Automatic glaze spraying equipment for water storage tank of toilet

A water storage tank and glaze spraying technology, which is applied in the field of automatic glaze spraying equipment for toilet water storage tanks, can solve problems such as slow production speed, uneven glaze on blanks, pollution, etc., to prevent loosening or falling off, facilitate assembly line operation, increase Effect of Gripping Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

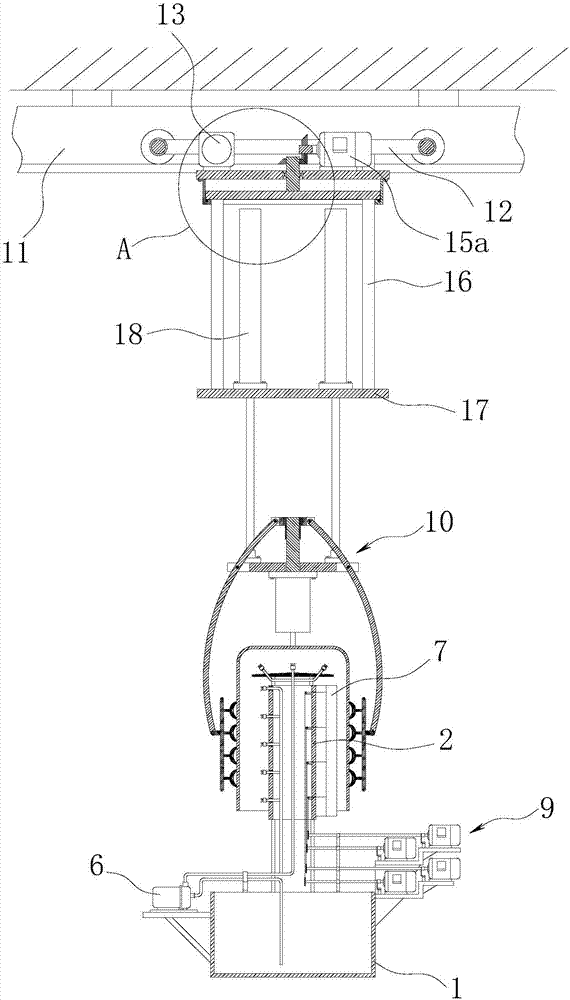

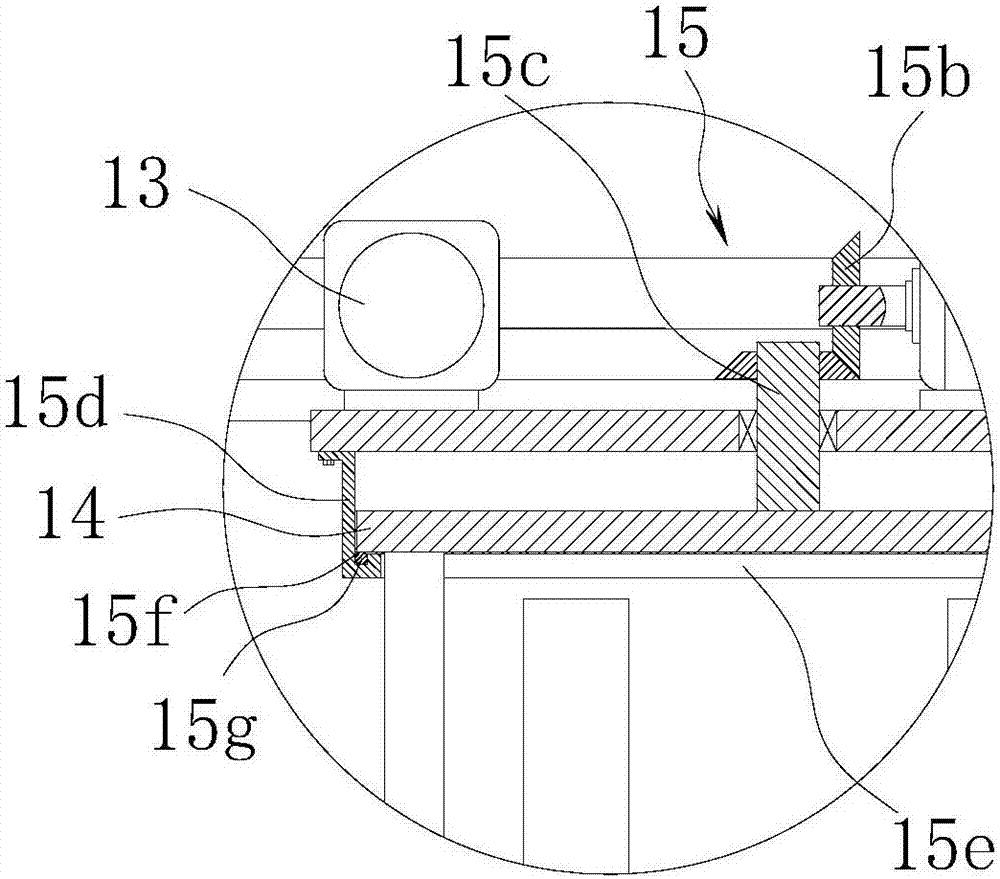

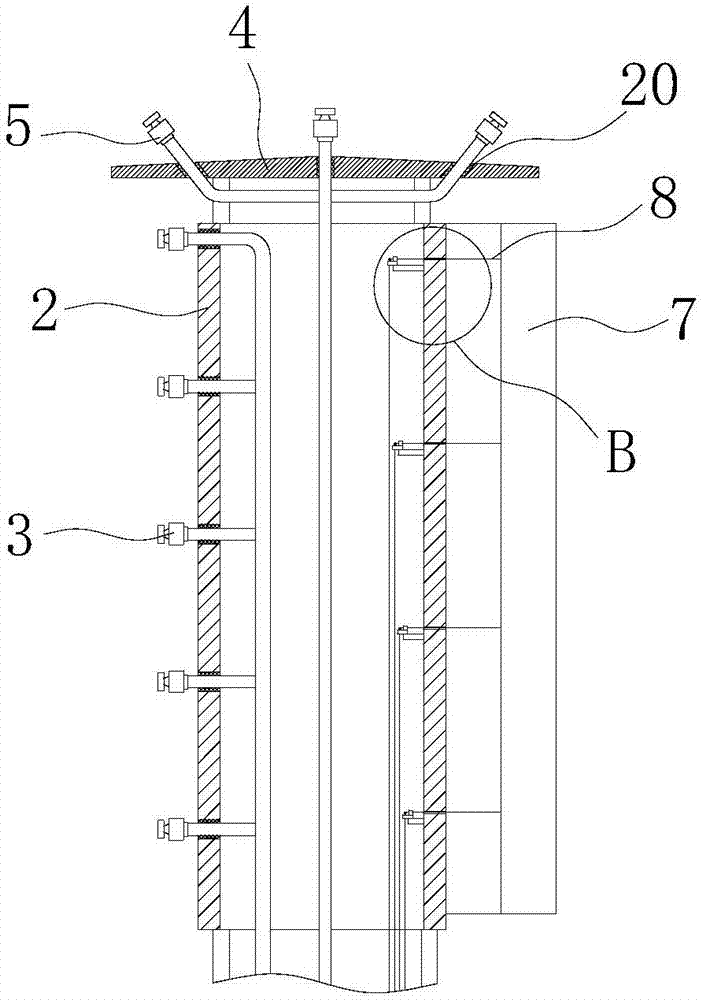

[0028] refer to Figure 1 to Figure 9 As shown, an automatic glaze spraying equipment for a toilet water storage tank of the present invention includes a liquid storage tank 1, an installation cylinder 2 is arranged above the liquid storage tank 1, and a number of first A nozzle 3 is provided with a fixed seat 4 on the upper side of the installation cylinder 2, and a number of second nozzles 5 are distributed on the fixed seat 4. The first and second nozzles 3 and 5 cooperate to spray glaze on the inner wall of the green body. The spray speed of the nozzle allows easy and convenient control of the glazing effect. The edge of the upper end surface of the fixing seat 4 is inclined downward, and the inclination angle is 3°-5°; a sealing rubber sleeve 20 is provided between the pipeline passing through the fixing seat 4 and connected to the second nozzle 5 and the fixing seat 4 . With this structure, the sealing rubber sleeve 20 can prevent the glaze material from dripping into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com