Boiling bed for pre-crystallization of polyester yarn production

A pre-crystallization and polyester yarn technology, applied in the field of polyester yarn production, can solve the problems of affecting the quality of polyester yarn, dust filtration, PET slice pollution, etc., to reduce the probability of bonding together, facilitate feeding and discharging, The effect of increasing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

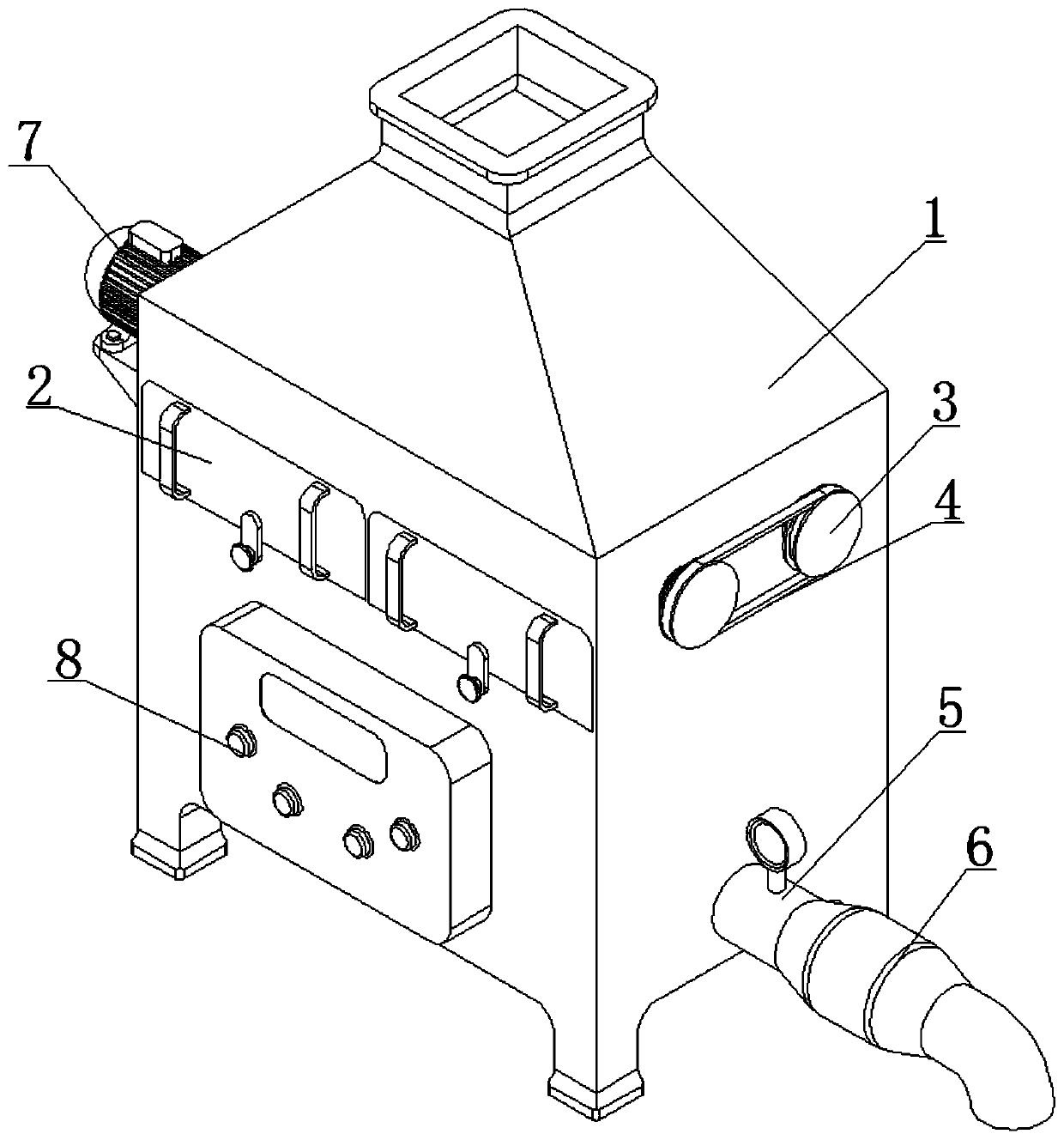

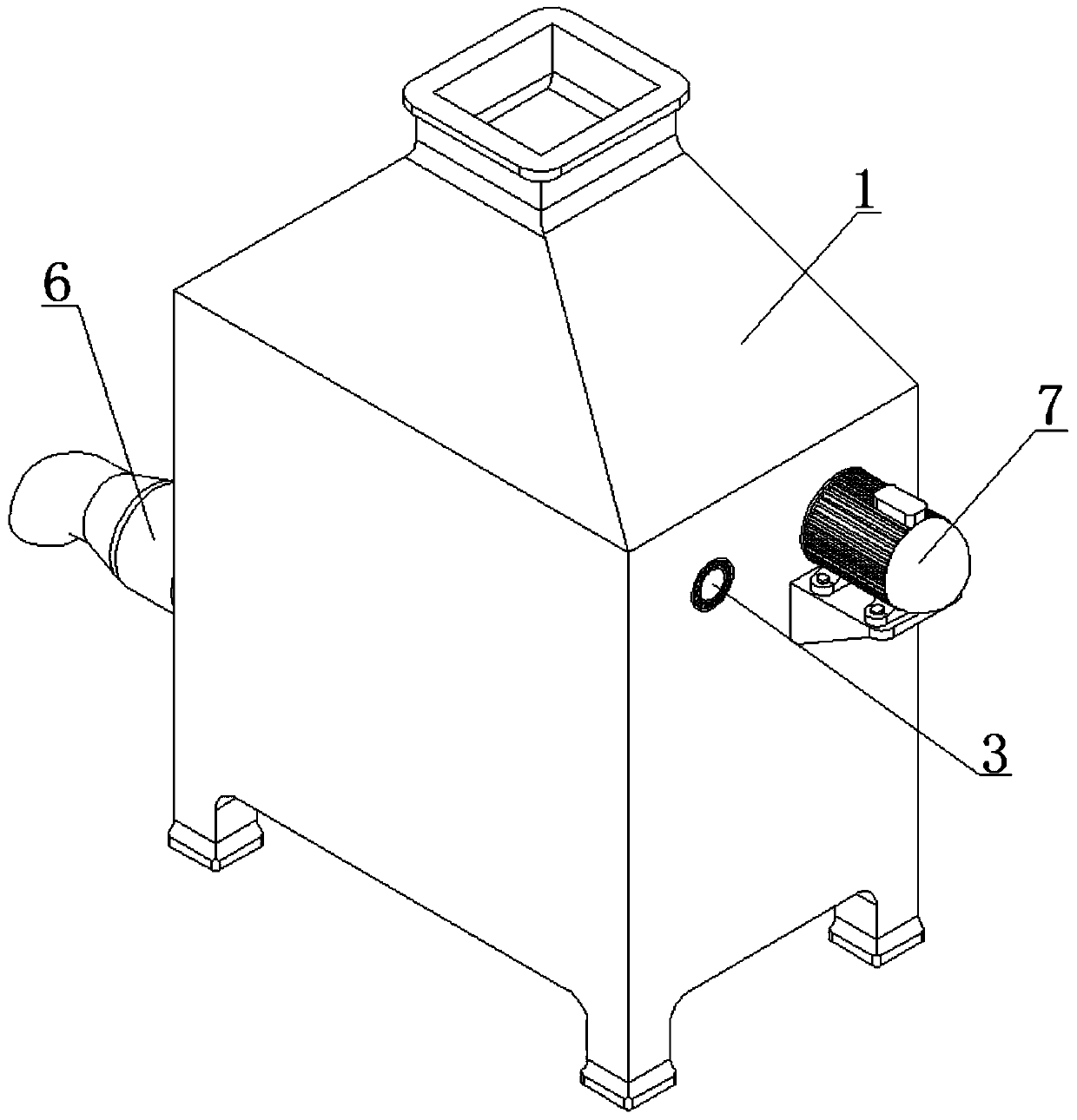

