Patents

Literature

66results about How to "No irritating taste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinegar egg beverage and production method thereof

The invention belongs to the field of nutrition health-care beverages, in particular relates to a vinegar egg beverage. The vinegar egg beverage is formed by processing and mixing the following raw materials in parts by weight: 50-60 parts of eggs, 10-40 parts of rice vinegar, 900 parts of water, 10-30 parts of honey, 70-120 parts of white granulated sugars, 2-5 parts of citric acid and 2-5 parts of sodium carboxymethylcellulose. The production method comprises the following steps of: performing acidolysis on the eggs by using the rice vinegar at the first time; adding enzyme to perform enzymolysis on the eggs; adding water and seasoning stabilizer to mix with the eggs; and finally, canning and sterilizing. Protein macromolecules in the eggs are decomposed into micromolecule substances of polypeptide and the like by using the vinegar and the enzyme so as to easily absorb by the human body; and therefore, the vinegar egg beverage can be used as a beverage for daily drinking, and also has a certain nutritional supplement function.

Owner:HUBEI SHENDAN HEALTHY FOOD

Machine-made charcoal and preparation method thereof

The invention discloses machine-made charcoal. The machine-made charcoal is prepared from the following components in parts by weight: 40-50 parts of Chinese herbal medicine residues, 2-5 parts of a combustion improver, 35-52 parts of biomass waste and 6-10 parts of a binder, wherein the Chinese herbal medicine residues consist of 60-65 parts of wormwood, 10-15 parts of lavender platycodon grandiflorum, 4-6 parts of dried tangerine or orange peel, 2-4 parts of lotus leaves, and 10-24 parts of momordica grosvenori and a branch-leaf mixture thereof. The machine-made charcoal disclosed by the invention takes waste Chinese herbal medicine residues as raw materials, so that the waste is changed into things of value; the properties of the residual medicines are utilized, so that the machine-made charcoal not only has no irritant small, but also has fresh scent; more importantly, the machine-made charcoal has a health effect and a certain action on cough, sphagitis and bronchial asthma, and does not cause a dryness-heat feeling.

Owner:FUJIAN ZHONGMEI CHEM ENVIRONMENTAL PROTECTION TECH CO LTD

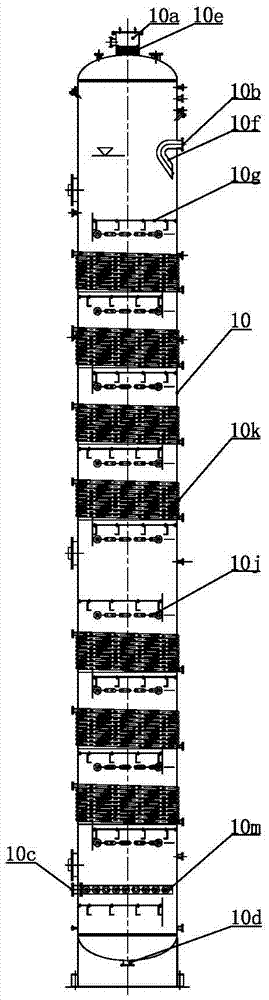

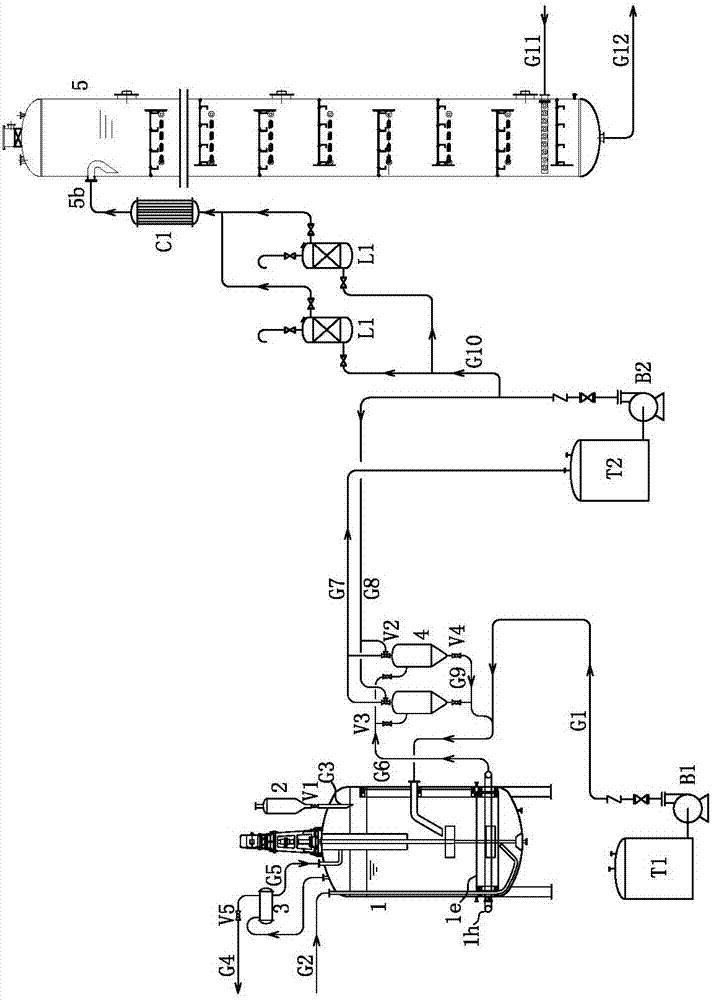

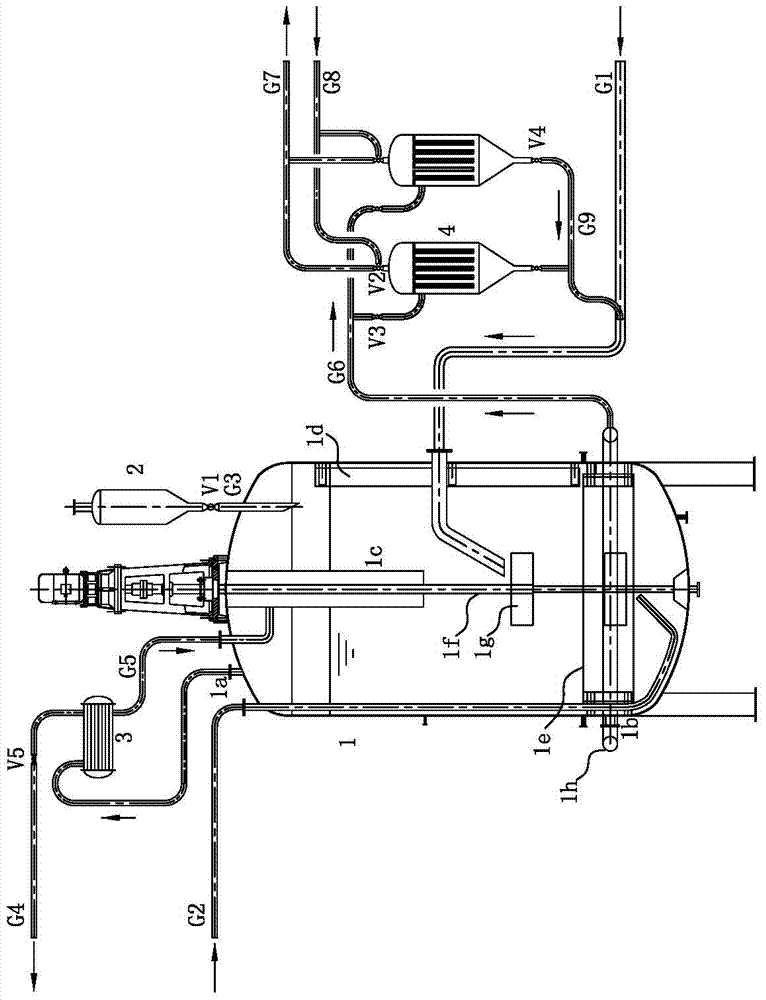

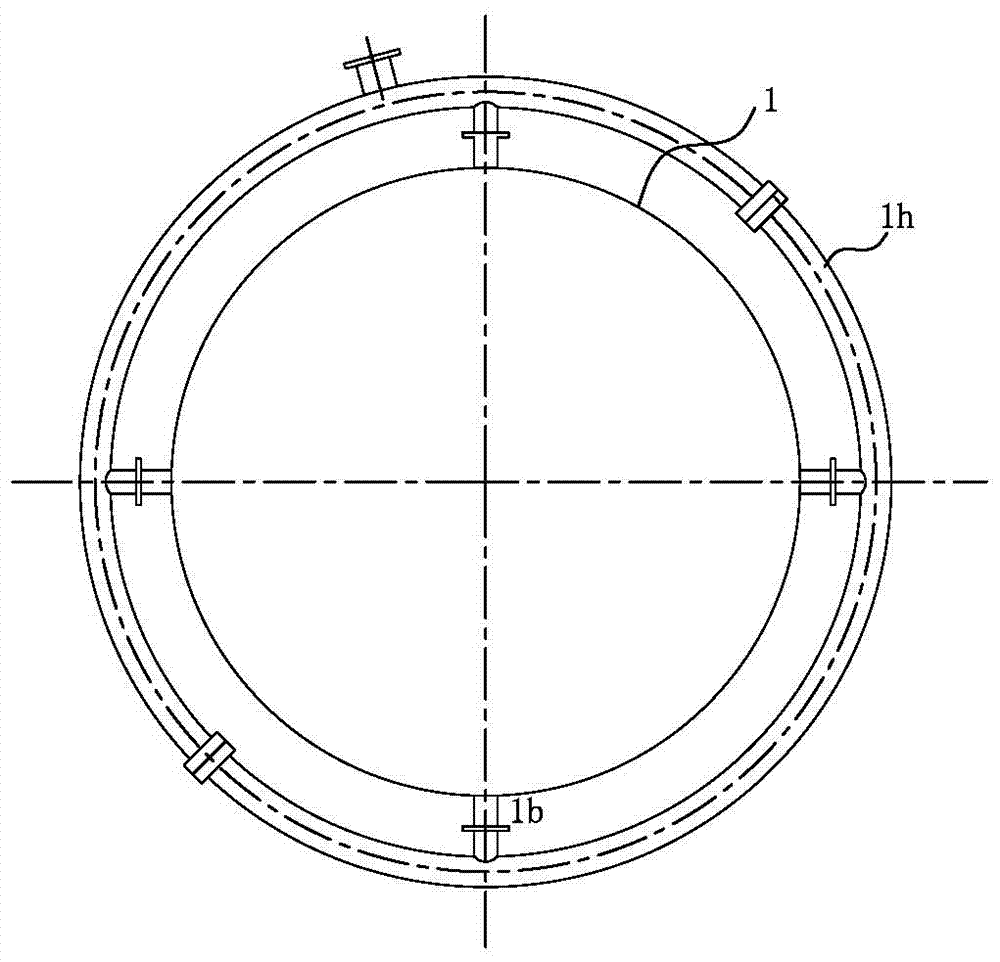

Fluidized bed production system and production method for hydrogen peroxide

ActiveCN107032303AEasy recoilContinuous and stable productionPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesEnergy inputFluidized bedProcess engineering

The invention relates to a fluidized bed production system and production method for hydrogen peroxide. The bottom of a working liquid tank is connected with an inlet of a hydrogenation device through a working liquid pump and a working liquid supply pipe; an outlet of the hydrogenation device is connected with a hydrogenated liquid tank through a net hydrogenated liquid outlet pipe; the bottom of the hydrogenated liquid tank is connected with the inlet of an oxidation tower through a hydrogenated liquid pump, a hydrogenated liquid tank outlet pipe, a hydrogenated liquid filter and a hydrogenated liquid cooler; the outlet of the oxidation tower is connected with an oxidized liquid output pipe; the bottom of a hydrogenation reactor is connected with the working liquid supply pipe and a fresh hydrogen supply pipe; the outlet of the reactor on the middle circumference of the hydrogenation reactor is connected with the middle circumference of a catalyst preseparator along the tangential direction; the bottom of the catalyst preseparator is connected with the lower circumference of the hydrogenation reactor; the outlet of the catalyst preseparator is connected with a bottom inlet of a catalyst filter through a three-way valve; and the top of the catalyst filter is connected with the net hydrogenated liquid outlet pipe. According to the system, continuous production can be achieved, the unit consumption of a product is low, and the production efficiency is high.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Low-alcohol fermented brier grape beverage and processing method thereof

The invention relates to a low-alcohol fermented brier grape beverage and a processing method thereof. The processing method comprises the steps of: taking brier grapes as a raw material, adding white granulated sugar accounting for 8-12 percent of the brier grapes by weight, naturally fermenting for 2 days at 25-30 DEG C by using original wild strains on the epidermises of the brier grapes, turning over while fermenting, then filter-pressing to obtain juice, carrying out fine filtering by using a plate frame to remove skin slag of the brier grapes to obtain clarified juice, carrying out hot filling and sealing, pasteurizing and cooling to obtain the beverage. The beverage is obtained by natural fermentation in a short time, has alcohol content lower than 5% and special fermenting flavor of fruit wine without stimulating mouthfeel of alcohol, and is a unique new food between the traditional fruit wine and soft beverages.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Substrate for making health-care food matrix with lead-eliminating function, and food therewith

InactiveCN1860925APromote digestion and absorptionFull of nutritionMilk preparationFood scienceCarboxymethyl starchAdditive ingredient

A matrix of the health-care food for discharging Pb from human body and supplementing the trace elements (Fe, Ca, etc) to human body is proportionally prepared from milk powder, sugar, vegetative butter, pvp, carboxymethyl starch sodium, EDTA calcium sodium, EDTA iron sodium, sweetening agent, essence tablet, superfine SiO2, sodium citrate and citric acid.

