Redispersible acrylate hot melt adhesive for paper products and preparation method thereof

A technology of acrylate and methyl methacrylate, which is applied in the field of redispersible acrylate hot melt adhesive for paper products and its preparation, can solve the problem of low cohesive strength of starch adhesive, quality problems of recycled paper products, and deposits remaining in the machine. Moderate problem, to achieve the effect of not easy to oxidize and decompose, improve efficiency and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

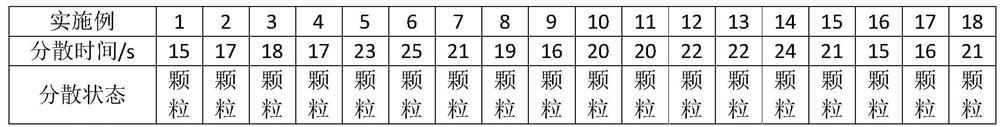

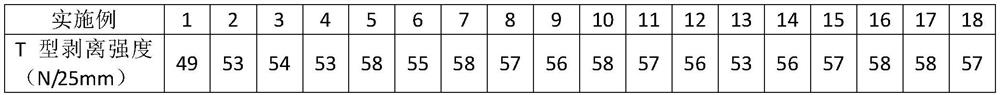

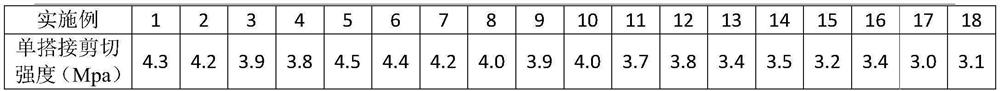

Examples

Embodiment 1

[0029] A kind of redispersible acrylate hot melt adhesive for paper products, its preparation steps are as follows:

[0030] (1) prepare paraffin-modified acrylate polymer:

[0031] S1. Put 25 parts of sliced paraffin and 5 parts of compound emulsifier A in a reaction vessel, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring evenly, add 70 parts of isothermal emulsifier A dropwise to it within 20 minutes. Deionized water, continue to insulate and stir for 40min, obtain paraffin wax emulsion after cooling; Wherein, emulsifier A is the composite emulsifier of alkylphenol polyoxyethylene ether-10 and Span 80 by weight ratio of 11:9;

[0032] S2. Mix and stir 35 parts of deionized water, 0.4 parts of composite emulsifier B and 0.1 part of sodium bicarbonate for 10 to 15 minutes to obtain a mixed solution; wherein, emulsifier B is an alkyl group with a weight ratio of 3.5:1 Compound emulsifier formed by mixing phenol polyo...

Embodiment 2

[0039] A kind of redispersible acrylate hot melt adhesive for paper products, its preparation steps are as follows:

[0040] (1) prepare paraffin-modified acrylate polymer:

[0041] S1. Put 20 parts of sliced paraffin and 5 parts of compound emulsifier A in a reaction container, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring evenly, add 75 parts of isothermal emulsifier A dropwise to it within 20 minutes. Deionized water, continue to insulate and stir for 40min, obtain paraffin wax emulsion after cooling; Wherein, emulsifier A is the composite emulsifier of alkylphenol polyoxyethylene ether-10 and Span 80 by weight ratio of 11:9;

[0042] S2. Mix and stir 37 parts of deionized water, 0.6 parts of composite emulsifier B and 0.2 parts of sodium bicarbonate for 10 to 15 minutes to obtain a mixed solution; wherein, emulsifier B is an alkyl group with a weight ratio of 3.5:1 Compound emulsifier formed by mixing phenol pol...

Embodiment 3

[0049] A kind of redispersible acrylate hot melt adhesive for paper products, its preparation steps are as follows:

[0050] (1) prepare paraffin-modified acrylate polymer:

[0051] S1. Put 15 parts of sliced paraffin and 5 parts of compound emulsifier A in a reaction container, and raise the temperature to 75°C. After the paraffin is completely melted, start stirring. After stirring evenly, add 70 parts of isothermal emulsifier A to it dropwise within 20 minutes. Deionized water, continue to insulate and stir for 40min, obtain paraffin wax emulsion after cooling; Wherein, emulsifier A is the composite emulsifier of alkylphenol polyoxyethylene ether-10 and Span 80 by weight ratio of 8:9;

[0052] S2. Mix and stir 39 parts of deionized water, 0.8 parts of composite emulsifier B and 0.3 parts of sodium bicarbonate for 10 to 15 minutes to obtain a mixed solution; wherein, emulsifier B is an alkyl group with a weight ratio of 3:1 Compound emulsifier formed by mixing phenol poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com