Coal-oil slurry heating furnace system using thermal circulation liquid stream in process of hydrogenating direct liquefaction of coal

A technology for oil-coal slurry and coal hydrogenation, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the processing of hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

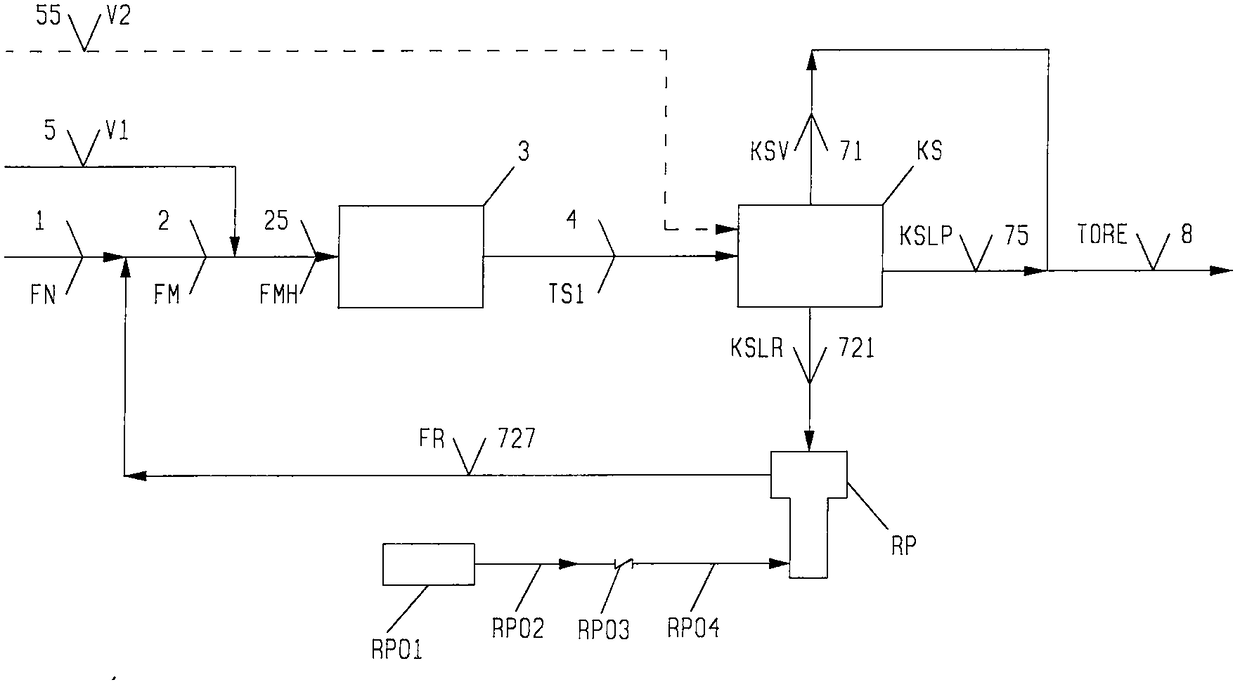

[0130] In the direct liquefaction reaction process of coal hydrogenation with a pulverized coal processing capacity of 250 tons / hour, the oil-coal slurry heating furnace system adopts the method of the present invention to set up a circulation loop, and the operating conditions are as follows:

[0131] ① During the oil-coal slurry preparation process, according to the weight ratio of 1:1, the raw coal powder SF and the hydrogen-donating solvent SHVGO are formulated into oil-coal slurry FN, the solid concentration of the oil-coal slurry is 50% by mass, and the temperature of the oil-coal slurry is 169°C;

[0132] ②Fresh oil-coal slurry FN at 169°C is mixed with a hydrogen stream at a temperature of 400°C with a hydrogen / oil-coal slurry volume ratio of 100, and then enters the oil-coal slurry heating furnace X, and the TS1 temperature of the oil-coal slurry heating furnace X outlet material is 369°C ;

