Patents

Literature

82results about How to "Production compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

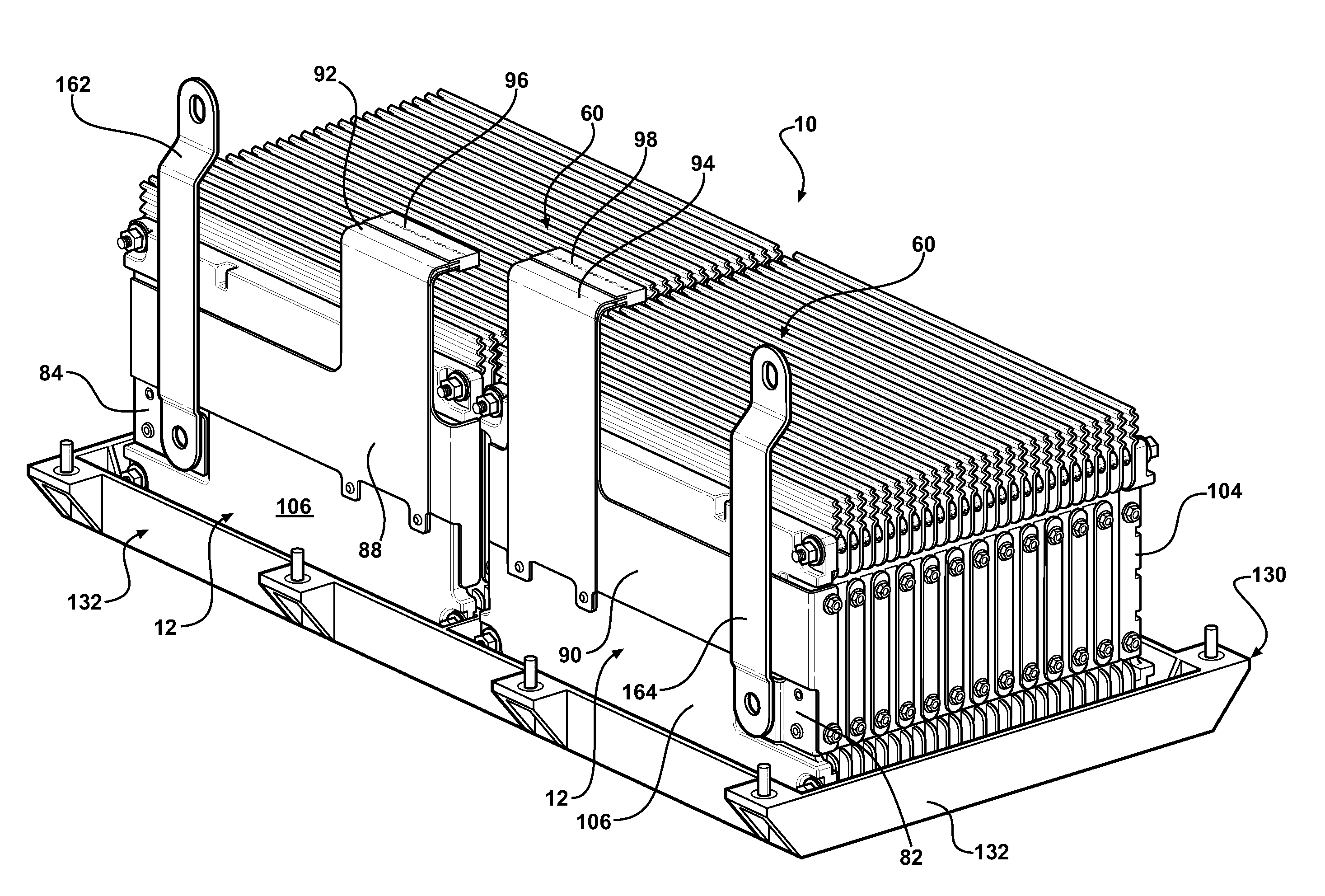