Owner:TIANJIN UNIV OF COMMERCE

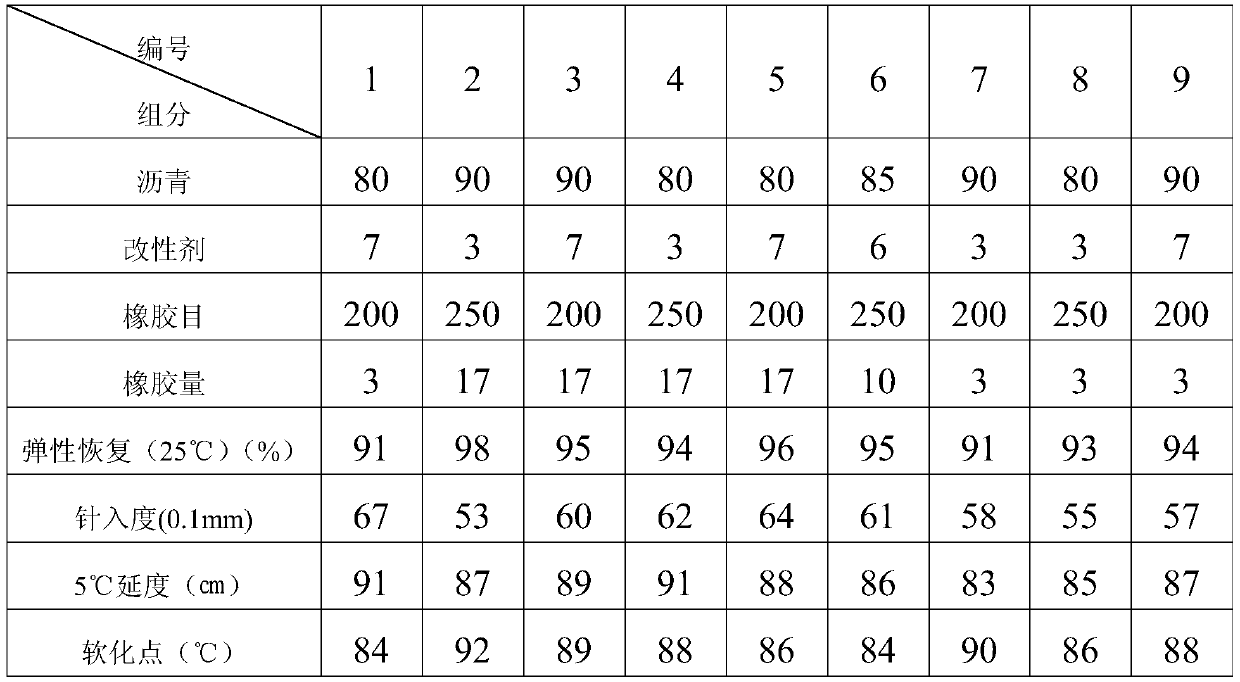

Medium-temperature modified crack pouring adhesive and preparation method thereof

ActiveCN105505307AEasy to integrateGood for healthNon-macromolecular adhesive additivesBituminous material adhesivesAdhesiveRoad surface

The invention discloses a medium-temperature modified crack pouring adhesive and a preparation method thereof. A formula of the medium-temperature modified crack pouring adhesive comprises 80-90 parts of matrix asphalt, 3-7 parts of crack pouring adhesive modifier and 3-17 parts of rubber powder, wherein the matrix asphalt is a medium-temperature modified asphalt with a high solid content, and is composed of the following components in parts by weight: 75-82 parts of matrix petroleum asphalt, 3-7 parts of medium-temperature modifier and 11-22 parts of water. A medium-temperature modified crack pouring adhesive product prepared with the method has a curing effect significantly higher than that of a conventional crack pouring adhesive, can be cured in 1-2 hours, can significantly shorten the time duration of road closure caused by construction, and is conducive to easing the traffic pressure, thereby meeting needs of people. The medium-temperature modified crack pouring adhesive prepared with the method has a wider range of construction temperature and can be constructed under a climatic condition of 0-10 DEG C. However, a modified asphalt in the prior art cannot be constructed at a construction temperature below 10 DEG C, by comparison, the number of days for construction can be extended by 60 days, thereby meeting needs of road maintenance.

Owner:WUHAN CHENGSHITONG ENVIRONMENTAL ASPHALT ENG CO LTD

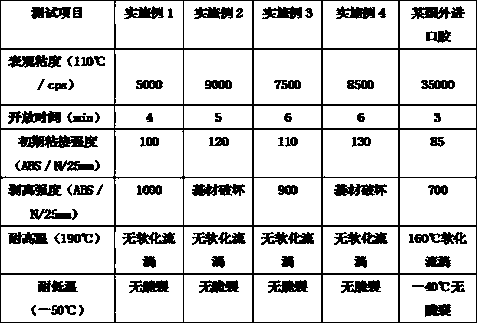

Moisture-curing polyurethane hot melt adhesive for automobile lighting and preparation method thereof

InactiveCN108467702ALow sizing temperatureThe method and process are simple and easyPolyureas/polyurethane adhesivesChemistryIsocyanate compound

The invention relates to a moisture-curing polyurethane hot melt adhesive for an automobile lighting and a preparation method thereof. The moisture-curing polyurethane hot melt adhesive is prepared from, by mass, 10-45 parts of polyester polyol, 20-55 parts of polyether polyol, 10-45 parts of polyacrylic resin, 0.01-5 parts of chain extender, 10-20 parts of isocyanate and 0.0001-0.001 parts of catalyst. The moisture-curing polyurethane hot melt adhesive for the automobile lighting has the advantages that the hot melt adhesive is prepared by copolymerizing polyhydric alcohols (hydroxide radical) containing active groups and isocyanate groups (NCO), the tail end of a polymer chain contains a reactive group NCO, and an irreversible cross-linking reaction between the NCO and moisture in the air or adhered matters can be performed, so that the high bonding strength is finally obtained.

Owner:浙江吉仑高分子材料股份有限公司

Novel wallpaper base film

The invention discloses a novel wallpaper base film. The novel wallpaper base film is prepared from, by weight, 60-70 parts of acrylic emulsion, 5-10 parts of methacrylamide, 5-10 parts of acrylic acid, 4-6 parts of diisooctyl phenyl phosphite, 8-16 parts of methylene cellulose, 6-9 parts of sodium stearate, 5-8 parts of calcium carbonate, 1-3 parts of a stabilizer and 2-5 parts of a corrosion inhibitor. The novel wallpaper base film is safe, environmentally friendly, free of pungent smells, good in heat stability, resistant to water, damp and corrosion and capable of protecting wallpaper and making the service life of the wallpaper longer.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

