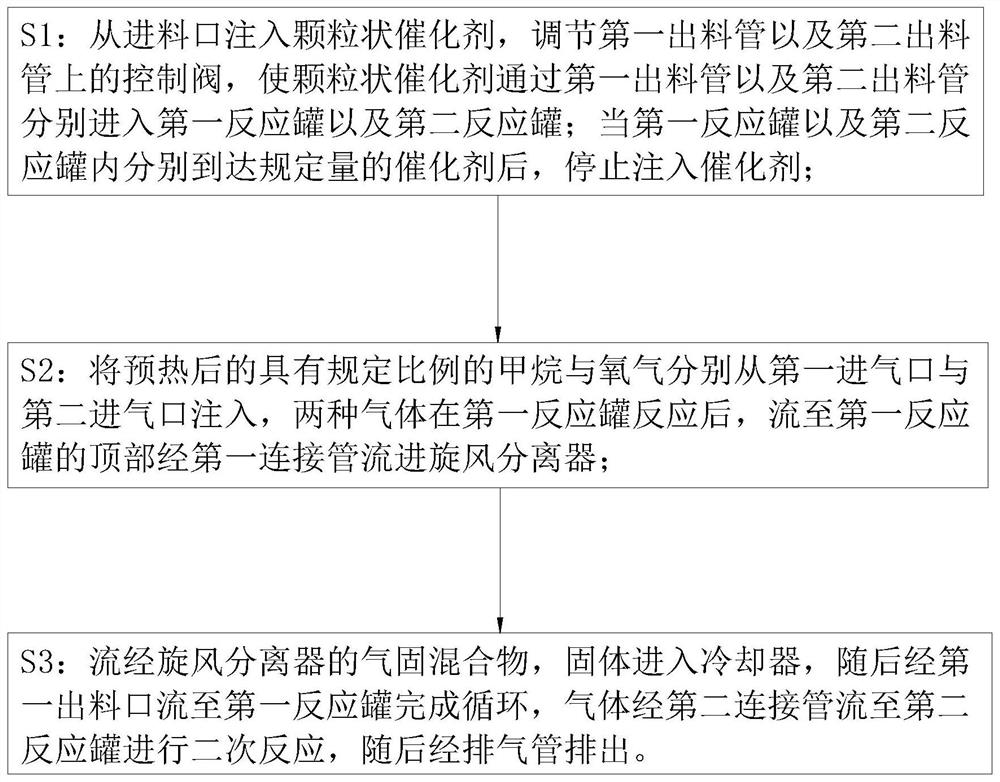

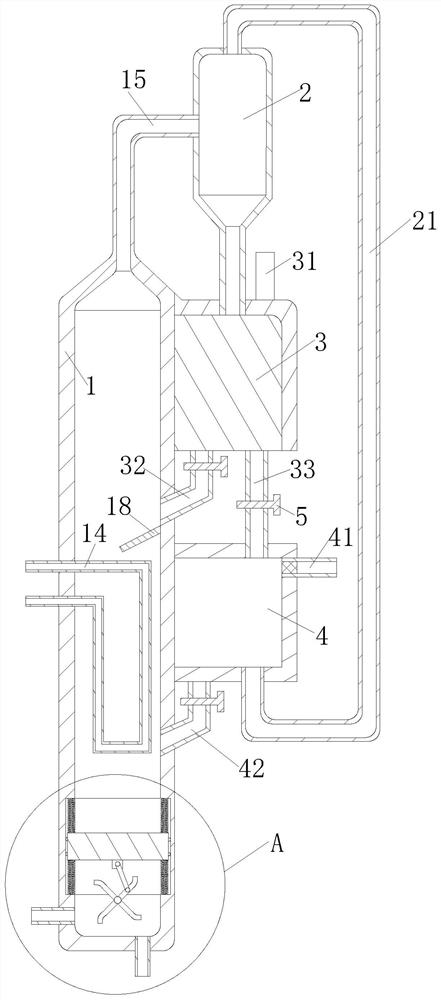

Reaction device and process for preparing ethylene through oxidative coupling of methane

