Amorphous vertical type shaft bearing

A vertical shaft and amorphous technology, applied in the field of bearings, can solve the problems of high price, high bearing requirements, and model restrictions, and achieve the effects of simple processing, improved production efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

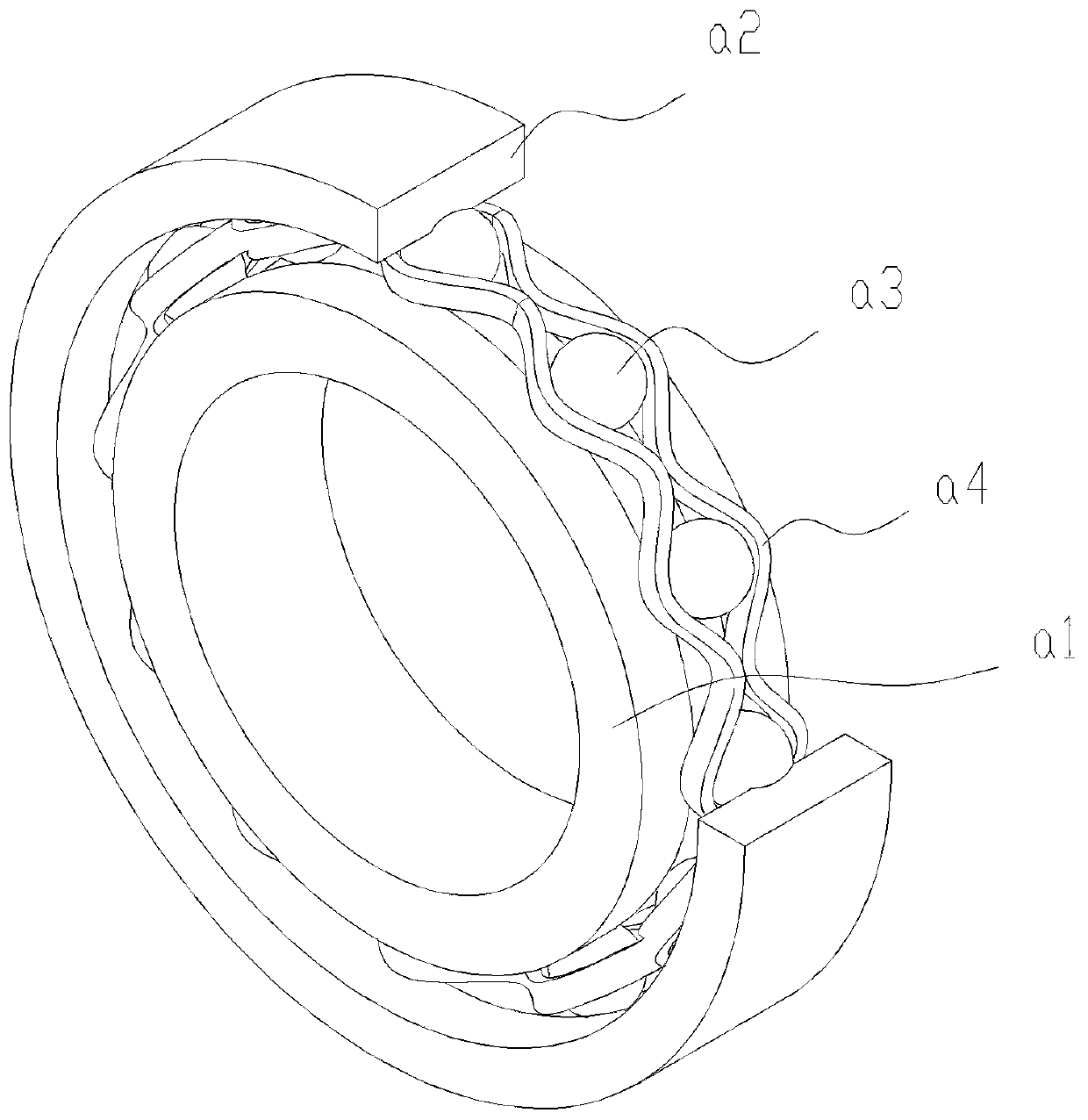

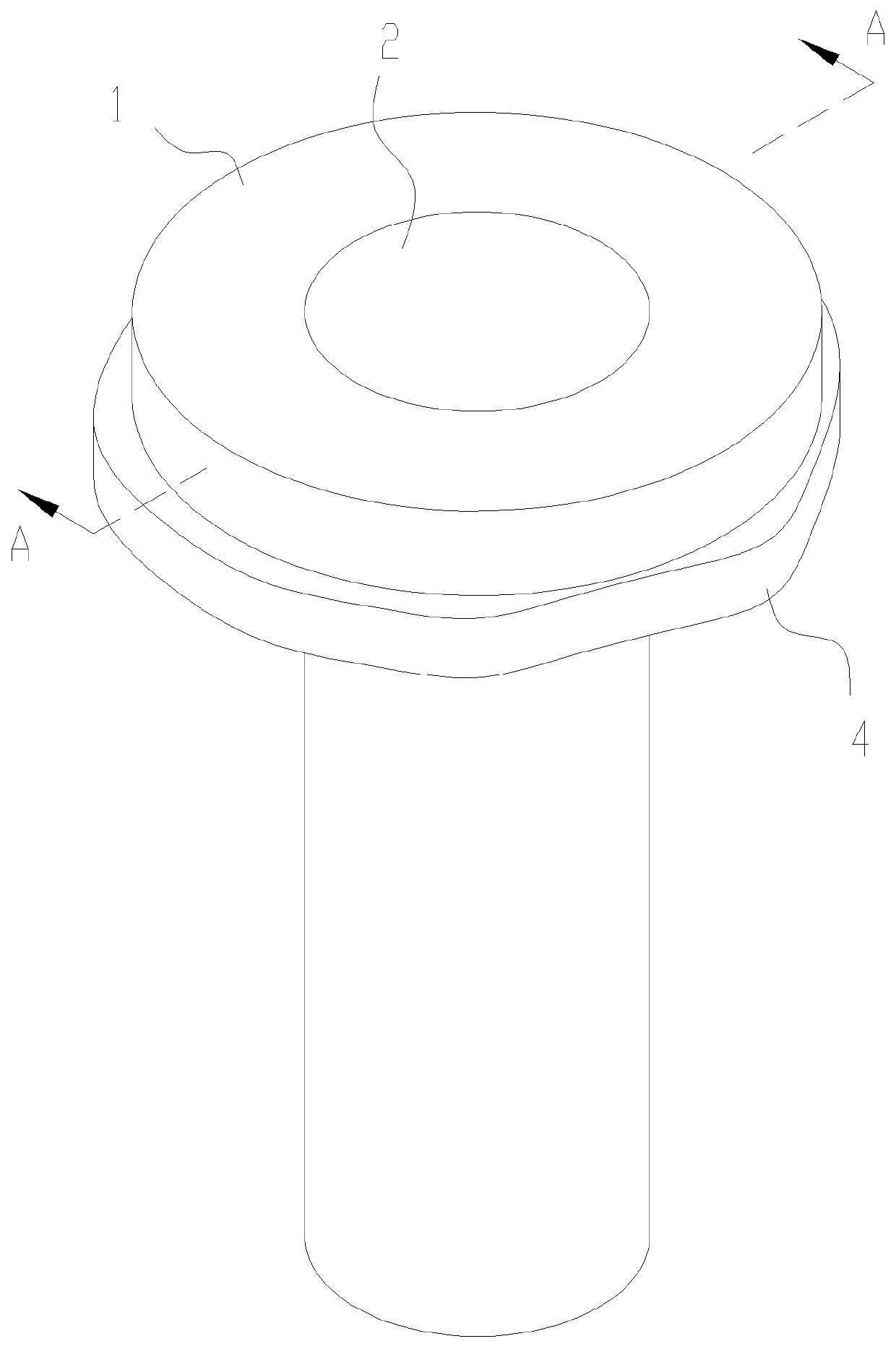

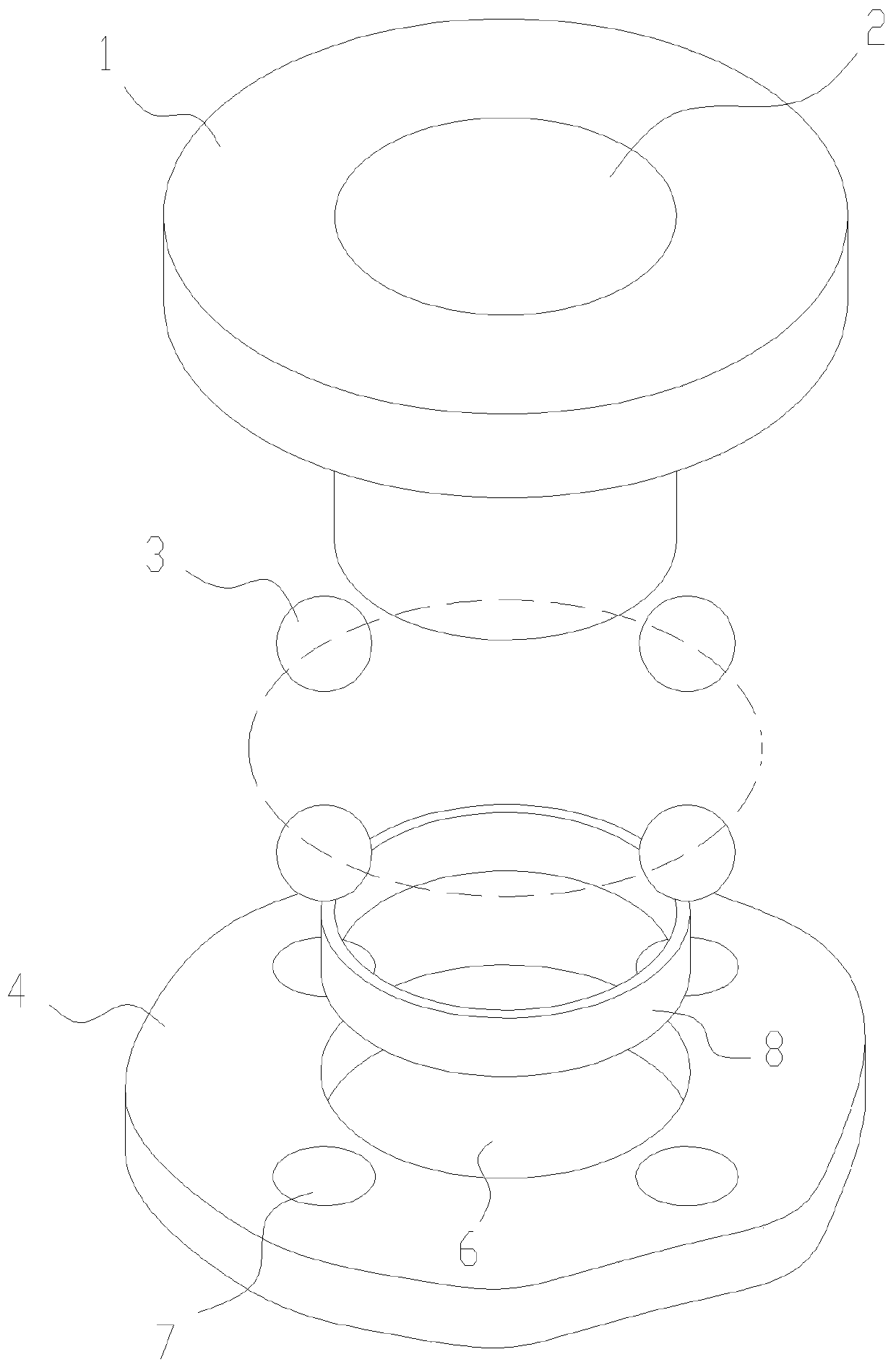

[0018] Such as Figure 2-5 As shown, an amorphous vertical shaft bearing includes a flange 1, a vertical shaft 2, a rolling element 3 and a body 4, the flange 1 is fixedly connected to the vertical shaft 2, and the flange 1 The lower bottom surface is provided with an annular groove 5 concentric with the vertical shaft 2, the section of the annular groove 5 is arc-shaped, and the body 4 is provided with a shaft hole 6 for the vertical shaft 2 to pass through. Four hemispherical holes 7 are evenly arranged around the shaft hole 6 on the upper surface of 4, and the position of the hemispherical holes 7 corresponds to the annular groove 5. body 3, that is, the number of rolling bodies 3 is consistent with the number of hemispherical holes 7, and the depth of the annular groove 5 and hemispherical hole 7 is smaller than the radius of the rolling body 3, preventing the flange from contacting and rubbing with the body. The annular groove 5 The arc radius of the section and the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com