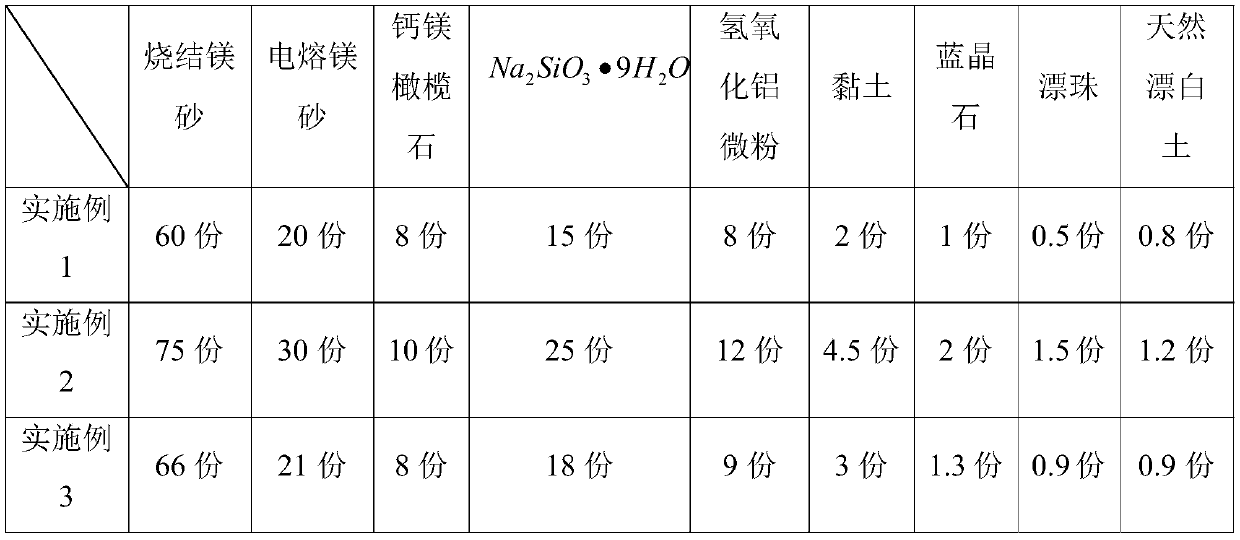

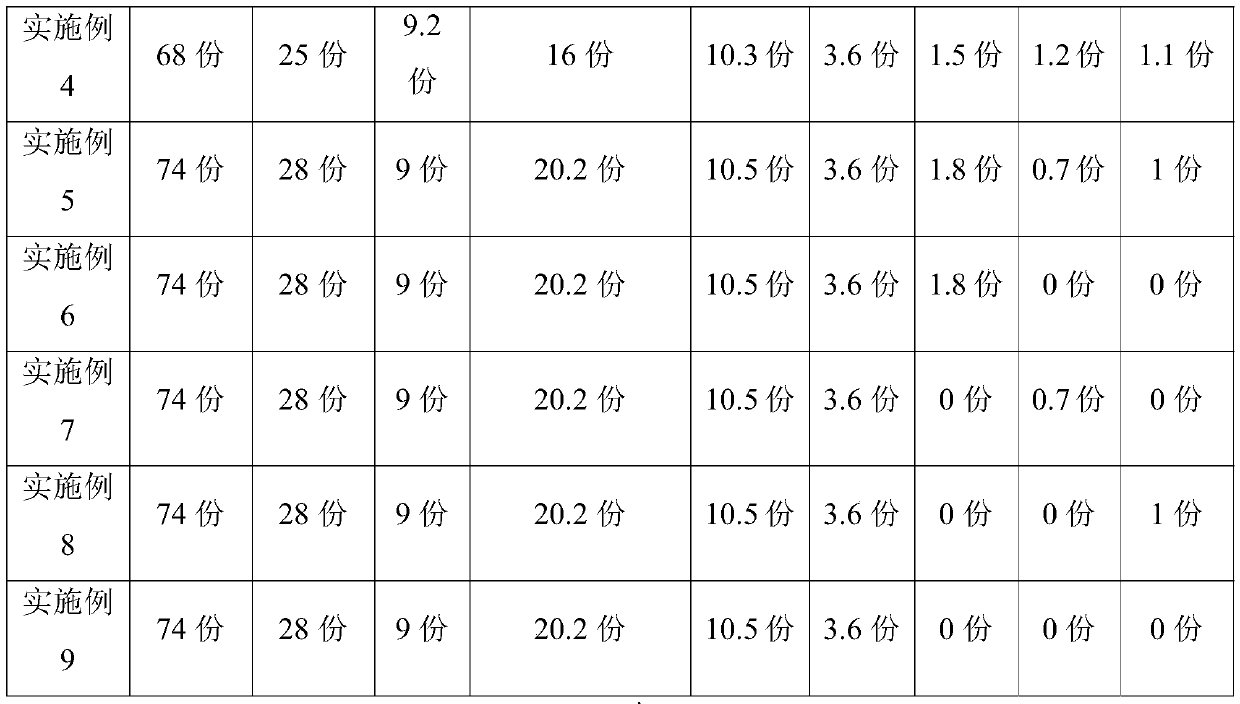

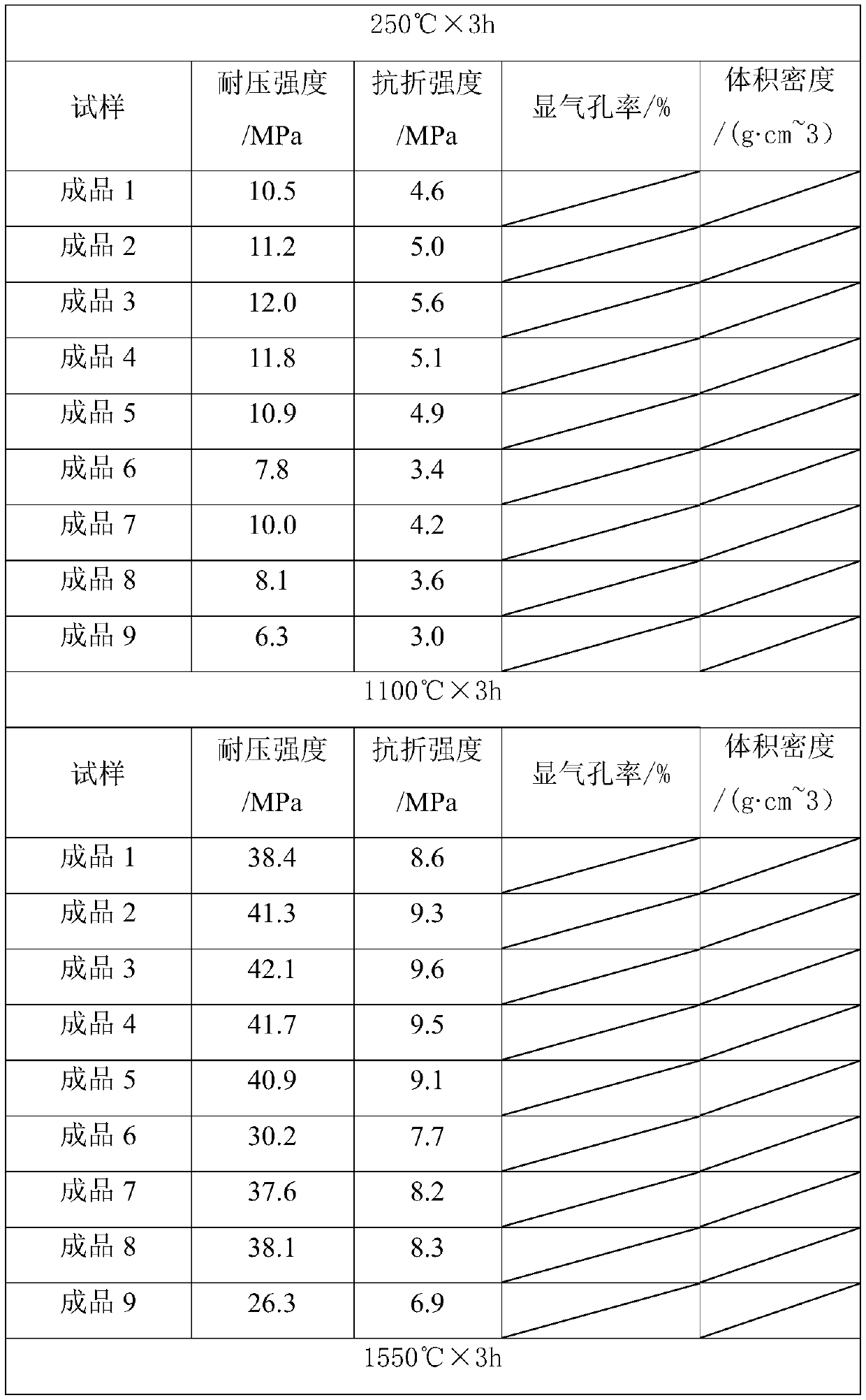

Environment-friendly magnesian dry material and preparation process thereof

An environment-friendly magnesian dry material comprises sintered magnesia, fused magnesia, calcium forsterite, a binding agent, aluminum hydroxide micro powder, a high-temperature sintering agent, anexpanding agent, floating beads and bentonite in a mass ratio of (60-75): (20-30): (8-10): (15-25): (8-12): (2-4.5): (1-2): (0.5-1.5): (0.8-1.2). According to the invention, the proportion of each component of the dry material is optimized; by adopting the environment-friendly binding agent, the problem that the binding agent is decomposed into toxic and harmful substances under a high-temperature condition can be effectively solved, the dry material is more energy-saving and environment-friendly, the hardness requirement of the dry material in the using process can be ensured on the premisethat the dry material has no pungent smell in the using process and is more beneficial to the production environment, and the scouring resistance of the dry material is ensured.

Owner:浙江欣辉耐火材料股份有限公司

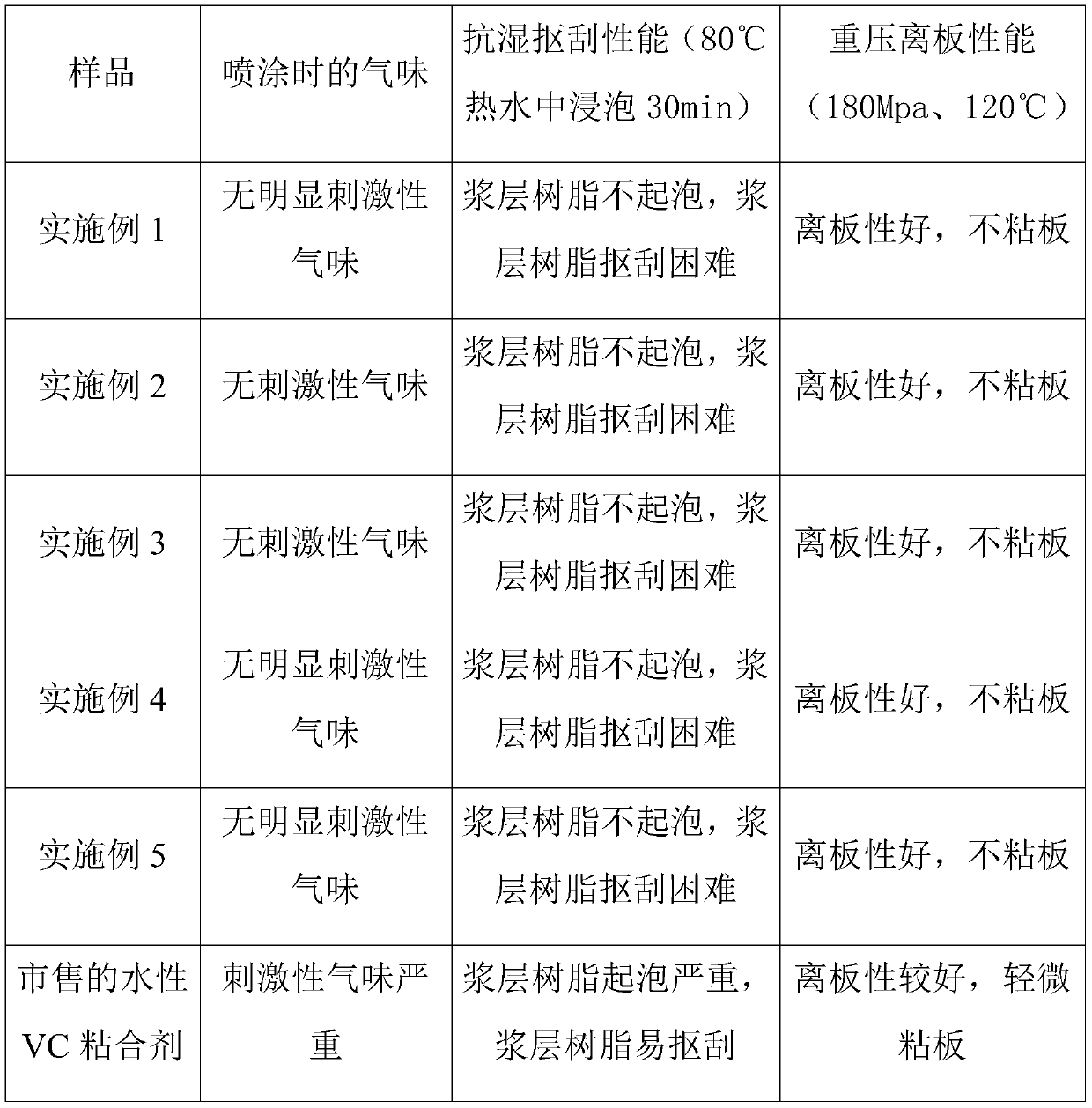

Leather isolating layer finishing agent, preparation method thereof, and leather

ActiveCN109880504AGood wet scratch performanceWill not pollutePolyurea/polyurethane coatingsEpoxy resin coatingsWater basedEpoxy

The invention discloses a leather isolating layer finishing agent, a preparation method thereof, and a leather. The preparation method of the leather isolating layer finishing agent comprises the following steps: reacting 10-25 parts of isocyanate, 10-20 parts of diol and 1-3 parts of a hydrophilic chain extender at 70-90 DEG C for 1-4 h, adding 0-5 parts of an organic solvent, cooling the obtained solution to 40-50 DEG C, adding 1-3 parts of an organic alkali and 150-200 parts of water, performing uniform dispersion, then adding 1-2.5 parts of an amine chain extender to extend the chain, andstirring and reacting the obtained solution for 1-2 h to obtain waterborne polyurethane containing an amino group in the terminal group; and taking 40-70 parts of the waterborne polyurethane, adding 30-60 parts of water-based epoxy resin, and stirring and reacting the obtained mixture for 3-5 h. Zero amount or a very small amount of an organic solvent is added in the preparation process of the leather isolating layer finishing agent, so the finishing agent has no irritating smell when sprayed, and has no environmental pollution; and the finishing agent is applied to the leather isolating layerto make the leather isolating layer have good wet squeegee performance and heavy pressure off-board property, and does not stick to the board.