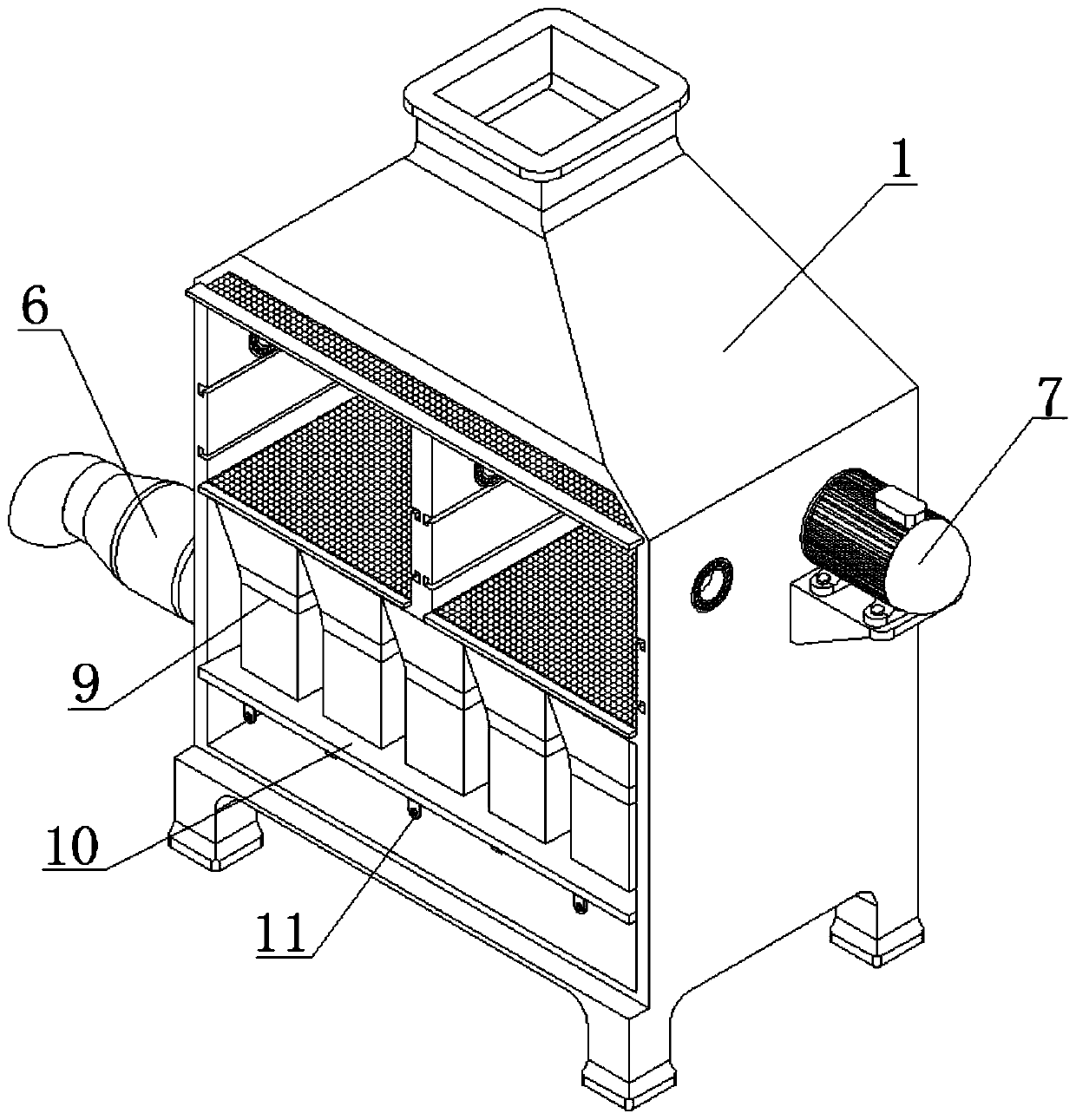

[0037] Example: refer to figure 1 , figure 2 with image 3 Shown: a fluidized bed for polyester yarn production pre-crystallization, including body 1, material box 2, stirring shaft 3, belt 4, air inlet pipe 5, heater 6, motor 7, control box 8, air-inducing branch pipe 9, Dust removal bag 10 and fixed frame 11; several air-introduction branch pipes 9 are evenly arranged on the inner lower part of the body 1, and the bottom of the air-induction branch pipe 9 is inserted with a dust removal bag 10, and a fixed frame 11 is inserted inside the dust removal bag 10, and the fixed frame 11 is connected to the body 1 The inner surface is connected, the body 1 is provided with a material box 2 along the air-inducing branch pipe 9, and the inside of the body 1 is provided with two stirring shafts 3 along the upper side of the material box 2, and the two stirring shafts 3 are connected by a belt 4, and The side of the body 1 is provided with a motor 7 along the end of the stirring sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com