Engine performance recovery protective agent and processing technology thereof

An engine and protective agent technology, applied in the directions of additives, petroleum industry, lubricating compositions, etc., can solve the problems of increased fuel consumption, increased oil consumption, unstable idling operation, etc., to prevent engine wear, inhibit oxidative degradation, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

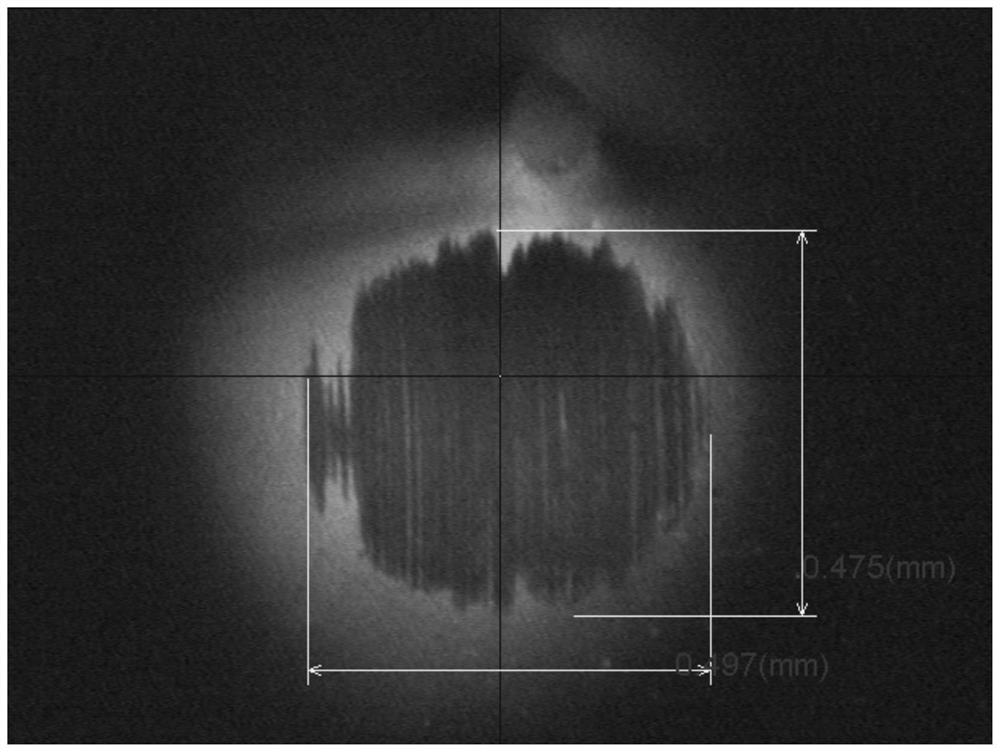

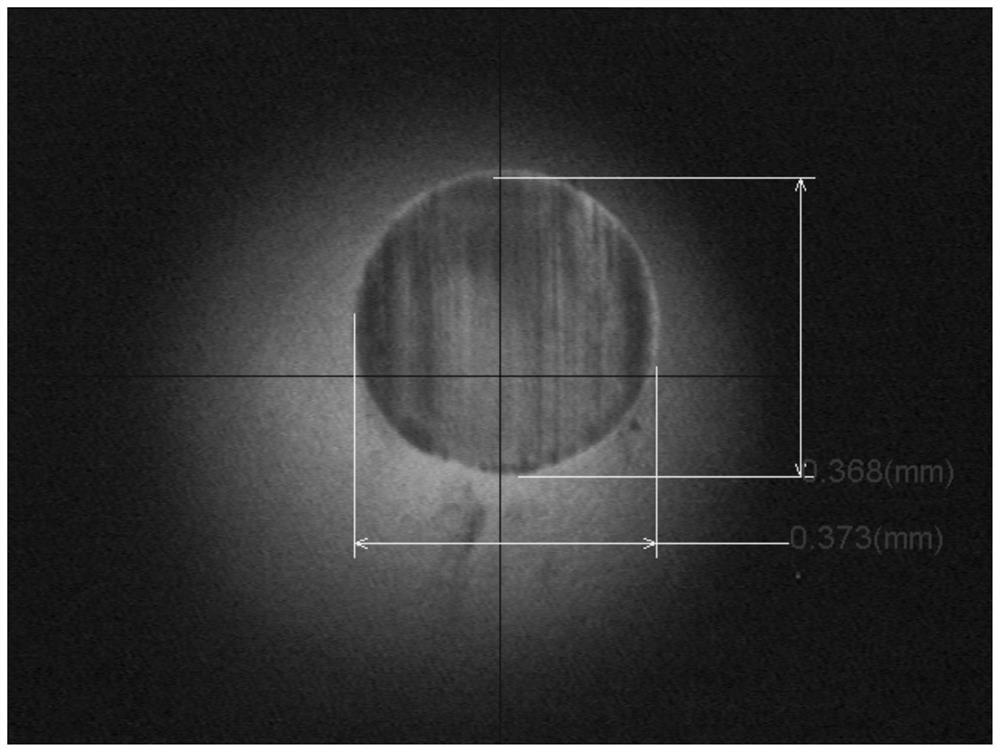

Image

Examples

preparation example Construction

[0035] The preparation of the purified MoDTC comprises the following steps:

[0036] A1. According to the mass ratio of 10:(0.1-1):(0.1-1), put MoDTC, clay and refined preparation into the stirring tank, heat to 50°C, and mix the materials;

[0037] A2. The above mixture is filtered through a plate and frame filter press to obtain purified MoDTC.

[0038] The purification process uses refiner and clay to activate and adsorb molybdenum dialkyldithiocarbamate. Utilizes molybdenum dialkyldithiocarbamate’s decomposing and filling performance at high temperature, and selects it as an additive of protective agent. Its product market is black liquid, and it is difficult to use. After the purification treatment of the present invention, the purity can be effectively improved and the proportion of ash content can be reduced. , remove impurities, increase the proportion of active ingredients, not only retains its excellent performance, and the product is clear and transparent yellow oi...

Embodiment 1

[0045] An engine performance recovery protection agent has the following mass components, 20 parts of secondary hydrogenated 100N, 5 parts of purified MoDTC, 10 parts of ZDDP, 5 parts of tricresyl phosphate, 10 parts of sodium chloride-52, dibutyl 5 parts of imide ashless dispersant, 5 parts of sodium petroleum sulfonate, prepared according to the above method.

Embodiment 2

[0047] An engine performance recovery protection agent has the following mass components, 40 parts of secondary hydrogenated 150N, 10 parts of purified MoDTC, 30 parts of ZDDP, 10 parts of tricresyl phosphate, 20 parts of sodium chloride-52, dibutyl 15 parts of imide ashless dispersant, 10 parts of calcium petroleum sulfonate, prepared according to the above method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com