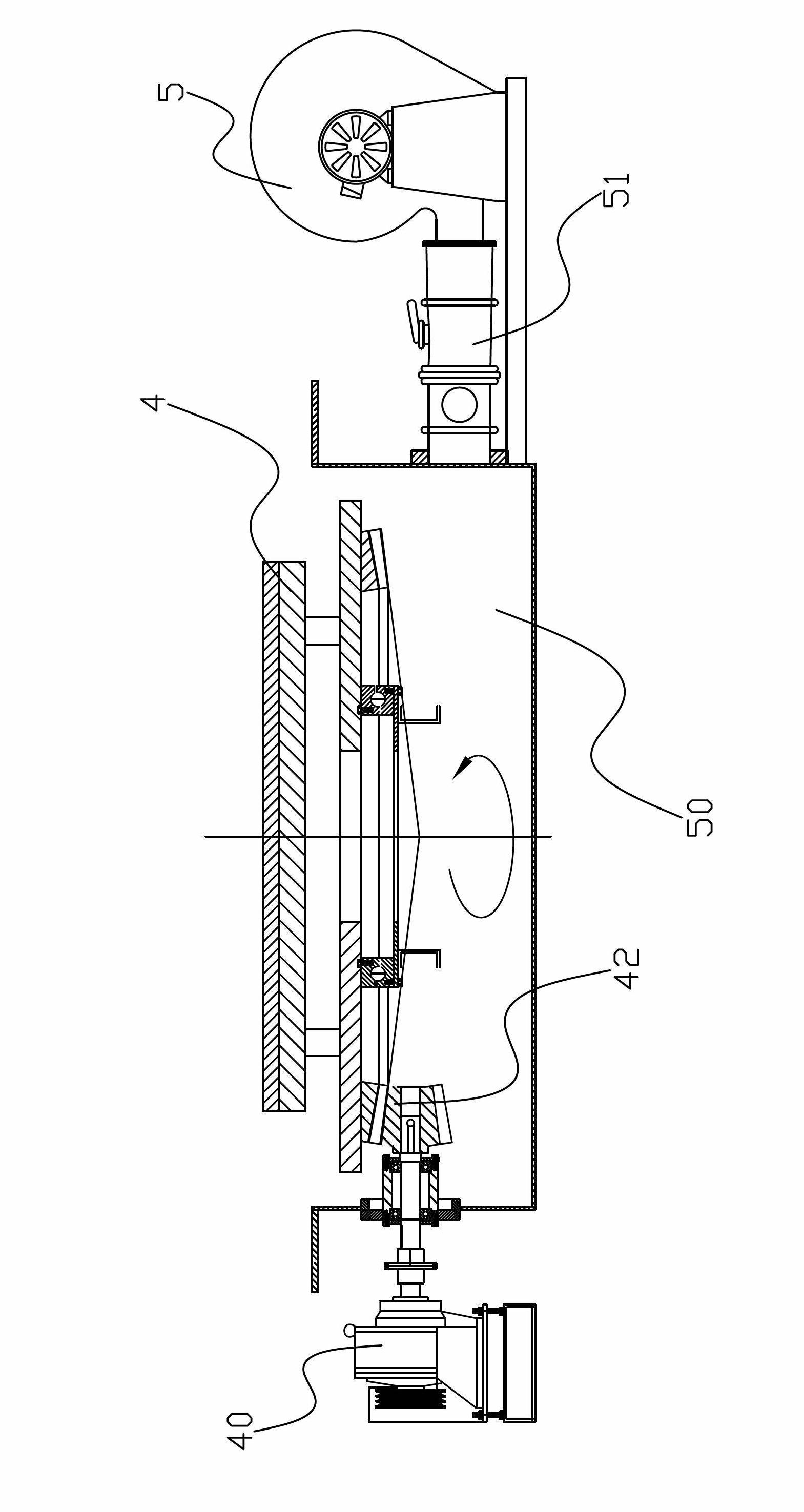

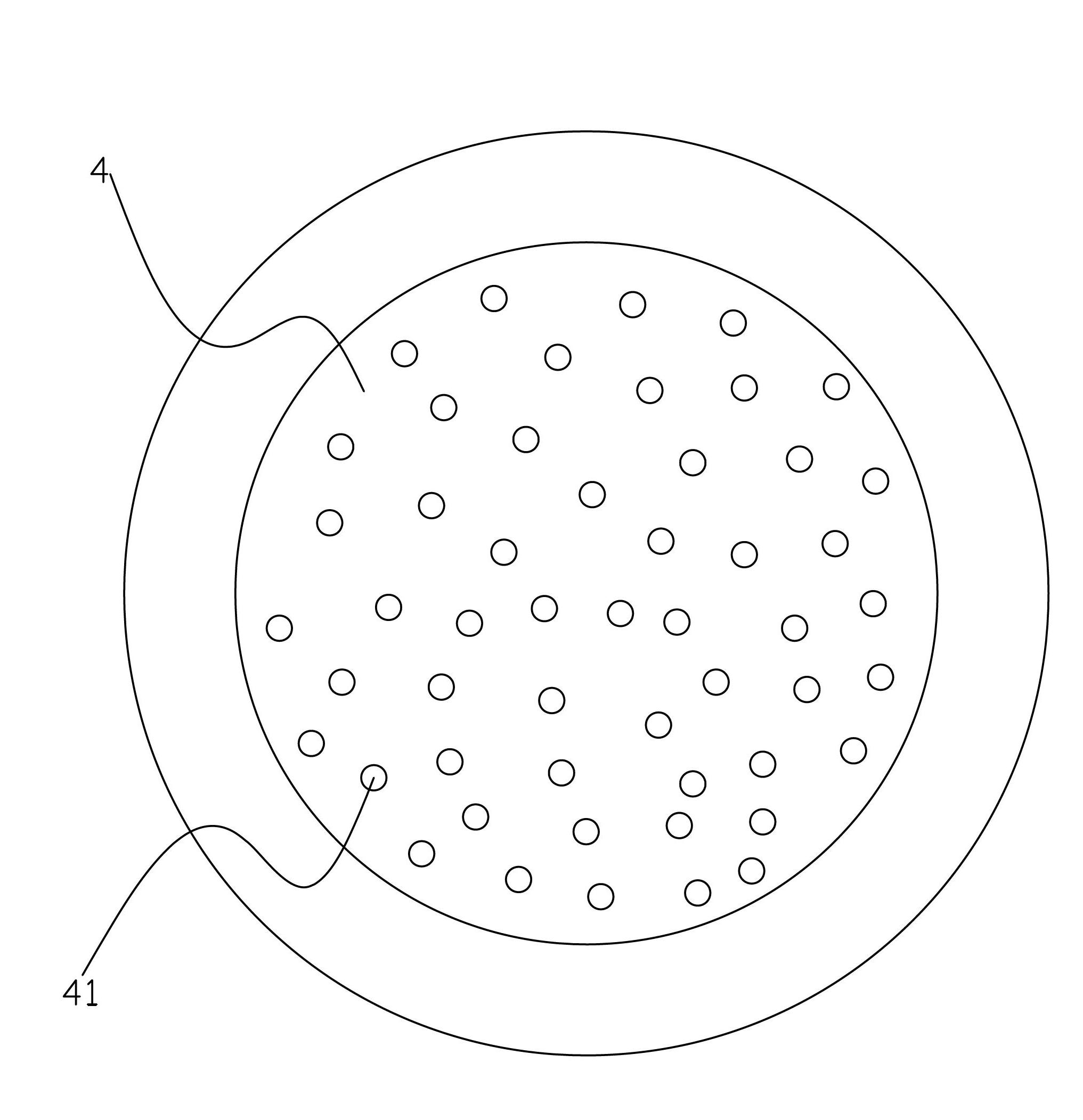

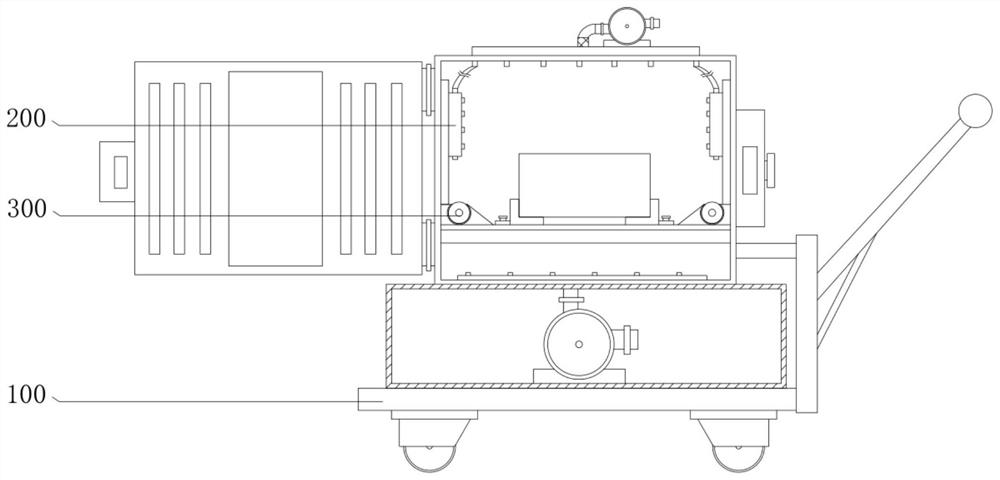

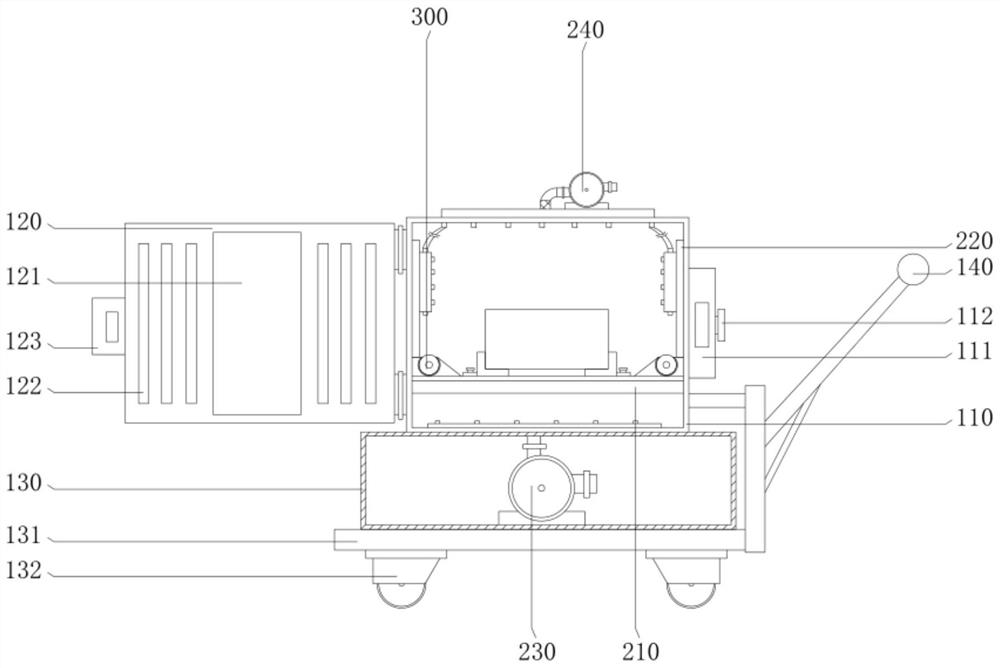

Biomass burning machine of rotary furnace bridge

InactiveCN102679322AAvoid accumulationEasy to blow upSolid fuel combustionCombustion apparatusSpray nozzleEngineering

The invention discloses a biomass burning machine of a rotary furnace bridge. The biomass burning machine comprises a main body with a burning inner cavity, wherein the side wall of the main body is provided with an auger communicated with the burning inner cavity, and the upper part of the other side wall of the main body is provided with a spray nozzle communicated with the burning inner cavity; the lower part of the burning inner cavity is provided with a furnace bridge for carrying biomass fuels; a driving motor is arranged at one side or the lower part of the furnace bridge; the furnace bridge is driven to rotate by the driving motor; and while being driven to rotate by the driving motor, the furnace bridge can uniformly distribute the biomass fuels, which are continually delivered in along the auger, on the surface of the furnace bridge, and therefore the condition of insufficient burning caused by the accumulation of the biomass fuels can be avoided.

