Preparation method of acidification-resistant Xuan paper

An acid-resistant, rice paper technology, applied in paper, papermaking, textiles and papermaking, etc., can solve the problem that ancient calligraphy and paintings are not easy to be preserved for a long time, and achieve the effect of improving the service life and preservation time, preventing acidification degradation, and inhibiting oxidative degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

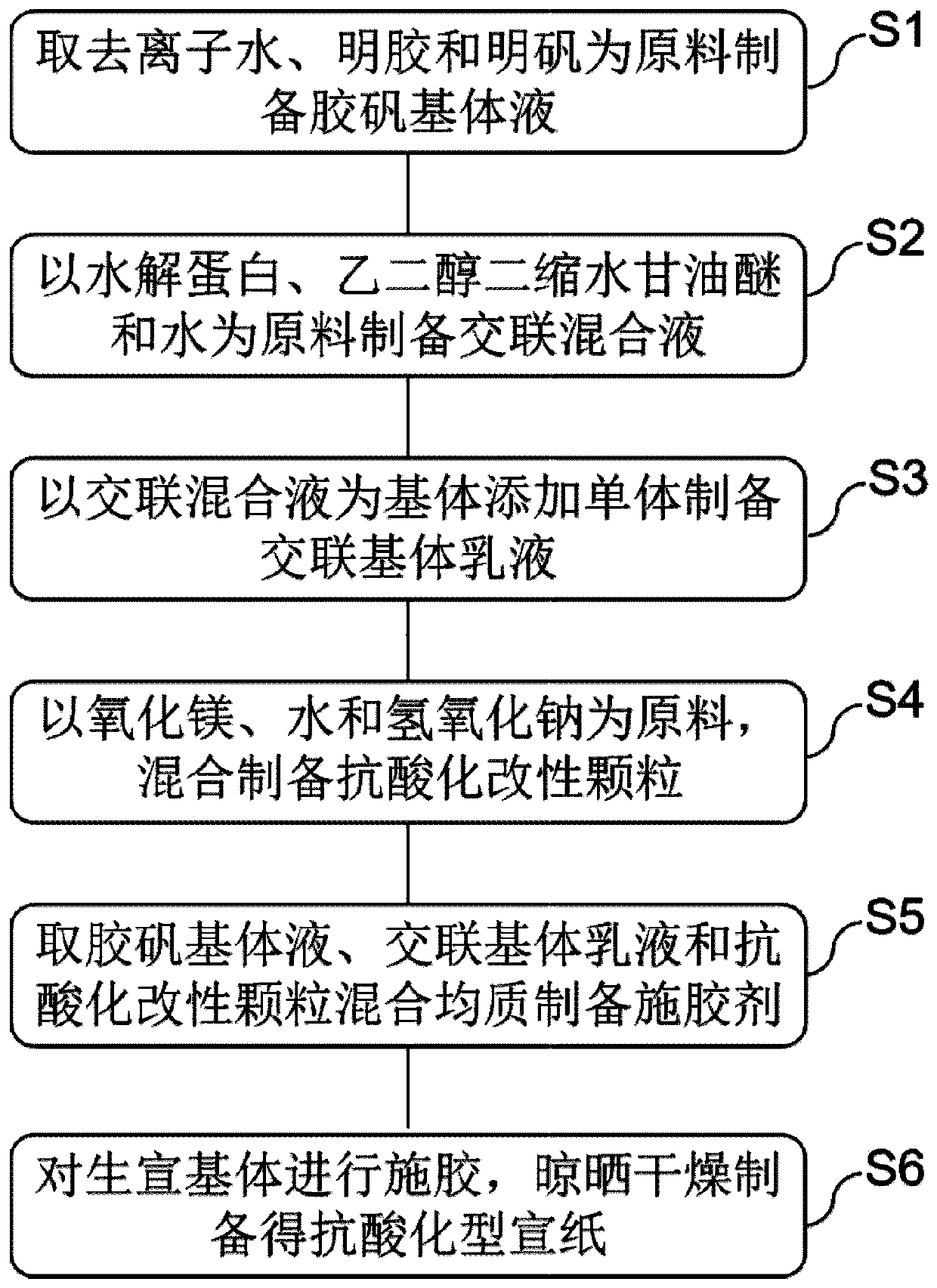

[0023] Such as figure 1 As shown, the preparation method of the anti-acidification type rice paper according to the embodiment of the present invention comprises the following preparation steps:

[0024] S1. Take deionized water, gelatin and alum as raw materials to prepare gelatin-based body fluid.

