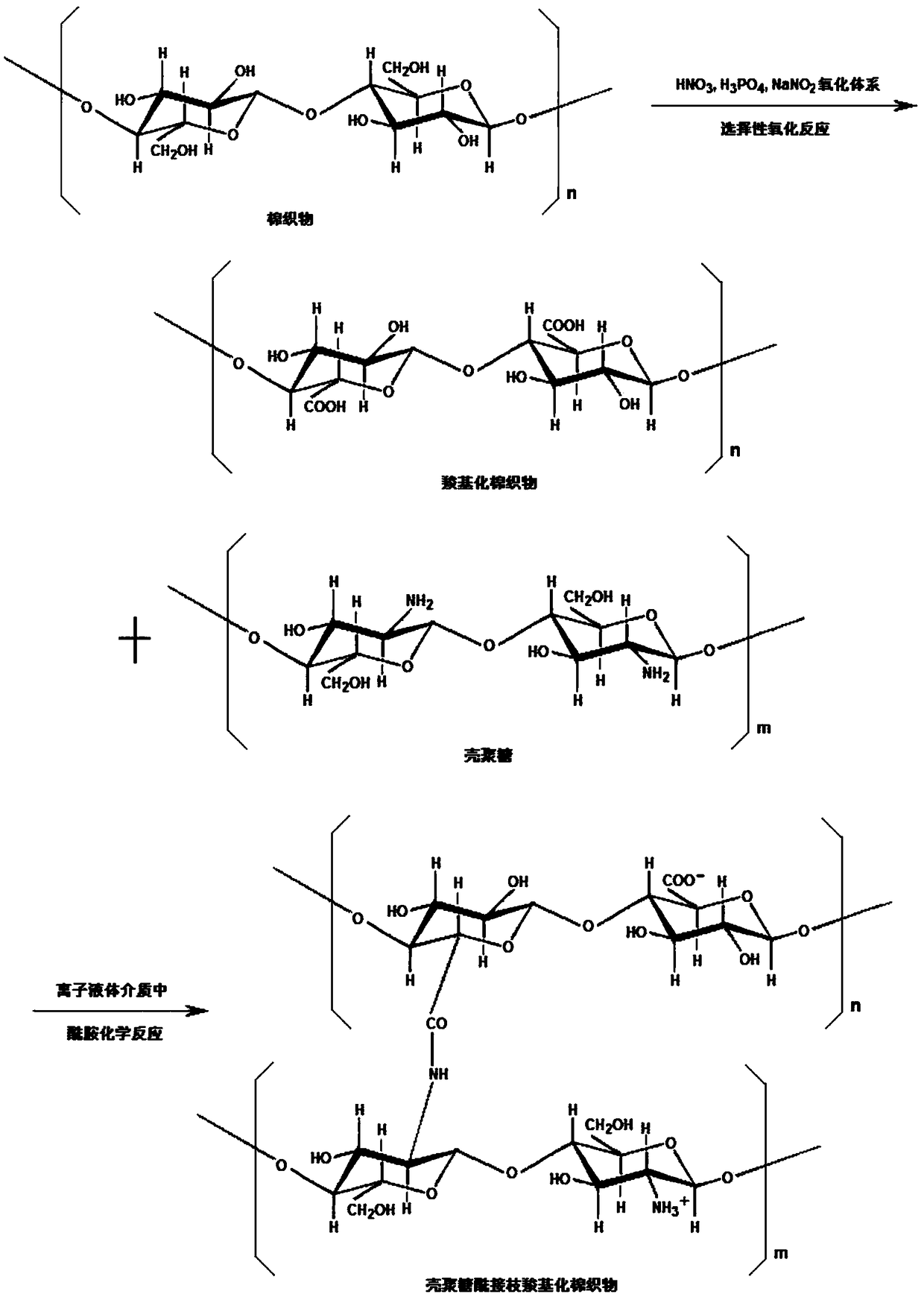

Method for preparing chitosan modified carboxylation cotton fabric in ionic liquid medium

A chitosan modification, ionic liquid technology, applied in plant fiber, biochemical fiber treatment, textiles and papermaking, etc., can solve the problems of mechanical mechanical damage of fabrics, various finishing liquid components, and high process equipment requirements, and achieve mechanical properties. Small damage, increased selectivity and oxidation rate, and promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

