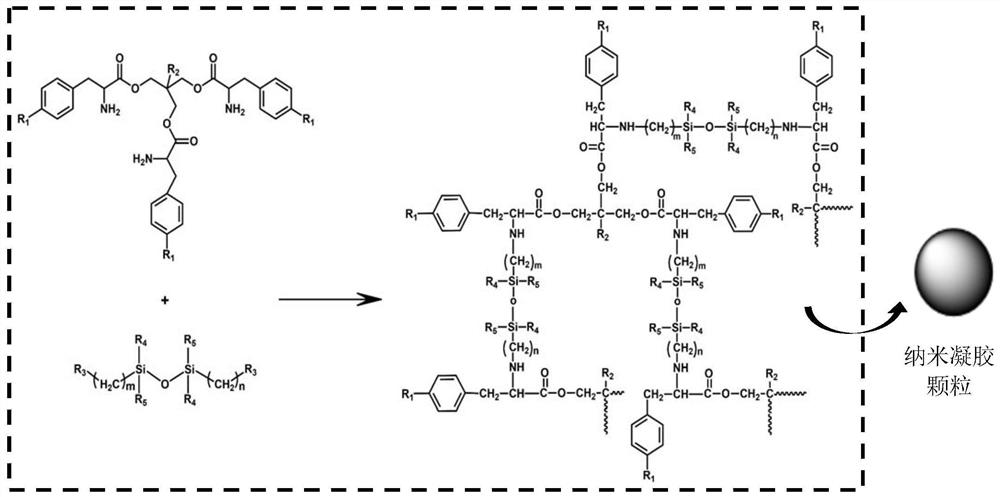

A kind of n-si series nano hydrogel flame retardant and its preparation and application

A nano-hydrogel and reaction technology, which is applied in the direction of flame-retardant fibers, textiles, papermaking, fiber treatment, etc., can solve the problems of reducing the mechanical and mechanical properties of the matrix material, adding a large amount of flame retardants, and poor durability. High efficiency, strong stability, and achieve the effect of isolated flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Weigh 4.53g of 0.025mol tyrosine and 3.00g of 0.025mol trimethylolethane and dissolve them in 500mL of toluene, put 0.125mol (23.75g) of p-toluenesulfonic acid into amino protection, and react in the single layer glass The reaction was carried out in a kettle, stirred mechanically, heated to 120°C in an oil bath, and reacted for 20 hours. The reactant was first dissolved with isopropanol, then precipitated at low temperature, and vacuum-dried at 50°C for 12 hours. The obtained intermediate product (II) was white powder.

[0046] (2) Weigh 2.48 g of 0.01 mol of 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane, dissolve it in 15 mL of tetrahydrofuran, and weigh 0.07 mol of triethylamine 7.08g, all were put into a three-necked flask; 3.14g of 0.03mol methacryloyl chloride was weighed, put into a 50mL constant-pressure separating funnel, and slowly added dropwise to the three-necked flask within 1 hour, stirred magnetically, and cooled to -20°C, reacted for 18 hours...

Embodiment 2

[0052] (1) Weigh 4.13g of 0.025mol phenylalanine and 3.00g of 0.025mol trimethylolethane and dissolve them in 500mL of tetrahydrofuran, the reaction temperature is 70°C, and the other reaction conditions are the same as in Example I to obtain the intermediate product (II) It is milky white powder.

[0053] (2) Weigh 0.01mol 1,3-bis(3-aminopropyl)-1,1,3,3-tetramethyldisiloxane 2.48g, 0.07mol triethylamine 7.08g, 0.03mol methacrylic Acid chloride 3.14g was dissolved in 20mL of dichloromethane, and the other reaction conditions were the same as in Example I to obtain the intermediate product (III) as a yellow oily substance.