Owner:SHANGHAI GOLD LION CHEM CO LTD

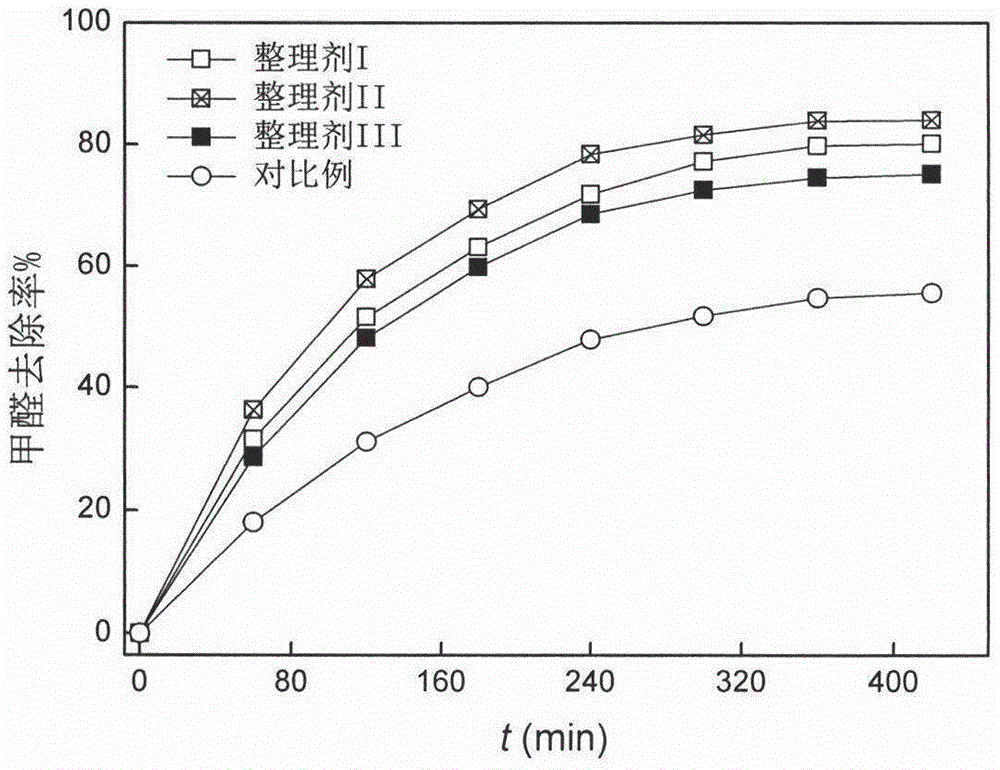

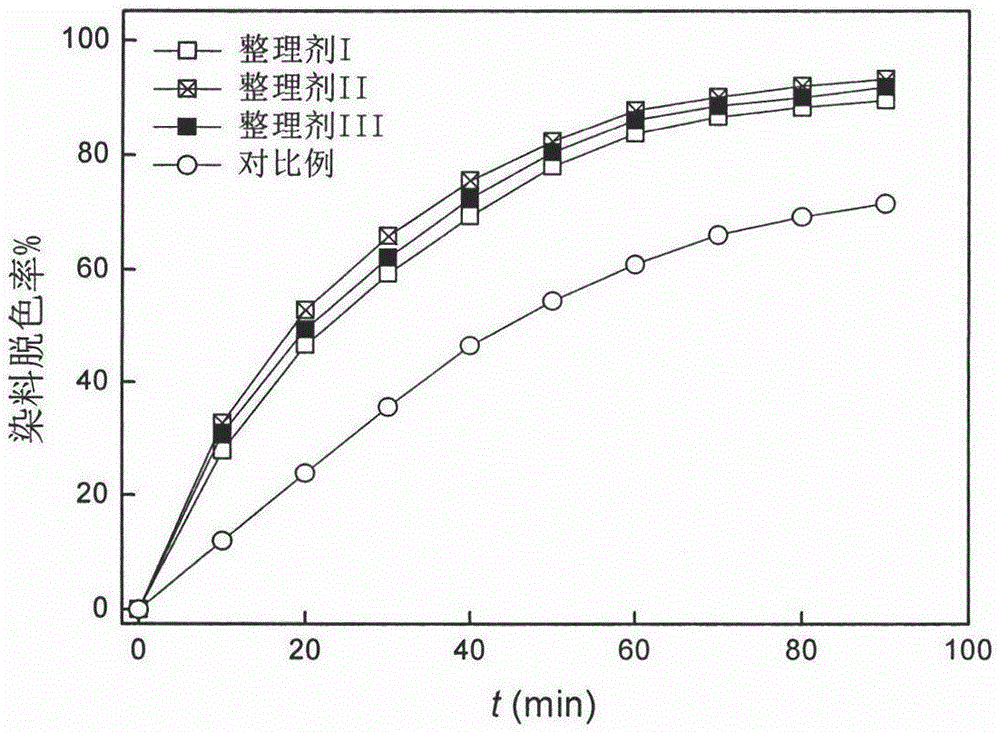

Preparation method of environment purifying finishing agent based on nano-titanium dioxide hydrosol

InactiveCN105561962ALittle damage to fiber mechanical propertiesEasy to useGas treatmentPhysical/chemical process catalystsOrganic acidEnvironmental chemistry

The invention relates to a preparation method of an environment purifying finishing agent based on a nano-titanium dioxide hydrosol, and is characterized in that the method mainly comprises the steps of reduced pressure distillation process, organic acid esterification, addition of a non-ionic surfactant, addition of a coupling agent KH570, regulation of pH and posttreatment process, wherein an organic acid can be formic acid, acetic acid, butyric acid and the like, and the addition amount is 4 g / L to 10 g / L; the surfactant can be OP-10, peregal O, JFC and the like, and the addition amount is 2 g / L. In the obtained environment purifying finishing agent, the content of nano-titanium dioxide is 1.0%, and the n-butanol residual amount is less than 0.05%; the environment purifying finishing agent can be loaded on a fiber fabric through a common rolling baking method, so that the fabric has better catalytic degradation performance on formaldehyde and other pollutants in air and organic pollutants in water bodies.

Owner:TIANJIN POLYTECHNIC UNIV

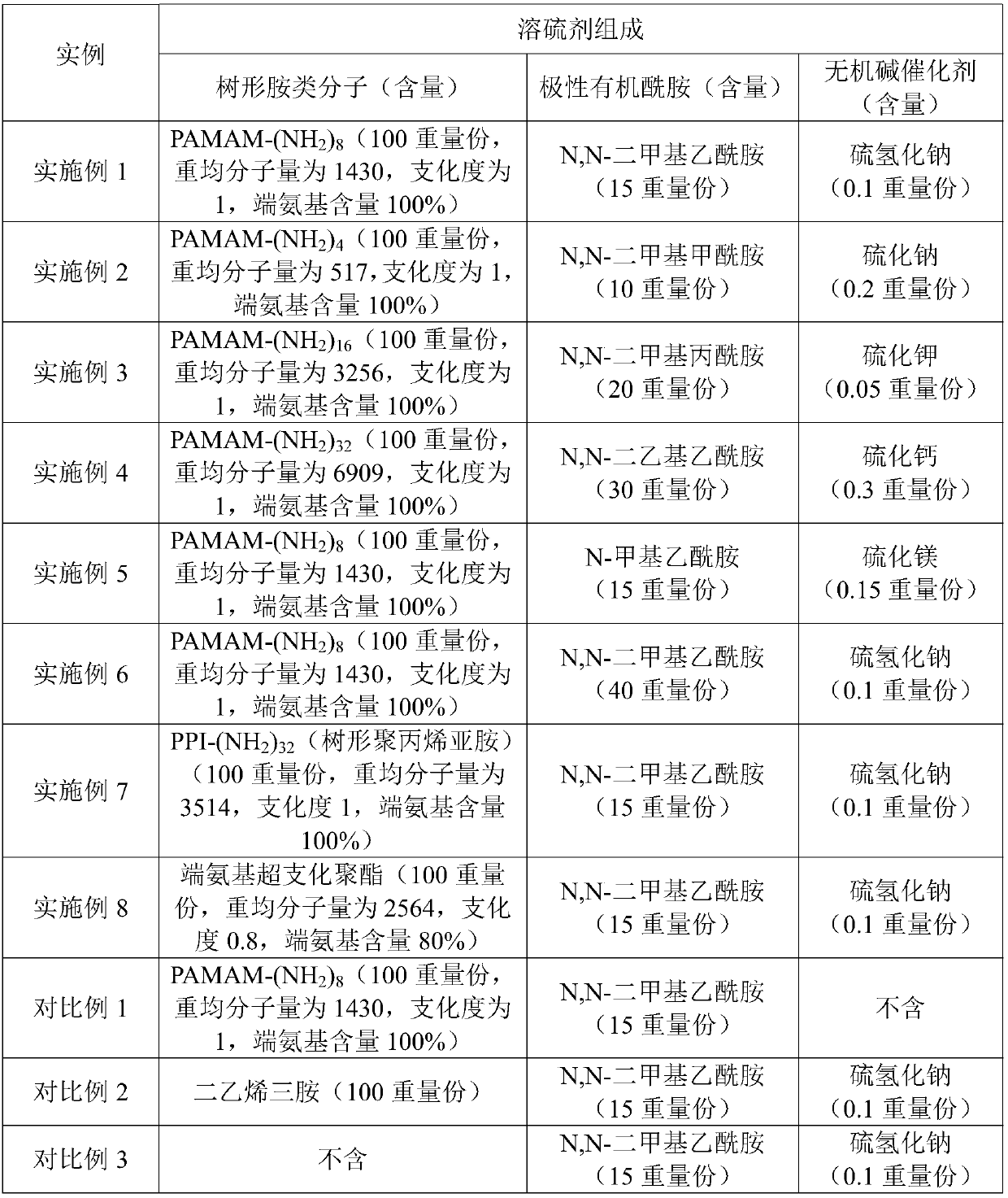

Sulfur dissolving agent and preparation method and application thereof

ActiveCN110964492AImprove sulfur dissolving abilityNon-volatileDrilling compositionPolymer scienceEnd-group

The invention relates to a sulfur dissolving agent and a preparation method and application thereof. The sulfur dissolving agent contains a highly branched polymer, a polar physical solvent and an inorganic base catalyst, wherein the branching degree of the highly branched polymer is 0.8-1, the molecular weight of the highly branched polymer is 400-10000, and the ends group of the highly branchedpolymer contain 70-100 mol% of amino groups. The sulfur dissolving agent contains the highly branched polymer, and the highly branched polymer structurally contains a large number of branched units, has a large number of end groups, contains a large number of amino groups in the end groups, so the sulfur dissolving capacity of the sulfur dissolving agent is effectively improved, and the polymer isfree of volatility and pungent smell, safer in use and friendlier to environment. The method for preparing the efficient sulfur dissolving agent is simple and convenient in process, can prepare the sulfur dissolving agent only by one-step room-temperature stirring and mixing, and is convenient for preparation and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Chain anti-rust lubricating grease and preparation method thereof

The invention discloses chain anti-rust lubricating grease. According to the scheme, the lubricating grease comprises, by mass, 44.0-65.0% of base oil, 10.0-12.0% of solid paraffin, 3.0-5.0% of petroleum barium sulfonate, 2.0-3.0% of barium dinonyl napthalene sulphonate, 0-5.0% of sorbitan mono-oleic acid esters and 0-40.0% of polyisobutene. According to the technical scheme, the base oil mainly has a lubricating effect, the polyisobutene increases viscosity of the lubricating grease, and the solid paraffin serves as a carrier of the base oil; the special additives including the petroleum barium sulfonate, barium dinonyl napthalene sulphonate and sorbitan mono-oleic acid esters are added, wherein the petroleum barium sulfonate and barium dinonyl napthalene sulphonate mainly have anti-rust and oxidation-resistant effects, the sorbitan mono-oleic acid esters change the surface tension of the lubricating grease, and therefore the lubricating grease can be evenly attached to the surface of a chain.

