A kind of finishing method of machine-washable wool fabric

A technology for washing wool and fabrics, applied in the finishing field of machine-washable wool fabrics, can solve the problems of reducing the unidirectional movement and entanglement of fibers, damage to the mechanical properties of wool fabrics, damage to the structure of wool scales, etc. Weak, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

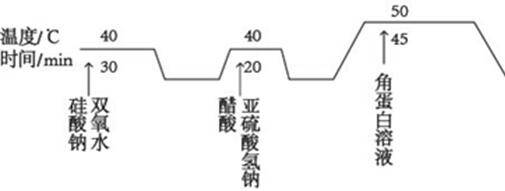

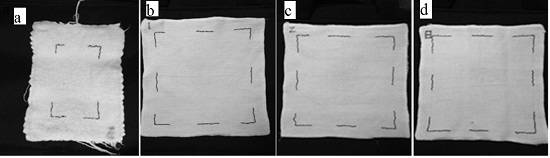

[0020] A finishing method of "machine washable" woolen fabric, the steps are as follows:

[0021] a. Wool fabric preparation: Wash the wool fabric and then dry it at 20°C.

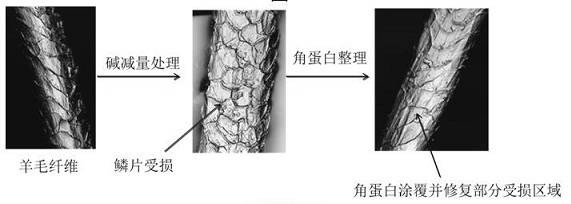

[0022] b. Weight reduction pretreatment: soak the washed woolen fabric in a solution of 30% hydrogen peroxide (3g / L) and sodium silicate (1g / L) for 30min at a bath ratio of 1:30 at a temperature of 40°C; After washing, the wool fabric was treated in a solution of 1% (o.w.f) acetic acid and 2% (o.w.f) sodium bisulfite for 20 min at a temperature of 40°C and a bath ratio of 1:30.

[0023] c. Restorative increase treatment: soak the wool fabric after weight reduction treatment in 1% keratin solution at a bath ratio of 1:30, and treat for 45 minutes at a temperature of 50°C.

[0024] d. Preparation of 1% keratin solution: Dissolve wool in an aqueous solution containing 3% sodium sulfide, 7mol / L urea and 1% SDS at a bath ratio of 1:20, react at 50°C for 10 hours, and measure It is obtained by filtering throug...

Embodiment 2

[0029] A finishing method of "machine washable" woolen fabric, the steps are as follows:

[0030] a. Wool fabric preparation: Wash the wool fabric and then dry it at 20°C.

[0031] b. Weight reduction pretreatment: soak the washed woolen fabric in a solution of 30% hydrogen peroxide (3g / L) and sodium silicate (1g / L) for 30min at a bath ratio of 1:30 at a temperature of 40°C; After washing, the wool fabric was treated in a solution of 1% (o.w.f) acetic acid and 2% (o.w.f) sodium bisulfite for 20 min at a temperature of 40°C and a bath ratio of 1:30.

[0032] c. Restorative increase treatment: soak the wool fabric after weight reduction treatment in 2% keratin solution at a bath ratio of 1:30, and treat for 45 minutes at a temperature of 50°C.

[0033] d. Preparation of 2% keratin solution: Dissolve wool in an aqueous solution containing 3% sodium sulfide, 7mol / L urea and 1% SDS at a bath ratio of 1:20, react at 50°C for 10 hours, and measure It is obtained by filtering throug...

Embodiment 3

[0038] A finishing method of "machine washable" woolen fabric, the steps are as follows:

[0039] a. Wool fabric preparation: Wash the wool fabric and then dry it at 20°C.

[0040] b. Weight reduction pretreatment: soak the washed woolen fabric in a solution of 30% hydrogen peroxide (3g / L) and sodium silicate (1g / L) for 30min at a bath ratio of 1:30 at a temperature of 40°C; After washing, the wool fabric was treated in a solution of 1% (o.w.f) acetic acid and 2% (o.w.f) sodium bisulfite for 20 min at a temperature of 40°C and a bath ratio of 1:30.

[0041] c. Restorative increase treatment: soak the wool fabric after weight reduction treatment in 3% keratin solution at a bath ratio of 1:30, and treat for 45 minutes at a temperature of 50°C.

[0042] d. Preparation of 3% keratin solution: Dissolve wool in an aqueous solution containing 3% sodium sulfide, 7mol / L urea and 1% SDS at a bath ratio of 1:20, react at 50°C for 10 hours, and measure by mesh It is obtained by filterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com