Environment-friendly absorbing wallpaper base film and processing method thereof

A technology of wallpaper base film and processing method, applied in coating, biocide-containing paint, antifouling/underwater paint, etc., can solve problems such as inability to inhibit mildew of wallpaper glue, harm to human health, wallpaper peeling, etc. Good alkali resistance and mildew resistance, VOC adsorption, and the effect of improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

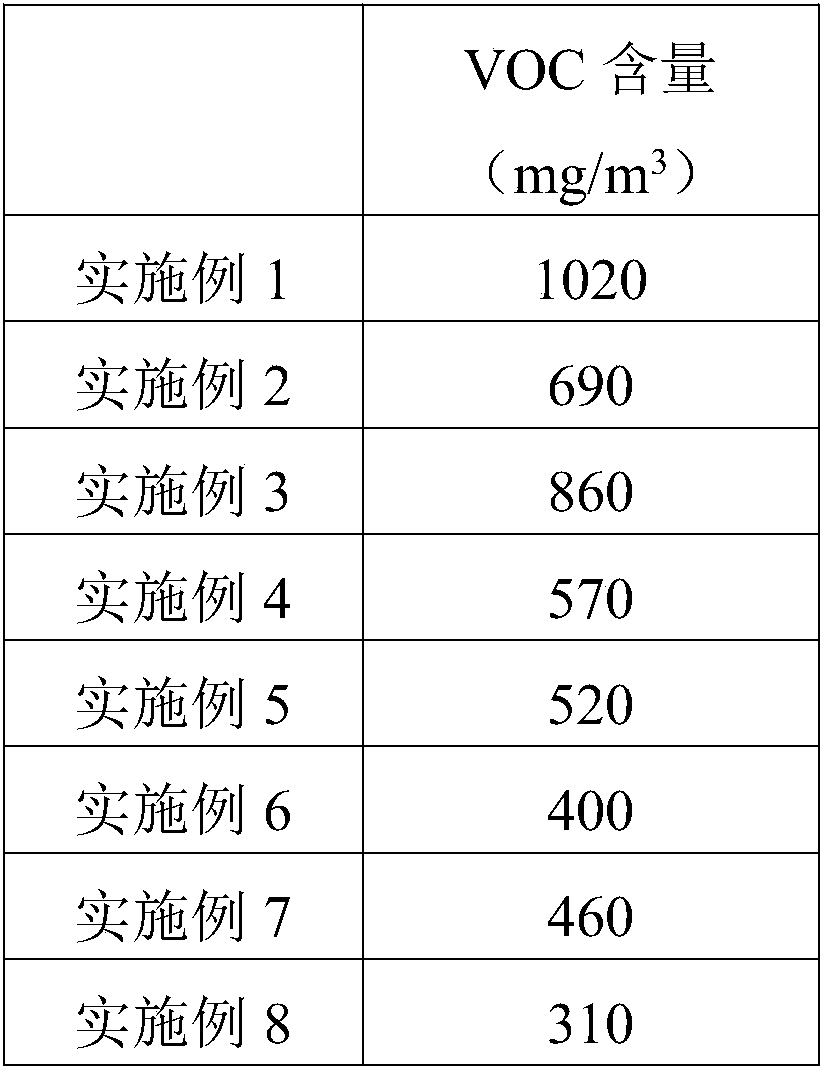

Examples

Embodiment 1

[0069] The processing method of the environmental protection adsorption wallpaper base film comprises the following steps:

[0070] (1) Weigh each raw material according to the formula: 40 parts by weight of polyacrylate emulsion, 70 parts by weight of deionized water, 3 parts by weight of tourmaline powder, 5 parts by weight of zeolite, 0.6 parts by weight of sodium polyacrylate dispersant, potassium sorbate 1 part by weight;

[0071] (2) Add tourmaline powder, zeolite, sodium polyacrylate dispersant, and potassium sorbate to deionized water, and stir at 30°C at a speed of 600 rpm for 45 minutes to obtain a mixed solution A;

[0072] (3) Add polyacrylate emulsion to mixed solution A, and stir at 30°C at a speed of 400 rpm for 60 minutes to obtain mixed solution B;

[0073] (4) Adjust the pH value of the mixture B to 7 with methyldiethanolamine, filter with a 100-mesh filter cloth, collect the filtrate, and obtain the base film of the environment-friendly anti-mold wallpaper....

Embodiment 2

[0075] The processing method of the environmental protection adsorption wallpaper base film comprises the following steps:

[0076] (1) Weigh each raw material according to the formula: 40 parts by weight of polyacrylate emulsion, 70 parts by weight of deionized water, 3 parts by weight of tourmaline powder, 5 parts by weight of porous alumina, 0.6 parts by weight of sodium polyacrylate dispersant, Potassium acid 1 weight part;

[0077] (2) Add tourmaline powder, porous alumina, sodium polyacrylate dispersant, and potassium sorbate to deionized water, and stir at 30°C at a speed of 600 rpm for 45 minutes to obtain a mixed solution A;

[0078] (3) Add polyacrylate emulsion to mixed solution A, and stir at 30°C at a speed of 400 rpm for 60 minutes to obtain mixed solution B;

[0079] (4) Adjust the pH value of the mixture B to 7 with methyldiethanolamine, filter with a 100-mesh filter cloth, collect the filtrate, and obtain the base film of the environment-friendly anti-mold wa...

Embodiment 3

[0081] The processing method of the environmental protection adsorption wallpaper base film comprises the following steps:

[0082] (1) Weigh each raw material according to the formula: 40 parts by weight of polyacrylate emulsion, 70 parts by weight of deionized water, 3 parts by weight of tourmaline powder, 5 parts by weight of carbon nanotubes, 0.6 parts by weight of sodium polyacrylate dispersant, Potassium acid 1 weight part;

[0083] (2) Add tourmaline powder, carbon nanotubes, sodium polyacrylate dispersant, and potassium sorbate to deionized water, and stir at 30° C. at a speed of 600 rpm for 45 minutes to obtain a mixed solution A;

[0084] (3) Add polyacrylate emulsion to mixed solution A, and stir at 30°C at a speed of 400 rpm for 60 minutes to obtain mixed solution B;

[0085] (4) Adjust the pH value of the mixture B to 7 with methyldiethanolamine, filter with a 100-mesh filter cloth, collect the filtrate, and obtain the base film of the environment-friendly anti-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com