Preheating method for mother liquor in re-consolidation boiling section

A technology for cooking material and mother liquor, applied in the direction of organic chemistry, etc., can solve the problems of restricting production capacity, large fluctuation of heating steam pressure, and long time for re-cooking material, so as to increase production and processing capacity, reduce the frequency of mechanical seal damage, The effect of reducing runtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

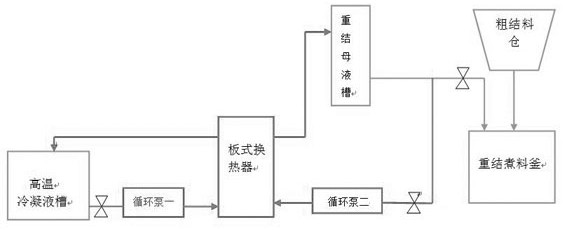

[0019] (1) Recover the high-temperature steam condensate (3m³, 90°C) of the fluidized bed to the high-temperature condensate tank, use the circulation pump 1 to pump the liquid in the high-temperature condensate tank into the plate heat exchanger, and pass the circulation pump 2 to pump the heavy The heavy solidification mother liquor (3m³, 15°C) in the solidification mother liquor tank is put into the plate heat exchanger, and the heavy solidification mother liquor is preheated to 85°C in the plate heat exchanger (it takes 0.5h), and the heavy solidification mother liquor after heat exchange Beat back to the heavy knot mother liquor tank for standby;

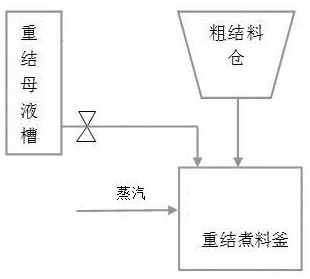

[0020] (2) Pour 3200kg of raw sugar and 3m³ preheated re-condensation mother liquor into the re-consolidation cooking kettle, turn on the re-consolidation circulation pump and steam (steam pressure 1.5kg), and carry out the re-consolidation cooking operation. After 2.2 hours, the temperature of the re-condensed cooking material...

Embodiment 2

[0022] (1) Recover the high-temperature steam condensate (3m³, 95°C) of the fluidized bed to the high-temperature condensate tank, use the circulation pump 1 to pump the liquid in the high-temperature condensate tank into the plate heat exchanger, and pass the circulation pump 2 to pump the heavy The heavy solidification mother liquor (3.2m³, 15°C) in the solidification mother liquor tank is poured into the plate heat exchanger, and the heavy solidification mother liquor is preheated to 85°C in the plate heat exchanger (it takes 0.6 h), and the heavy solidification mother liquor after heat exchange The mother liquor is put back into the heavy knot mother liquor tank for standby;

[0023] (2) Pour 3500kg of raw sugar and 3.2m³ preheated re-condensation mother liquor into the re-consolidation cooking kettle, turn on the re-consolidation circulation pump and steam (steam pressure 1.5kg), and carry out the re-consolidation cooking operation. After 2.5 hours of feeding, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com