Foundry waste sand regeneration device

A technology of regeneration device and casting waste sand, which is applied in casting molding equipment, manufacturing tools, machinery for cleaning/processing of casting materials, etc. Vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

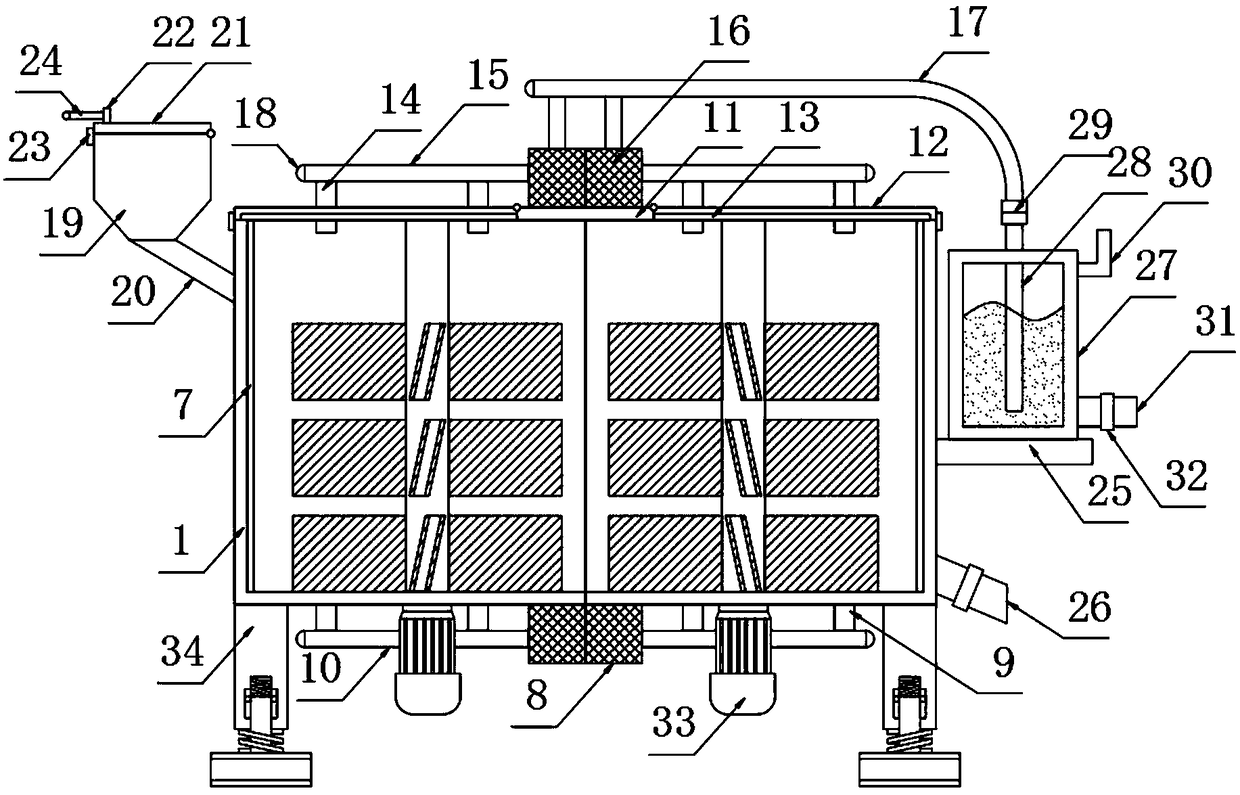

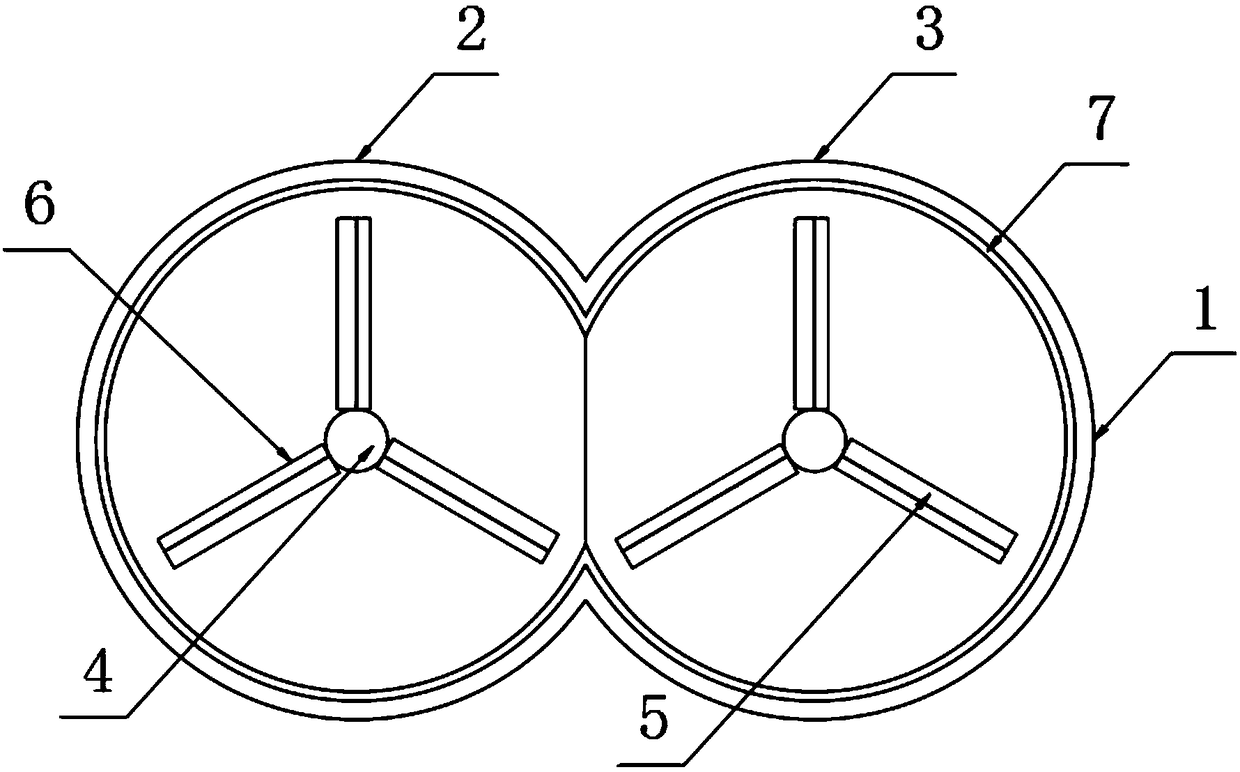

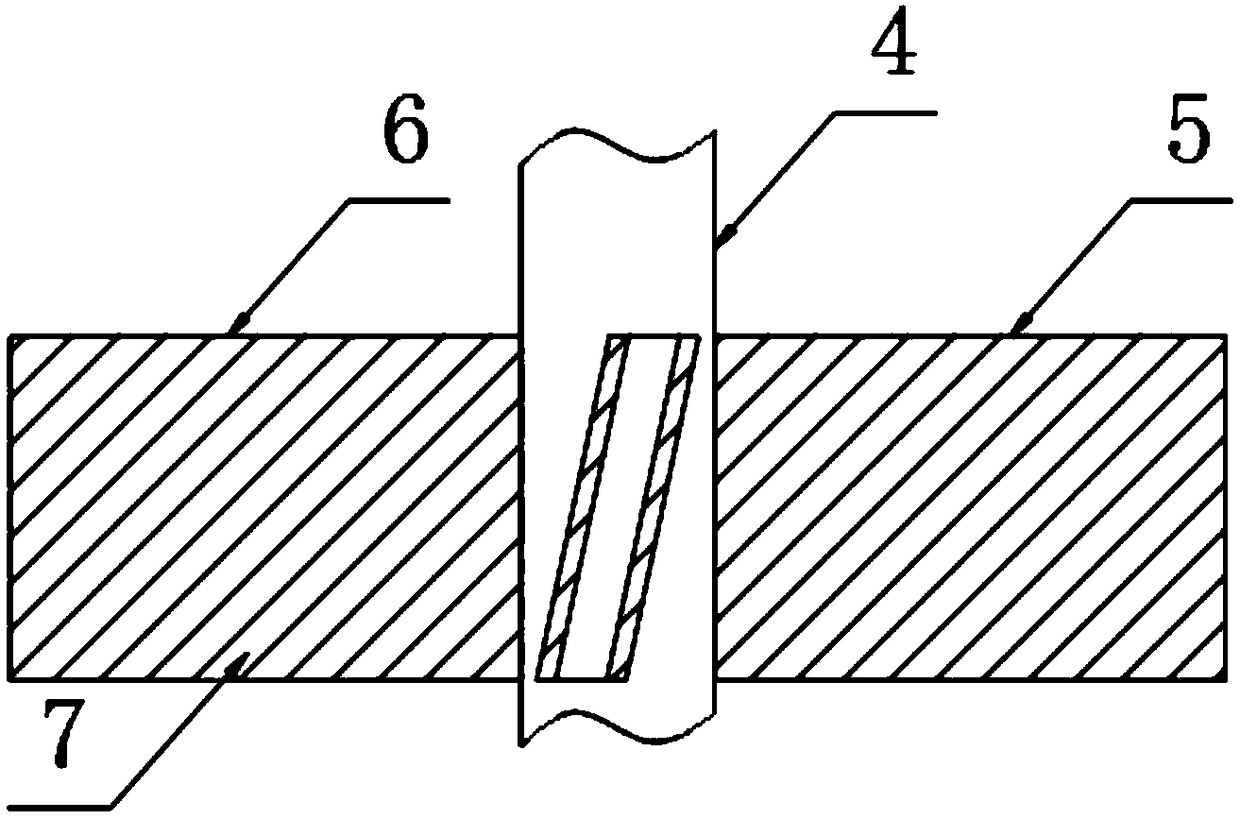

[0026] The present invention provides such Figure 1-4 The casting waste sand regeneration device shown includes a casing 1, and the casing 1 includes a left casing 2 and a right casing 3, and the right casing 3 is arranged on the side of the left casing 2, and the left casing 2 Both the casing 2 and the bottom of the inner cavity of the right casing 3 are provided with a rotating rod 4, and a stirring