Owner:苏州铱诺化学材料有限公司

Environment-friendly absorbing wallpaper base film and processing method thereof

ActiveCN108148477ANo irritating tasteGood alkali and mildew resistanceAntifouling/underwater paintsPaints with biocidesSide effectEmulsion

The invention discloses a processing method of an environment-friendly absorbing wallpaper base film. The processing method comprises the following steps of: (1) weighing all raw materials according to a formula; (2) adding tourmaline powder, an adsorbing material, a sodium-polyacrylate dispersing agent and an antibacterial agent into deionized water, and stirring to obtain mixed liquid A; (3) adding high-molecular emulsion into the mixed liquid A, and stirring to obtain mixed liquid B; (4) regulating the pH value of the mixed liquid B to 7-8, filtering, collecting filtrate and obtaining the environment-friendly absorbing wallpaper base film. The environment-friendly absorbing wallpaper base film disclosed by the invention has no irritating smell, has no side effects to a human body, has good alkali resistant and mildew resistance, can form a hard protective film between wallpaper and a wall surface, can improve the bonding force between the wallpaper and the wall surface and has the functions of being waterproof, mildew-resistant and antibacterial and adsorbing VOCs (Volatile Organic Compounds).

Owner:上海奥尔利材料科技有限公司

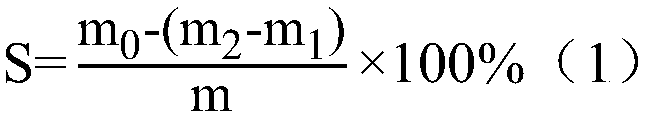

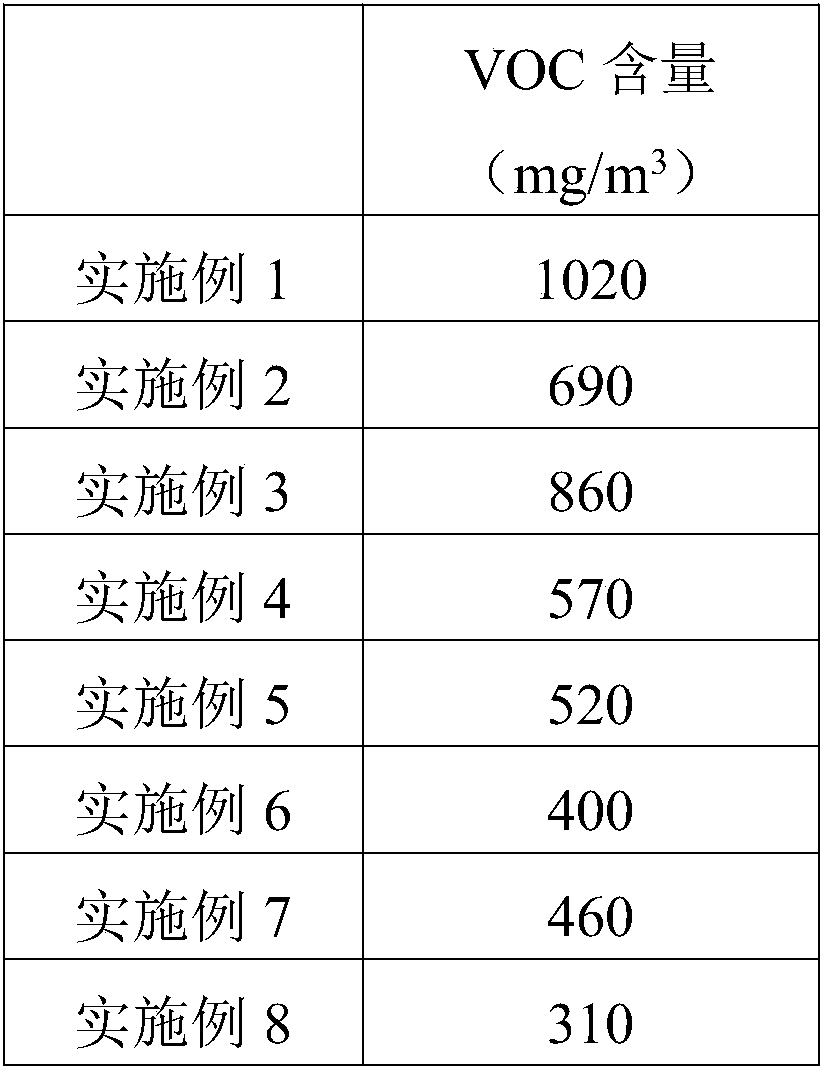

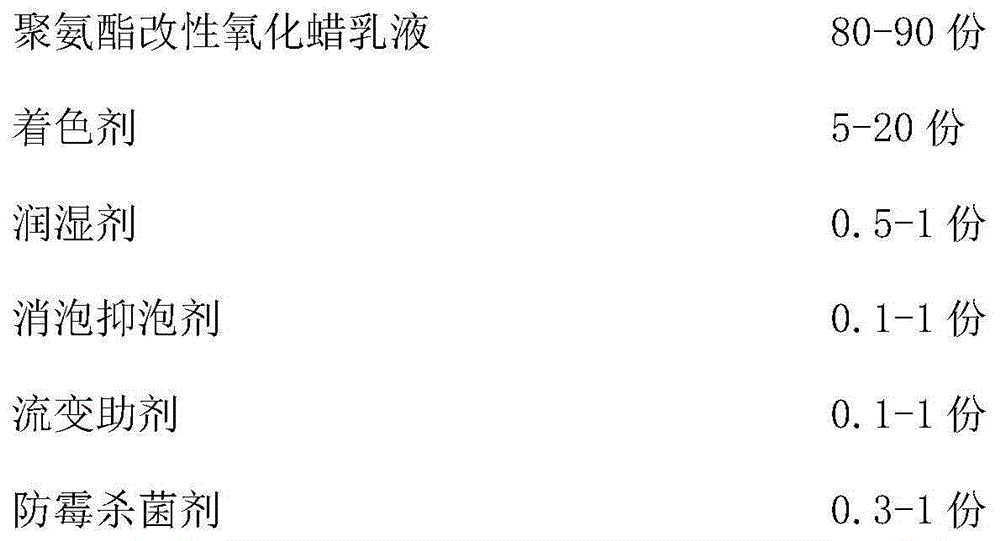

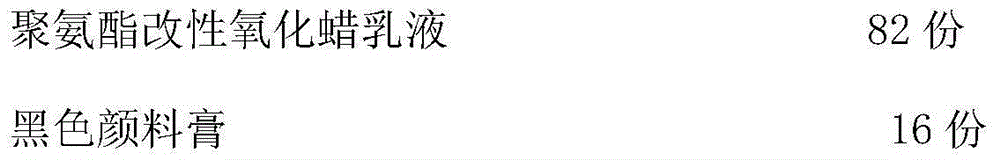

Water-borne wax-emulsion shoe polish finishing agent based on anionic polyurethane modified oxidized wax and preparation method of water-borne wax-emulsion shoe polish finishing agent

ActiveCN106281046AOutstanding and Beneficial Technical EffectsNon-toxicPolishing compositionsShoe polishPolymer chemistry

The invention relates to a water-borne wax-emulsion shoe polish finishing agent based on anionic polyurethane modified oxidized wax and a preparation method of the water-borne wax-emulsion shoe polish finishing agent. The water-borne wax-emulsion shoe polish finishing agent comprises polyurethane modified oxidized wax emulsion, coloring agent, wetting agent, defoaming foam inhibitor, rheological auxiliaries and anti-mildew bactericide. The preparation method includes: sufficiently grinding the coloring agent, the wetting agent and the polyurethane modified oxidized wax according to the mass of the components of the shoe polish finishing agent, stirring and dispersing for 10-40 minutes at the rotation speed of 2000-4000r / minute, lowering the rotation speed to 400-500r / minute, sequentially adding the defoaming foam inhibitor, the anti-mildew bactericide and the rheological auxiliaries, and continuing stirring for 10-20 minutes to obtain the water-borne wax-emulsion shoe polish finishing agent. The water-borne wax-emulsion shoe polish finishing agent is safe, environmentally friendly, nontoxic during use, free of pollution, less prone to combustion, free of offensive smell, good in storage stability, good in adhesive force, excellent in weather resistance and durability, excellent in scrub resistance and waterproof performance, widely applicable to the finishing and maintenance of leather shoes, leather bags, leather coats and the like, and extremely high in environment protection benefit, social benefit and economic benefit.

