System and method for producing hydrogen peroxide by anthraquinone process

A technology of hydrogen peroxide and anthraquinone method, applied in chemical instruments and methods, peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, etc., can solve the problem of hydrogenation liquid and air Problems such as small contact area, low oxidation efficiency, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

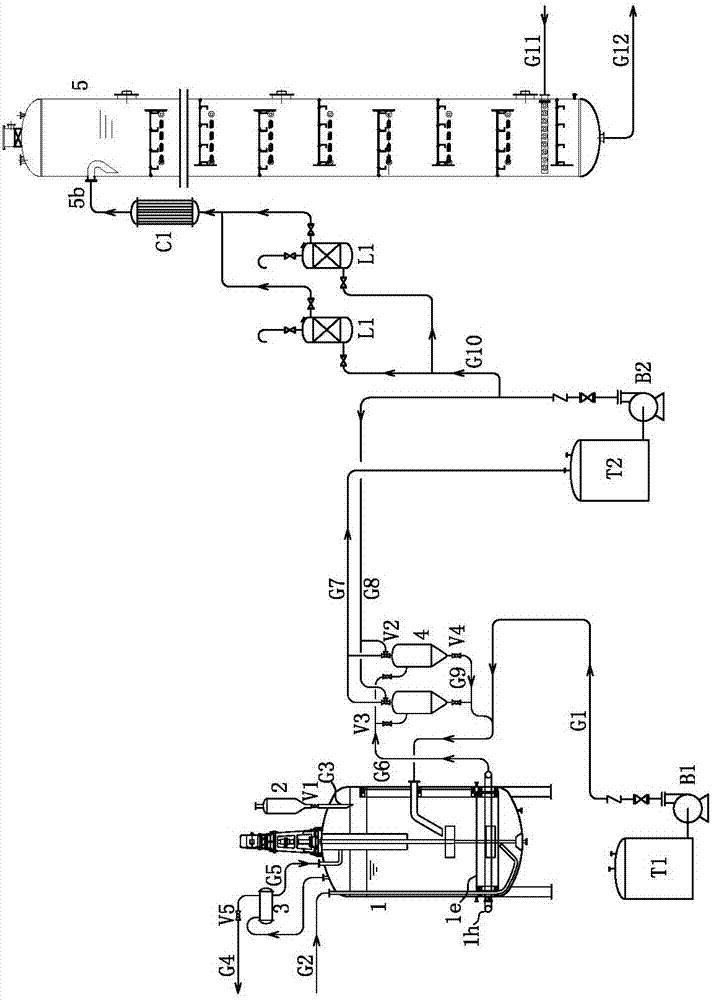

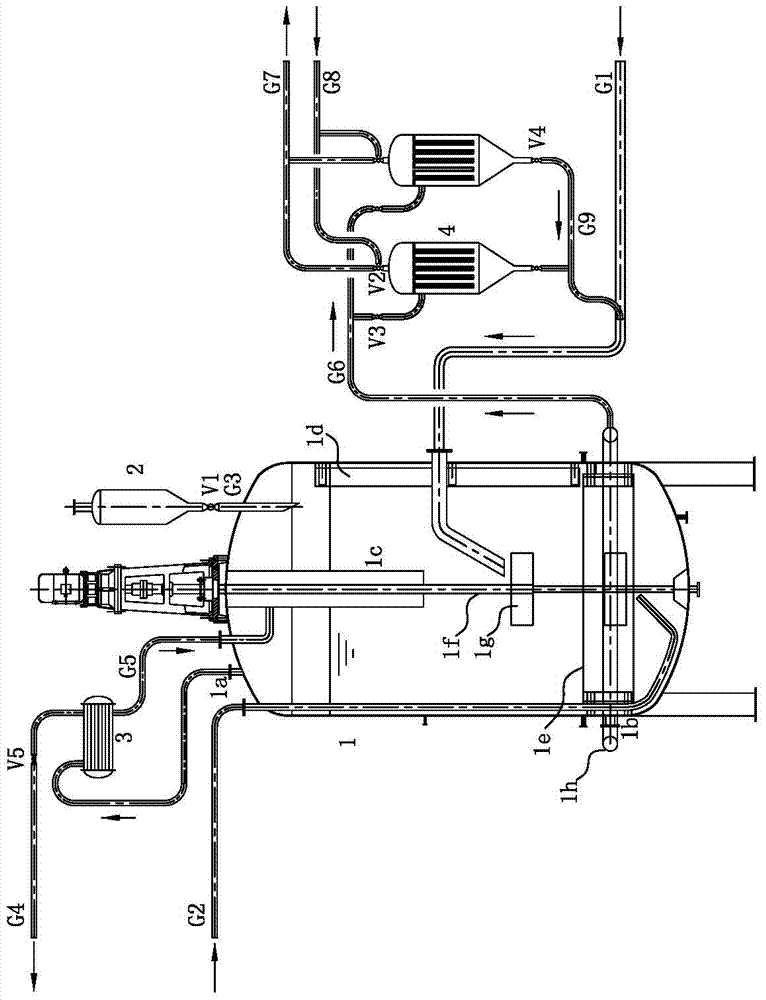

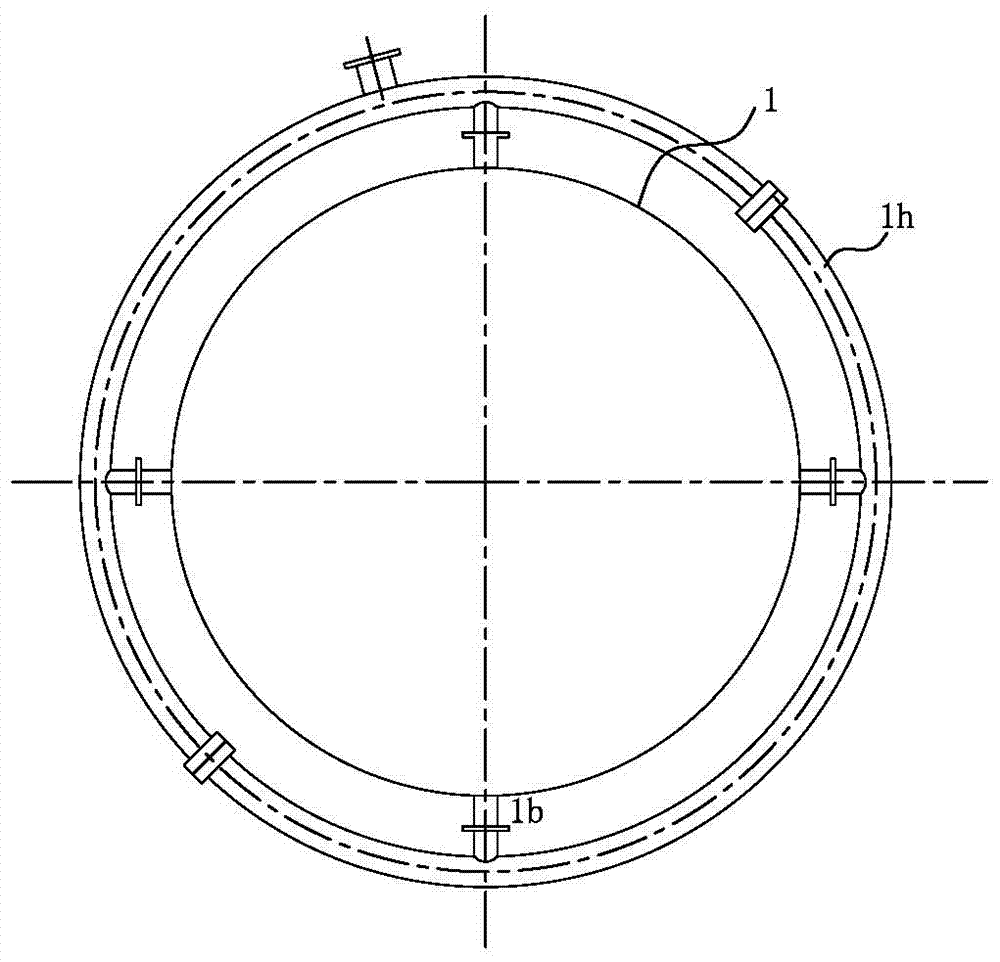

[0033] Such as figure 1 , figure 2 As shown, the system for producing hydrogen peroxide by anthraquinone method of the present invention comprises working liquid tank T1, hydrogenation reaction device, hydrogenation liquid tank T2 and oxidation tower 5, and the bottom of working liquid tank T1 is connected with the inlet of working liquid pump B1, and working liquid The outlet of the pump B1 is connected to the inlet of the hydrogenation reaction device through the working fluid supply pipe G1, the outlet of the hydrogenation reaction device is connected to the hydrogenation liquid tank T2 through the hydrogenation liquid outlet pipe G7, and the bottom of the hydrogenation liquid tank T2 is connected to the inlet of the hydrogenation liquid pump B2 , the outlet of hydrogenation liquid pump B2 is connected to the inlet of oxidation tower 5 through hydrogenation liquid tank output pipe G10, hydrogenation liquid filter L1 and hydrogenation liquid cooler C1, and the outlet of oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com