Method for preparing ceramifiable silicon rubber refractory material by adopting radiation crosslinking process

A technology of radiation cross-linking and refractory materials, applied in the direction of plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of harmful gas and waste water environmental pollution, slow cross-linking speed of hot vulcanized rubber, and health threats to workers, etc. Achieve the effects of no three wastes discharge, convenient cross-linking degree, and improved mechanical and electrical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

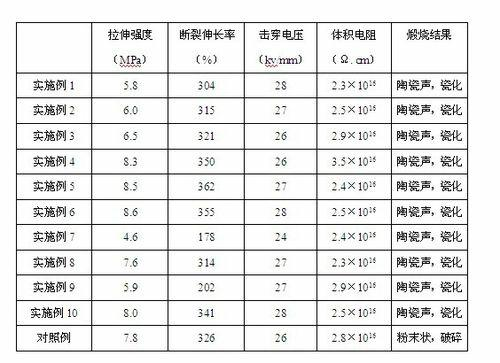

Examples

Embodiment 1

[0039] The composition of raw materials by weight is:

[0040] Methyl vinyl silicone rubber 100 parts

[0041] Fumed silica 50 parts

[0042] Cyclosilazane 3.5 parts

[0043] Aluminum hydroxide 45 parts

[0044] Chloroplatinic acid 5×10-5 share

[0045] Mix the above raw materials evenly to make clay-like silicone rubber, and then put it in a rubber extruder for extrusion processing at a temperature of 30°C to obtain the initial product of porcelain-able silicone rubber refractory material; Gamma rays are irradiated to obtain vitrified silicone rubber refractory products.

Embodiment 2

[0047] The composition of raw materials by weight is:

[0048] Methyl vinyl silicone rubber 100 parts

[0049] Fumed silica 50 parts

[0050] Cyclosilazane 3.5 parts

[0051] Calcium carbonate 25 parts

[0052] Aluminum hydroxide 20 parts

[0053] Chloroplatinic acid 5×10 -5 share

[0054] Mix the above raw materials evenly to make clay-like silicone rubber, and then place it in a rubber extruder for extrusion processing at a temperature of 25°C to obtain the initial product of porcelain-able silicone rubber refractory material; Electron beams are irradiated to obtain ceramic silicone rubber refractory products.

Embodiment 3

[0056] The composition of raw materials by weight is:

[0057] Methyl vinyl silicone rubber 100 parts

[0058] Fumed silica 50 parts

[0059] Cyclosilazane 3.5 parts

[0060] Aluminum hydroxide 25 parts

[0061] Magnesium hydroxide 20 parts

[0062] Chloroplatinic acid 5×10 -5 share

[0063] Mix the above raw materials evenly to make clay-like silicone rubber, and then place it in a rubber extruder for extrusion processing at a temperature of 40°C to obtain the initial product of the molded porcelain-able silicone rubber refractory material; Electron beams are irradiated to obtain ceramic silicone rubber refractory products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com