Heat preservation and insulation wall body structure of architectural decoration

A technology for thermal insulation and wall structure, which is applied in building components, building structures, buildings, etc., can solve the problems of affecting building construction and use, complicated preparation process steps, and irritating taste, etc., and achieves great application value and technology. Simple, excellent thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

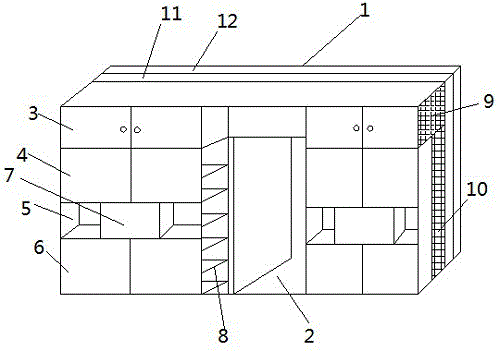

Image

Examples

Embodiment 1

[0026] The preparation steps of the heat insulation layer 11 raw materials are as follows:

[0027] S1: Weigh a certain amount of 45 parts of medium sand, 25 parts of composite light bone admixture, 11 parts of perlite powder, 22 parts of glass fiber, 25 parts of silicone modified epoxy resin, 19 parts of black clay, and azodimethazine 8 parts of amide, 6 parts of fly ash, and 12 parts of synthetic rubber are pulverized through a pulverizer respectively, passed through an 80-mesh sieve, and set aside;

[0028] S2: Add the crushed medium sand in step S1, composite lightweight bone admixture, perlite powder, glass fiber, silicone modified epoxy resin, black clay, azodicarbonamide, fly ash, and synthetic rubber into the reactor , heated and stirred for 20 minutes, cooled;

[0029] S3: In step S2, continue to add 4 parts of silicone water-repellent agent, 6 parts of water-repellent agent, 5 parts of superplasticizer, and 3 parts of curing agent; fully stir for 5-10 minutes to pre...

Embodiment 2

[0031] The preparation steps of the heat insulation layer 11 raw materials are as follows:

[0032] S1: Weigh a certain amount of 35 parts of medium sand, 14 parts of composite light bone admixture, 6 parts of perlite powder, 9 parts of glass fiber, 15 parts of silicone modified epoxy resin, 10 parts of black clay, and azodimethazine 1 part of amide, 2 parts of fly ash, and 3 parts of synthetic rubber are pulverized through a pulverizer respectively, passed through a 40-mesh sieve, and set aside;

[0033] S2: Add the crushed medium sand in step S1, composite lightweight bone admixture, perlite powder, glass fiber, silicone modified epoxy resin, black clay, azodicarbonamide, fly ash, and synthetic rubber into the reactor , heated and stirred for 10 minutes, cooled;

[0034] S3: In step S2, continue to add 2 parts of silicone water-repellent agent, 2 parts of water-repellent agent, 2 parts of superplasticizer, and 1 part of curing agent; fully stir for 5 minutes to obtain a hea...

Embodiment 3

[0036] The preparation steps of the heat insulation layer 11 raw materials are as follows:

[0037] S1: Weigh a certain amount of 37 parts of medium sand, 18 parts of composite light bone admixture, 7 parts of perlite powder, 21 parts of glass fiber, 22 parts of silicone modified epoxy resin, 17 parts of black clay, and azodimethazine 7 parts of amide, 5 parts of fly ash, and 11 parts of synthetic rubber are pulverized through a pulverizer respectively, passed through a 66-mesh sieve, and set aside;

[0038] S2: Add the crushed medium sand in step S1, composite lightweight bone admixture, perlite powder, glass fiber, silicone modified epoxy resin, black clay, azodicarbonamide, fly ash, and synthetic rubber into the reactor , heated and stirred for 15 minutes, cooled;

[0039] S3: In step S2, continue to add 3 parts of silicone water-repellent agent, 5 parts of water-repellent agent, 3 parts of superplasticizer, and 2 parts of curing agent; fully stir for 10 minutes to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com