Owner:浙江芬尼斯工贸有限公司 +1

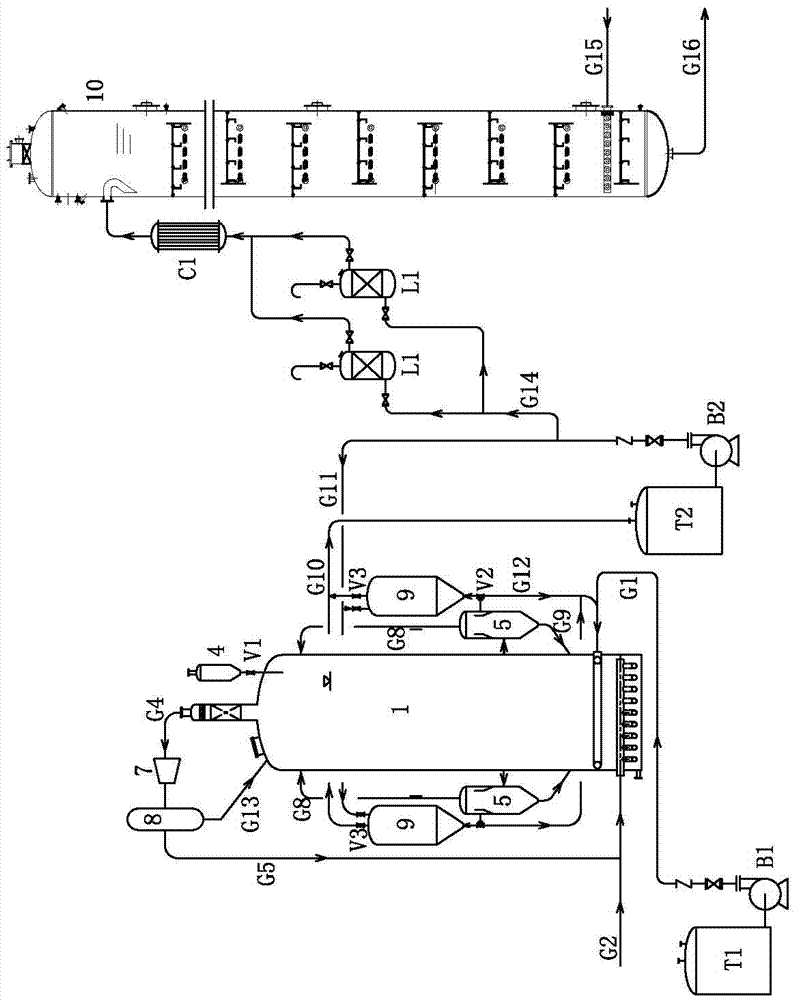

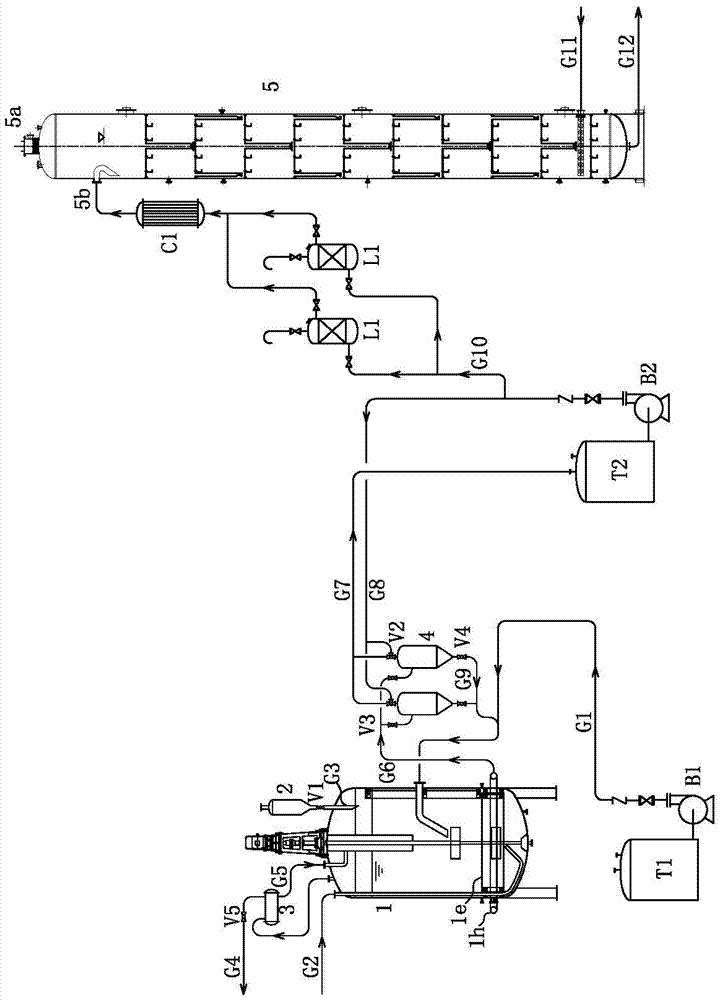

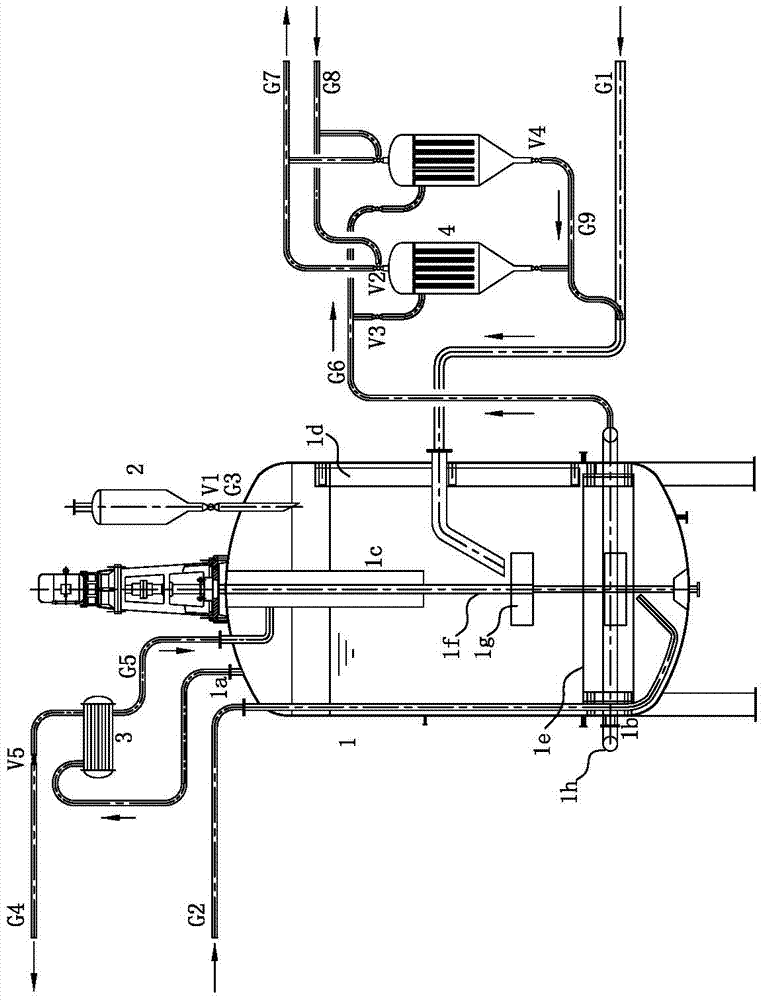

System and method for producing hydrogen peroxide by anthraquinone process

ActiveCN107098317AMix and react quicklyOutflow smoothlyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingWorking fluidProcess engineering

The system of the invention relates to a system and a method for producing hydrogen peroxide by anthraquinone process, the bottom of a working liquid tank is connected with an inlet of a hydrogenation device by a working liquid pump and a working liquid supply pipe, an outlet of the hydrogenation device is connected with a hydrogenation liquid tank, the bottom of the hydrogenation liquid tank is connected with an inlet of an oxidation tower by a hydrogenation liquid pump, a hydrogenation liquid tank output pipe, a hydrogenation liquid filter and a hydrogenation liquid cooler, an outlet of the oxidation tower is connected with an oxidation liquid output pipe, an outlet of a hydrogenation reactor is connected with catalyst filters, outlets of the catalyst filters are respectively connected with a hydrogenation liquid outlet pipe and a hydrogenation reactor working fluid backflush tube; the bottoms of the catalyst filters are connected with the working liquid supply pipe, the working liquid supply pipe is inserted into the inner cavity of the hydrogenation reactor from the middle part, the top of the hydrogenation reactor is in plug connection with a catalyst adding pipe, and a hydrogen supply pipe extends downward to the bottom of the hydrogenation reactor, and bends to extend upward to the lower center of the hydrogenation reactor. The system can be continuous in manufacture, and has low unit consumption of product and high production efficiency.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Environment-friendly EVA/PE foam material not containing formamide and preparation method thereof

The invention discloses an environment-friendly EVA / PE foam material not containing formamide and a preparation method thereof. The foam material is prepared from, by weight, 30-60 parts of resin, 5-10 parts of foaming agent, 10-15 parts of blowing promoter, 1-5 parts of coupling agent and 30-50 parts of filler. The raw materials are evenly mixed and subjected to banburying through a banbury mixer, milling, thinning and sheet discharge are conducted, EVA / PE sheets are obtained, and finally the environment-friendly EVA / PE foam material is prepared by conducting oil pressure plastification foaming on the EVA / PE sheets. The prepared EVA / PE foam material does not contain formamide, is safe and environmentally friendly, and can be widely used for manufacturing sports apparatuses, mattresses, child floors, lifesaving products, high-grade sneakers and the like. The preparation process is simple and convenient, and cost is low.

Owner:FUJIAN SANSHENG IND

Strawberry gray mold control agent and preparation method thereof

The invention discloses a strawberry gray mold control agent and a preparation method thereof, and relates to the technical field of agricultural cultivation. The strawberry gray mold control agent is prepared from, by weight, 25-30 parts of roots and leaves of rumex madaio makino, 15-20 parts of leaves of panax notoginseng, 13-17 parts of tobacco straw, 10-15 parts of radix sophorae tonkinensis, 10-15 parts of Chinese alangium roots, 8-13 parts of common threewingnut roots, 6-10 parts of common carpesium fruit, 5-8 parts of dried ginger, 5-8 parts of fructus gleditsiae abnormalis, 4-7 parts of camellia olelfera abel, 3-6 parts of mineral powder, 3-6 parts of semen allii tuberosi, 2-4 parts of semen ricini, 0.5-1 part of chromium trichloride and 0.5-1 part of nanometer zinc oxide. The control agent is mild in taste, free of pungent taste and high in pesticide effect, diseases can be thoroughly eradicated by spraying the strawberry gray mold control agent on diseased or infected plants two times to three times, the pesticide effect of the control agent is further improved by means of sterilization of the mineral powder, the pesticide effect is prolonged, the application frequency is decreased, and the planting labor capacity and the cost are reduced.

