Moisture-curing polyurethane hot melt adhesive for automobile lighting and preparation method thereof

A polyurethane hot melt adhesive and moisture curing technology, which is applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problem of unsatisfactory operation time, short opening time of hot melt adhesive, and long bonding process and other problems, to achieve the effect of simple and easy process, easy large-scale production, and low sizing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

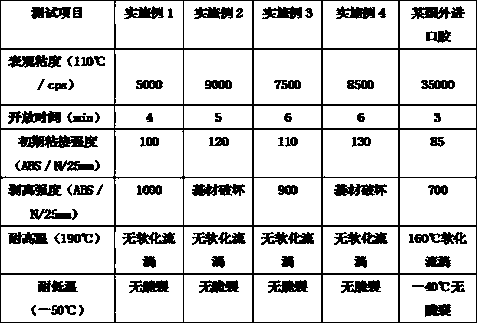

Examples

Embodiment 1

[0014] This example provides a method for preparing a moisture-curing polyurethane hot-melt adhesive for car lamps, which specifically includes the following steps: in parts by mass, 39 parts of adipic acid-1,4-butanediol (PBA), 20 parts of polypropylene glycol, 20 parts of polyacrylic acid resin (molecular weight 20,000, Tg of 70°C) and 1 part of 1,4-butanediol as a chain extender are placed in a reactor, heated to 120°C, and stirred Vacuum dehydration for 1 hour, then add 20 parts of MDI, react under stirring for 2 hours, and vacuumize, when the NCO reaches the theoretical value, add 0.001 part of stannous octoate as a catalyst, vacuumize and stir for 30 minutes, and then pass nitrogen protection conditions The product is poured out, sealed and packaged to obtain a moisture-curing polyurethane hot-melt adhesive for car lights.

Embodiment 2

[0016] This example provides a method for preparing a moisture-curing polyurethane hot-melt adhesive for car lamps, which specifically includes the following steps: 29 parts by mass of 1,6-hexanediol adipate (PHA) , 35 parts of polytetrahydrofuran diol, 25 parts of polyacrylic acid resin (molecular weight 50,000, Tg of 50°C) and 1 part of 1,4-butanediol as a chain extender are placed in a reactor, heated to 120°C, Vacuum dehydration under stirring for 1 hour, then add 10 parts of MDI, react under stirring for 2 hours, and vacuumize, when the NCO reaches the theoretical value, add 0.01 part of stannous octoate as a catalyst, vacuumize and stir for 20 minutes, and then introduce The product was decanted under nitrogen protection conditions, sealed and packaged to obtain a moisture-curing polyurethane hot-melt adhesive for car lights.

Embodiment 3

[0018] This embodiment provides a method for preparing a moisture-curing polyurethane hot-melt adhesive for a car lamp, which specifically includes the following steps: 23 parts by mass of 1,6-hexanediol sebacate polyol, 40 parts of polypropylene glycol, 25 parts of polyacrylic acid resin (molecular weight 3000, Tg of 85 ° C) and 2 parts of diethylene glycol as a chain extender are placed in a reaction kettle, heated to 130 ° C, and vacuumed under stirring Dehydration for 1 hour, then add 10 parts of MDI, react under stirring for 2 hours, and vacuumize, when the NCO reaches the theoretical value, add 0.001 part of dimorpholino diethyl ether as a catalyst, vacuumize and stir for 20 min, The product was poured out under nitrogen protection conditions, sealed and packaged to obtain a moisture-curing polyurethane hot-melt adhesive for car lights.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com