A kind of preparation method of environmental purification finishing agent based on nano-titanium dioxide hydrosol

A nano-titanium dioxide and environmental purification technology, applied in chemical instruments and methods, water treatment of special compounds, physical/chemical process catalysts, etc., can solve the problems of textile fiber cracking, large damage to fiber mechanical properties, and poor bonding fastness of fabrics , to achieve the effect of less damage to the mechanical properties of the fiber, which is conducive to industrialization and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

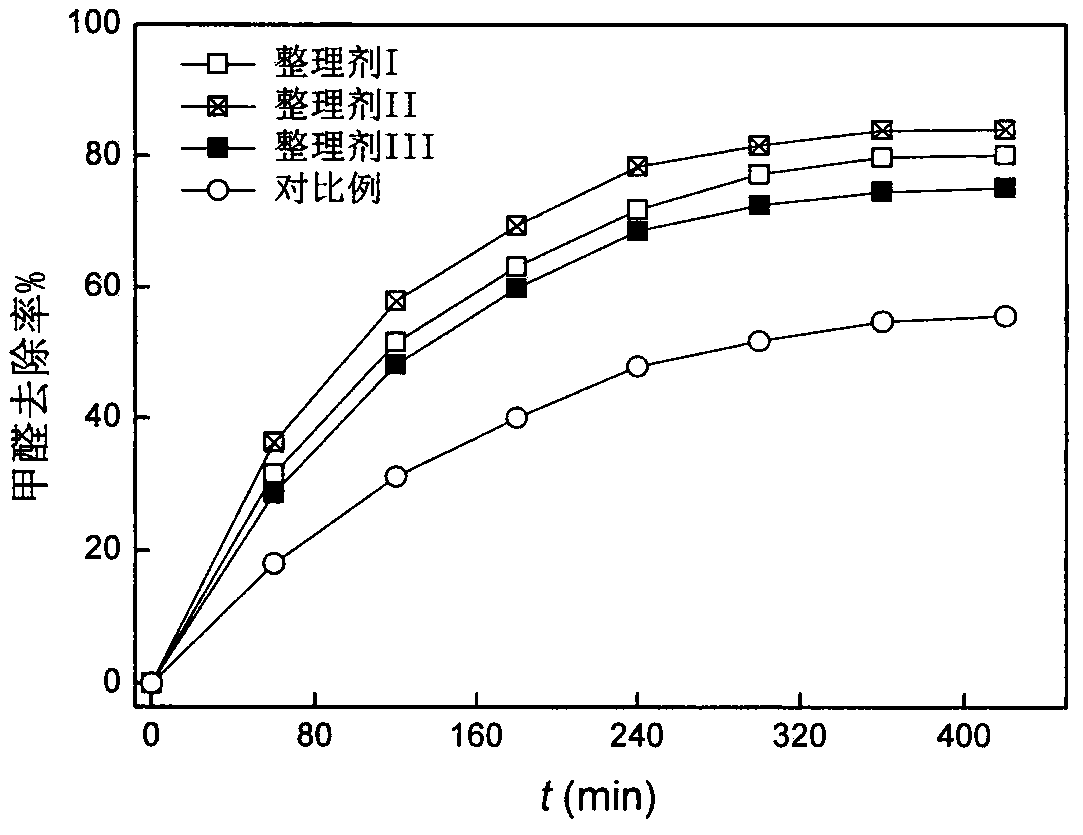

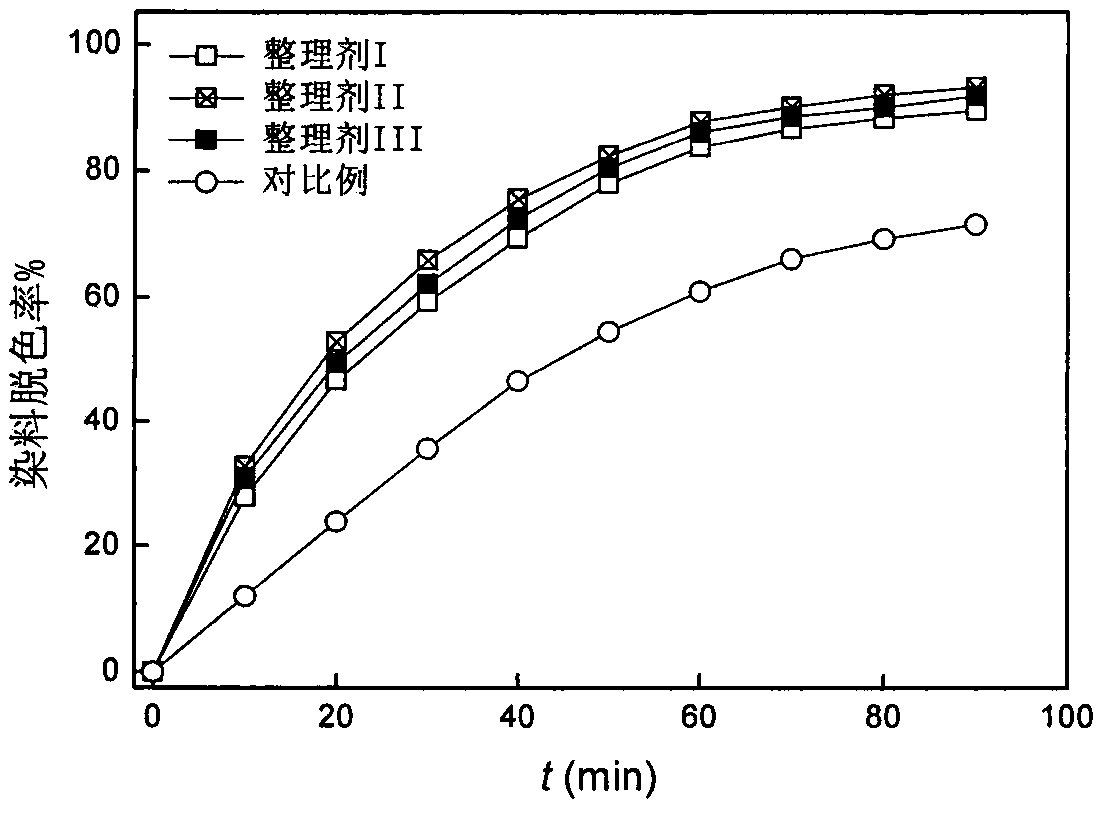

Embodiment 1

[0020] 1. Preparation of nano-titanium dioxide hydrosol: first, 50 ml of butyl titanate was dissolved in 75 ml of absolute ethanol at room temperature to form an ethanol solution of butyl titanate. At the same time, add a specified volume of nitric acid to 435 ml of distilled water to obtain an aqueous solution of dilute nitric acid, then drop the ethanol solution of butyl titanate into the aqueous solution of nitric acid at room temperature and under stirring conditions, and continue stirring for 5 hours after the dripping is completed to obtain a milky white water dispersion Finally, it was left to stand and aged for several days to form about 500 milliliters of nano-titanium dioxide hydrosol, which was slightly yellow and translucent, wherein the content of nano-titanium dioxide was 2.62%, and the content of n-butanol was 7.65%;

[0021] 2. Vacuum distillation process: Distill 500 milliliters of nano-titanium dioxide hydrosol at 40°C for 3.5 hours under reduced pressure to o...

Embodiment 2

[0028] 1. The process is the same as the 1-step process in Example 1.