Owner:固镇玉鹏生态农业文化园有限公司

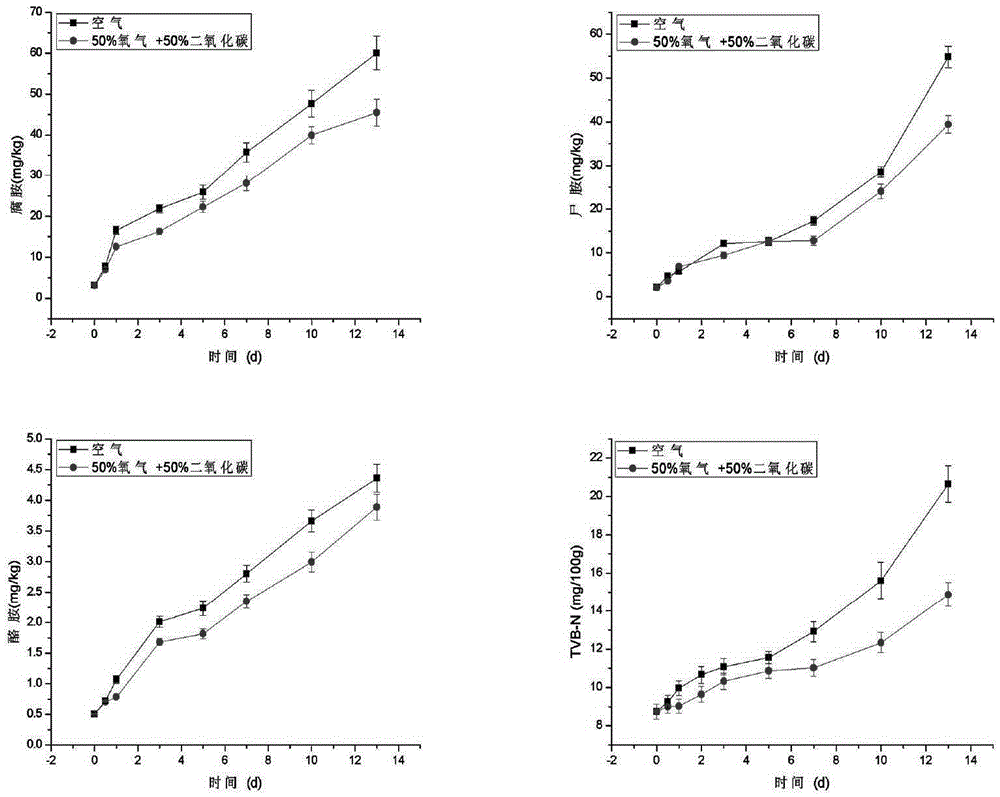

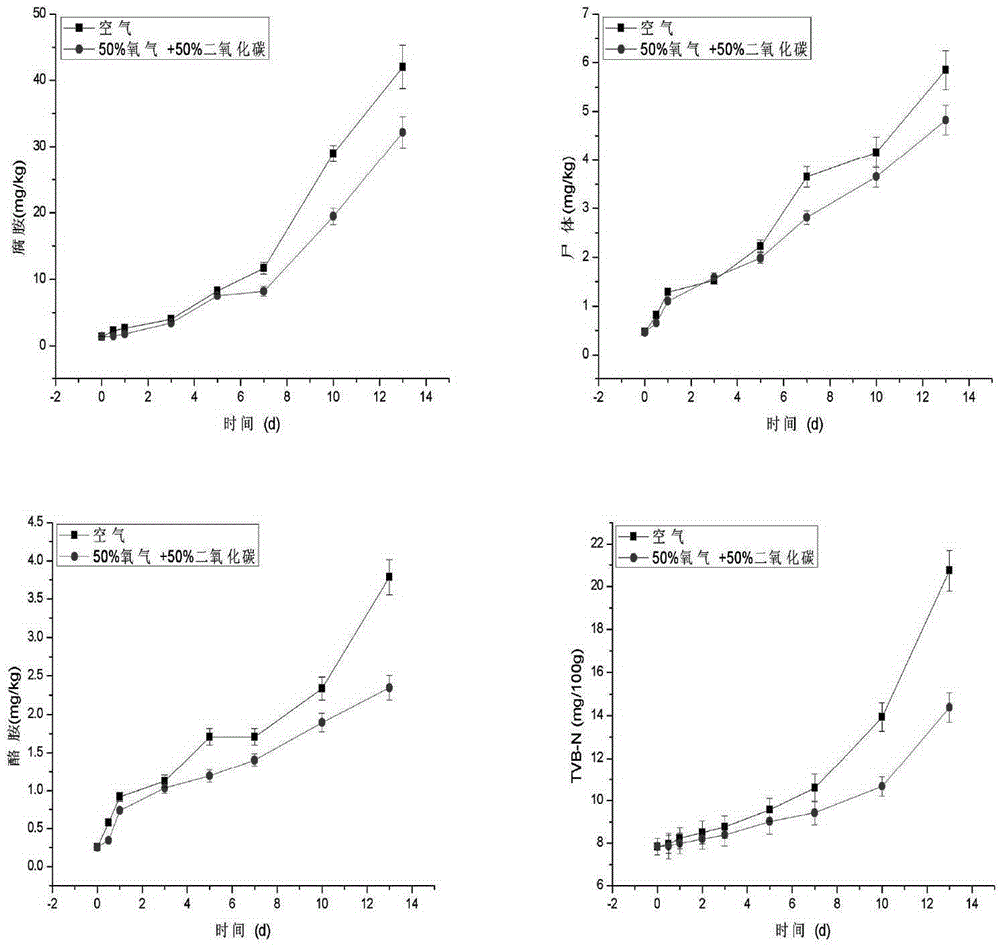

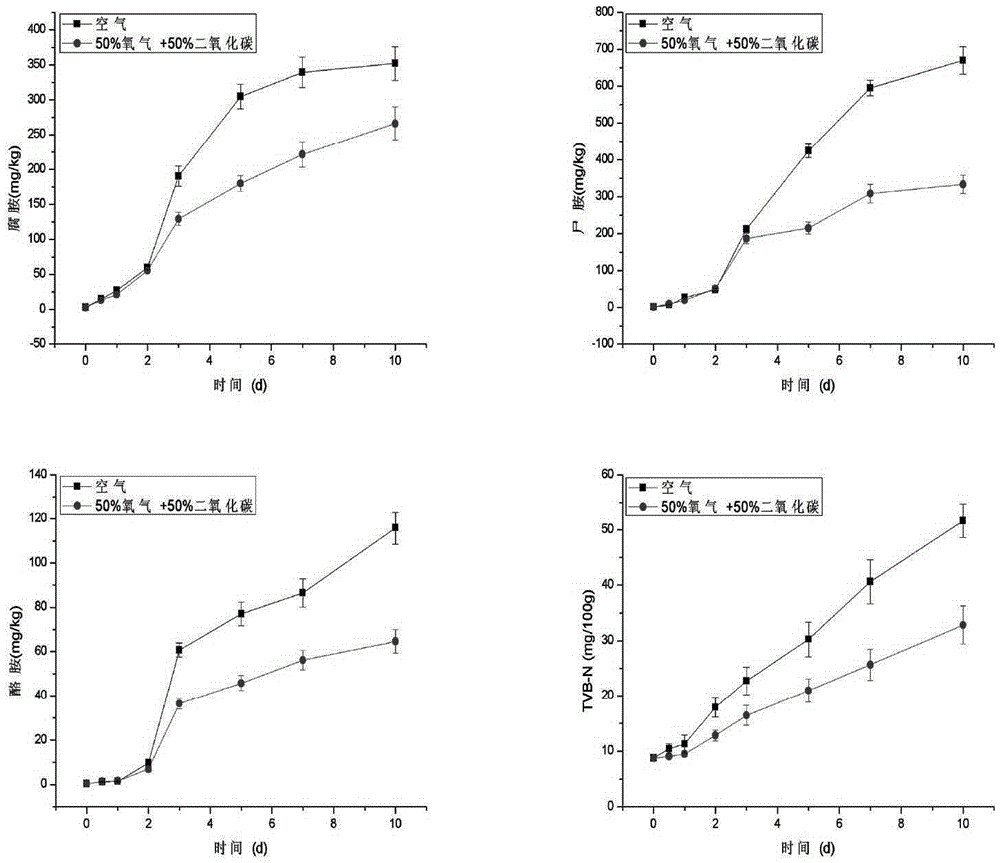

Modified atmosphere package capable of delaying deterioration of livestock meat and detection method of deterioration of livestock meat

InactiveCN105285059AGood colorGood taste substancesMeat/fish preservationComponent separationAnimal scienceAlcohol

The invention discloses modified atmosphere package capable of delaying deterioration of livestock meat and a detection method of the deterioration of the livestock meat. The modified atmosphere package and the detection method are realized through the following steps of: performing acid discharge on the livestock meat for 48 hours at 0-4 DEG C, cleaning the livestock meat after acid discharge with alcohol, and performing ultraviolet sterilization treatment; putting packed samples in a modified atmosphere package box which is cleaned with the alcohol and on which ultraviolet sterilization disinfection treatment is performed, and performing modified atmosphere packaging by using a modified atmosphere packaging machine; immediately putting the modified atmosphere package sample box which is inspected to be intact in an incubator shaking box of 3-25 DEG C, and stimulating a logistic transportation link; and taking samples, detecting the content of biogenic amine and total volatile basic nitrogen, and judging the freshness of the livestock meat. According to the modified atmosphere package and the detection method disclosed by the invention, the modified atmosphere package is combined with the incubator shaking box for stimulating the logistic transportation mode, so that the deterioration of the livestock meat is delayed, the quality guarantee period from the production process link to the consumption link is prolonged, and the damage of the deterioration of the livestock meat to human bodies or environment is reduced.

Owner:重庆玉成产品质量检测有限公司 +1

Antibacterial bed sheet disinfectant

InactiveCN104824056AImprove the bactericidal effectImprove disinfection effectBiocideDisinfectantsBiotechnologySodium bicarbonate

The invention discloses an antibacterial bed sheet disinfectant, which is prepared from the following raw materials in parts by weight: 3-5 parts of sodium bicarbonate, 2-4 parts of rheum officinale, 3-6 parts of purslane, 1-2 parts of alkylolamides, 2.5-4.6 parts of sodium carboxymethylcellulose, 1.2-1.9 parts of citrate, 6-12 parts of cordate houttuynia, 4-8 parts of a grapefruit extract, 3-7 parts of a disinfectant, 3-6 parts of polyethylene glycol, 15-25 parts of lysozyme, 20-40 parts of distilled water, 4-8 parts of isopropyl alcohol, 2.5-4.5 parts of serrate chloranthus herb and 5-7 parts of fructus cnidii. The antibacterial bed sheet disinfectant has the beneficial effects that the antibacterial bed sheet disinfectant has good bactericidal activity and disinfecting property, is free of an irritating smell, and is free of an effect on a human body and environment.

Owner:青岛千帆高新技术有限公司

Rubber floor

The invention discloses a rubber floor. The rubber floor is prepared from the following raw materials in parts by weight: 30-60 parts of black natural emulsion reclaimed rubber, 15-30 parts of white emulsion, 5-20 parts of transformer oil, 20-50 parts of porcellanite, 10-30 parts of high styrene, 0.6-1 part of urea formaldehyde, 0.8-1 part of a pore-foaming agent H, 2-3 parts of a rubber coloring agent and 2 parts of a vulcanizing agent. The rubber floor disclosed in the invention does not have toxicity, irritant flavor, heavy metal or harmful ingredients, and conforms to the EU standard; the rubber floor has very good acid and alkali resistance and antioxidant ability, and further has dampproof, waterproof, anti-skidding and ground chill isolating effects; meanwhile, the rubber floor is relatively good in elasticity, high in comfort, low in cost and convenient in use, and can be widely applied to families, plants, public places, exercise and fitness places and the like. According to the rubber floor, a physic mechanical method is adopted to obtain the black emulsion reclaimed rubber, the manufacturing process is simplified, and the cost of the product is reduced by a large margin.

Owner:青岛丽安防护新材有限公司

Rice wine prepared from various grain species

InactiveCN105112224ANo irritating tasteHigh protein contentAlcoholic beverage preparationYeastAlcohol

The invention relates to the field of food, in particular to rice wine prepared from various grain species. The rice wine is prepared from the following raw materials in parts by weight: 10-20 parts of pea, 10-20 parts of barley, 20-30 parts of distiller's yeast, 50-70 parts of rice, 30-60 parts of sorghum rice, 30-60 parts of corn, 10-30 parts of panicum miliaceum, and 70-120 parts of millet. The rice wine is prepared through the steps of grinding the raw materials into powder, adding 200-500 parts of water, and fermenting at the temperature of 25 DEG C for 36 hours. Compared with the prior art, the rice wine has the benefits as follows: the protein content is high, the mouth feel is good, the pungent taste of alcohol is avoided, the rice wine is mellow, fragrant and full-bodied, and the manufacture time is short.

Owner:刘春华

Health-care beer and preparation method thereof

InactiveCN107446735ADrink in moderationHas health benefitsBeer fermentationDigestive systemHigh-fructose corn syrupLycium chinense

The invention relates to health-care beer and a preparation method thereof. The traditional maca products have the problems of complex taking process, low component utilization rate and bad taste. The health-care beer provided by the invention comprises a maca component and a medlar component. The health-care beer particularly is prepared from the following raw materials in parts by weight: 48 to 52 parts of barley malt, 0.3 to 0.4 part of lupulus, 3 to 4 parts of high fructose corn syrup, 0.1 to 3 parts of maca, 2 to 3 parts of beer yeast, 0.1 to 5 parts of medlar and 300 to 1000 parts of water. The invention further provides a preparation method of the health-care beer. According to the method, the maca and the medlar are added at the later stage of brewing the beer, low-temperature fermentation and soaking are conducted for 25 to 47 days, and the nutritional components in the maca and the medlar are completely immerged into the original beer. The health-care beer has a health-care effect and has the effects of nourishing and maintaining bodies. Compared with the traditional maca products, the health-care beer has the advantages of being convenient to take, high in utilization rate of nutritional components, good in taste and the like, and is suitable for most people to drink.

Owner:徐宝松

Preparation method of thermal insulation material

InactiveCN105967633ALight in massImprove thermal insulation performanceThermal insulationReaction temperature

The invention relates to a preparation method of a thermal insulation material. The material comprises the following raw materials: 30-50 parts of basalt powder, 10-15 parts of perlite powder, 5-10 parts of rutile titanium dioxide, 5-8 parts of ceramic powder, 1-5 parts of calcium oxide, 1-5 parts of sodium nitrate, and 1-3 parts of a smell removing agent. The basalt powder, the perlite powder, the rutile titanium dioxide, the ceramic powder, calcium oxide, and sodium nitrate are mixed and injected into a reaction vessel, the reaction temperature is 85-105 DEG C, after sodium nitrate is fully dissolved, the smell removing agent is added with stirring, the reaction is stopped, and cooling is carried out. The method has the advantages of simple process and short production period; warming plates prepared by the material has the advantages of light mass, good thermal insulation effects without toxicity and stimulating smell, and wide application range.

Owner:LUOYANG DEWEI ELECTROMECHANICAL TECH CO LTD

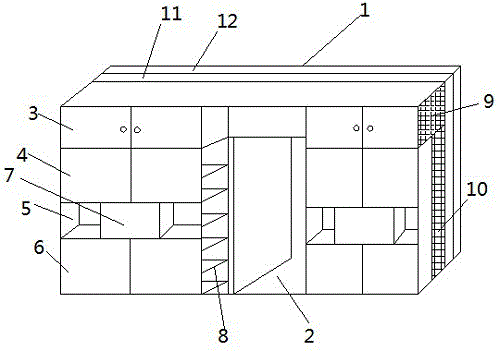

Heat preservation and insulation wall body structure of architectural decoration

The invention discloses a heat preservation and insulation wall body structure of architectural decoration. The heat preservation and insulation wall body structure comprises a wall body and a door, wherein the door is arranged below the middle part of the wall body; decorative cabinets are arranged at positions, which are located on two sides of the door, on the wall body; the decorative cabinets comprise top cabinets, upper glass sliding-door cabinets, landscape grooves, lower glass sliding-door cabinets and partition grooves; the upper glass sliding-door cabinets are arranged below the top cabinets; and the landscape grooves are formed below the upper glass sliding-door cabinets. The wall body is fixedly connected with the decorative cabinets through pre-buried fixing pieces, and the decorative cabinets comprise the top cabinets, the upper glass sliding-door cabinets, the landscape grooves, the lower glass sliding-door cabinets and the partition grooves, and landscape fish tanks are arranged between the landscape grooves, so that storage and decorative ornamenting are realized; by the arrangement of an air purifier and loudspeaker boxes, air purification and multimedia entertainment operation are respectively performed; and furthermore, a heat preservation and insulation layer and a waterproof layer are arranged in the wall body, and a fireproof layer is arranged between the heat preservation and insulation layer and the waterproof layer, so that a good heat preservation effect is achieved, and water and fire can be effectively prevented.