Owner:开平市雅科机电设备有限公司

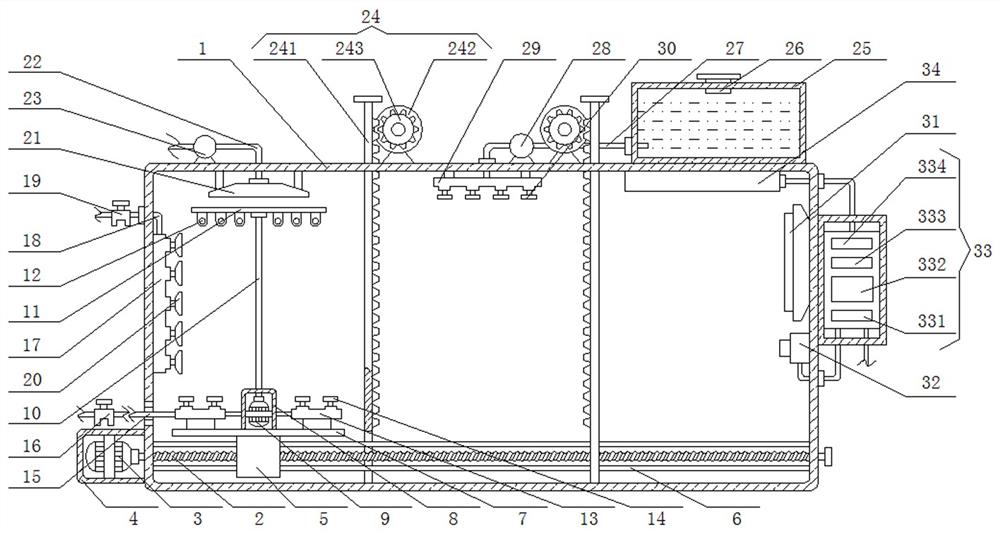

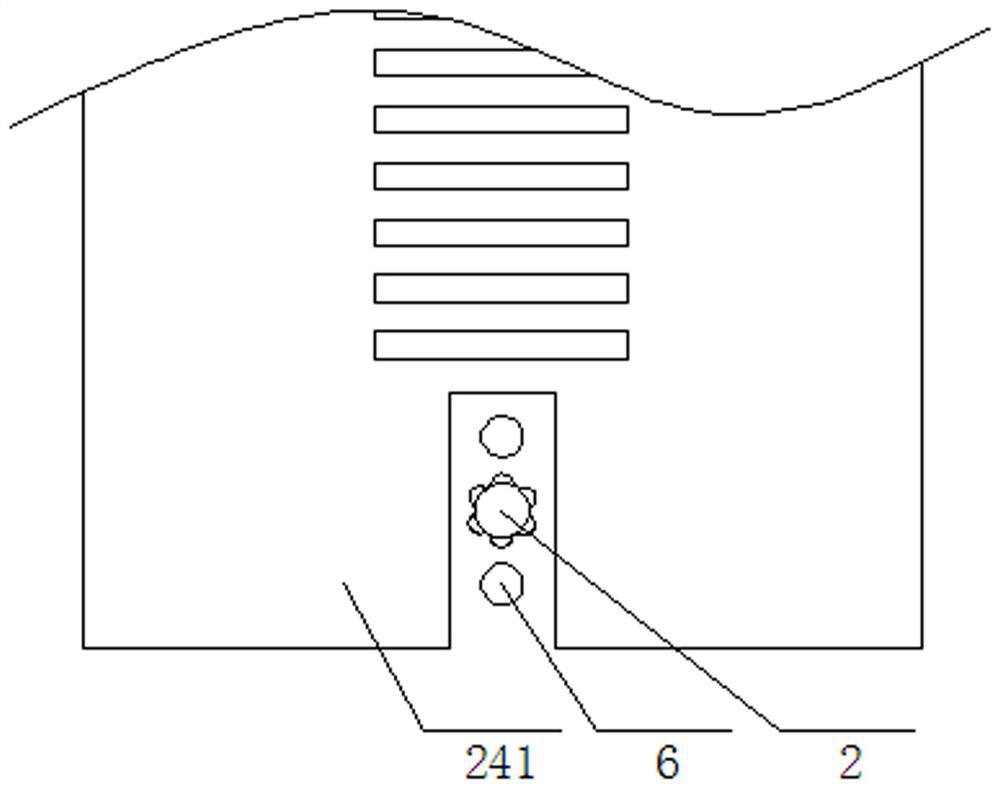

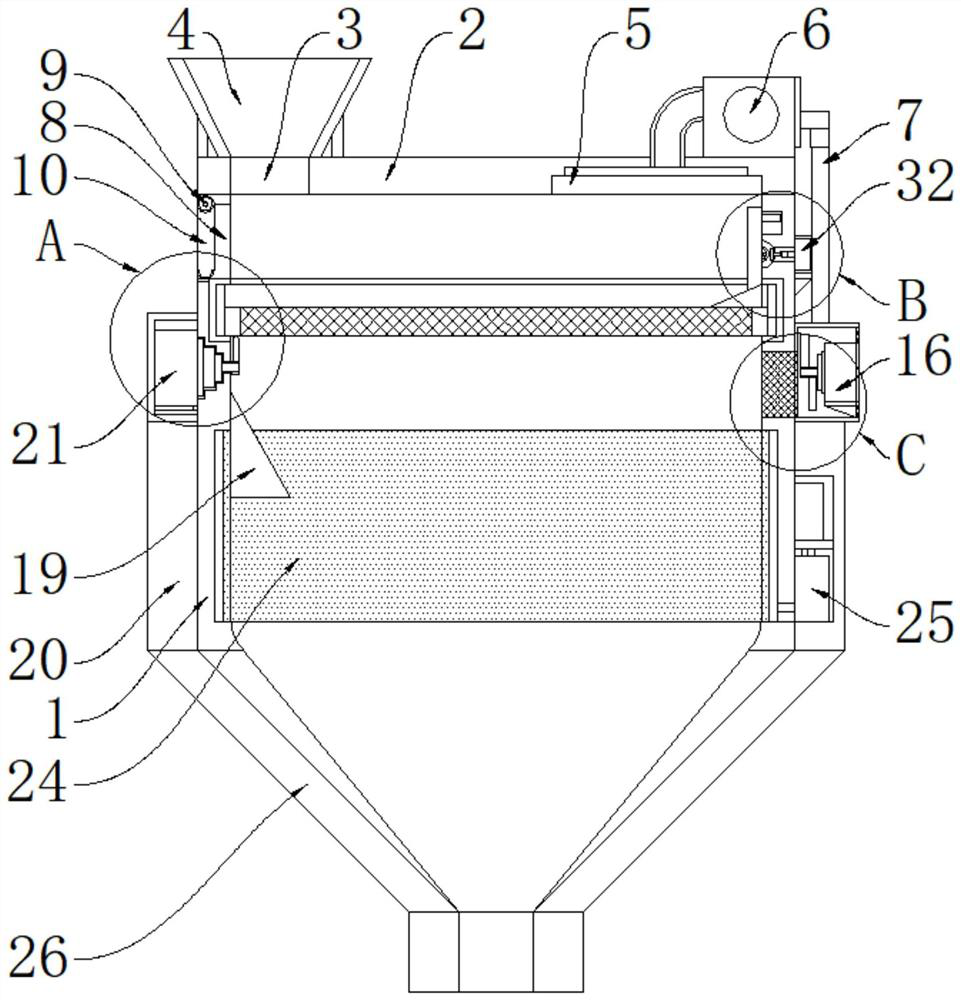

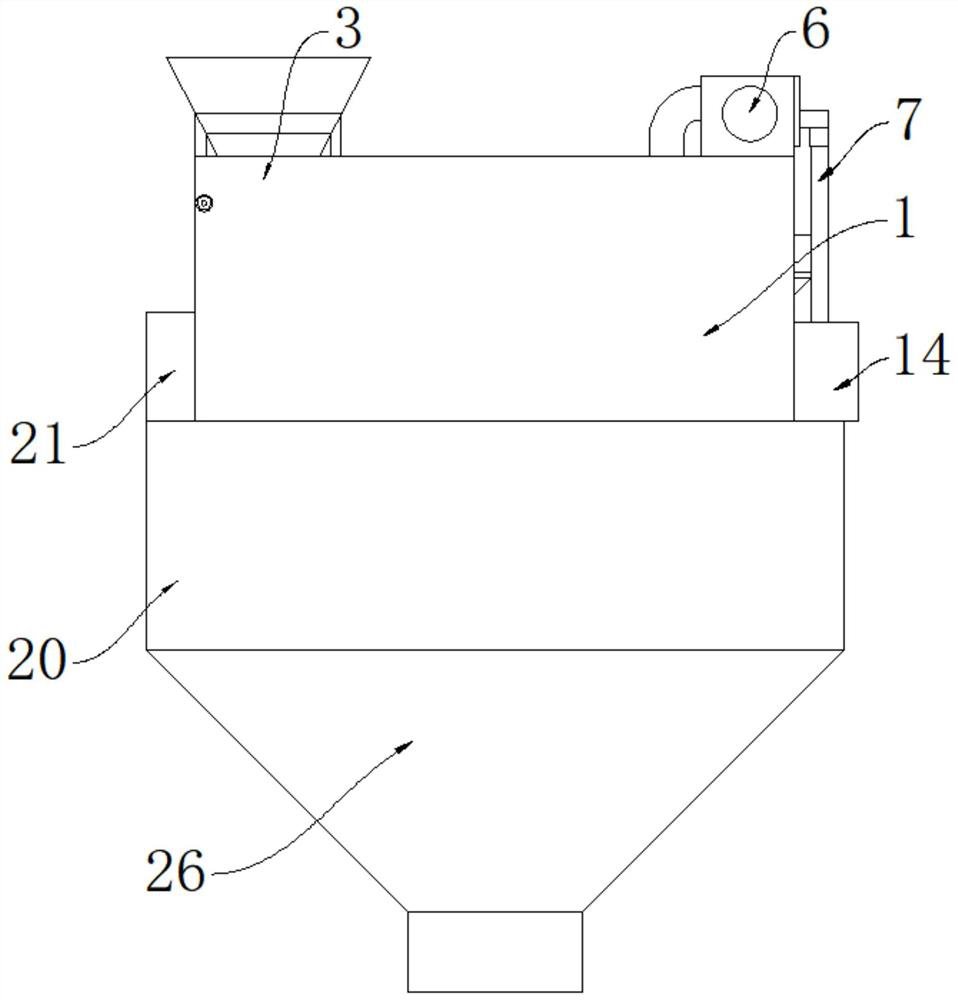

Casting waste sand regeneration device

InactiveCN111283136AEasy to bulge outReduce moistureMould handling/dressing devicesProcess engineeringFan blade

The invention discloses a casting waste sand regeneration device which comprises a machine enclosure. The machine enclosure comprises a left machine enclosure body and a right machine enclosure body.The right machine enclosure body is arranged on one side of the left machine enclosure body. Rotating rods penetrate through the bottoms of inner cavities of the left machine enclosure body and the right machine enclosure body. A stirring mechanism is fixedly arranged on the outer side of each rotating rod. Each stirring mechanism comprises multiple stirring fan blades. Frosting layers are fixedlyarranged on the inner wall of the machine enclosure and the side faces of the stirring fan blades. A high-pressure air heater is fixedly arranged at the bottom of the machine enclosure, and air inletbranch pipes are arranged on the machine enclosure in a penetrating manner. An air inlet main pipe is arranged at the ends of the air inlet branch pipes. A top plate is arranged at the top of the machine enclosure. Top covers are arranged on the two sides of the top plate. A sealing ring is arranged at the bottom of each top cover in a nested manner. Air outlet branch pipes are arranged on each top cover in a penetrating manner. By means of the casting waste sand regeneration device, the structure of equipment in the prior art is simplified effectively, casting waste sand regeneration is carried out effectively, meanwhile, the equipment structure is quite simple, the equipment cost is low, operation is quite convenient, the regeneration efficiency is effectively improved, and design is reasonable.

