Powder conveying device and application thereof

A powder material conveying and powder material technology is applied in the field of powder material conveying device, which can solve the problems of blanking and large pressure drop, and achieve the effect of preventing material agglomeration, good effect and uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

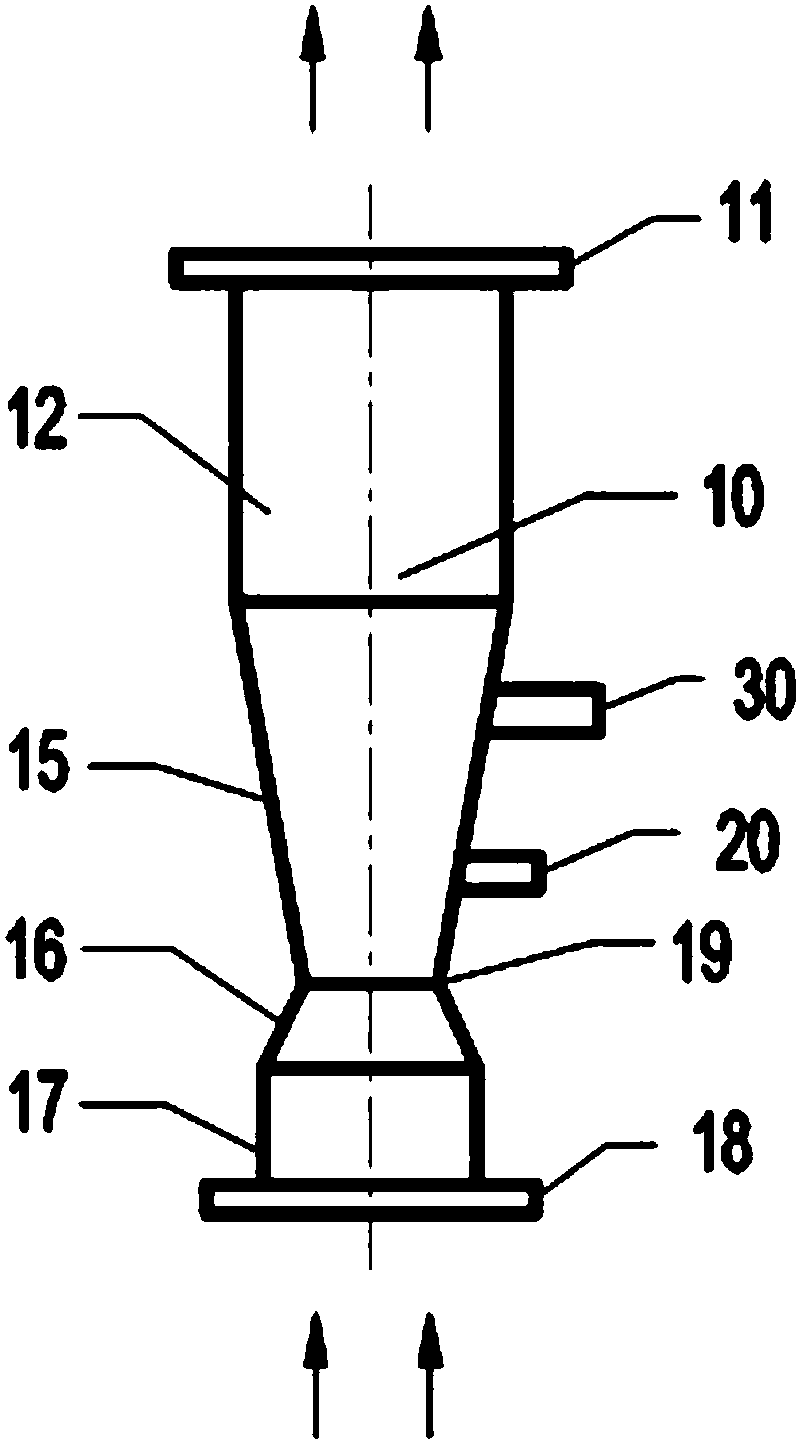

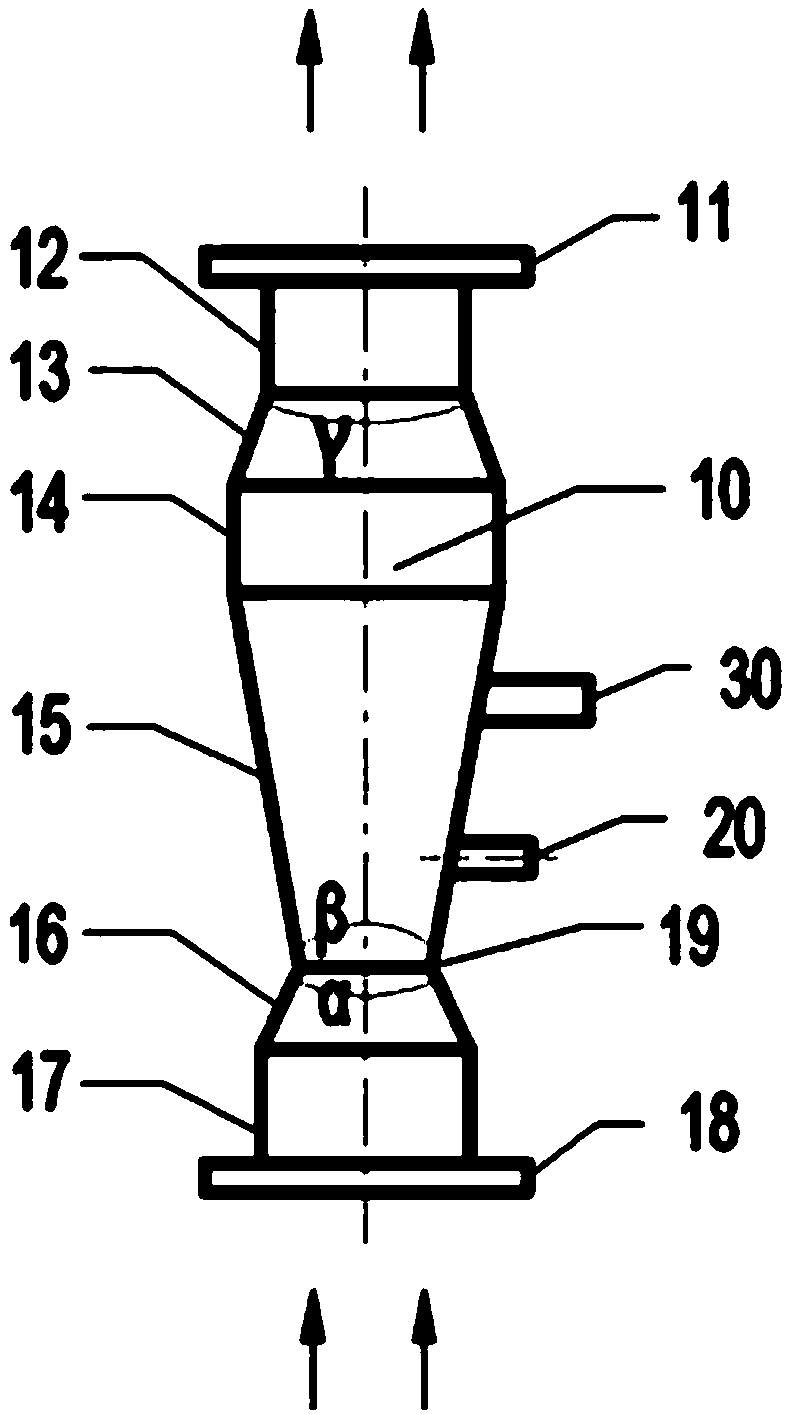

[0052] Such as figure 1 As shown, a powder conveying device includes a lifting pipeline 10 and a feeding pipeline 30, and the lifting pipeline 10 includes an inlet, a lower contraction section 16, an expanding section 15 and an outlet arranged sequentially from bottom to top, and the feeding pipeline 30 is arranged on the expansion section 15 and communicates with the expansion section 15, and the expansion section 15 is also provided with a purge pipeline 20, the purge pipeline 20 is located directly below the feed pipeline 30 and is connected to the expansion section 15. The expansion section 15 communicates with each other.

[0053] Compared with the structure of the powder conveying device in this embodiment, the structure of the existing powder conveying device differs in that: no purge pipe 20 is provided below the feeding pipe 30, and the lifting pipe 10 does not include a constriction structure Therefore, in the existing powder conveying device, after the powder enter...

Embodiment 2

[0056] Such as figure 1 As shown, a powder conveying device, its structure is compared with that of Example 1, the difference is that: the axis of the purging pipe 20 is perpendicular to the outer wall of the expansion section 15, in this arrangement, the purge gas After passing through the purge pipeline 20, the impact force on the material stream is relatively large. In addition, the diameter of the purge pipeline 20 is larger than the diameter of the feed pipeline 30, thereby ensuring that the purge gas can completely blow the material stream. The dispersed material is more easily blown up by the smoke and mixed thoroughly. During specific implementation, it is also possible to adopt a setting method in which the axis of the purging pipe 20 is perpendicular to the axis of the lifting pipe, that is, installing the purging pipe 20 horizontally can also achieve the effect of blowing the material away from the wall.