[0029] 2. described underpressure distillation temperature is 60 ℃, and the time is 2.5 hours, and nano-titanium dioxide content is 3.86%, and n-butanol content is 0.21%, and all the other are identical with the 2nd step process among the embodiment 1.

[0030] 3. The added amount of acetic acid is 10.8 grams, the temperature of reaction is 60 DEG C, and the reaction time is 24 hours, and all the other are the same as the second step process in Example 1, wherein the n-butanol content is 0.015%;

[0031] 4. technology is identical with the 4 step technology in embodiment 1;

[0032] 5. technology is identical with 5 steps of technology among the embodiment 1;

[0033] 6. technology is identical with 6 steps of technology among the embodiment 1;

[0034] 7. The process is the same as the 7-step process in Example 1 to obtain the environmental purification finishing agent II.

Embodiment 3

[0036] 1. The process is the same as the 1-step process in Example 1.

[0037] 2. described underpressure distillation temperature is 80 ℃, and the time is 1.5 hours, and nano-titanium dioxide content is 3.97%, and n-butanol content is 0.09%, and all the other are identical with the 2nd step process among the embodiment 1.

[0038]3. described acetic acid addition is 7.2 grams, and temperature of reaction is 40 ℃, and the reaction times is 12 hours, and all the other are identical with the 2nd step technology among the embodiment 1, and wherein n-butanol content is 0.023%.

[0039] 4. technology is identical with the 4 step technology in embodiment 1;

[0040] 5. technology is identical with 5 steps of technology among the embodiment 1;

[0041] 6. technology is identical with 6 steps of technology among the embodiment 1;

[0042] 7. The process is the same as the 7-step process in Example 1 to obtain the environmental purification finishing agent III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com