Ceramic fire-resistant flame-retardant silicone rubber as well as preparation method and use method thereof

A fire-retardant and ceramic technology, applied in the field of silicone rubber, can solve the problems of wire and cable are not fire-resistant, non-flame-retardant, non-fire-resistant, easy to burn, etc., and achieve the effects of improving mechanical strength, increasing strength and reducing moisture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

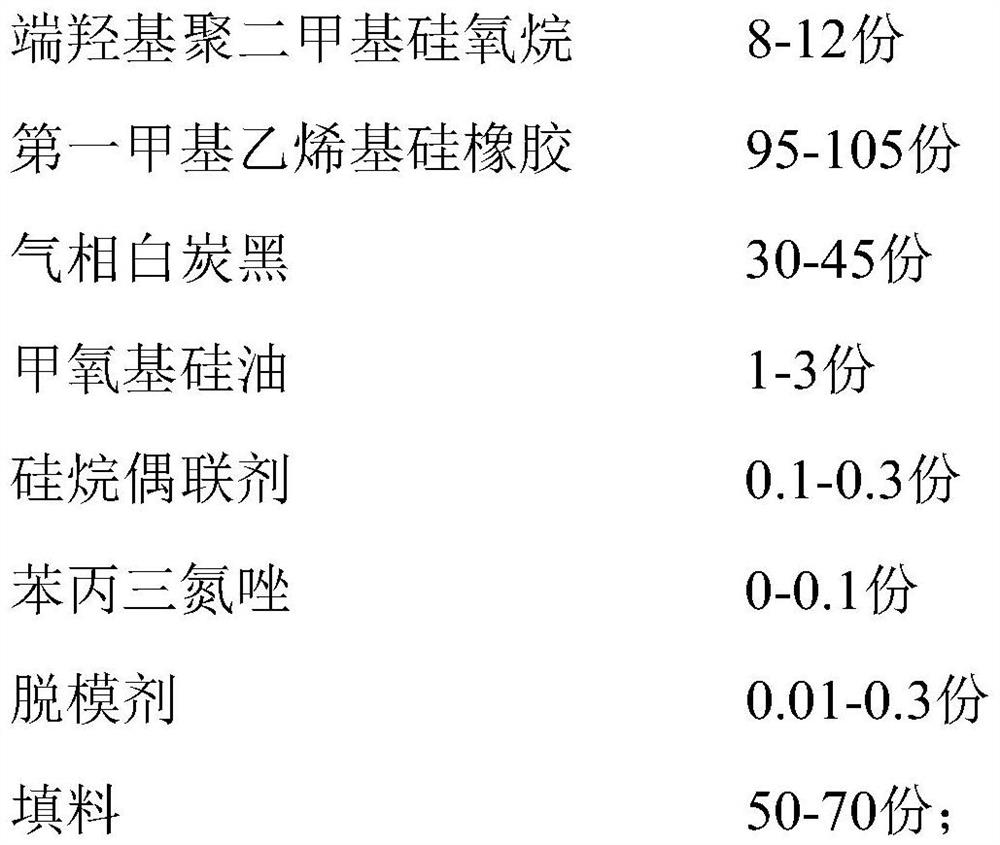

[0036] A ceramic fire-resistant and flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0037] First component:

[0038]