A technology of oxidative coupling and reaction device, which is applied in organic chemistry, chemical recovery, chemical instruments and methods, etc., can solve the problem of too thick catalyst bed, and achieve the effects of avoiding repeated addition, increasing reaction efficiency, and facilitating circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

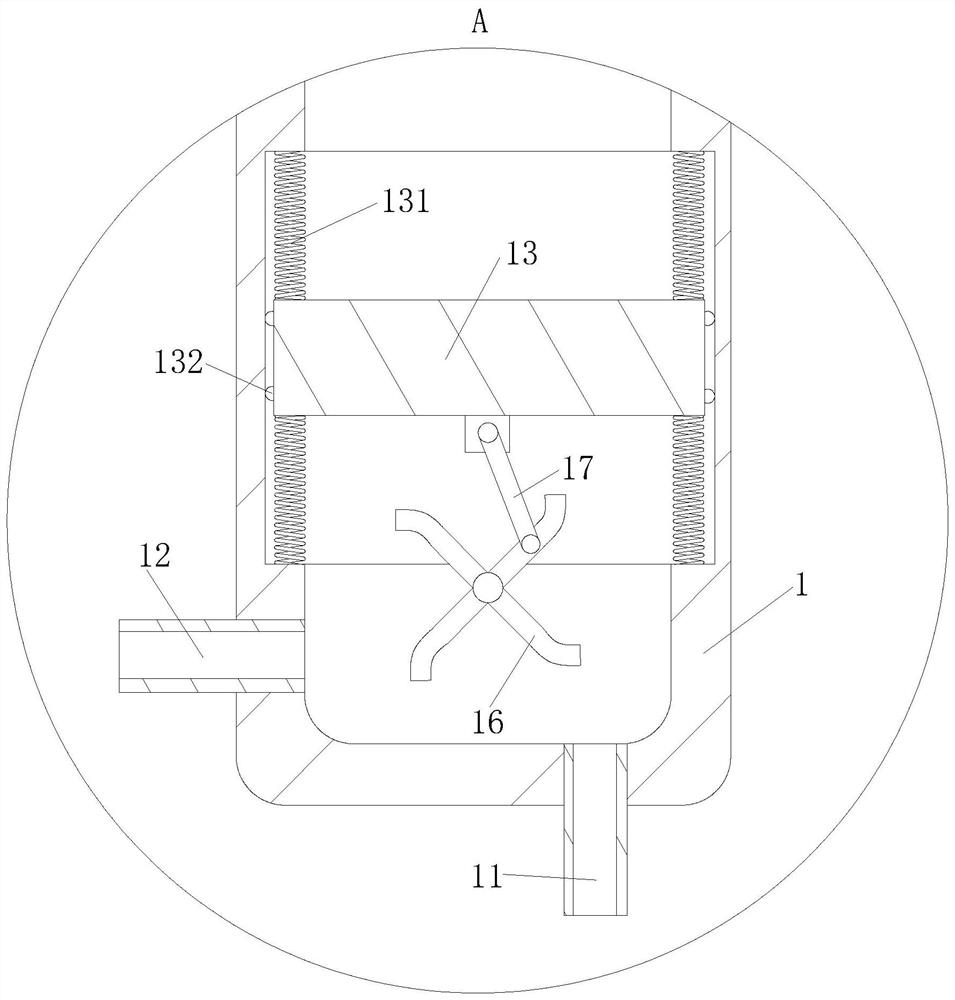

[0038] As a specific embodiment of the present invention, the first air inlet 11 is fixedly installed on the bottom of the first reaction tank 1, and the second air inlet 12 is fixedly installed on the side wall of the first reaction tank 1 and is close to bottom part.

[0039] During work, the first air inlet 11 is fixedly installed on the bottom of the first reaction tank 1, and the second air inlet 12 is fixedly installed on the side wall of the first reaction tank 1 and a position near the bottom. The bottom of the first reaction tank 1 impacts, so that the methane and oxygen are evenly mixed at the bottom of the first reaction tank 1, and then pass through the gas distributor 13 to contact with the catalyst to make the reaction more complete and obtain ethylene with higher purity.

[0040] As a specific embodiment of the present invention, a fan blade 16 is arranged below the gas distributor 13, the blade end of the fan blade 16 is curved, and the fan blade 16 is rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com