Owner:姚仿英

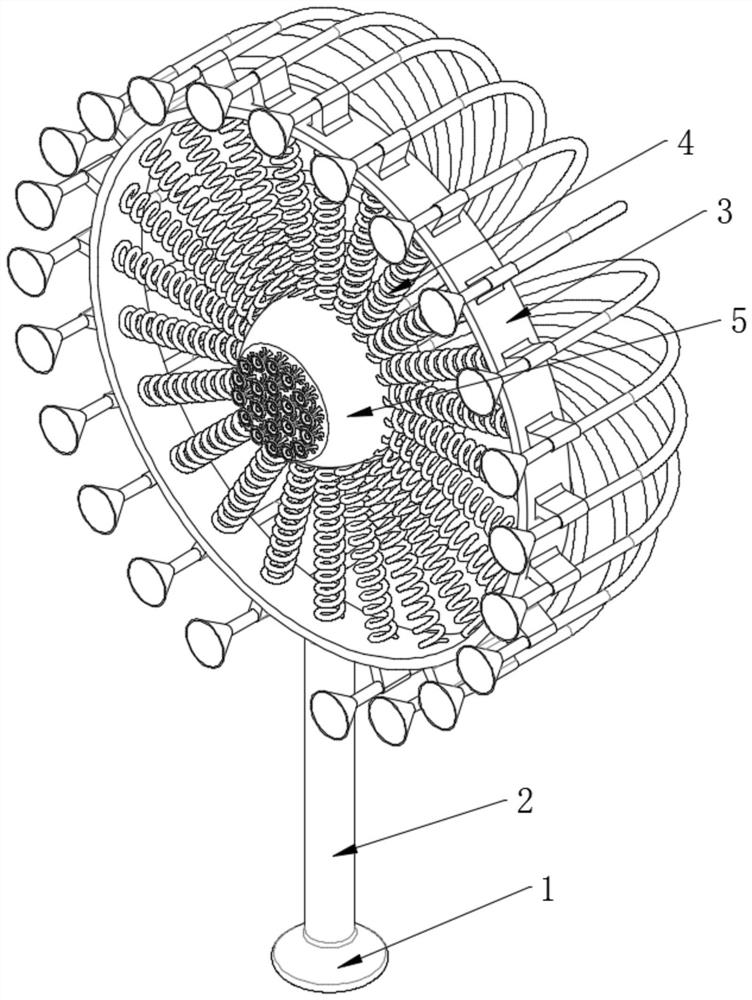

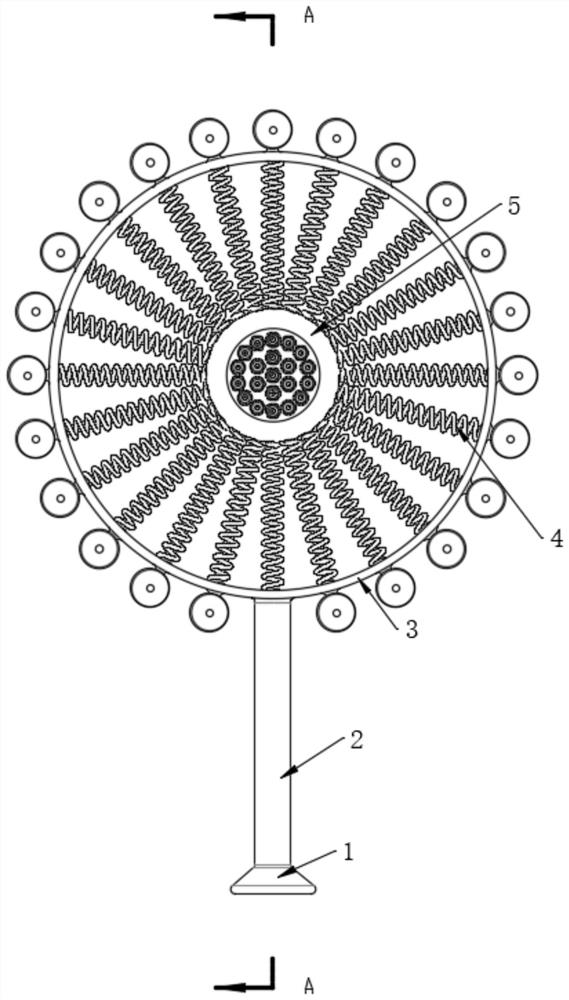

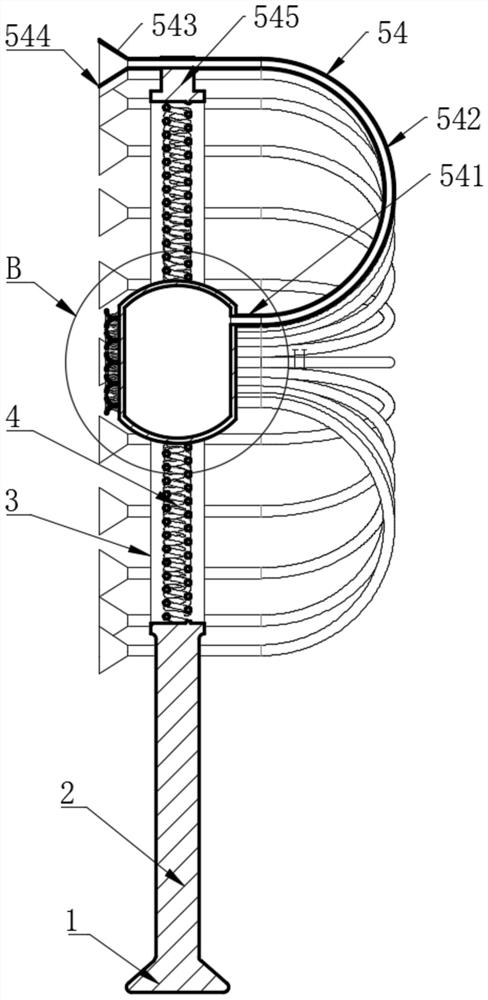

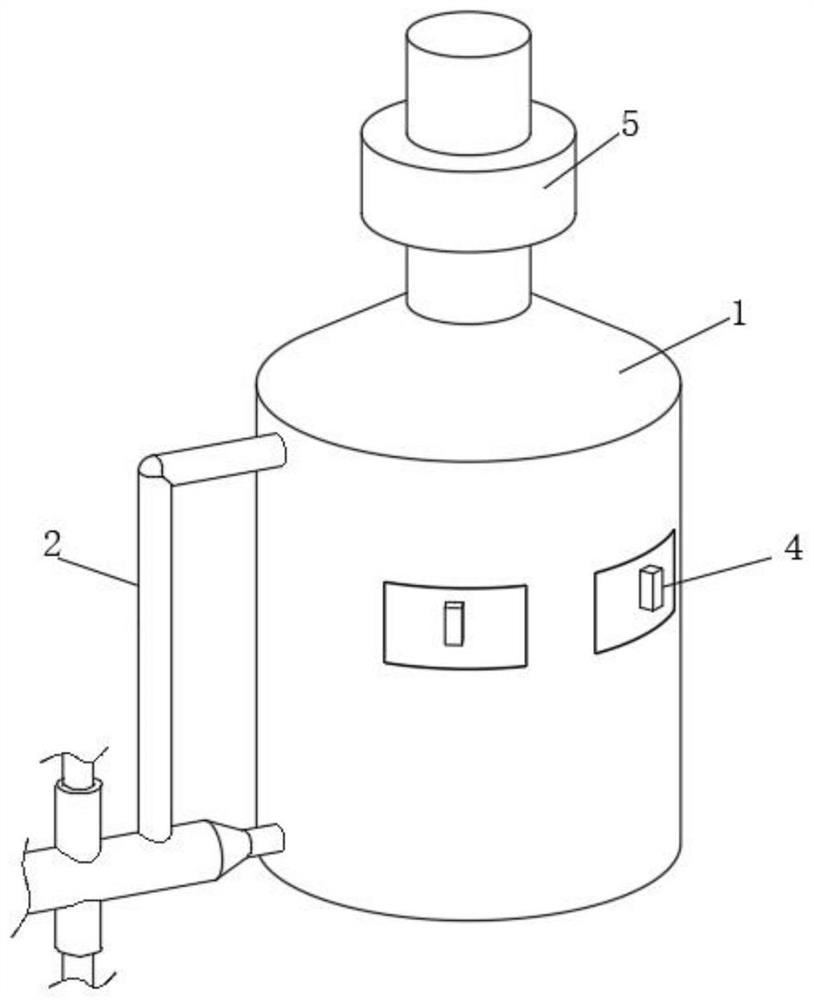

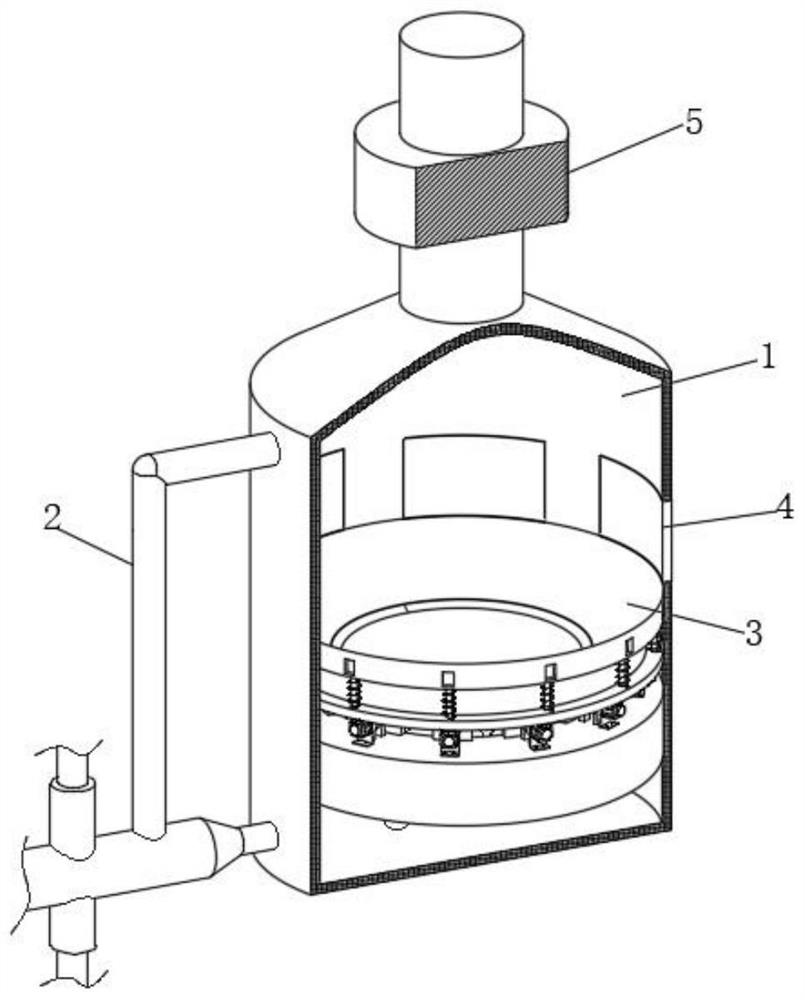

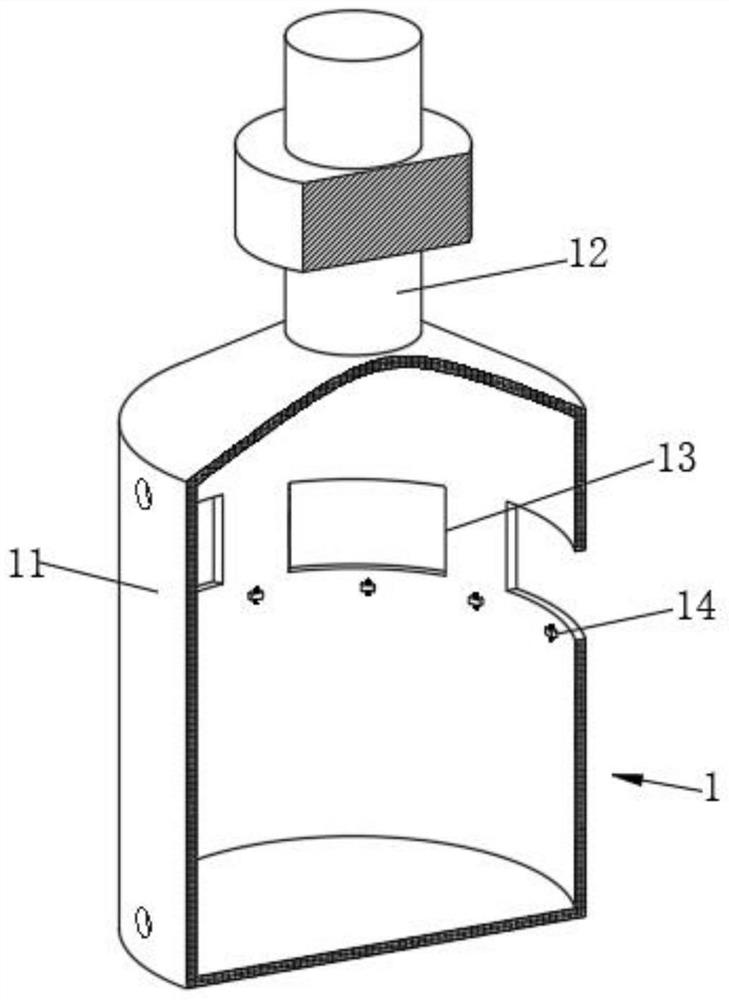

Carpet beater for treating dust with airflow

InactiveCN112267283AEasy to operateMentioned efficiencyMechanical cleaningPressure cleaningStructural engineeringMechanical engineering

The invention belongs to the technical field of carpet beaters, and particularly relates to a carpet beater for treating dust with airflow. The carpet beater comprises a base, a support and an annularbracket, wherein the top of the base is fixedly connected with the support; the top of the support is fixedly connected with the annular bracket; a plurality of sets of telescopic springs are fixedlyconnected to the inner wall of the annular bracket; and a beating mechanism is arranged among the multiple telescopic springs. According to the invention, by arranging the beating mechanism and a buffer type carpet beating mechanism, airflow in a waist drum beating block flows to a carpet airflow blowing mechanism through airflow holes under the beating effect, and dust is treated with the airflow; and therefore, the operation is superior to that in the prior art and is more convenient, beating does not take longer time, the efficiency can be improved, and the dust left at the bottom can be treated.

