Punching equipment

A punching die and punching device technology, applied in the field of punching processing equipment, can solve the problems of inconvenient adjustment of the position and distance between a feeding device and a punching machine, heavy weight, and high requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

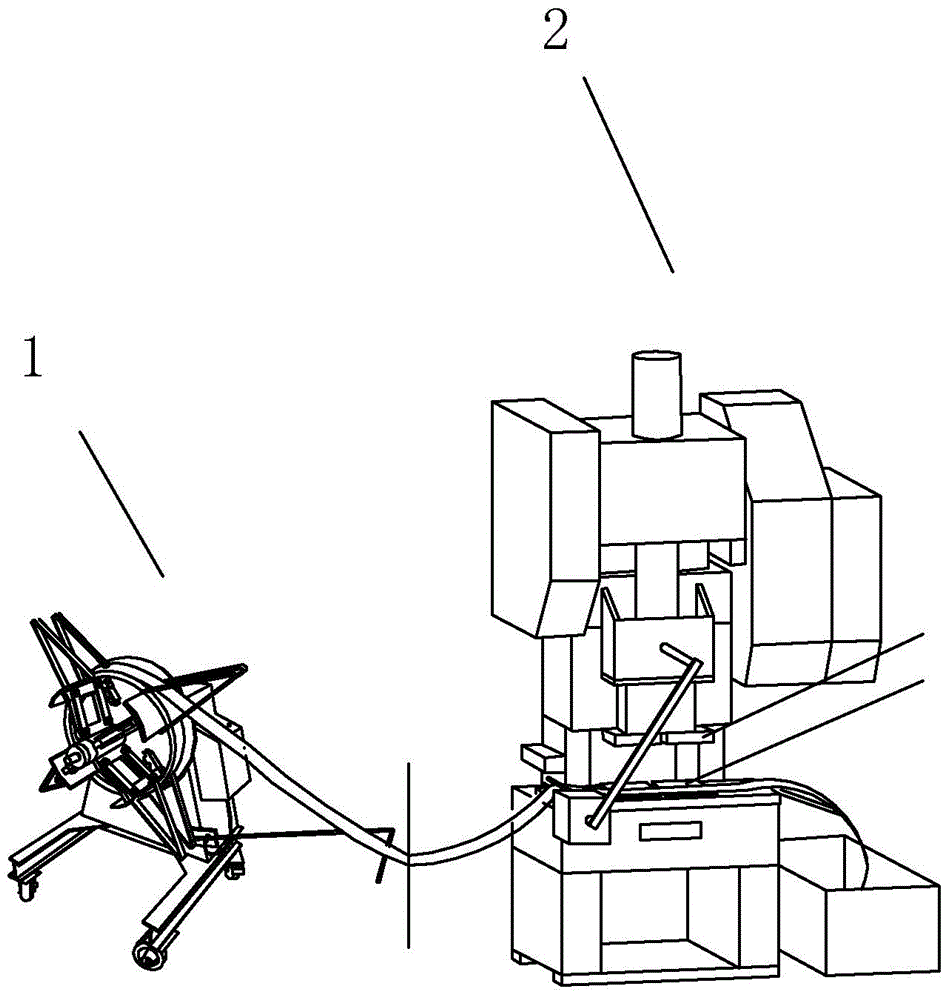

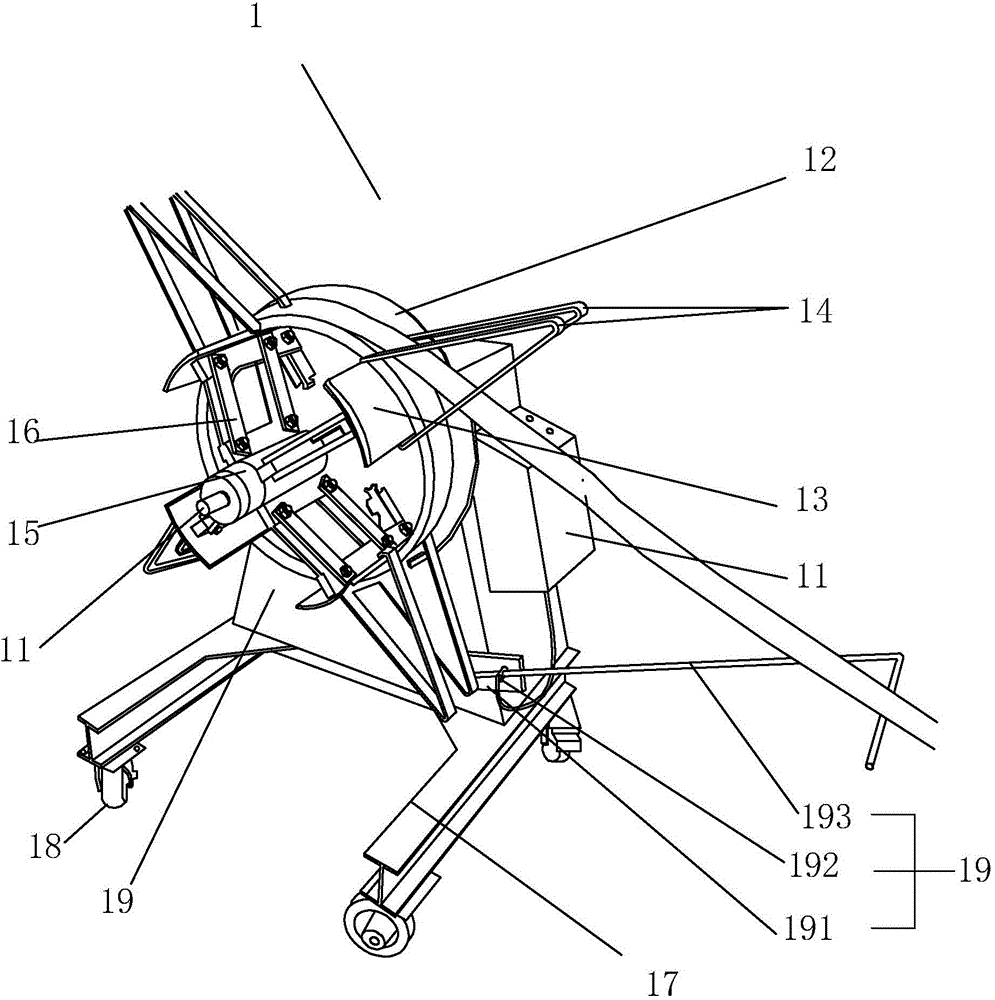

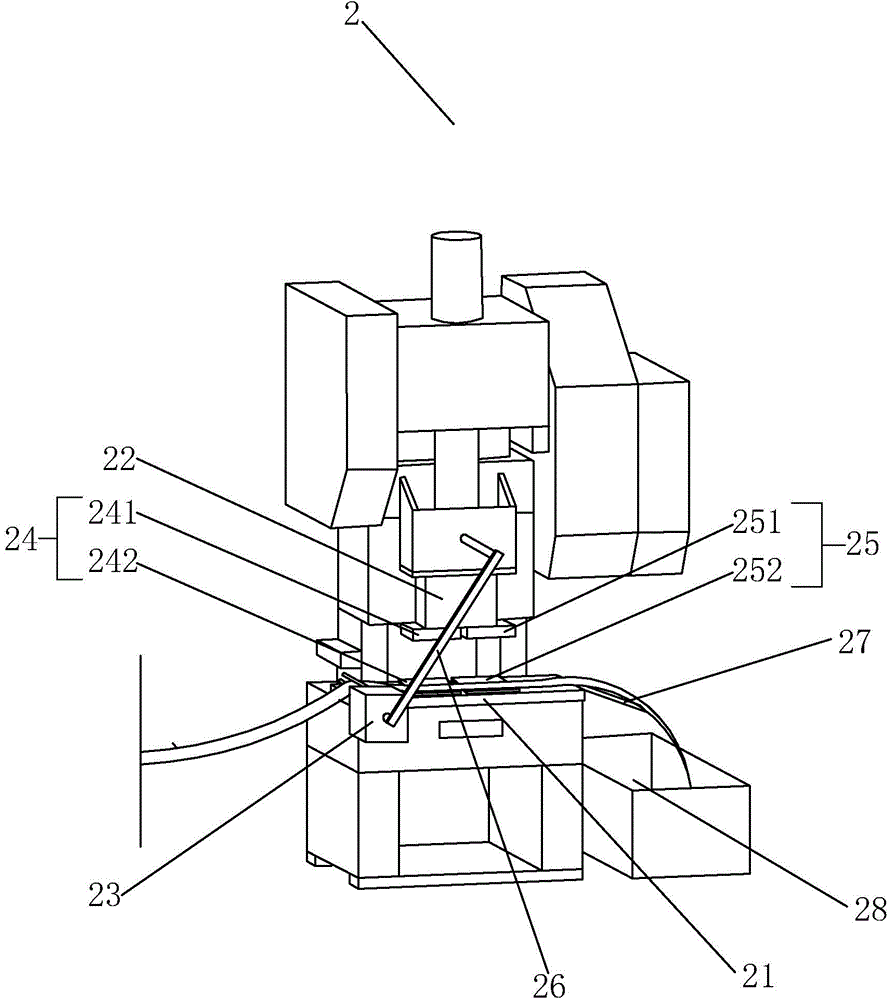

[0021] refer to Figure 1 to Figure 3 The embodiment of the punch press equipment of the present invention will be further described.

[0022] A kind of stamping equipment, comprises feeding device 1 and punching machine 2 that are arranged in sequence, feeding device 1 comprises machine base 10, and machine base 10 is provided with rotating shaft 11 and coiler that coils for strip material winding, rotating shaft 11 and coiling The coiler is coaxially arranged, and the coiler includes a fixed baffle 12 and a number of movable baffles 13 that can be wound around the strip coil. The retaining bar 14, the base 10 bottom is provided with a chassis 17, the chassis 17 is provided with a roller, the base 10 is provided with an induction device 19 and a stepping motor 100 linked with the rotating shaft 11, the induction device 19 and the stepping motor 100 electrical connections.

[0023] By adopting the above-mentioned technical scheme, the stamping equipment includes a feeding de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com