Special hot-melt pressure-sensitive adhesive for low-temperature waterproof coiled material butt-joint adhesive tape and preparation method thereof

A hot-melt pressure-sensitive adhesive and waterproof membrane technology, which is applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of insufficient adhesion of non-polar materials, and achieve improved production and processing performance , Improve low temperature resistance and reduce high temperature viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

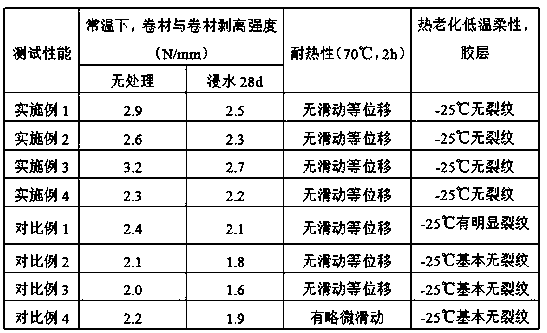

Examples

Embodiment 1

[0021] A special hot-melt pressure-sensitive adhesive for low-temperature waterproof roll-to-splicing tapes, including the following components in parts by weight: 55 parts of SIS thermoplastic elastomer, polyisobutylene compound (the mass ratio of the first polyisobutylene to the second polyisobutylene 1:1) 25 parts, 7 parts of hydrogenated monomer resin, 12 parts of tackifying resin compound, 1.5 parts of antioxidant and 1 part of ultraviolet absorber, wherein, the tackifying resin compound is hydrogenated C9 The compound of petroleum resin and hydrogenated C5 petroleum resin has a mass ratio of 1:1; the antioxidant is antioxidant 1010; and the ultraviolet absorber is UV-328.

[0022] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is specifically as follows:

[0023] Add the reaction kettle body, put SIS thermoplastic elastomer, polyisobutylene compound, hydrogenated monomer resin, tackifying resin compound, antioxidant and ultraviolet abs...

Embodiment 2

[0025] A special hot-melt pressure-sensitive adhesive for low-temperature waterproof roll-to-fold adhesive tape, including the following components in parts by weight: 50 parts of SIS thermoplastic elastomer, 20 parts of polyisobutylene compound (the first polyisobutylene and the second polyisobutylene The mass ratio is 1:1), 5 parts of hydrogenated monomer resin, 10 parts of tackifying resin compound, 1 part of antioxidant and 0.5 parts of ultraviolet absorber, wherein the tackifying resin compound is hydrogenated C9 The compound of petroleum resin and hydrogenated C5 petroleum resin has a mass ratio of 2:1; the antioxidant is antioxidant 168; and the ultraviolet absorber is UV-P.

[0026] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is specifically as follows:

[0027] Add the reaction kettle body, put SIS thermoplastic elastomer, polyisobutylene compound, hydrogenated monomer resin, tackifying resin compound, antioxidant and ultraviolet...

Embodiment 3

[0029] A special hot-melt pressure-sensitive adhesive for low-temperature waterproof roll-to-fold adhesive tape, including the following components in parts by weight: 60 parts of SIS thermoplastic elastomer, 40 parts of polyisobutylene compound (the first polyisobutylene and the second polyisobutylene The mass ratio is 1:1), 10 parts of hydrogenated monomer resin, 15 parts of tackifying resin compound, 2 parts of antioxidant and 1.5 parts of ultraviolet absorber, wherein the tackifying resin compound is hydrogenated C9 The compound of petroleum resin and hydrogenated C5 petroleum resin, the mass ratio of the two is 1.5:1; the antioxidant is antioxidant 1010 and antioxidant 168 (mass ratio 1:1); the ultraviolet Absorbents are UV-328 and UV-P (mass ratio 1:1).

[0030] The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive is specifically as follows:

[0031] Add the reaction kettle body, put SIS thermoplastic elastomer, polyisobutylene compound, hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com