Owner:李山仁

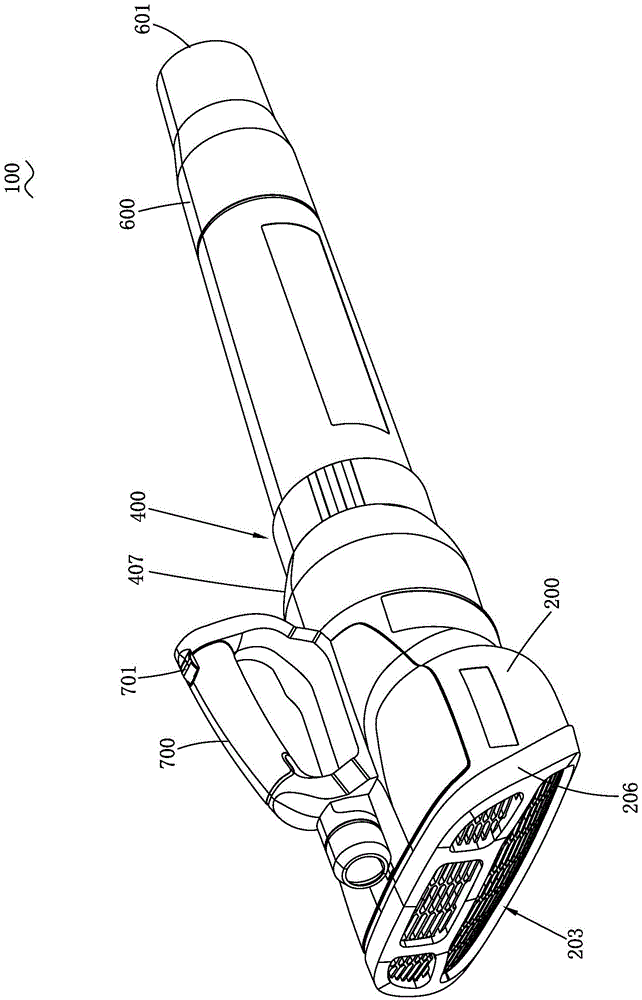

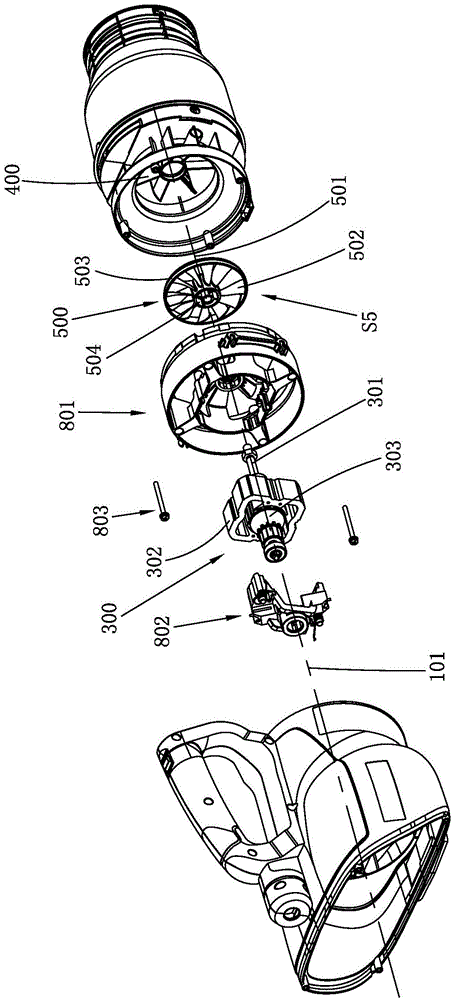

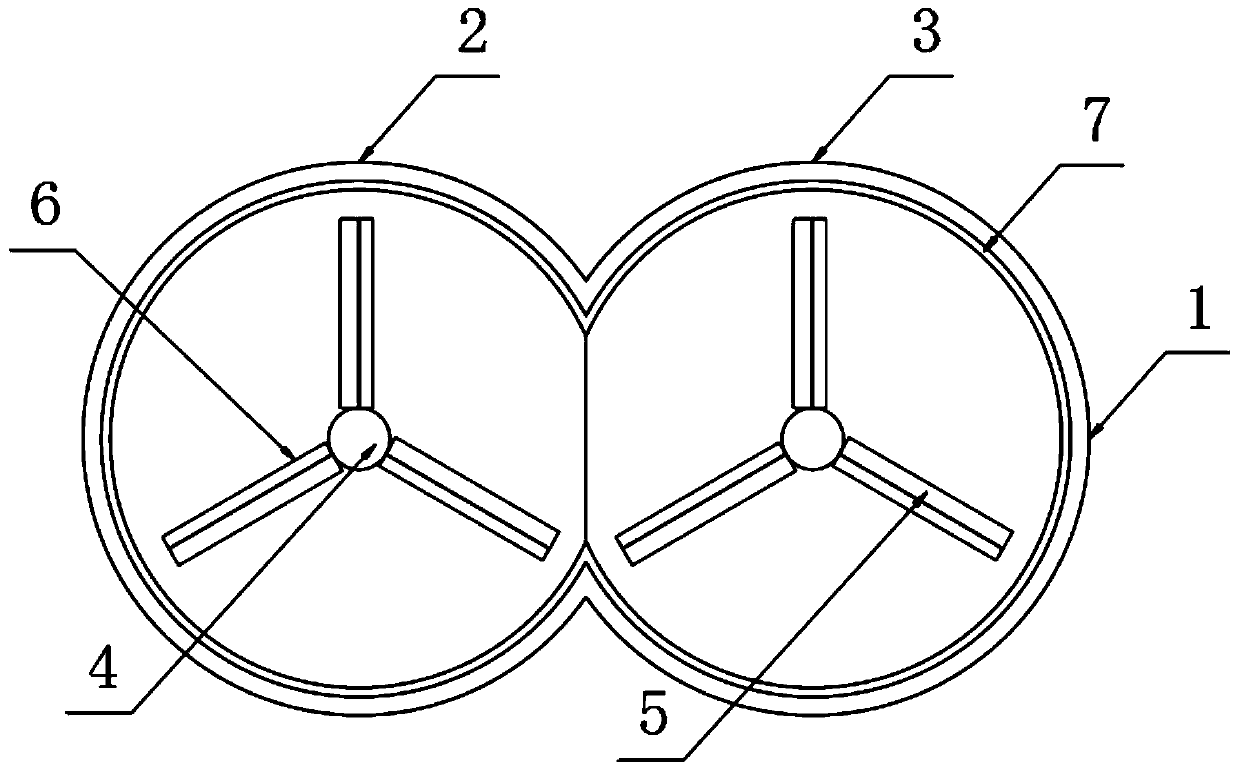

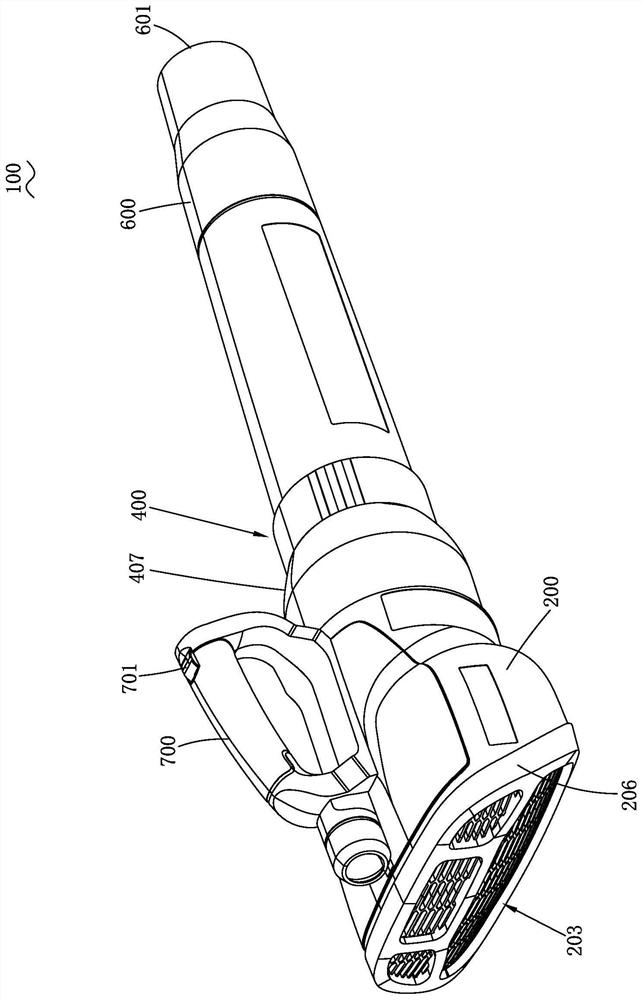

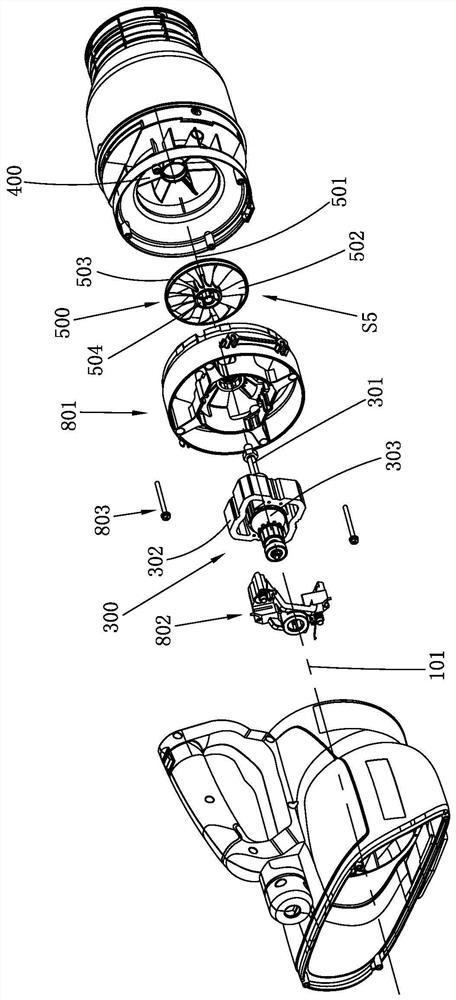

A blower fan

ActiveCN105370589AReduce fatigueEasy to blow upPump componentsPump installationsMotor driveEngineering

The invention provides a blower fan comprising a main machine which comprises an outer shell, a motor and a fan. The outer shell comprises a main machine air duct in which the motor and the fan are at least partially accommodated. The motor drives the fan to rotate with a first axis as the axis. The blower fan also comprises an air flow guide component which comprises an air drum used for guiding air flow, and a diversion member capable of guiding a part of air flow in the air drum to flow in other directions deviating from the first axis. The blower fan at least can serve as a dryer. With the diversion member, the blower fan can output combined air flow, and air flow, which deviates from the original guide direction, in the air flow disperses the counter-acting force brought by blowing, so that the feeling of fatigue of users during use is reduced and the operation feel is improved; air flow output at multiple angles improve the blowing effect, so that slice-shaped objects such as leaves can be blown easily.

