Production method for agricultural greenhouse film master batch reinforced by calcium salt crystal whiskers

A production method and agricultural shed technology, applied in the field of calcium salt whisker reinforced agricultural shed film masterbatch, can solve the problems of lack of shed film reinforcement, strength and toughness decline, etc., to improve quality, improve strength performance and use performance , Conducive to the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for producing calcium salt whisker-reinforced agricultural shed film masterbatch, the production raw materials are composed of the following mass components: 65 parts of calcium carbonate whiskers, 35 parts of metallocene polyethylene, 10 parts of liquid ethylene-propylene rubber, Malay 3 parts of anhydride-modified liquid ethylene propylene rubber, 3.5 parts of compound processing aid: prepared from 2 parts of insect wax, 0.5 parts of stearic acid and 0.5 parts of bis-stearic acid amide. The calcium carbonate whiskers are produced by Nanjing Zhenjin Calcium Carbonate Co., Ltd., the metallocene polyethylene is MLLPPE model ECD341 of EXXSON Company, and the liquid ethylene-propylene rubber is CP-80, which is produced by Uniroxa Company of the United States. Maleic anhydride modified liquid ethylene propylene rubber was developed by Nanjing University of Aeronautics and Astronautics.

[0025] Calcium salt whisker reinforced greenhouse film masterbatch is prepared...

Embodiment 2

[0039] Calcium salt calcium sulfate whisker reinforced and toughened agricultural grid film, the masterbatch formula is shown in Example 2 of Table 2, the production process conditions of the masterbatch are the same as in Example 1, and the actual performance of the masterbatch for strengthening and toughening is shown in Table 3.

Embodiment 3

[0041] The formulation of calcium salt calcium silicate whisker reinforced agricultural gate film masterbatch is shown in Example 3 of Table 2, the production process conditions of the masterbatch are the same as in Example 1, and the actual application performance of the masterbatch for strengthening and toughening is shown in Table 3.

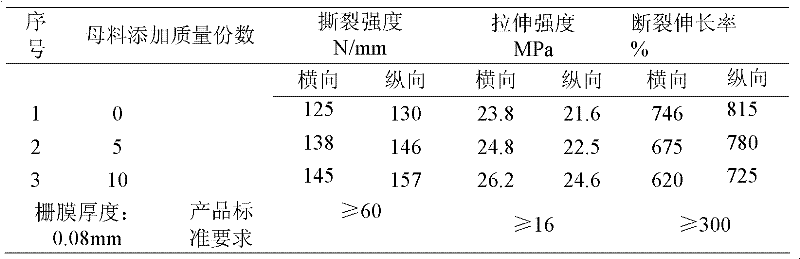

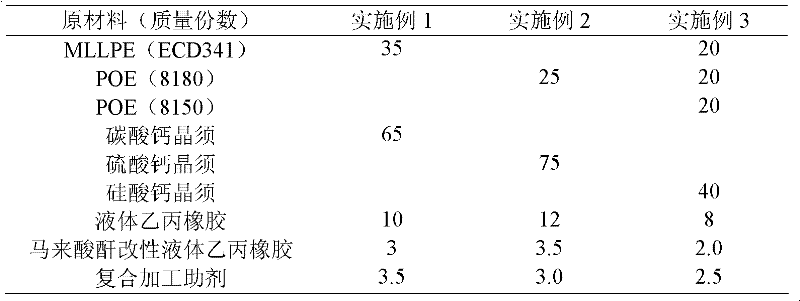

[0042] The calcium salt whisker reinforcement masterbatch formula of table 2 embodiment 1-3

[0043]

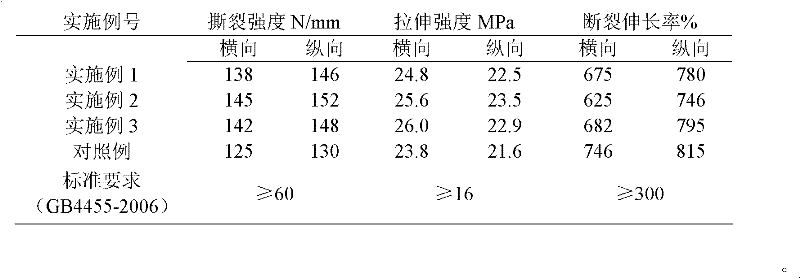

[0044] Table 3 The actual application effect of the calcium salt whisker reinforced and toughened agricultural shed film masterbatch, the thickness of the shed film is 0.08mm, and the addition amount of the masterbatch is 5%.

[0045] table 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com