Acrylic ester adhesive and preparing method thereof

An acrylate and methacrylic acid technology, applied in the field of acrylate-based adhesives and their preparation, can solve the problems of poor peelability, difficult carrier separation, tearing labels, etc. The effect of low thermal peak temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

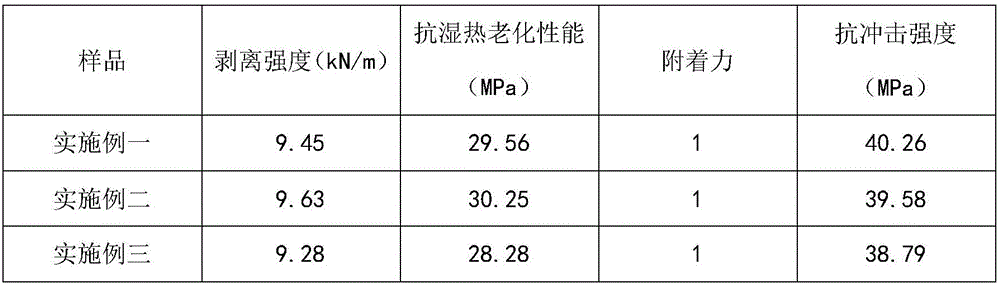

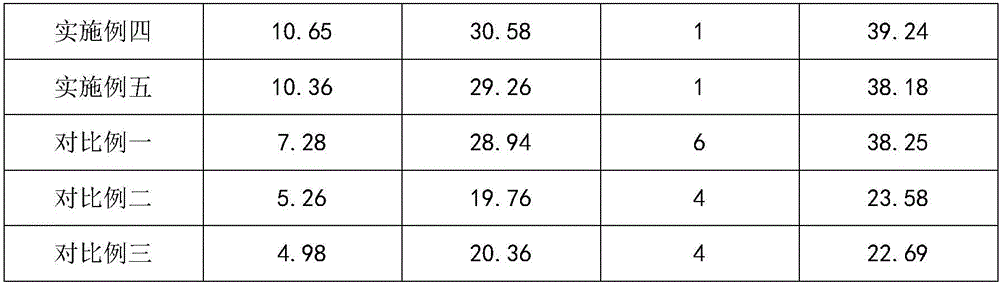

Examples

Embodiment 1

[0042] (1) Preparation of component A: in parts by weight, 60 parts of hydroxyethyl methacrylate, 30 parts of methacrylic acid, 10 parts of modified EPDM rubber, 20 parts of polyethylene glycol, hydroquinone Put 0.5 parts into the stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 1 part of tetramethylthiourea, 0.5 parts of o-benzenesulfonimide and continue stirring; finally add nano-TiO 2 5 parts were stirred to form a homogeneous mixture;

[0043] (2) Preparation of component B: in parts by weight, 60 parts of methyl methacrylate, 30 parts of methacrylic acid, 10 parts of methyl vinyl silicone rubber, 0.5 parts of vinyltrimethoxysilane, polyethylene glycol Put 20 parts and 0.5 parts of hydroquinone into the stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 1 part of benzoyl peroxide and 3 parts of sodium lauryl sulfate and continue stirring; finally add white carbon Black 5 parts, to be stirred into a ...

Embodiment 2

[0045] (1) Preparation of component A: According to parts by weight, 62 parts of methyl methacrylate, 33 parts of methacrylic acid, 12 parts of modified EPDM rubber, 23 parts of polyethylene glycol, and 0.7 parts of hydroquinone Put one part into a stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 2 parts of tetramethylthiourea and 0.8 parts of o-benzenesulfonimide and continue stirring; finally add 9 parts of nano-talc powder and stir to form a uniform mixture body;

[0046] (2) Preparation of component B: in parts by weight, 63 parts of isobornyl methacrylate, 33 parts of methacrylic acid, 13 parts of methyl vinyl silicone rubber, 0.8 parts of vinyltrimethoxysilane, polyethylene glycol Put 23 parts of alcohol and 0.7 parts of p-tert-butylcatechol into the stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 2 parts of dicumyl peroxide and 4 parts of sodium lauryl sulfate to continue stirring; Finally, ad...

Embodiment 3

[0048] (1) Preparation of component A: in parts by weight, 65 parts of hydroxyethyl methacrylate, 35 parts of methacrylic acid, 15 parts of modified EPDM rubber, 25 parts of polyethylene glycol, hydroquinone Put 0.8 parts into the stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 3 parts of vanadium acetylacetonate and 1 part of o-benzenesulfonimide and continue stirring; finally add 12 parts of nano talc powder and stir to form a uniform mixture ;

[0049] (2) Preparation of component B: in parts by weight, 65 parts of methyl methacrylate, 35 parts of methacrylic acid, 15 parts of methyl vinyl silicone rubber, 1.2 parts of vinyl trimethoxysilane, polyethylene glycol Put 25 parts and 0.8 parts of hydroquinone into the stirring tank, the stirring speed is 100r / min, and the stirring time is 0.5h; then add 3 parts of benzoyl peroxide and 5 parts of sodium lauryl sulfate and continue stirring; finally add nano-TiO 2 10 parts, to be stirred int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com