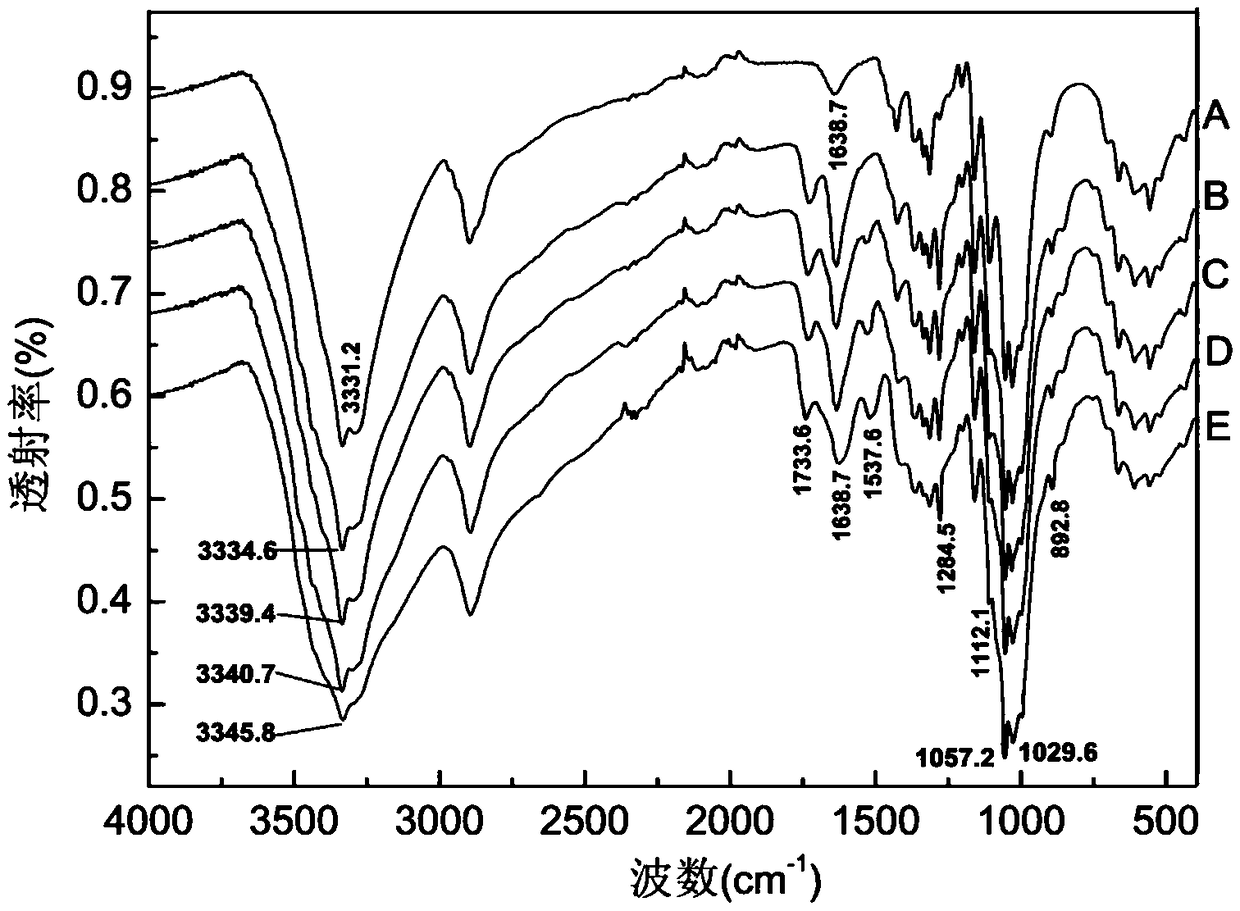

Method used

Image

Examples

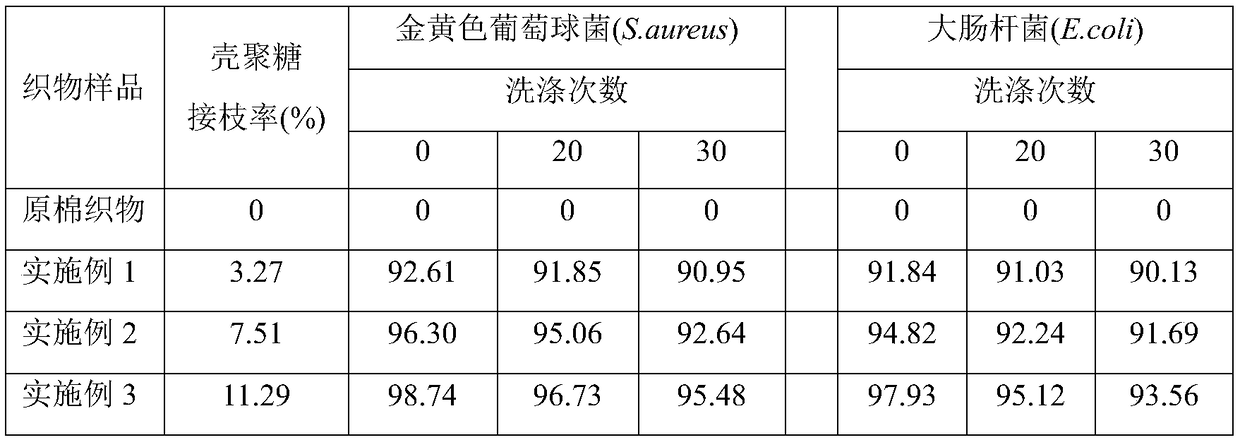

Embodiment 1

[0027] (1) Mix the ionic liquid 1-hydro-3-methylimidazolium chloride with 1-allyl-3-methylimidazolium chloride in a mass ratio of 1:9, and then dry at 105° C. for 2 hours to obtain ionic liquid liquid mixture;

[0028] (2) Dissolve chitosan with a viscosity-average molecular weight of 250,000 and a degree of deacetylation of 91.6% in a 0.5 mol / L acetic acid solution, dropwise add a 1.0 mol / L sodium hydroxide solution until the pH of the solution is about 7.5, After the white chitosan precipitate is completely precipitated, it is fully smashed, washed with water until neutral, and then filtered; the chitosan precipitate was soaked in 150 mL of absolute ethanol and ultrasonically oscillated for 3 times (ultrasonic power was 326 W) for 30 minutes each time. The water in the chitosan precipitation is replaced, filtered, and vacuum-dried at 70° C. for 4 hours, and pulverized to obtain low-crystalline chitosan; then the low-crystalline chitosan is added to the ionic liquid mixture p...

Embodiment 2

[0032] (1) Mix the ionic liquid 1-hydro-3-methylimidazolium chloride with 1-allyl-3-methylimidazolium chloride in a mass ratio of 2:8, and then dry at 110° C. for 2 hours to obtain ionic liquid liquid mixture;

[0033] (2) Dissolve chitosan with a viscosity average molecular weight of 250,000 and a degree of deacetylation of 91.6% in a 0.6 mol / L acetic acid solution, add dropwise a 1.2 mol / L sodium hydroxide solution until the pH of the solution = about 