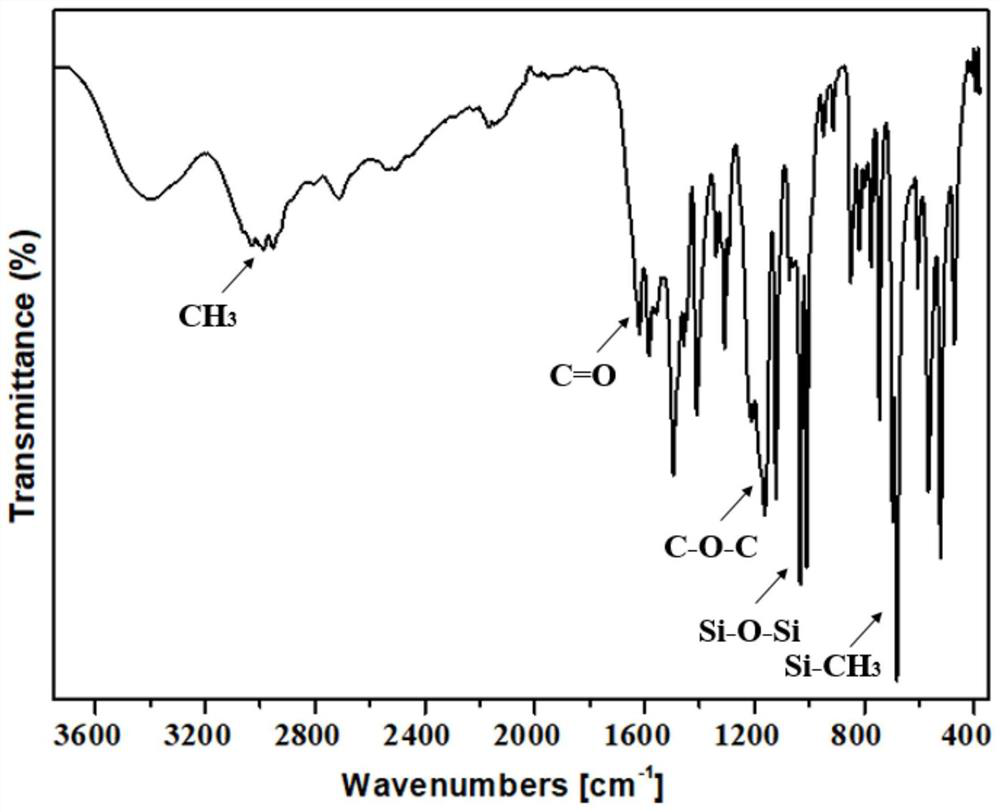

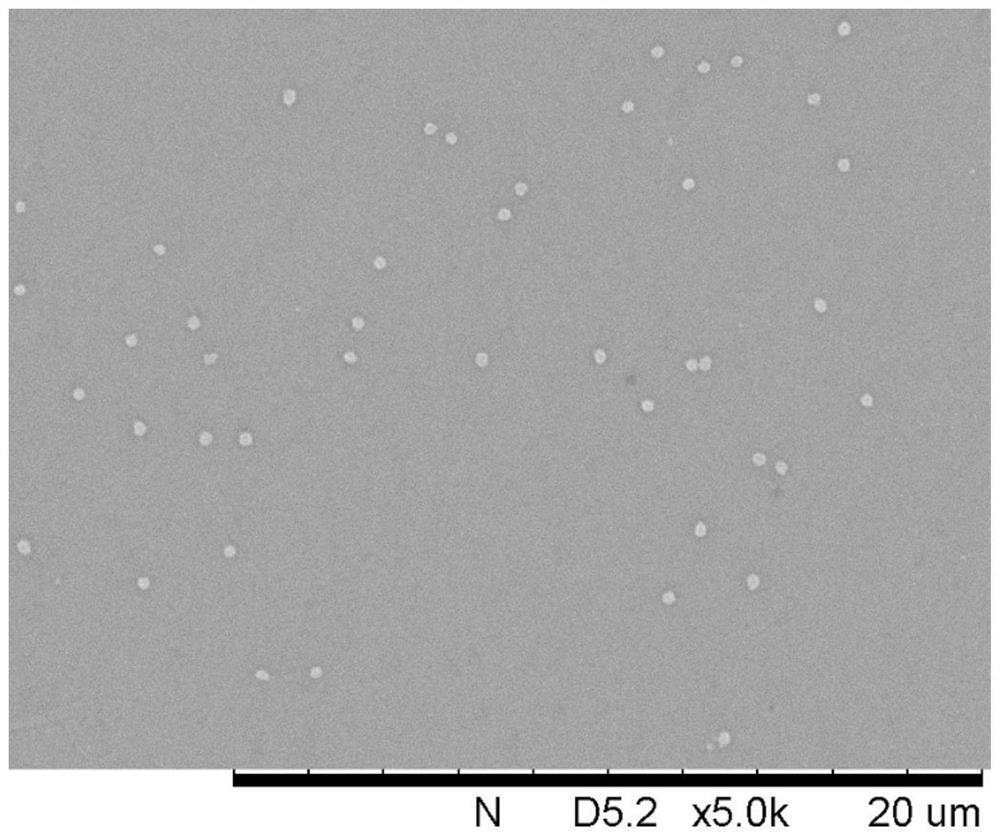

[0054] (3) Weigh 2.52 g of 0.0025 mol intermediate product (II) and 3.24 g of 0.01 mol intermediate product (III), and control the speed at 1000 rpm. Other conditions are the same as those in Example 1 to obtain a white flame-retardant nanogel with a particle size of about 600 nm. . Infrared spectrum data of gel: 2950~3050cm -1 (-CH 3 ),1725~1700cm -1 ...

Embodiment 3

[0059] (1) Weigh 12.38 g of 0.075 mol of phenylalanine and 3.03 g of 0.025 mol of tris hydroxymethylaminomethane and dissolve them in 500 mL of tetrahydrofuran. The other reaction conditions are the same as in Example 1, and the intermediate product (II) is obtained as a white powder.

[0060] (2) Weigh 3.25 g of 0.0025 mol product (II), 12.96 g of intermediate product (III) prepared in 0.04 mol example II, 2.03 g of 0.02 mol triethylamine, add a three-necked flask; dropwise add sodium hydroxide with a pH of 9 The solution obtains an alkaline environment with a pH of 8, the rotational speed is controlled at 1500 rpm, and other conditions are the same as in Example 1, and a white flame-retardant nanogel with a particle size of about 400 nm is obtained. Infrared spectrum data: 2950~3050cm -1 (-CH 3 ),1725~1700cm -1 (C=O), 1100~1270cm -1 (C-O-C),1050cm -1 (Si-O-Si), 830cm -1 (Si-CH 3 ).

[0061] The flame retardant nano gel is fully mixed with the regenerated cellulose sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com