Crusher for sweet potato starch processing

A technology of sweet potato starch and crusher, which is applied in the direction of grain processing, etc., can solve the problems of low crushing efficiency and incomplete crushing of sweet potato tubers, etc., and achieve the effects of improving production and processing efficiency, enhancing production and processing effects, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

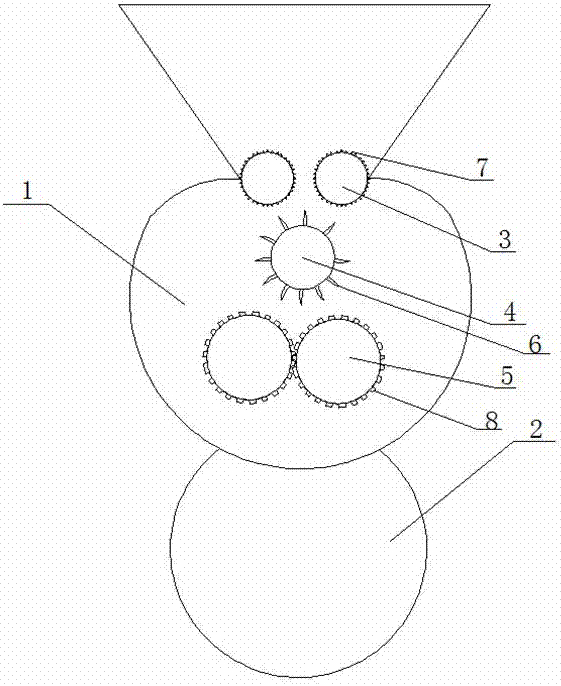

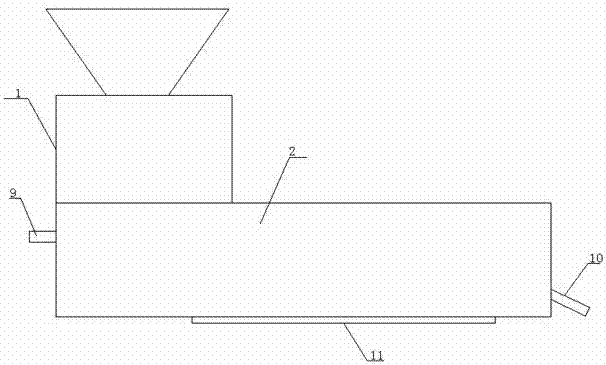

[0016] As a preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0017] A crusher for sweet potato starch processing, comprising a crushing bin 1 and a starch separation bin 2, the crushing bin 1 is arranged above the starch separation bin 2; There are two crushing rollers 5, two of which are the feeding rollers 3, which are arranged symmetrically at the feed port of the crushing bin 1, the cutting roller 4 is arranged below the feeding roller 3, and the crushing roller 5 is arranged on the cutting roller 4 Below; the cutting roller 4 is provided with several cutting knives 6 .

Embodiment 2

[0019] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0020] A crusher for sweet potato starch processing, comprising a crushing bin 1 and a starch separation bin 2, the crushing bin 1 is arranged above the starch separation bin 2; There are two crushing rollers 5, two of which are the feeding rollers 3, which are arranged symmetrically at the feed port of the crushing bin 1, the cutting roller 4 is arranged below the feeding roller 3, and the crushing roller 5 is arranged on the cutting roller 4 Below; the cutting roller 4 is provided with several cutting knives 6;

[0021] There is a gap between the two shifting rollers 3 , and the two shifting rollers 3 rotate relatively. The shifting rollers 3 are provided with a number of shifting teeth 7 , and the shifting teeth 7 protrude from the surface of the shifting rollers 3 .

Embodiment 3

[0023] As another preferred embodiment of the present invention, with reference to the attached figure 1 and 2 , this example discloses:

[0024] A crusher for sweet potato starch processing, comprising a crushing bin 1 and a starch separation bin 2, the crushing bin 1 is arranged above the starch separation bin 2; There are two crushing rollers 5, two of which are the feeding rollers 3, which are arranged symmetrically at the feed port of the crushing bin 1, the cutting roller 4 is arranged below the feeding roller 3, and the crushing roller 5 is arranged on the cutting roller 4 Below; the cutting roller 4 is provided with several cutting knives 6;

[0025] There is a gap between the two shifting rollers 3, and the two shifting rollers 3 rotate relatively, and a number of shifting teeth 7 are arranged on the shifting roller 3, and the shifting teeth 7 protrude from the surface of the shifting roller 3;

[0026] There are two crushing rollers 5, which are symmetrically arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com