7.5, After the white chitosan precipitate is completely precipitated, it is fully smashed, washed with water until neutral, and then filtered; the chitosan precipitate was soaked in 200 mL of absolute ethanol, and ultrasonically oscillated 4 times (ultrasonic power was 382 W) for 30 min each time. The water in the chitosan precipitation is replaced, filtered, and vacuum-dried at 75° C. for 5 hours, and pulverized to obtain low-crystalline chitosan; then the low-crystalline chitosan is added to the ionic liquid mixture prepared ...

Embodiment 3

[0037] (1) Mix the ionic liquid 1-hydro-3-methylimidazolium chloride with 1-allyl-3-methylimidazolium chloride in a mass ratio of 1:4, and then dry at 115° C. for 1.5 hours to obtain Ionic liquid mixture;

[0038] (2) Dissolve chitosan with a viscosity average molecular weight of 250,000 and a degree of deacetylation of 91.6% in a 0.6 mol / L acetic acid solution, add dropwise a 1.2 mol / L sodium hydroxide solution until the pH of the solution = about 7.5, After the white chitosan precipitate is completely precipitated, it is fully smashed, washed with water until neutral, and then filtered; the chitosan precipitate was soaked in 200 mL of absolute ethanol and ultrasonically oscillated for 3 times (ultrasonic power was 415 W) for 30 minutes each time. The water in the chitosan precipitation is replaced, filtered, and vacuum-dried at 78° C. for 4 hours, and pulverized to obtain low-crystalline chitosan; then the low-crystalline chitosan is added to the ionic liquid mixture prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com