Composite artificial endocranium and preparation method thereof

A technology of artificial dura mater and French silica, which is applied in the field of medical supplies to achieve the effects of long-term salt water resistance, long-term urine resistance, and excellent constant elongation and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

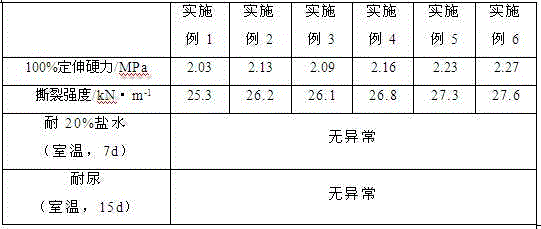

Examples

Embodiment 1

[0017] A composite artificial dura mater, comprising the following raw materials in parts by mass: vinyl silicone rubber: 50 parts; hydroxyl silicone oil: 2 parts; polyethylene glycol: 1 part; meteorological white carbon black: 40 parts; vulcanizing agent Bis-25: 0.7 parts; polylactic acid: 20 parts; tricalcium phosphate: 5 parts; chitosan: 2 parts; polytetrafluoroethylene: 1 part.

[0018] A preparation method of a composite artificial dura mater, comprising the steps of:

[0019] (1) Mix vinyl silicone rubber, hydroxyl silicone oil, polyethylene glycol, meteorological silica, vulcanizing agent bis-25, polylactic acid, tricalcium phosphate, chitosan and polytetrafluoroethylene at a temperature of 150 Place it at ℃ for 20min to obtain the mixed material;

[0020] (2) Place the mixed material in the oven for 6 hours, and set the oven temperature to 150°C to obtain the mixed rubber;

[0021] (3) Mix the mixed rubber and gasoline at a mass ratio of 1:3.5 to make a glue, and the...

Embodiment 2

[0023] A composite artificial dura mater, comprising the following raw materials in parts by mass: vinyl silicone rubber: 75 parts; hydroxyl silicone oil: 5 parts; polyethylene glycol: 4 parts; meteorological white carbon black: 60 parts; vulcanizing agent Bi-25: 1.7 parts; polylactic acid: 35 parts; tricalcium phosphate: 12 parts; chitosan: 6 parts; polytetrafluoroethylene: 4 parts.

[0024] A preparation method of a composite artificial dura mater, comprising the steps of:

[0025] (1) Mix vinyl silicone rubber, hydroxyl silicone oil, polyethylene glycol, meteorological silica, vulcanizing agent bis-25, polylactic acid, tricalcium phosphate, chitosan and polytetrafluoroethylene at a temperature of 160 Place it at ℃ for 30min to obtain the mixed material;

[0026] (2) Place the mixed material in the oven for 8 hours, and set the oven temperature to 200°C to obtain the mixed rubber;

[0027] (3) Mix the mixed rubber and gasoline at a mass ratio of 1:3.5 to make a glue, and t...

Embodiment 3

[0029] A composite artificial dura mater, comprising the following raw materials in parts by mass: vinyl silicone rubber: 58 parts; hydroxyl silicone oil: 2.5 parts; polyethylene glycol: 2 parts; meteorological white carbon black: 45 parts; vulcanizing agent Bi-25: 1 part; polylactic acid: 23 parts; tricalcium phosphate: 7 parts; chitosan: 3 parts; polytetrafluoroethylene: 2 parts.

[0030] A preparation method of a composite artificial dura mater, comprising the steps of:

[0031] (1) Mix vinyl silicone rubber, hydroxyl silicone oil, polyethylene glycol, meteorological silica, vulcanizing agent bis-25, polylactic acid, tricalcium phosphate, chitosan and polytetrafluoroethylene at a temperature of 150 Place it at ℃ for 20min to obtain the mixed material;

[0032] (2) Place the mixed material in the oven for 6 hours, and set the oven temperature to 150°C to obtain the mixed rubber;

[0033] (3) Mix the mixed rubber and gasoline at a mass ratio of 1:3.5 to make a glue, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com