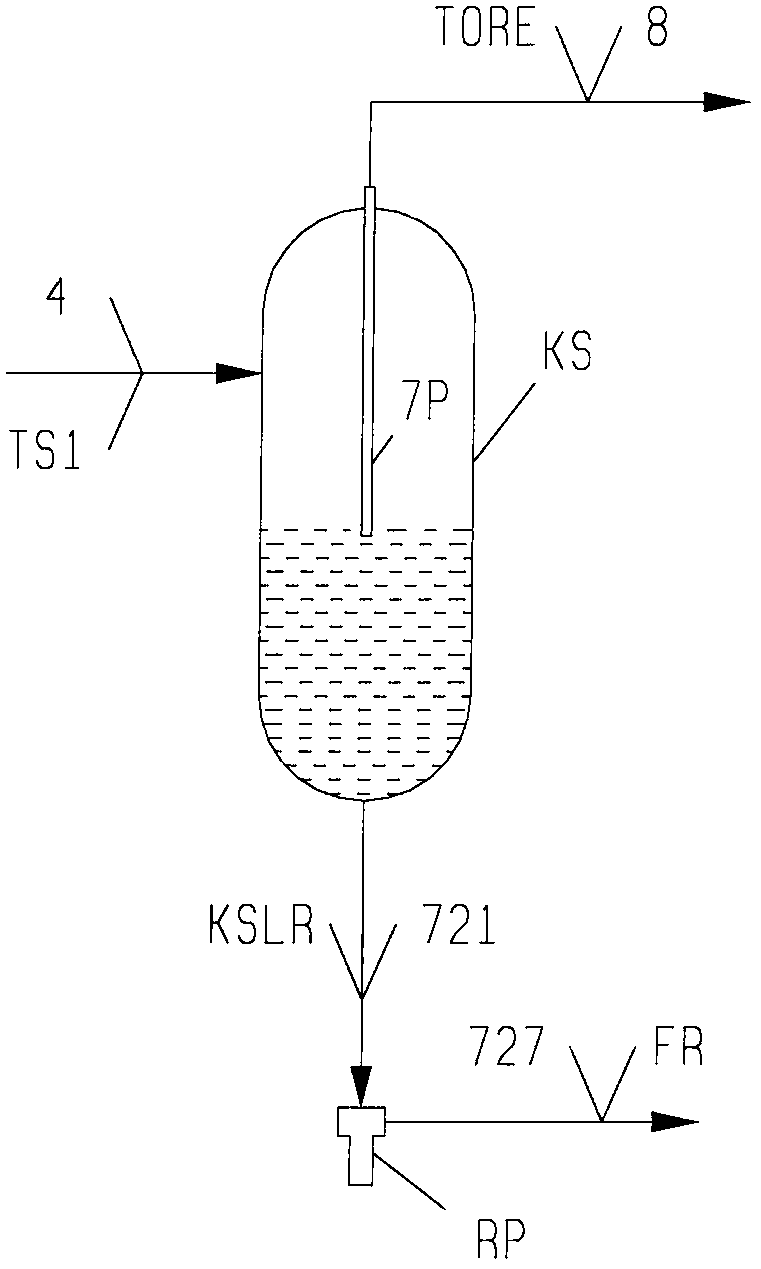

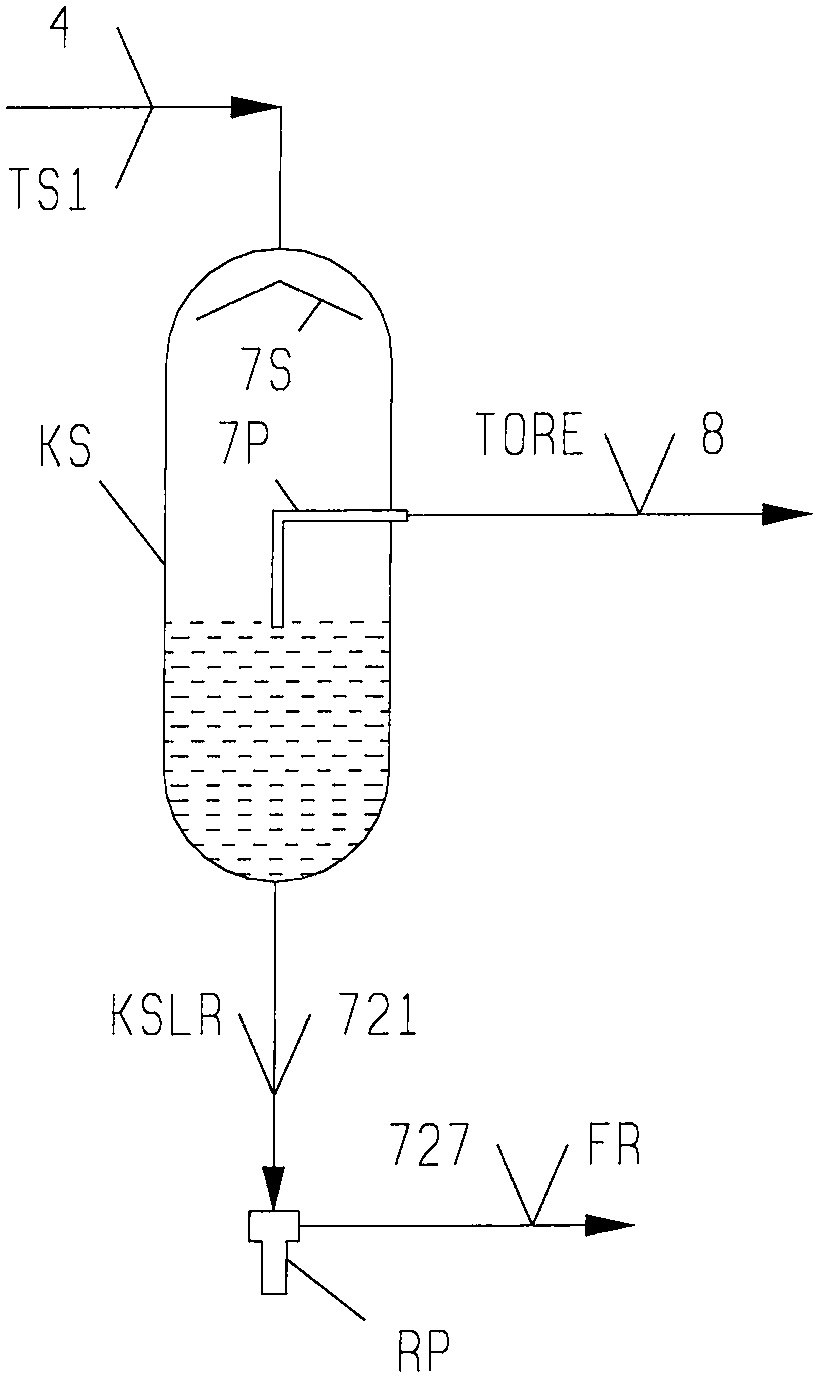

[0133] The material TS1 at the outlet of the oil-coal slurry heating furnace...

Embodiment 2

[0137] Based on Example 1, the material TS1 at the outlet of the oil-coal slurry heating furnace X enters the gas-liquid separator KS, and the circulating liquid material FR is separated to obtain the circulating liquid material FR. The fresh oil-coal slurry material is mixed, and the ratio of the weight flow rate of the circulating liquid material to the weight flow rate of the fresh oil-coal slurry material is 2:1; one part of fresh oil-coal slurry at 169 °C is mixed with two parts of 369 °C circulating liquid material at a temperature of about It is a mixed liquid material at 298°C.

[0138] Compared with Example 1, the quantity of the secondary circulating liquid material in this embodiment has been doubled, the flow rate and temperature of the furnace oil coal slurry liquid material have been improved, the concentration of dissolved hydrogen in the circulating oil has been improved, and the hydrogen supply solvent oil has been improved. The ability to supply hydrogen furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com