Owner:NANJING CHERVON IND

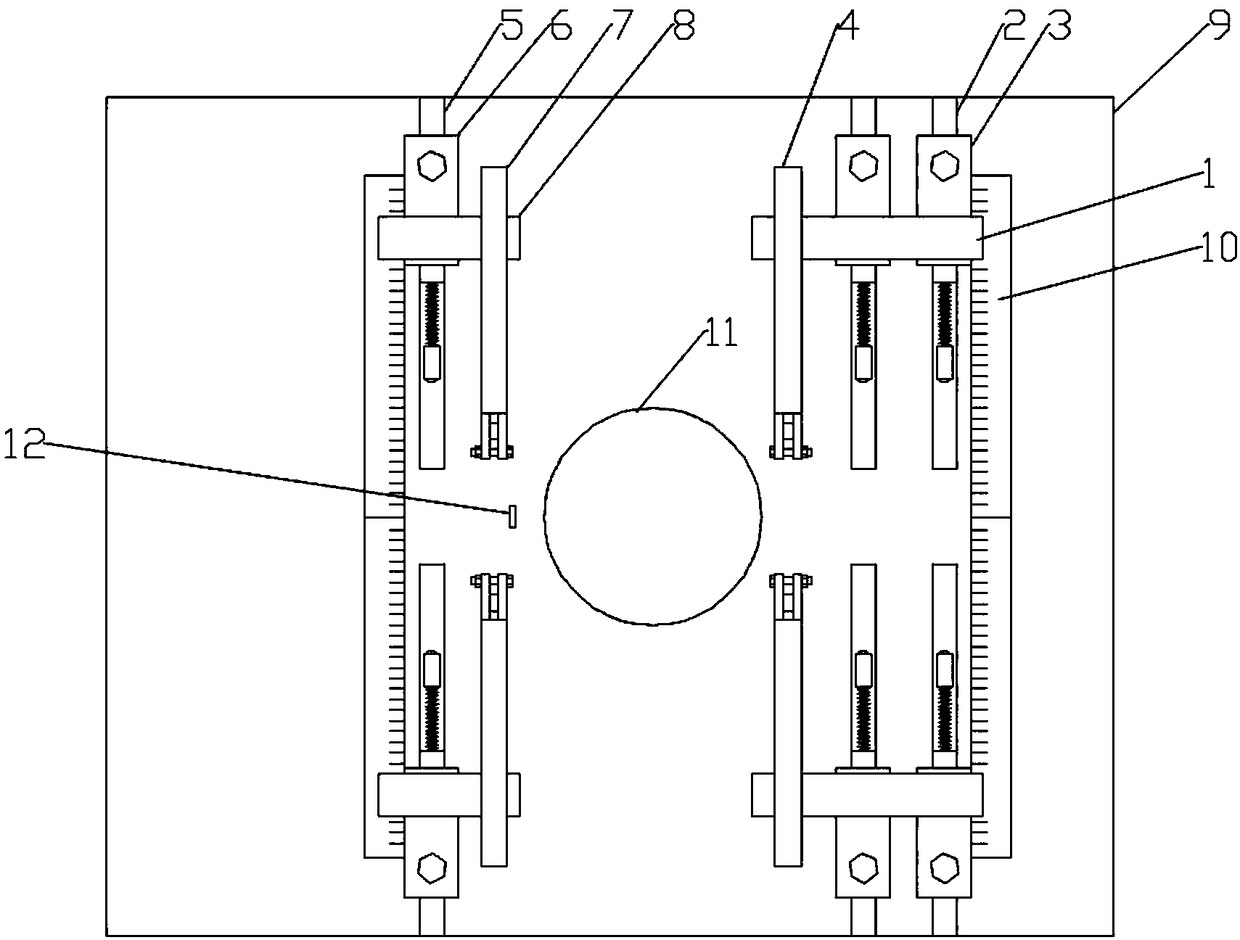

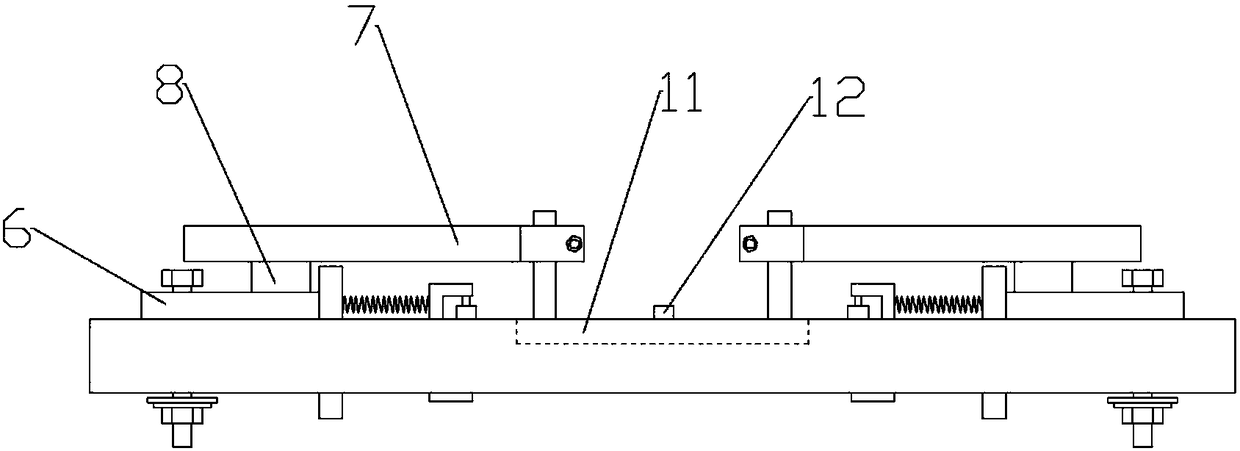

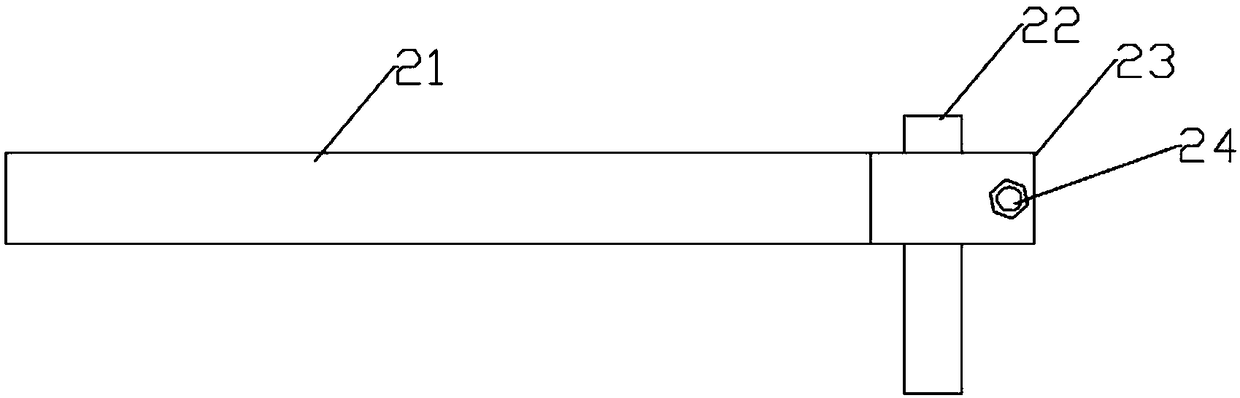

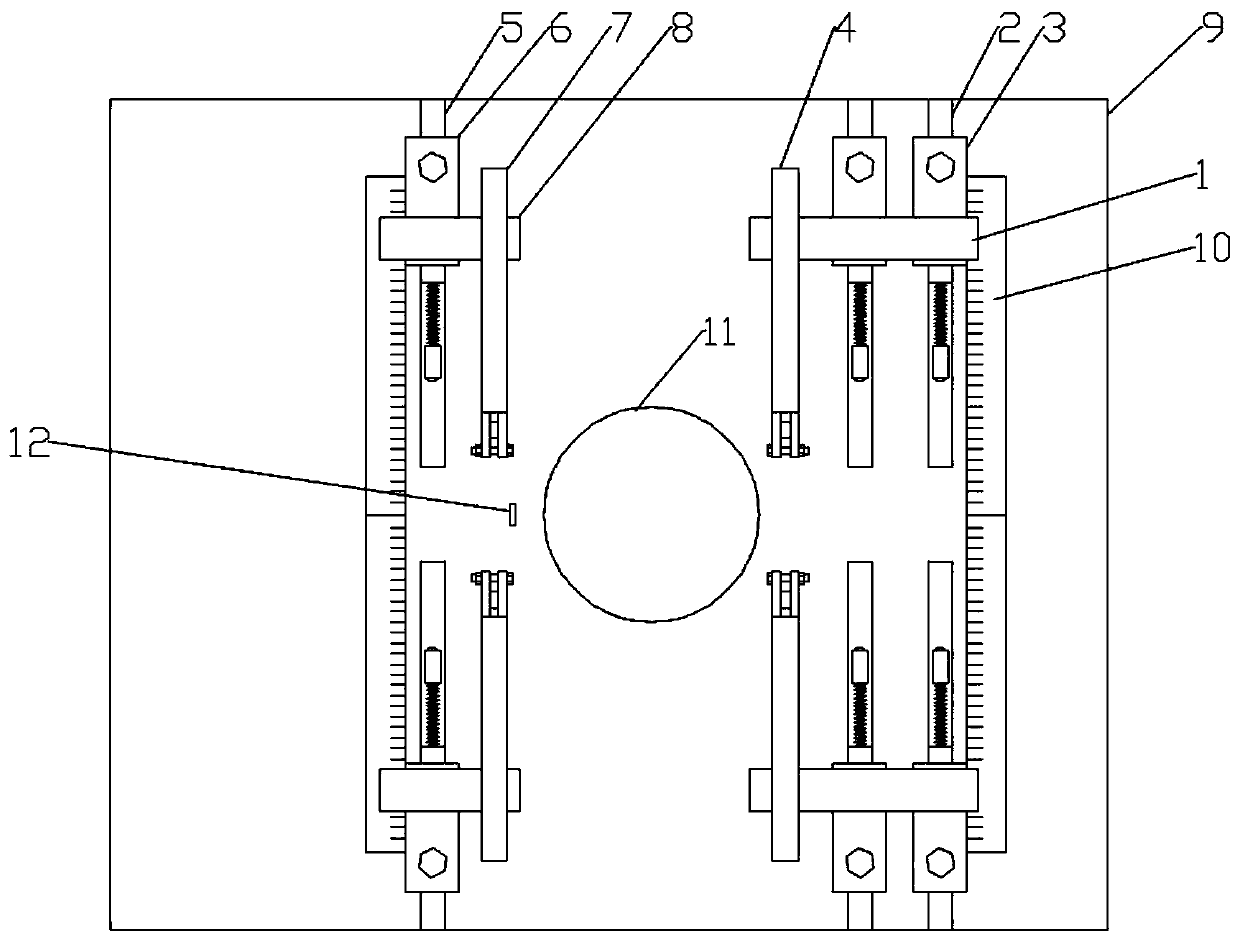

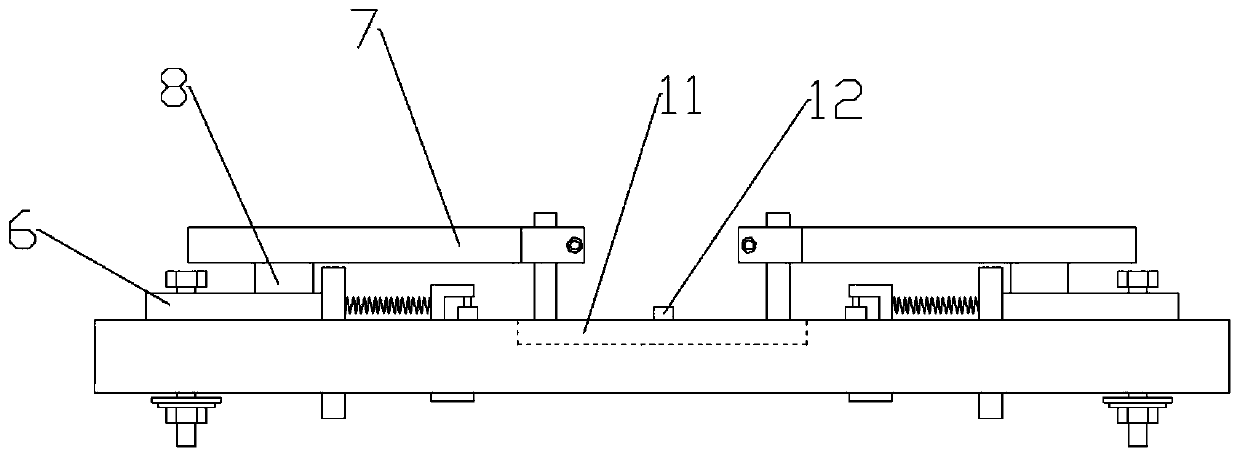

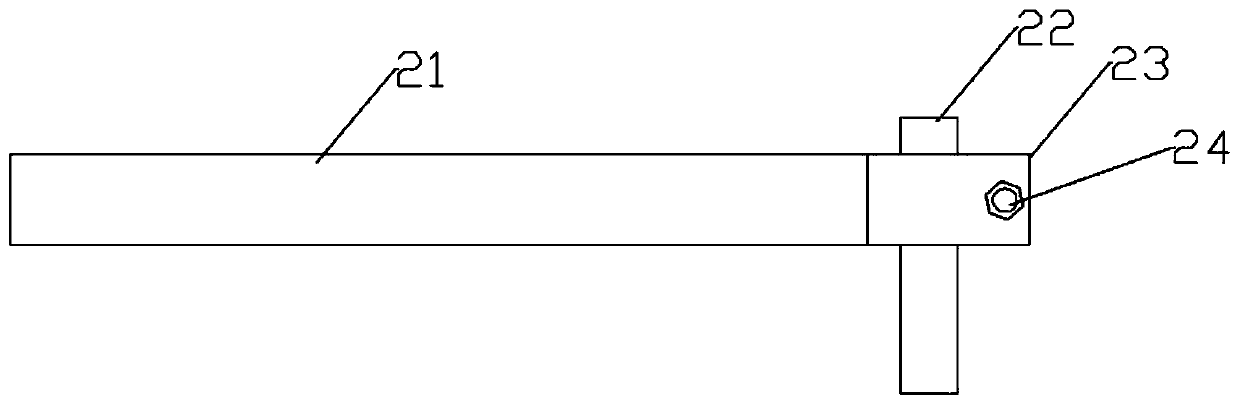

Feeding device for canister cover pressing working procedure

ActiveCN108453191ALight in massEasy to blow upMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention discloses a feeding device for a canister cover pressing working procedure. The feeding device for the canister cover pressing working procedure comprises a workbench. The center of theworkbench is provided with a bottom die and a thin elastic piece. One side of the bottom die is provided with four symmetrical first sliding grooves, and the other side of the bottom die is provided with two symmetric second sliding grooves. The first sliding grooves are internally provided with first rolling devices. The second sliding grooves are internally provided with second rolling devices.The first rolling devices are provided with first fulcrum bars, and the upper ends of the first fulcrum bars are provided with first pressing devices. The second rolling devices are provided with second fulcrum bars, and the upper ends of the second fulcrum bars are provided with second pressing devices. According to the feeding device for the canister cover pressing working procedure, correct positioning is firstly carried out when an iron sheet enters the upper end of the bottom die, and therefore the width of the iron sheet is reduced; and the distance between two times of pressing is judged through the thin elastic sheet, the utilization rate of the iron sheet is higher, the operation level of workers is reduced, meanwhile, during operation, only one hand is needed and is far away fromthe bottom die, potential safety hazards can be effectively eradicated, and the situation that the iron sheet deviates, and consequentially the edge of a canister cover cannot be pressed in place isalso avoided.