mechanism 5 is fixed on the outside of the rotating rod 4, and the stirring mechanism 5 includes a plurality of stirring blades 6. The casing 1 The inner wall and the side of the stirring fan blade 6 are fixed with a frosted layer 7, the bottom of the casing 1 is fixed with a high-pressure hot air blower 8 and an air intake branch pipe 9 is installed through it, and the end of the air intake branch pipe 9 is provided with an air intake main pipe 10. The top of the casing 1 is provided with a top plate 11, and both sides of the top plate 11 are provided with a top cover 12. The b...

Embodiment 2

[0029] Further, in the first embodiment above, the end of the intake main pipe 10 is connected to the high-pressure hot air blower 8 , and the air intake branch pipe 9 is connected to the high-pressure hot air blower 8 through the main intake pipe 10 .

[0030] Further, in the above-mentioned embodiment 1, the ends of the inlet main pipe 10, the outlet main pipe 15 and the exhaust pipe 17 are all fixedly provided with rubber sealing plugs 18, so that the ends of the inlet main pipe 10 and the outlet main pipe 15 and the end of the exhaust pipe 17 are sealed.

[0031] Further, in the above-mentioned embodiment 1, a hopper 19 is provided on one side of the casing 1, and the bottom of the hopper 19 is fixed with a feeding pipe 20, and the feeding pipe 20 runs through the side wall of the casing 1 and extends to Inside the casing 1 , the top of the hopper 19 is provided with a sealing cover 21 , the top of the sealing cover 21 is fixed with a connecting block 22 and the side is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com