Owner:芜湖浩权建筑工程有限公司

Heat-insulation material of household water flowing pipeline

The invention relates to a heat-insulation material of a household water flowing pipeline. The heat-insulation material comprises the ingredients: a fire retardant, diatomaceous earth, pigment, land plaster, magnesium oxide, magnesium chloride, medical stone, perlite and rock wool and belongs to the technical field of chemical industry. The heat-insulation material is free of toxic chemical release, convenient to paste, capable of directly being pasted on a surface of the water flowing pipeline and capable of natural withering. The heat-insulation material is free of any irritating taste, has the advantages of good heat insulation effect, simplicity in manufacture process, low cost and non-corrosiveness on the pipe surface, can be widely applied to the household water flowing pipeline, can effectively avoid heat loss, and can have effects of preventing frost crack of the pipeline, and the like.

Owner:王敏亮

Novel wear-resistant plastic barbell

The invention relates to a novel wear-resistant plastic barbell. The novel wear-resistant plastic barbell is prepared from the following components in parts by weight: 15 to 18 parts of polyvinyl chloride resin, 3 to 7 parts of zinc oxide, 7 to 9 parts of calcium carbonate powder, 4 to 10 parts of rubber latex powder, 6 to 12 parts of quartz powder, 3 to 7 parts of 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate), 3 to 8 parts of stabilizer, 12 to 23 parts of low-pressure polyethylene, 7 to 12 parts of POE, 10 to 14 parts of tetrapentaerythritol ester, 4 to 6 parts of paraffin, 25 to 35 parts of filling agent, 2 to 4 parts of tribasic lead sulfate, 7 to 8 parts of calcium carbonate, 6 to 9.4 parts of epoxy butyl stearate, 1 to 3 parts of calcium stearate, 4 to 8 parts of dibasic lead sulfate, 4 to 6 parts of dioctyl phthalate, 6 to 13 parts of lead stearate, 20 to 45 parts of polyethylene resin, 5 to 8 parts of carbon black, 3 to 4 parts of paraffin, 5 to 9 parts of sodium antimonite, 8 to 11 parts of nano silicon dioxide, 2.5 to 7 parts of tribasic lead sulfate, 3 to 6 parts of dimethyl siloxane and 30 to 45 parts of PE. The novel wear-resistant plastic barbell is relatively good in hand feeling, high in rate of finished products, and excellent in performance.

Owner:江苏攸途健身器材有限公司

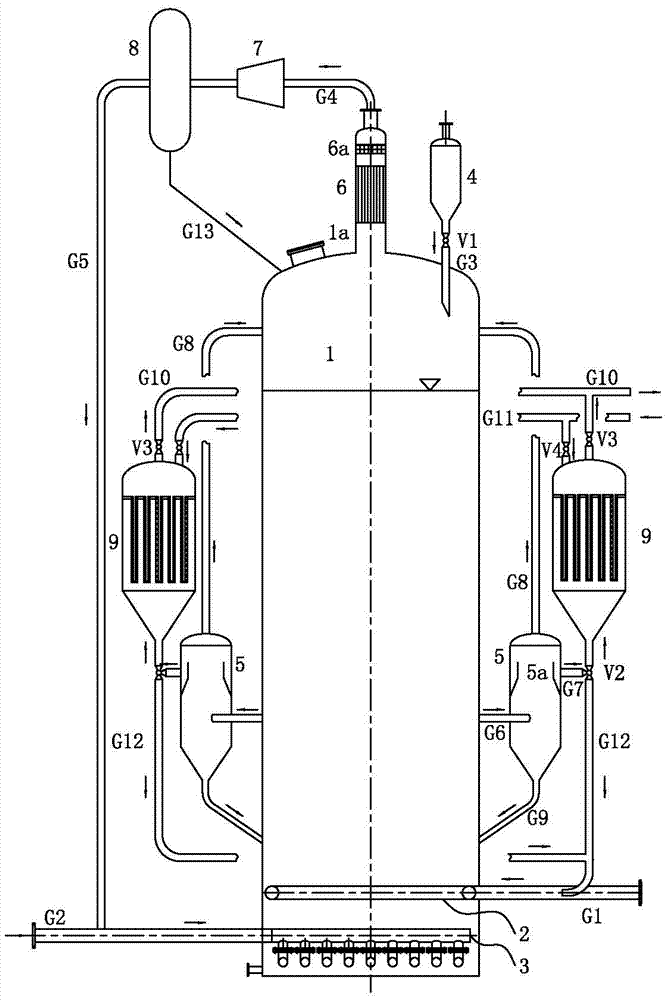

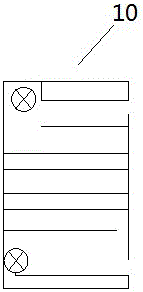

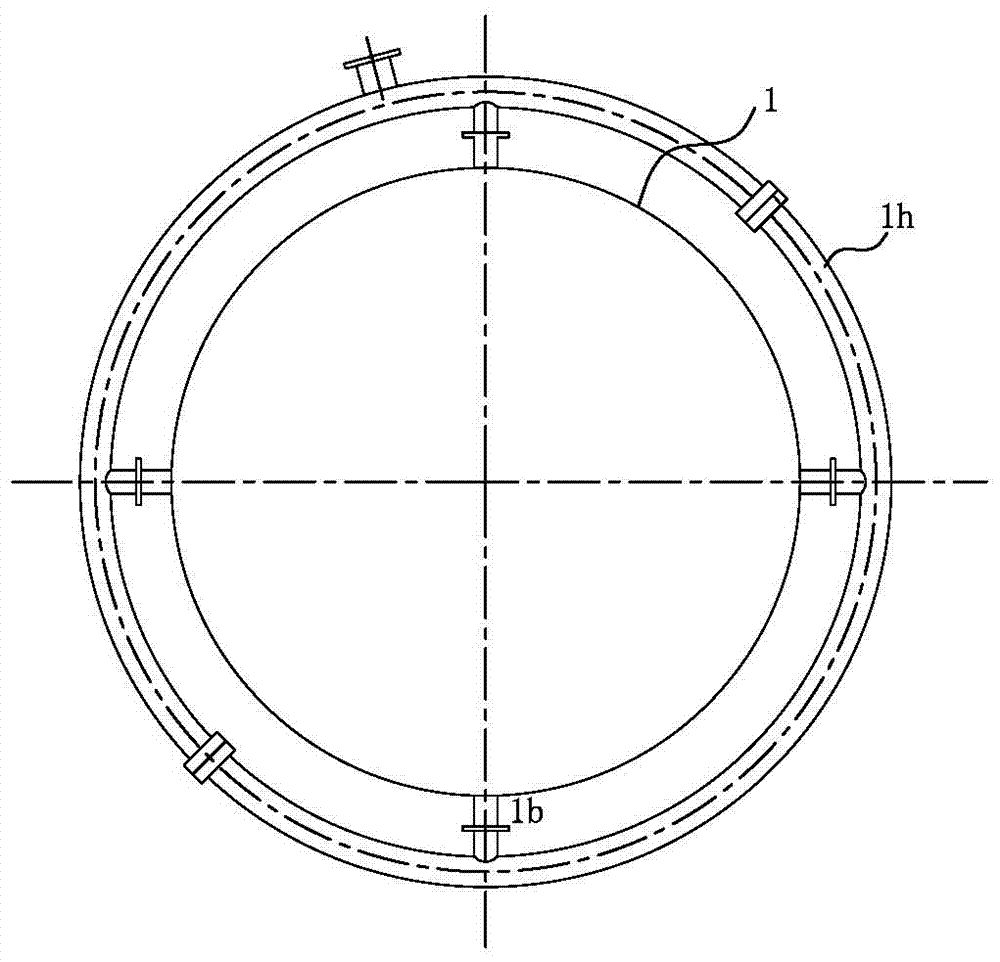

System and method for producing hydrogen peroxide through fluidized bed

ActiveCN107032306ALarge specific surface areaIncrease contact areaPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical recyclingHydrogenation reactionFluidized bed

The invention relates to a system and method for producing hydrogen peroxide through a fluidized bed. The bottom of a working liquid tank is connected with an inlet of a hydrogenation reaction device through a working liquid pump and a working liquid supply pipe; an outlet of the hydrogenation reaction device is connected with a hydrogenated liquid tank; the bottom of the hydrogenated liquid tank passes through a hydrogenated liquid pump, a hydrogenated liquid tank output pipe, a hydrogenated liquid filter and a hydrogenated liquid cooler and is connected with the inlet of an oxidation tower; the outlet of the oxidation tower is connected with an oxidized liquid outlet pipe; the outlet of a hydrogenation reaction kettle is connected with catalyst filters; the outlets of the catalyst filters are connected with a hydrogenated liquid outlet pipe and a hydrogenated liquid working liquid backwashing pipe respectively; and the bottoms of the catalyst filters are connected with a working liquid supply pipe; multiple oxidation tower trays are arranged in the oxidation tower, down-flow openings and down comers are arranged on various layers of oxidation tower trays respectively; and the down-flow openings in odd layers are located in the axis of the oxidation tower, and the down-flow openings in even layers are symmetrically formed and are close to the inner wall of the oxidation tower. The system is capable of achieving continuous production, and is small in floor area, low in unit consumption of a product and high in production efficiency.

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Improved disinfectant specially used for kitchen

InactiveCN104872199ADisinfection hasDisinfectant with antibacterial propertiesBiocideSurface-active non-soap compounds and soap mixture detergentsPhosphorous acidTriclosan

The invention relates to an improved disinfectant specially used for a kitchen. The disinfectant is prepared from the following raw materials in parts by weight: 4-8 parts of propylene glycol ether, 3-6 parts of hyperforin perforatum, 2.5-3.5 parts of zinc sulfate, 3.5-4.2 parts of methyl alcohol, 2.5-4.5 parts of lauric acid, 4-6 parts of terpilenol, 2-4 parts of phosphorous acid trioleyl ester, 3-5 parts of glycerin, 2-7 parts of triclosan, 20-31 parts of water-based polymer gel matrix, 3-6 parts of pseudo-ginseng, 4-7 parts of rhizoma corydalis, 2-5 parts of dandelion and 4-6 parts of artemisia apiacea. The improved disinfectant has the beneficial effects of having the functions of resisting bacteria, disinfecting, decontaminating and cleaning, and being free from pungent smell and environment-friendly.

Owner:QINGDAO GUOHANG XIANGYU TECH SERVICE

High-toughness plastic barbell plate

The invention relates to a high-toughness plastic barbell plate. The high-toughness plastic barbell plate is prepared by, by weight, 23-27 parts of SEBS, 6-9 parts of zinc oxide, 32-38 parts of PP, 5-8 parts of latex powder, 4-7 parts of zinc stearate, 2-5 parts of dodecyl alcohol ester, 6-12 parts of polyphenylene sulfide, 12-23 parts of low-pressure polyethylene, 4-9 parts of dihydroxy alkyl phosphinate, 14-17 parts of tetra-pentaerythritol ester, 5-8 parts of phthalate anhydride, 23-25 parts of filling agent, 6 parts of zinc oxide, 7-8 parts of calcium carbonate, 4-7 parts of melamine cyanurate, 2 parts of polyethylene resin, 3-6 parts of white carbon black, 5-7 parts of dioctyl phthalate, 33-36 parts of high-pressure polyethylene, 23-45 parts of polyethylene resin, 21-32 parts of polyethylene resin and 9-11 parts of nano silicon dioxide. The plastic barbell plate is good in touch, high in yield, excellent in performance, free of irritant smell and beneficial to health.

Owner:江苏攸途健身器材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com