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

Rice mill with paddy screening treatment function

The invention discloses a rice mill with a paddy screening treatment function. The rice mill comprises a base plate, a rice mill body arranged on the base plate, and a paddy tank formed in the base plate; a sucker is arranged on the rice mill body; a screen plate is arranged at the middle part in the paddy tank; a rotating motor is arranged at the bottom of the screen plate; an output end of the rotating motor is connected with stirring blades arranged above the screen plate; a fan is arranged on the base plate; the fan communicates with the upper part of the paddy tank through a wind pipe; and a magnet is arranged at the bottom of the screen plate. The rice mill is provided with the sucker; paddies only need to be poured into the paddy tank during milling; the sucker can send the paddiesinto a rice inlet hopper, so that both time and manpower are saved, and the working efficiency is improved; and through pretreatment of the paddies, stones or iron blocks cannot be sucked, so that thedamage of the rice mill is prevented, and meanwhile, the reduction of the rice quality is prevented.

Owner:重庆米之吉粮食有限公司

Clothes disinfection and sterilization device for textile industry

InactiveCN112618748AEasy to operateAccelerate the speed of disinfection and sterilizationLavatory sanitoryHeatProcess engineeringIndustrial engineering

The invention discloses a clothes disinfection and sterilization device for the textile industry, and belongs to the field of textile processing. The clothes disinfection and sterilization device comprises a disinfection and sterilization box, wherein a screw rod is movably connected to the bottom of the side surface of the disinfection and sterilization box in a sleeving manner; and a forward and reverse motor is fixedly connected to one end of the screw rod. According to the clothes disinfection and sterilization device for the textile industry, through the arrangement of the disinfection and sterilization box, the screw rod, the forward and reverse motor, a moving block, a positioning rod, a placing plate, a liquid storage box, a liquid conveying pipe, a liquid conveying pump, a liquid conveying sleeve, a spray head, an ultraviolet lamp and a heating plate, a plurality of working procedures of alcohol disinfection and sterilization, high-temperature sterilization, ultraviolet sterilization and the like can be integrated together, so that the problem that the operation is tedious because clothes to be treated need to be manually transferred to corresponding working procedure equipment in sequence in the prior art is solved, the labor amount of production workers can be reduced, the clothes disinfection and sterilization speed is also increased, the working efficiency of clothes disinfection and sterilization is improved, and besides, the cost of clothes disinfection and sterilization is reduced.

Owner:杜宇尘

Foundry waste sand regeneration device

The invention discloses a foundry waste sand regeneration device comprising a machine case including a left machine case body and a right machine case body. The right machine case body is arranged onone side of the left machine case body, rotating rods are arranged at the bottoms of inner cavities of the left machine case body and the right machine case body in a penetrating manner, the outer sides of the rotating rods are fixedly provided with stirring mechanisms, each stirring mechanism includes a plurality of stirring blades, dull polish layers are fixed to the inner wall of the machine case and the side faces of the stirring blades, the bottom of the machine case is fixedly provided with high-pressure hot air blowers and air intake branch pipes arranged in a penetrated manner, the ends of the air intake branch pipes are provided with air intake main pipes, the top of the machine case is provided with a top plate, the two sides of the top plate are provided with top covers, the bottoms of the top covers are provided with sealing rings in an embedded and sleeved manner, and air outlet branch pipes are arranged on the top covers in a penetrating manner. Compared with equipment inthe prior art, the structure is effectively simplified, while foundry waste sand regeneration is realized, the structure is relatively simple, equipment cost is relatively low, convenience is broughtto operation, the regeneration efficiency is effectively improved, and design is reasonable.

Owner:MAANSHAN XINGLONG FOUNDRY CO LTD

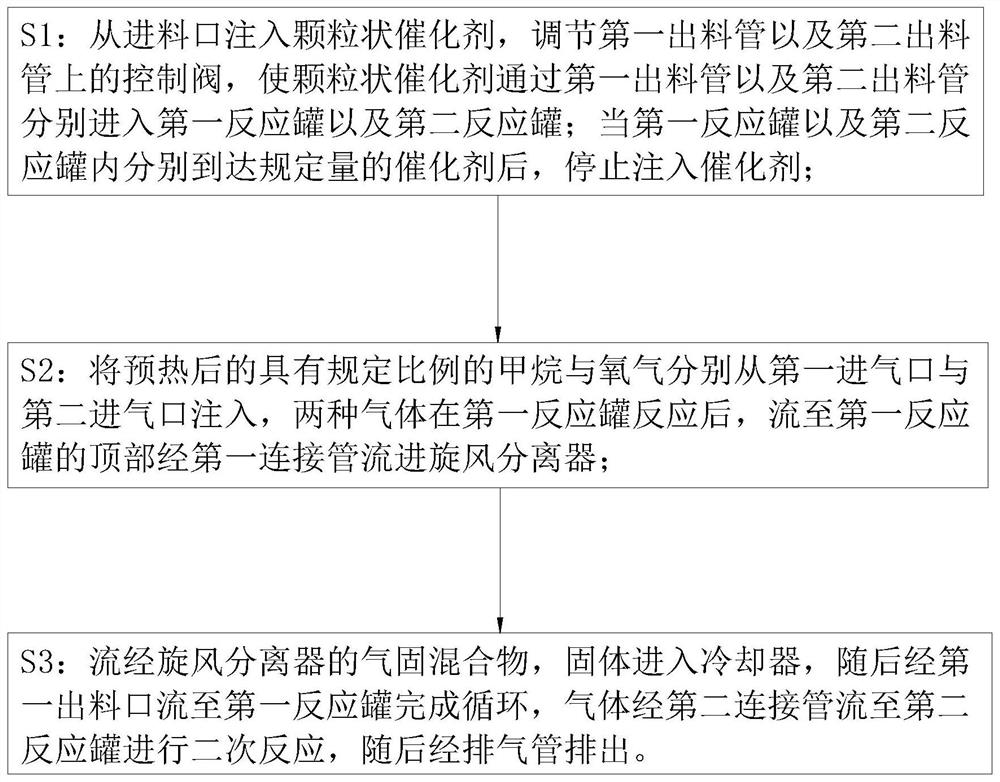

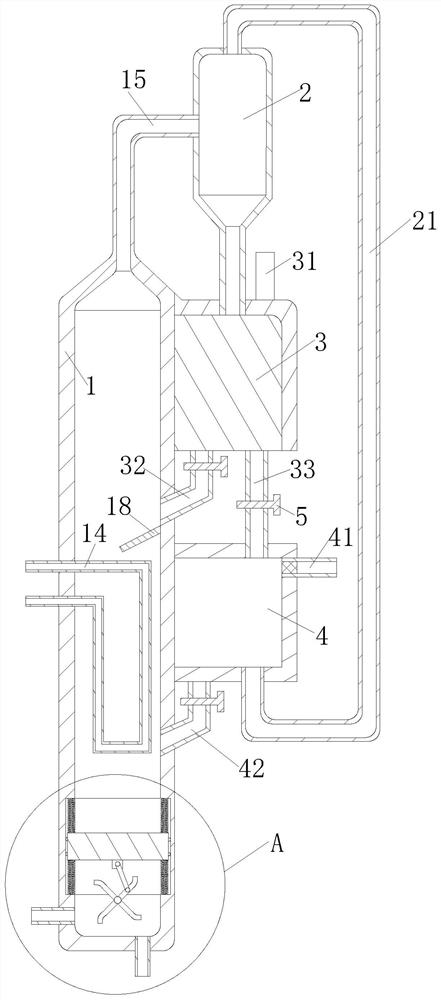

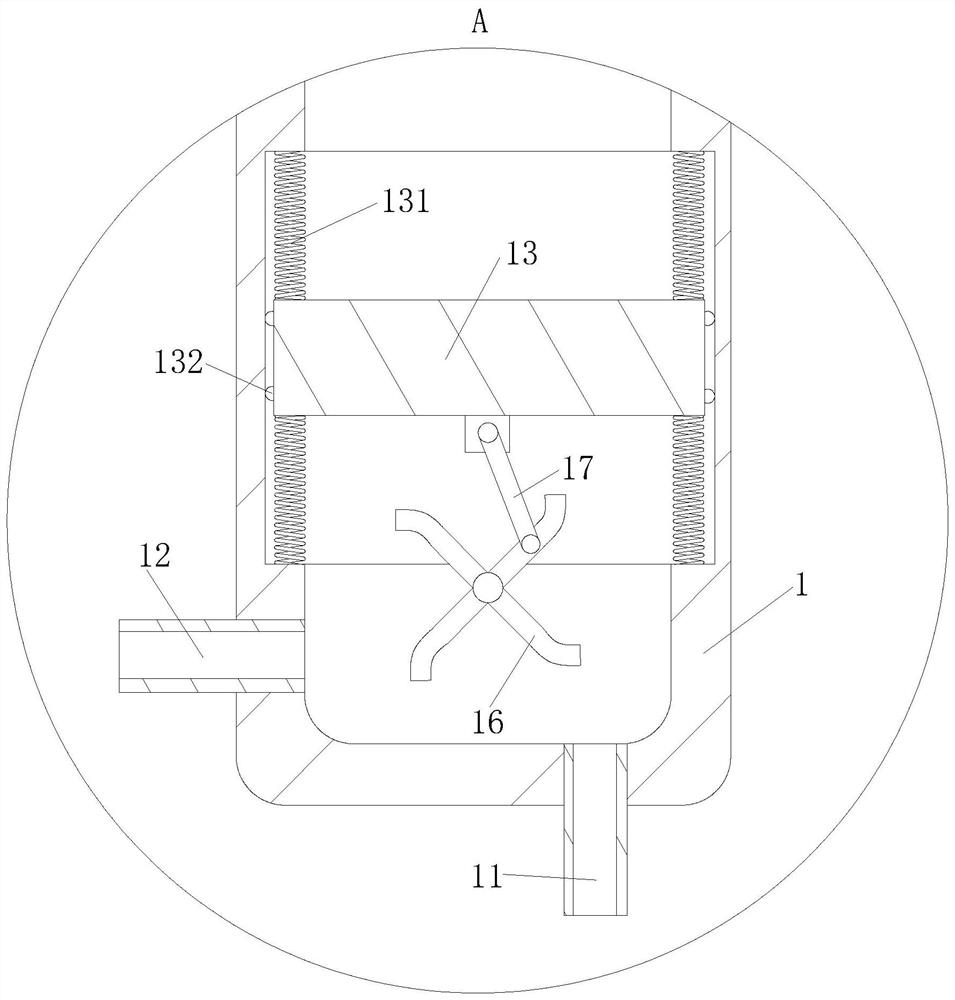

Reaction device and process for preparing ethylene through oxidative coupling of methane

PendingCN113976048AAvoid too thickAvoid duplicate joinsDispersed particle separationHydrocarbon by hydrocarbon condensationPtru catalystProcess engineering

The invention belongs to the technical field of ethylene preparation, and particularly relates to a reaction device and process for preparing ethylene through oxidative coupling of methane. The reaction device comprises a first reaction tank, a cyclone separator, a cooler and a second reaction tank. According to the invention, methane and oxygen are introduced from a first gas inlet and a second gas inlet respectively, mixed gas blows a catalyst to rise, a reaction is carried out in the process, the solid of a gas-solid mixture enters a cooler under the action of a cyclone separator and flows through a first reaction tank to complete circulation so as to prevent the catalyst from being accumulated too thick, recycle the catalyst and avoid repeated addition of the catalyst, the separated gas enters a second reaction tank for secondary reaction so as to make the reaction more sufficient, and then the gas is exhausted through an exhaust pipe.

Owner:杨凡

Feeding device for can lid pressing process

ActiveCN108453191BLight in massEasy to blow upMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:ANHUI YILIANG TANK IDUSTRY TECH CO LTD

A kind of preparation technology and device of vitamin D3 microcapsule powder

ActiveCN104306353BImprove liquidityGreat tasteOrganic active ingredientsPressurized chemical processSolubilityCalcium biphosphate

The invention relates to a preparation process and a preparation device of vitamin D3 microcapsule powder. In the preparation process, VD3 oil, sunflower seed oil or corn oil, medicinal starch, maltodextrin, modified starch, white sugar, calcium phosphate and 2,6-di-t-buty-4-methylphenol (BHT) are used as main raw materials. The preparation process and the preparation device are reasonably improved and optimized, the production time is greatly shortened and the whole production process is controlled; through layer-by-layer drying and step-by-step recycling, the prepared vitamin D3 microcapsule powder has smooth and flat surface, and the safety, the fluidity, the mouth feel and the water solubility of the vitamin D3 microcapsule powder are greatly improved; the waste of resources is reduced, the continuous large-scale production is implemented, and the production cost is reduced.