Embodiment 3

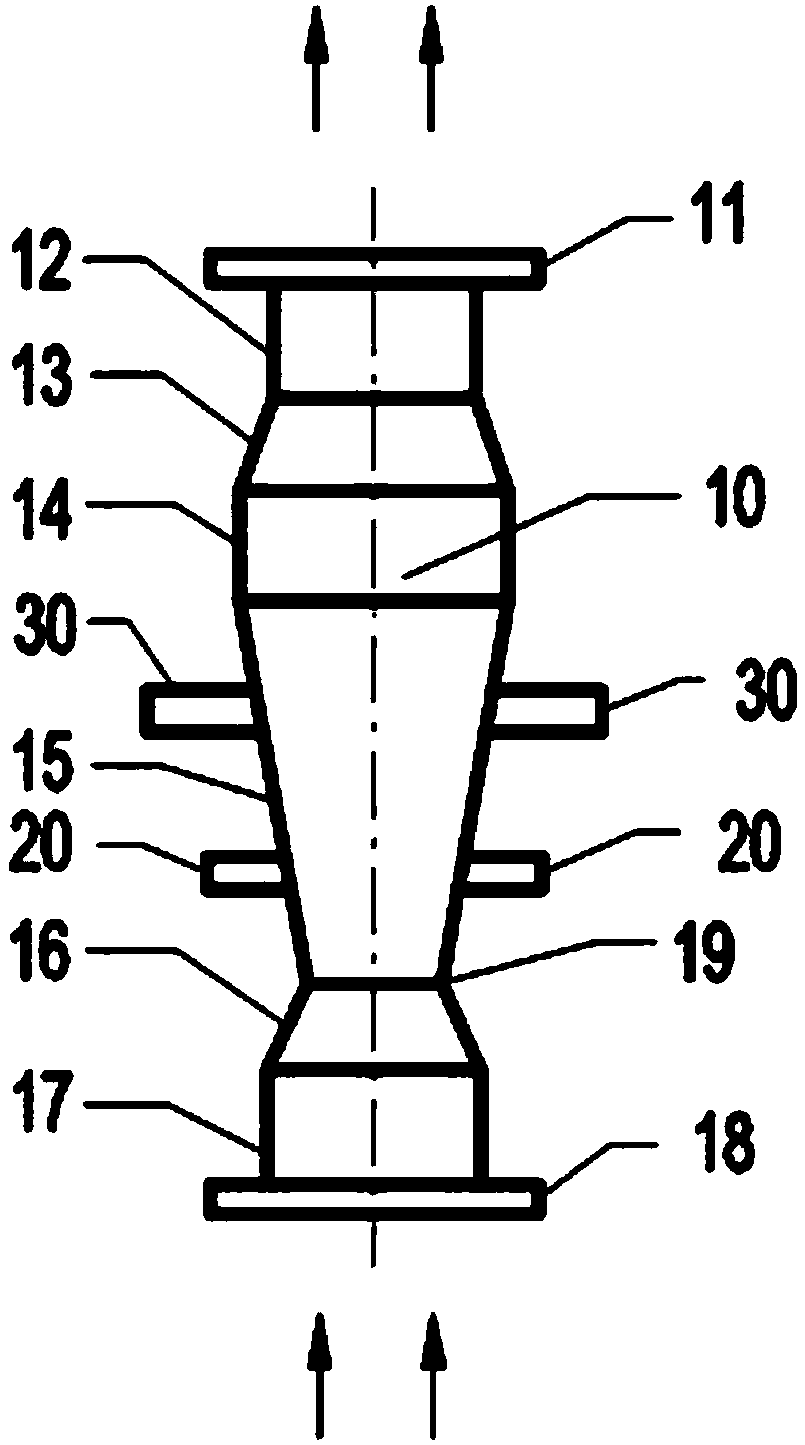

[0058] A kind of powder conveying device, its structure is compared with embodiment 1, and the difference is: the described expansion section 15 is provided with at least one described feeding pipeline 30, the quantity of described purging pipeline 20 and described The number of feed pipes 30 is the same, and the feed pipes 30 and the purge pipes 20 are evenly distributed on the outer periphery of the riser pipe 10, and a blower is arranged directly below each of the feed pipes 30. Sweeping pipeline 20, through the way of evenly arranging multiple feeding pipelines 30 and purge pipeline 20 on the outer periphery of lifting pipeline 10, improves the material feeding mode, makes the material feeding distribution more uniform, prevents the material from agglomerating, and makes the flue gas and material Mix more fully, evenly, during concrete implementation, the quantity of feed pipeline 30 can be two, three, four etc., in the present embodiment the quantity of feed pipeline 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com