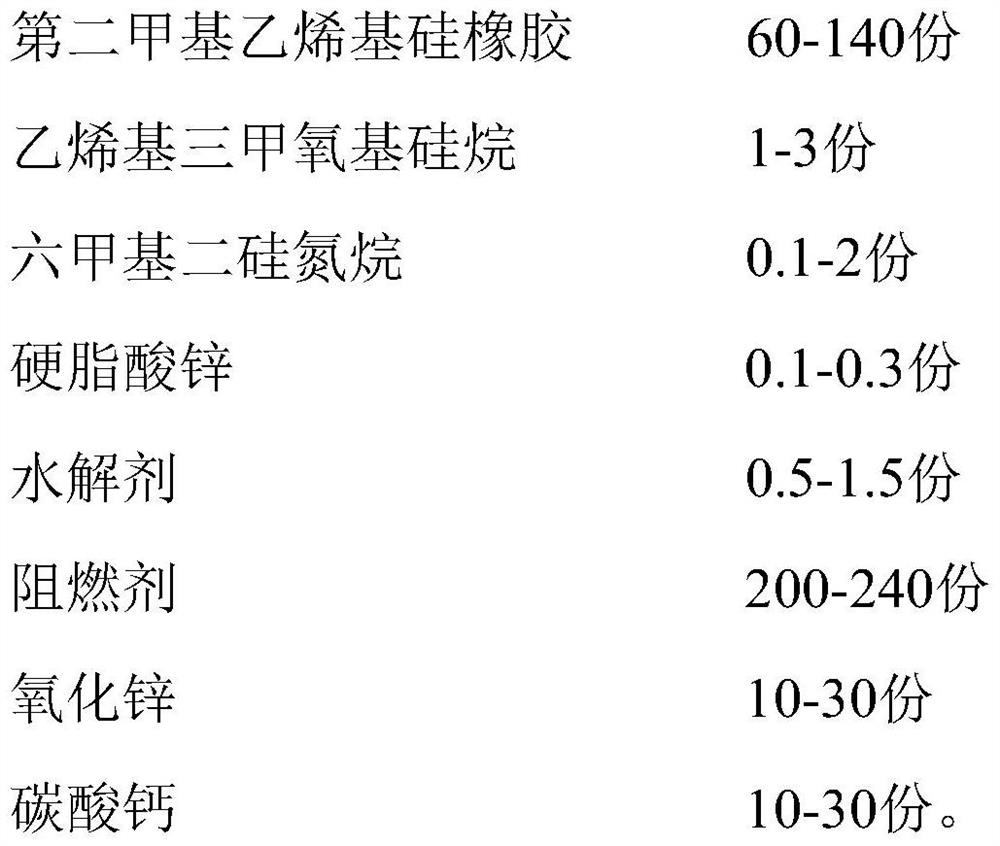

[0039] Second component:

[0040]

[0041] Each part of the first methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 90:1, the methyl vinyl silicone rubber A The vinyl content is 0.06%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber B is 2.8%, and the molecular weight is 550,000.

[0042] Each part of the second methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber a and methyl vinyl silicone rubber b in a weight ratio of 1:1, and the ethylene content of the methyl vinyl silicone rubber a The vinyl content is 0.14%, and the molecular weight is 650,000; the vinyl content of the methyl vinyl silicone rubber b is 0.2%, and the molecular weight is 650,000.

[0043] Ea...

Embodiment 2

[0058] A ceramic fire-resistant and flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0059] First component:

[0060]

[0061] Second component:

[0062]

[0063]

[0064] Each part of the first methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 93:1.5, the methyl vinyl silicone rubber A The vinyl content is 0.07%, and the molecular weight is 680,000; the vinyl content of the methyl vinyl silicone rubber B is 2.9%, and the molecular weight is 580,000.

[0065] Each part of the second methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber a and methyl vinyl silicone rubber b in a weight ratio of 1:1, and the ethylene content of the methyl vinyl silicone rubber a The base content is 0.15%, and the molecular weight is 680,000; the vinyl content of the methyl vinyl silicone rubber b is 0.21%, and the molecular weight is 680,000...

Embodiment 3

[0081] A ceramic fire-resistant and flame-retardant silicone rubber, comprising the following raw materials in parts by weight:

[0082] First component:

[0083]

[0084]

[0085] Second component:

[0086]

[0087]Each part of the first methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber A and methyl vinyl silicone rubber B in a weight ratio of 95:2, the methyl vinyl silicone rubber A The vinyl content is 0.08%, and the molecular weight is 700,000; the vinyl content of the methyl vinyl silicone rubber B is 3.0%, and the molecular weight is 600,000.

[0088] Each part of the second methyl vinyl silicone rubber is a mixture of methyl vinyl silicone rubber a and methyl vinyl silicone rubber b in a weight ratio of 1:1, and the ethylene content of the methyl vinyl silicone rubber a The base content is 0.16%, and the molecular weight is 700,000; the vinyl content of the methyl vinyl silicone rubber b is 0.22%, and the molecular weight is 700,000. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com