Owner:豆源和(山东)食品饮料有限公司

Hair dryer

The invention provides a hair dryer. The air dryer comprises a shell, a motor, an axial fan, an air blowing pipe and a duct, wherein an air inlet is formed in the shell, and air enters from the air inlet; the motor is located in the shell; the axial fan is driven by the motor to rotate and generate airflow; the air blowing pipe is connected with the shell and provided with an air outlet, and airflow is blown out from the air outlet; the duct is used for guiding airflow to move towards the air outlet; the duct comprises a flow guide cone, a duct outer cover containing the flow guide cone and a static blade located between the flow guide cone and the duct outer cover; the motor is arranged between the air inlet and the axial flow fan, and the flow guide cone and the motor are arranged on the two opposite sides of the axial flow fan. Compared with the prior art, the hair dryer drives the small-diameter fan at a high rotating speed, so power consumption is lower, higher blowing efficiency can be obtained, and heavier leaves on a lawn, leaves in cracks and the like can be conveniently blown.

Owner:POSITEC POWER TOOLS (SUZHOU) CO LTD

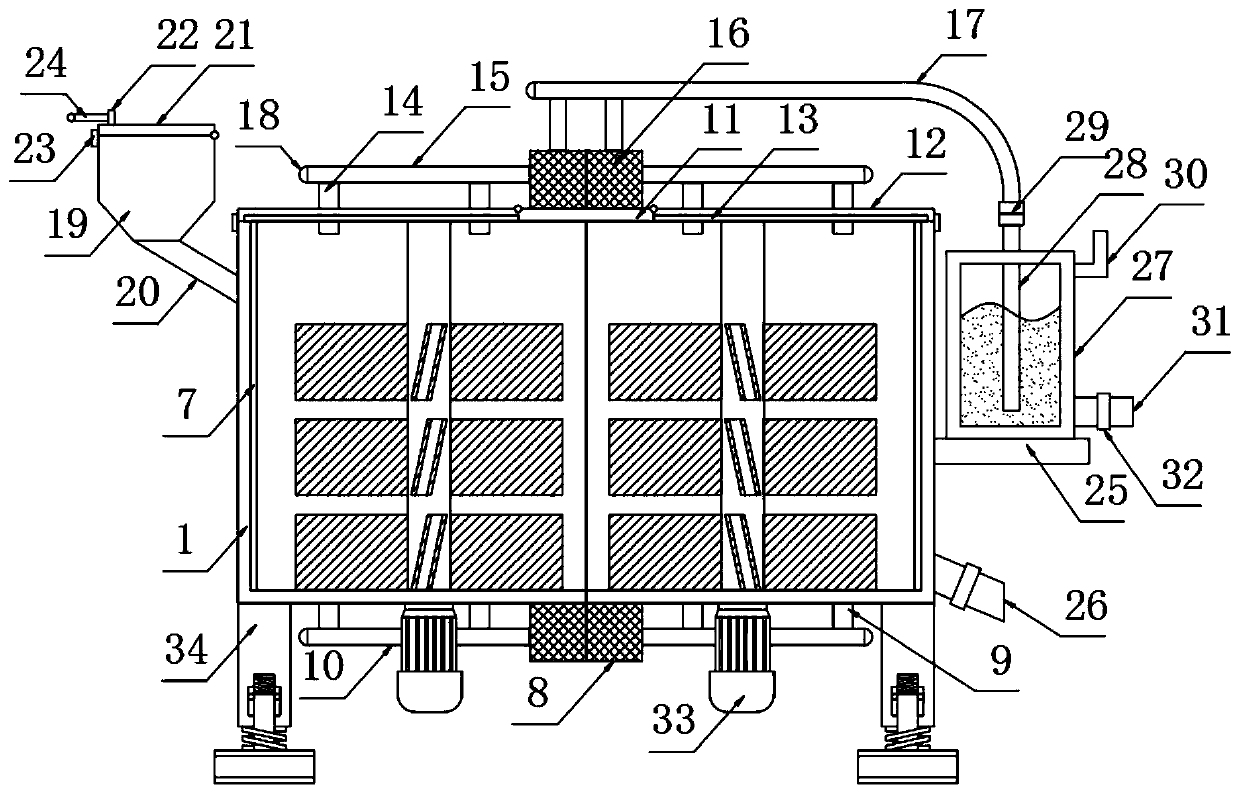

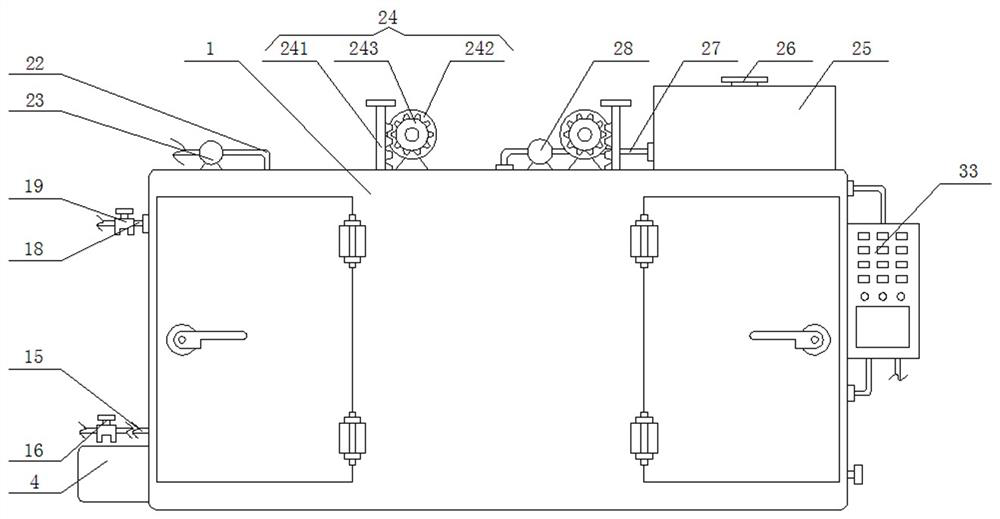

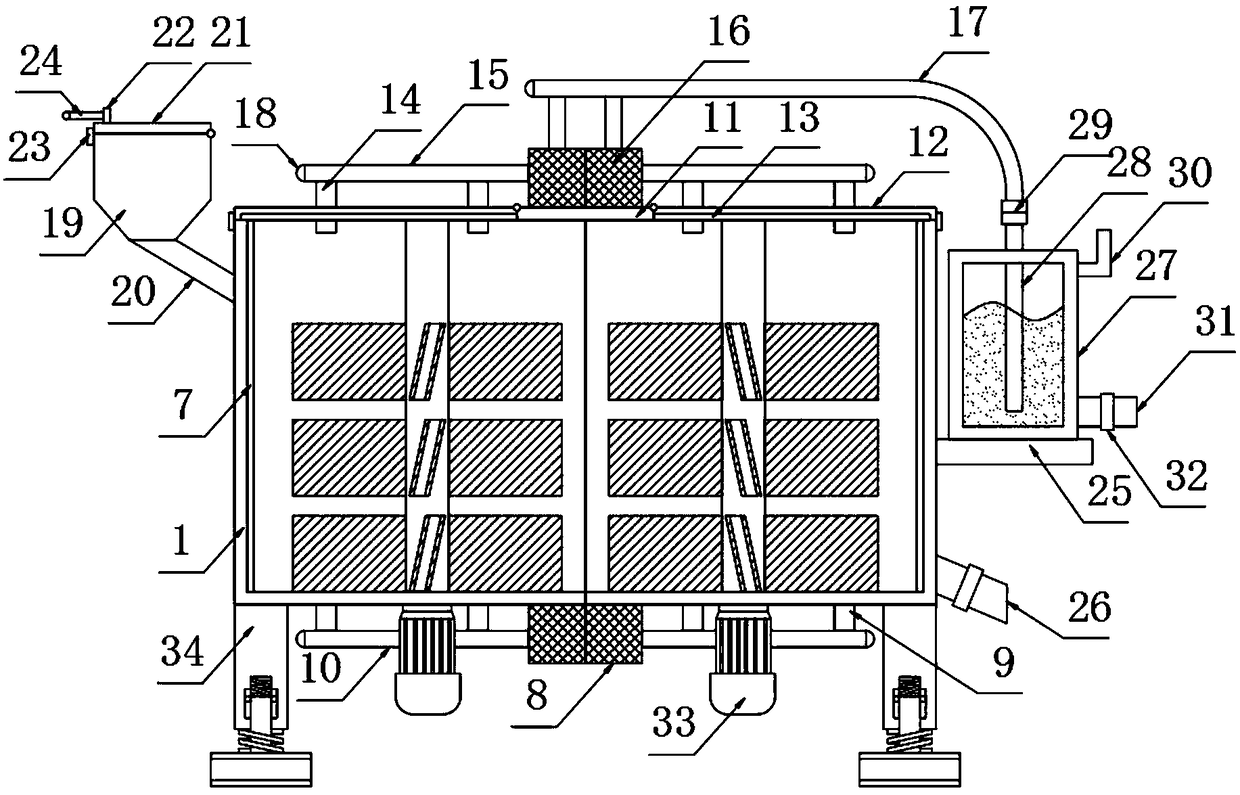

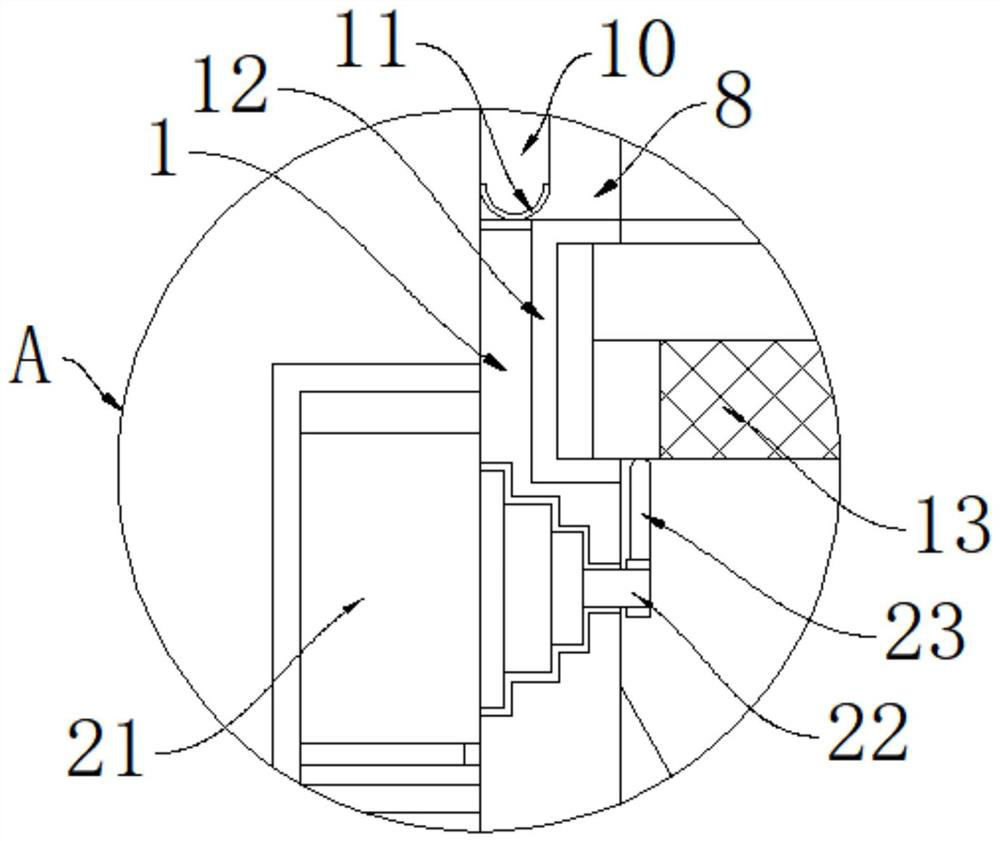

Boiling bed for pre-crystallization of polyester yarn production

InactiveCN110420479AEasy feedingEasy dischargeDispersed particle filtrationLiquid solutions solvent extractionYarnPolyester

The invention discloses a boiling bed for pre-crystallization of polyester yarn production. The boiling bed comprises a machine body, a material box, a stirring shaft, a belt, an air inlet pipe, a heater, a motor and a control box. The invention solves the following problem: in a prior boiling bed, hot air only can be blown from bottom to top, and dust in the hot air cannot be filtered out, so that the dust in the hot air is stuck to polyethylene terephthalate (PET) slices, then the PET slices are polluted, and the quality of produced polyester yarn is influenced; meanwhile, the prior boilingbed is difficult in discharging, so that the PET slices after pre-crystallization are inconvenient to take out from the boiling bed; and during pre-crystallization of PET, the airflow velocity is uncontrollable, so that a part of PET slices are bonded to form blocks. Through improvement of the structure of the boiling bed, air blown into the boiling bed can be filtered by the boiling bed, so thata large amount of dust is prevented from adhering to the PET slices.