[0025] S2. Prepare a cross-linking mixed solution by using hydrolyzed protein, ethylene glycol diglycidyl ether and water as raw materials.

[0026] S3, using the cross-linking mixture as a matrix to add monomers to prepare a cross-linking matrix emulsion.

[0027] S4. Using magnesium oxide, water and sodium hydroxide as raw materials, mixing them to prepare anti-acidification modified particles.

[0028] S5. Take the gelatin base liquid, the cross-linked base emulsion and the anti-acidification modified particles, mix and homogeneously prepare a sizing agent.

[0029] S6, sizing the raw rice base, drying in the sun to prepare acid-resistant rice paper.

[0030] Thus, accordi...

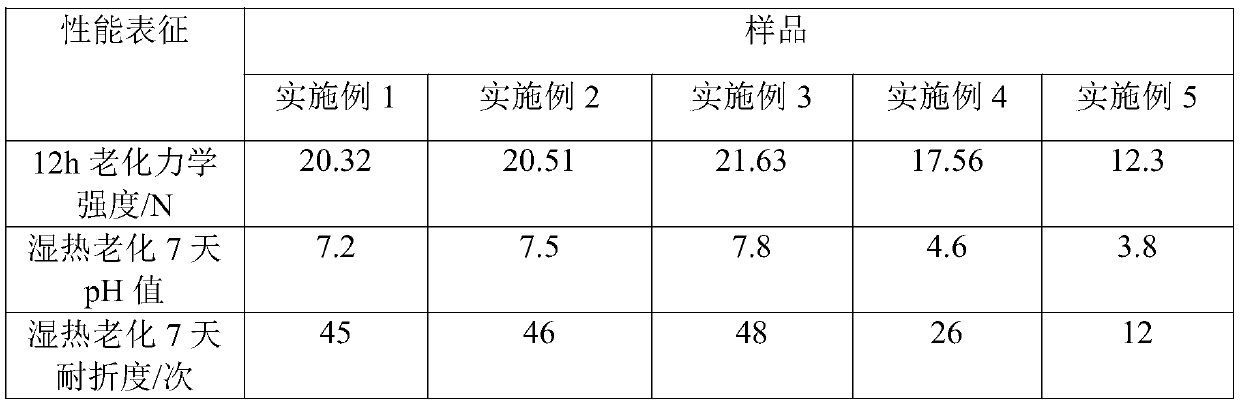

Embodiment 1

[0049] In parts by weight, weigh 45 parts of deionized water, 3 parts of gelatin particles and 2 parts of alum respectively and place them in a blender, stir and mix and grind to disperse, collect the dispersion to obtain the gelatin base liquid; hydrolyze the collagen and collect the hydrolyzed Protein granules, again in parts by weight, respectively weigh 60 parts of water, 10 parts of hydrolyzed protein granules, and 3 parts of ethylene glycol diglycidyl ether in a homogenizer, homogenize and oxidize with 1% by mass Adjust the pH to 8.5 with sodium solution, stir and mix, and place it at 45°C for 25 minutes to insulate and cross-link to obtain a cross-linking mixture; in parts by weight, weigh 45 parts of the cross-linking mixture, 3 parts of styrene and 3 parts of acrylic acid Butyl ester was placed in a three-necked flask, stirred and mixed and pre-emulsified at room temperature for 25 minutes, and the pre-emulsion was collected. According to the mass ratio of 1:100, the m...

Embodiment 2

[0051] In parts by weight, weigh 47 parts of deionized water, 4 parts of gelatin particles and 2 parts of alum respectively and place them in a blender, stir and mix and grind to disperse, collect the dispersion to obtain the gelatin base liquid; hydrolyze the collagen and collect the hydrolyzed Protein granules, counted in parts by weight, respectively weigh 70 parts of water, 12 parts of hydrolyzed protein granules, and 4 parts of ethylene glycol diglycidyl ether in a homogenizer, homogenize and oxidize with 1% by mass Adjust the pH to 8.5 with the sodium solution, stir and mix, and place it at 47°C for 27 minutes to insulate and cross-link to obtain a cross-linking mixture; in parts by weight, weigh 47 parts of the cross-linking mixture, 4 parts of styrene and 4 parts of acrylic acid Butyl ester was placed in a three-necked flask, stirred and mixed and pre-emulsified at room temperature for 27 minutes, and the pre-emulsion was collected. According to the mass ratio of 1:100,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com