A multi-machine parallel cross-laminated wood processing device

A cross-lamination and processing device technology, applied in wood processing appliances, adhesive application devices, veneer presses, etc., can solve the problems of short opening time, low annual processing capacity, and inability to achieve automatic production, and achieve high production efficiency , The effect of improving production and processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

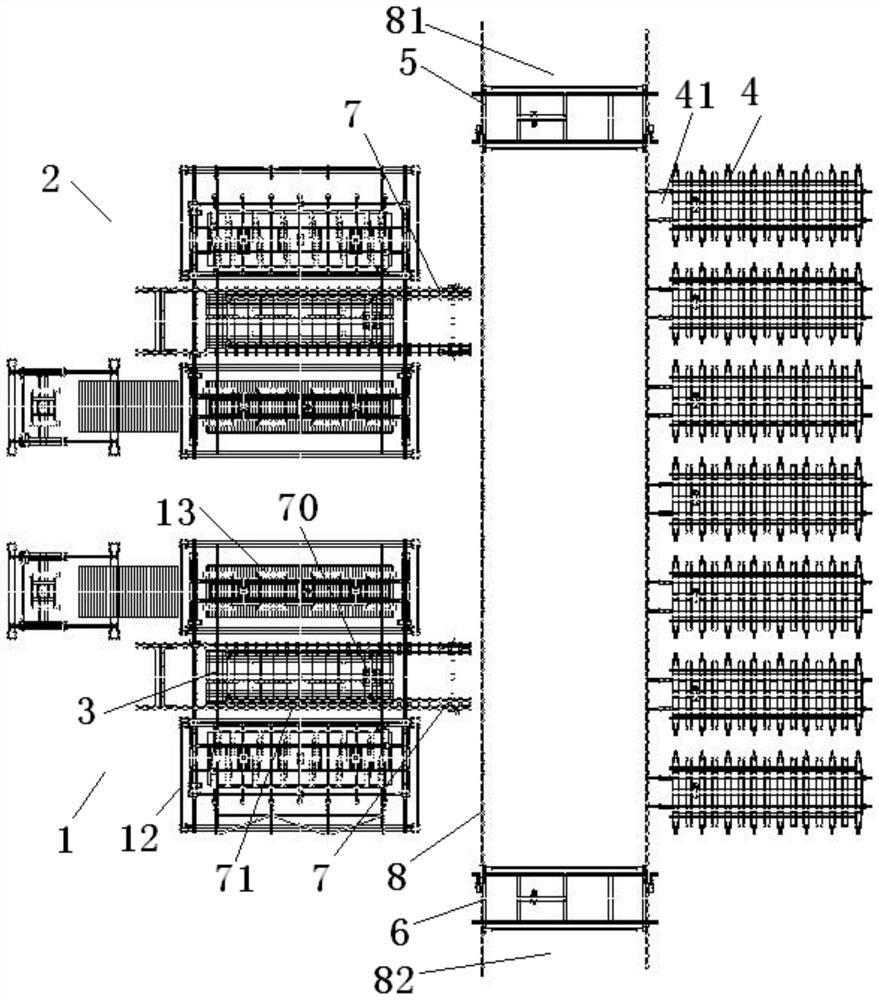

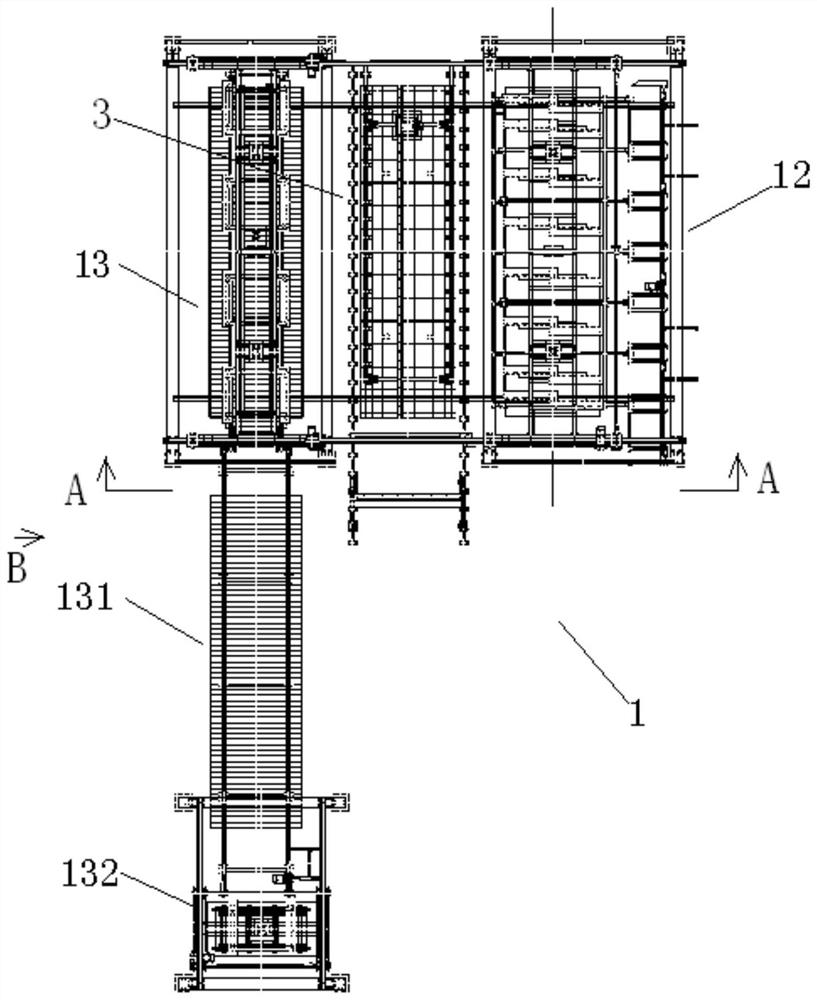

[0034] like figure 1 and figure 2 As shown, the multi-machine parallel cross-laminated wood processing device of the present invention includes two sets of feeding mechanisms 1, 2, multiple paving vehicles 3, 7 presses 4, 1 transfer vehicle 5 and 1 unloading vehicle 6 . The two groups of feeding mechanisms are exactly the same, and the feeding speed is increased at the same time.

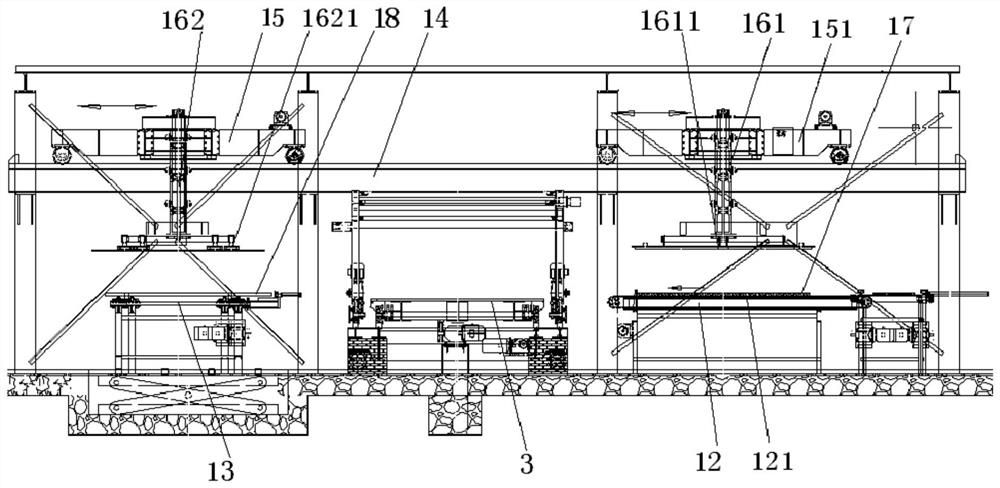

[0035] The number of longitudinal rails 7 is matched with the number of feeding mechanisms, and there are 2 groups, on which the paving vehicle 3 runs. On both sides of the paving vehicle 3 on the longitudinal track 7, the vertical plate paving platform 12 and the horizontal plate paving platform 13 of the feeding mechanism are respectively provided. Seven presses 4 are arranged on the other side of the transverse rail 8 , and the material opening 41 of each press 4 faces the transverse rail 8 . A group of blank station 71 is set on the longitudinal rail 7, a paving vehicle can be moved from th...

Embodiment 2

[0059] On the basis of Example 1, in order to further improve the work efficiency, after the blank assembly is completed on the paving vehicle at the blank assembly station 71, the next blank assembly can be continued to be superimposed on it. During the compaction process, the devices of the present invention are also provided with a lamination mechanism (not shown in the figure), and the lamination mechanism cross-laminates the first preform after the first preform The upper surface of the wood is covered with a layer of film, and then the second group of blanks is superimposed, so that the cross-laminated wood of the second group of blanks and the first group of blanks is separated by a film. The rest are the same as in Example 1.

[0060] In other embodiments, it is also possible to perform multiple blank assembly on the same paving vehicle, and repeat the above process, but it is necessary to ensure that the paving vehicle and the total height of the assembled blanks form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com