Owner:CHANGLE JIALUN TEXTILE IND CO LTD

Adjustable feeding equipment of rice processing line and feeding method thereof

PendingCN112845085AEasy accessImprove filtering effectSievingGas current separationAgricultural scienceAgricultural engineering

The invention discloses adjustable feeding equipment for a rice processing line and a feeding method thereof.The adjustable feeding equipment comprises a fixed barrel, wherein a fixed cover plate is fixedly connected to the upper surface of the fixed barrel, a feeding opening is formed in the upper surface of the fixed cover plate, and a feeding hopper is fixedly connected to the top of the inner wall of the feeding opening; the lower surface of the fixed cover plate is fixedly connected with a dust inlet funnel, a dust outlet of the dust inlet funnel is fixedly connected with a dust suction box, and the side face of the dust suction box is fixedly connected with a dust outlet pipe. According to the adjustable feeding equipment for the rice processing line and the feeding method thereof, the fixed barrel, the fixed cover plate, a feeding opening, a feeding hopper, a dust inlet hopper, a dust suction box, a dust outlet pipe, a limiting square hole, a positioning rotating shaft, a positioning baffle, a magnet plate, a circular ring groove, a filter screen plate, a motor protection cover, a triangular supporting plate, a fan, a ventilation hole, a filter plate and an air guide plate are arranged, such that the feeding equipment for the rice processing line has an adjustable effect.

Owner:福建泉州市金穗米业有限公司

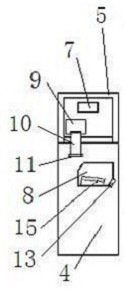

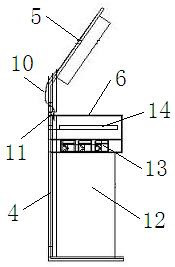

Bookcase console to realize book recycling

ActiveCN107274321BEffective preservationGuaranteed disinfection effectData processing applicationsBook cabinetsMechanical engineeringIndustrial engineering

The invention discloses a book cabinet control table for realizing cyclic utilization of books. The book cabinet control table comprises a control table body; a control box is arranged at the upper part of the control table body; an operation panel is arranged at the top of the control table body; an operation screen is arranged on the front end surface of the operation panel; the control box is electrically connected with the operation screen; a disinfection tank is arranged at the front end surface of the control table body; a fan is arranged on one side in the disinfection tank; an ultraviolet lamp is arranged on the same side of the fan in the disinfection tank; the fan and the ultraviolet lamp are electrically connected with the control box; a book placement table is arranged at the bottom in the disinfection tank; and the spines of the books are placed on the placement table in a manner of backing to the fan and the ultraviolet lamp. According to the structure of the book cabinet control table for realizing cyclic utilization of the books, through the effect of the disinfection tank, the books prepared to be stored can be disinfected, so that effective storage of the books is facilitated and the books fetched by book fetching personnel are ensured to be all disinfected.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

A kind of ding mandarin fish breeding equipment that is easy to put in feed

ActiveCN112586423BPrecise deliveryEasy to blow upTransportation and packagingRotary stirring mixersFisheryElectric machinery

The invention discloses a mandarin fish cultivating equipment that is convenient for feeding feed, and specifically relates to the technical field of mandarin fish cultivation. Cover plate, the cover plate and the storage box are locked by hasp, the storage box is fixedly connected with a partition plate, the bottom of the storage box is provided with a bottom plate, and the four corners of the bottom end face of the bottom plate are fixedly connected There are moving wheels, and the top of the bottom plate is provided with a throwing mechanism and a lifting mechanism. The invention drives the fan blades to rotate through the operation of the motor, and the rotation of the fan blades generates wind, the wind enters the inside of the storage box and blows the feed into the first feeding frame, the feed falls into the breeding pond through the leakage opening, and moves the second feeding frame Adjust the exposed quantity of the leakage port, turn the handle to drive the fourth shaft to rotate, and then drive the storage box to move vertically, the feed is put in accurately, effectively saves the feed, and at the same time, it is convenient to adjust the height and easy to use.

Owner:CHONGQING UNIV OF ARTS & SCI

A machine for ringing and stacking of paper seedling bags

ActiveCN109089635BEasy to blow upNot easy to tearCultivating equipmentsCircular discAgricultural engineering

The invention discloses a paper seedling raising bag looping and stacking machine. The machine comprises support rods; the machine is characterized in that a circular ring is fixed to the tops of themultiple support rods, the side ends of the support rods on the two sides are horizontally fixed to one ends of cross rods respectively, a vertical rod is vertically fixed to the other end of each cross rod, a sleeve slidably connected with each vertical rod sleeves the vertical rod, the side end of each sleeve is fixed to one end of an L-shaped rod, a disc is horizontally fixed to the other end of the L-shaped rod, the disc is arranged above the circular ring and corresponds to the circular ring, a looping plate is horizontally fixed to the bottom of the disc, a barrel is vertically fixed tothe middle of the base of the looping plate, the barrel is shaped like a circular truncated cone, a flange integrally formed with the looping plate is fixed to the bottom of the looping plate, a groove is formed between the flange and the barrel and matched with the circular ring, and the joint of the flange and the groove and the edge adopt circular beads. Accordingly, a seedling raising bag is looped easily and conveniently, multi-layer stacking is conducted, and tearing is not likely to occur; in addition, the seedling raising bag can be supported to be round, and planing and using are facilitated.

Owner:怀宁县惠民育苗容器有限公司

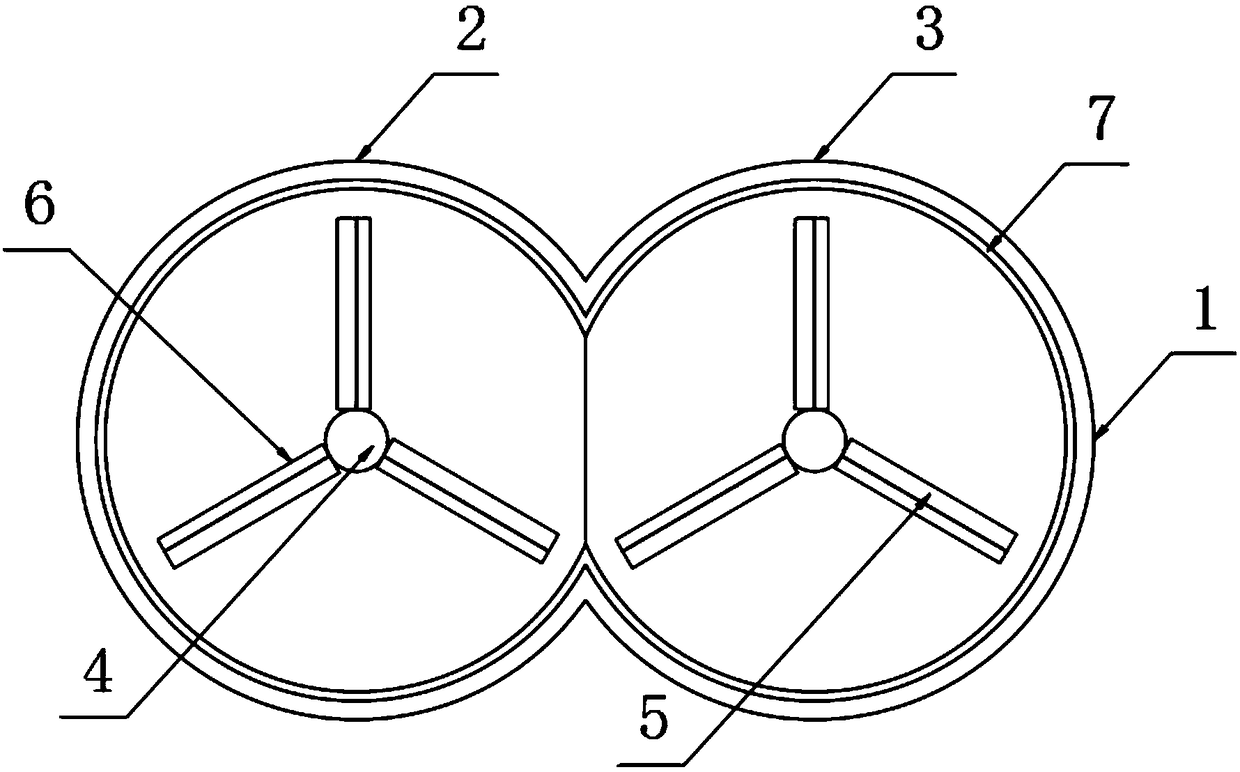

Air adjusting device for colored ribbon flying

InactiveCN108730232AEasy to blow upStable supportPump componentsPumpsEngineeringMechanical engineering

The invention discloses an air adjusting device for colored ribbon flying. The air adjusting device comprises a bottom shell, a convex shell is arranged on the end of the bottom shell, and an openingcavity is formed in the convex shell and the bottom shell; a rotating disc is arranged in the opening cavity, a plurality of air adjusting pieces are arranged on the rotating disc, and the cross section of each air adjusting piece is in an arc shape; the outer side wall of the convex shell is connected with an air inlet pipe, an air inlet is formed in the outer end of the air inlet pipe, a conveying opening is formed in the inner end of the air inlet pipe, the conveying opening is formed in the position located on the inner side wall of the convex shell, and the conveying opening communicateswith the opening cavity; a sealing cover is arranged on the end part of the convex shell, an air outlet pipe is arranged on the sealing cover, and an air outlet is formed in the end of the air outletpipe; and the lower end of the air outlet pipe communicates with the opening cavity. Through the air adjusting device, a colored ribbon can be conveniently blown up.

Owner:季德贵

Efficient dust removal equipment for heavy calcium carbonate production

InactiveCN113477620AAvoid stockpilingEasy to blow upDispersed particle filtrationCleaning using gasesRubber ringDust control

The invention provides efficient dust removal equipment for heavy calcium carbonate production, and belongs to the technical field of dust removal. The efficient dust removal equipment for the heavy calcium carbonate production comprises a base, a dust collection assembly and a dust removal assembly. The base comprises a cabinet body and a box body; one side of the cabinet body and one side of the box body are open; the cabinet body is fixed to the top of the box body; the dust collection assembly comprises a barrel, a dust inlet, a fixed sleeve, a push rod, a push handle, a dust pushing block, a rubber ring, an abutting block and a dust discharging inclined face; the barrel is fixed to the side edge of the bottom of the cabinet body; the dust inlet is arranged on the upper end of the barrel; the rear end of the barrel is connected with the fixed sleeve; the fixed sleeve extends out of the cabinet body; the push rod movably penetrates through the fixed sleeve; one end of the push rod is provided with the push handle, and the other end of the push rod is provided with the dust pushing block; and the outer wall of the dust pushing block is provided with the rubber ring and abuts against the inner wall of the barrel. Dust is collected through the dust inlet through the barrel, dust is prevented from being accumulated at corners, and the dust removal effect is good.

Owner:胡健

fan

ActiveCN105370589BReduce fatigueEasy to blow upPump componentsPump installationsMotor driveEngineering

Owner:NANJING CHERVON IND

Furfural residue combustion boiler with built-in vibration mechanism and high combustion efficiency

ActiveCN114688521APromote combustionFacilitated DiffusionSolid fuel pretreatmentSolid fuel combustionThermodynamicsCombustion

The invention relates to the technical field of furfural residue treatment, in particular to a furfural residue combustion boiler with a built-in vibration mechanism and high combustion efficiency. The device comprises a combustion furnace and an exhaust device arranged on one side of the combustion furnace, a treatment device is arranged in the combustion furnace, and the treatment device comprises a material guide device and a material bearing device arranged in the middle of the material guide device. According to the device, gas in the gas passing pipe is closed through the closing pipe, so that gas entering the exhaust pipe becomes torrent, meanwhile, the exhaust pipe is arranged to be in a spiral shape, gas coming out of the gas outlet is rotational flow, furfural residues placed on the bearing plate are blown up, furfural residue powder is conveniently diffused in the combustion barrel, combustion of the furfural residues is facilitated, and the combustion efficiency of the furfural residues is improved. And gas in the combustion barrel is recycled through the arranged gas return pipe, furfural residues combusted in the combustion barrel flow back again and are combusted again, the combustion effect of the furfural residues is improved, and the combustion effect of the furfural residues is improved.

Owner:BEIJING AOKE RUIFENG NEW ENERGY

Composite sintered wear-resistant plate, preparation method and special stirring and mixing device

ActiveCN107020382BReduce coefficient of frictionIncrease contentRotary stirring mixersTransportation and packagingRough surfaceWear resistant

The invention belongs to the technical field of composite sintered wear-resistant plates and preparation methods, and discloses a composite sintered wear-resistant plate, a preparation method and a special stirring and mixing device. Its main technical features are: including a substrate, a rough surface is provided on one side of the substrate, a copper powder layer is provided outside the rough surface, and a graphene-copper powder mixed layer is provided on the outer surface of the copper powder layer. The graphene powder and copper powder weight ratio are 1-2:100, and the particle size of the graphene powder and copper powder is 200-300 mesh, so that the graphene copper powder mixed layer is more firmly combined with the substrate, and the graphene The content of carbon dioxide is high, the lubricating effect is good, and the friction coefficient of the bearings and other products made is low, which greatly prolongs the service life. Inject high-pressure gas and turn on the stirring mechanism, so that the mixing is more uniform, which can effectively increase the content of graphene powder and improve the wear resistance of the composite sintered wear-resistant plate.

Owner:SHENZHEN YUANZHENG POLYMER COMPOSITE MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com