Bobbin tray

A technology for trays and bobbins, which is applied to spinning machines, textiles, papermaking, and splicing devices. It can solve problems that affect the success rate of threading, failure to blow out, and threading failure after tube replacement, and achieve low production costs and high efficiency. High success rate and tube replacement success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

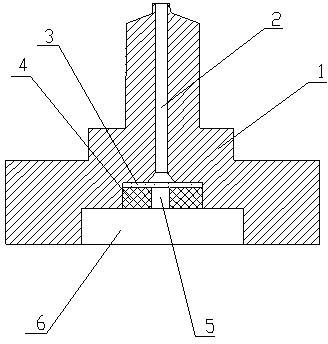

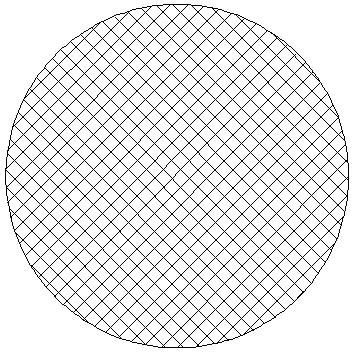

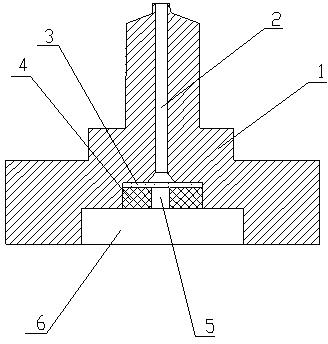

[0019] see figure 1 , figure 2 , an embodiment of a bobbin tray with a filter screen in the present invention, comprising: a tray body 1, a central hole 2 is arranged on the upper part of the tray body 1, a bottom hole is opened in the middle of the bottom surface of the tray body 1, and the diameter of the bottom hole is larger than the center hole 2 The aperture, and communicate with the central hole 2. A circular filter screen 3 consistent with the diameter of the bottom hole is set in the bottom hole and the near end of the central hole 2, and an annular jacket 4 is installed below the circular filter screen 3 to fix the circular filter screen 3. The outer diameter of the annular jacket 4 is slightly larger than the diameter of the bottom hole, and the annular jacket 4 and the bottom hole are tightly fitted and installed.

[0020] The bottom hole on the bottom surface of the tray body 1 is a stepped hole, and the diameter 6 of a section of the stepped hole near the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com