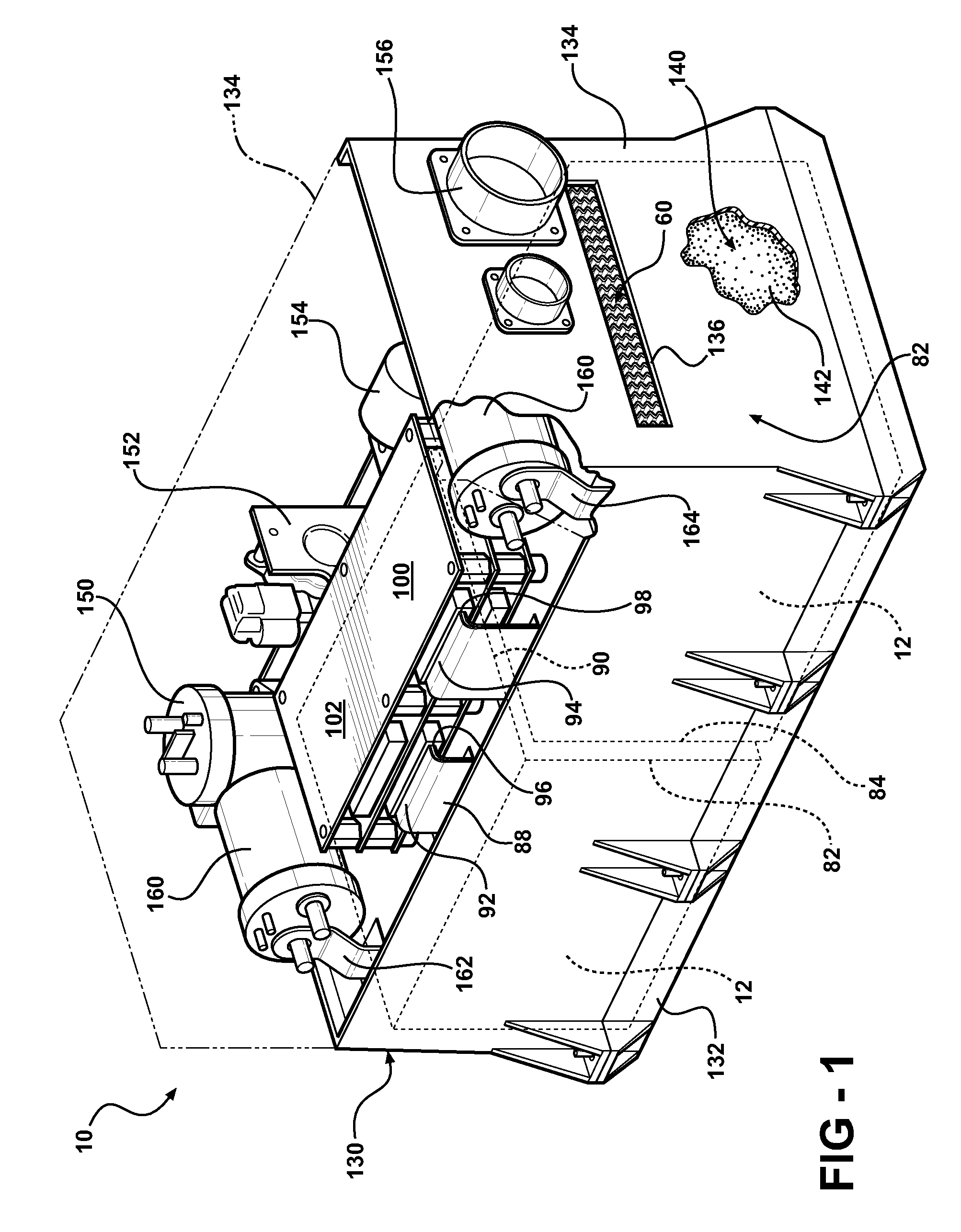

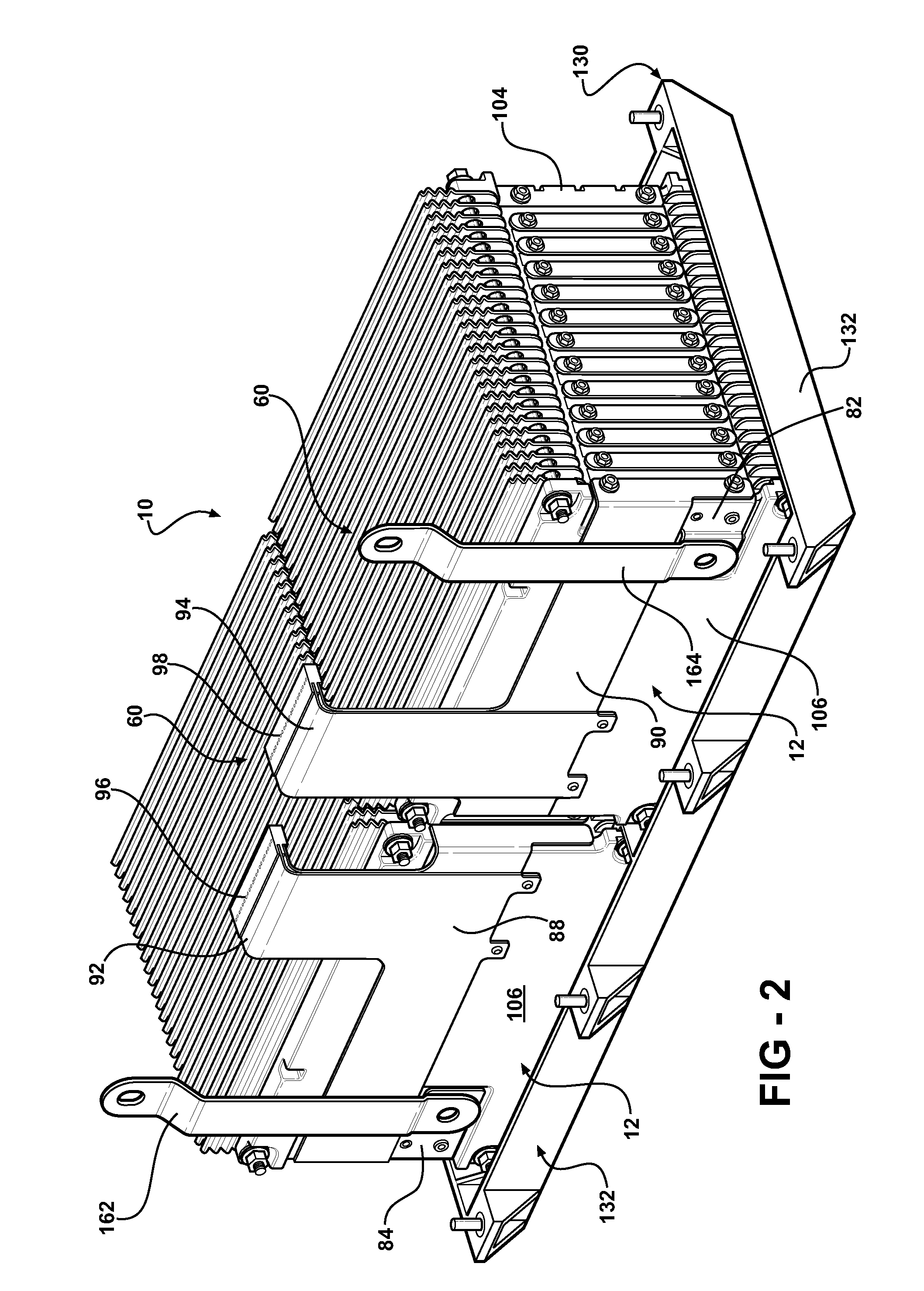

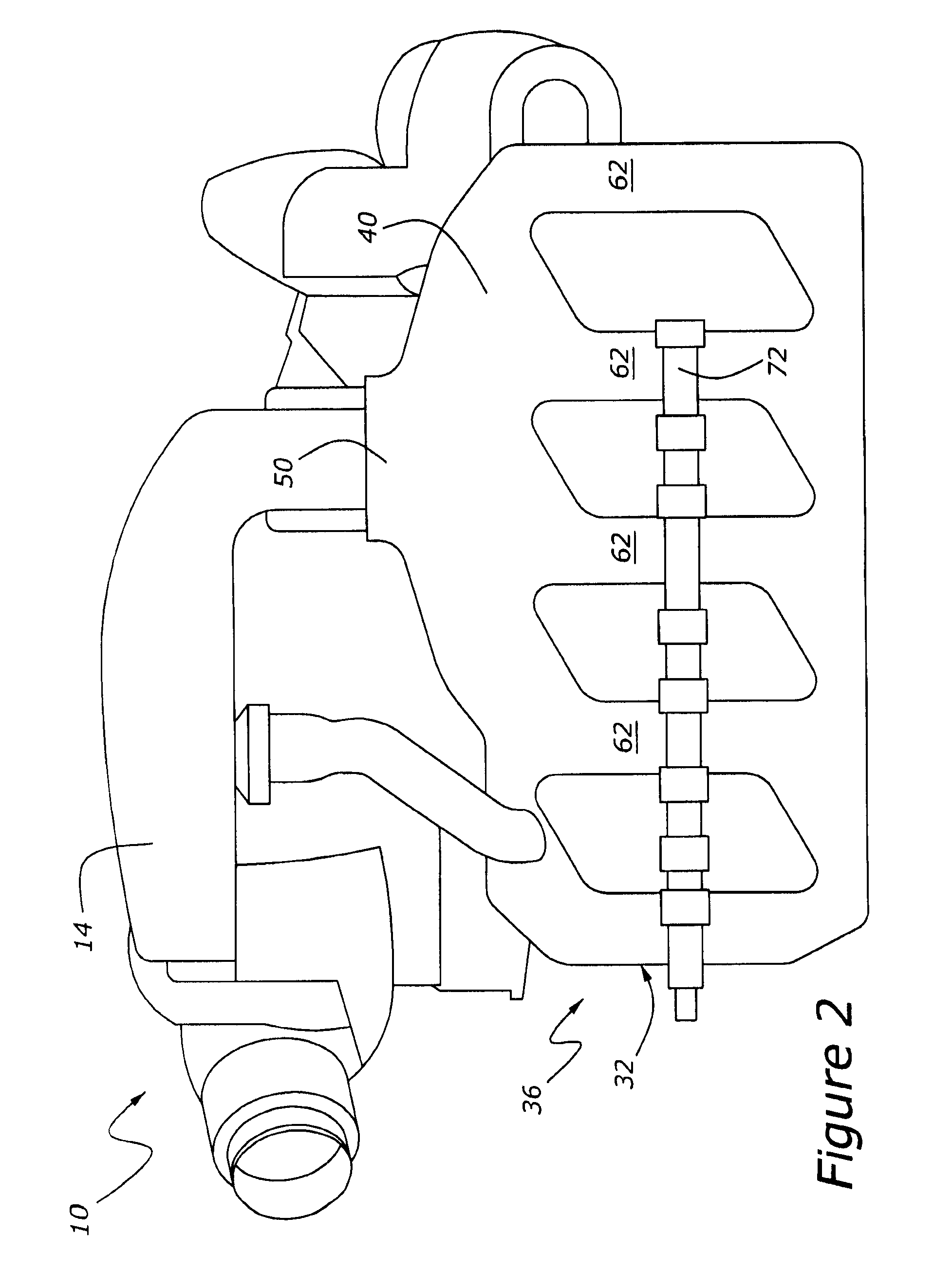

Battery pack with integral cooling and bussing devices

ActiveUS7531270B2High densityIncrease energy densityFinal product manufactureCell temperature controlMobile vehicleBattery cell

A battery module of the present invention is adaptable to be utilized in various configurations including and not limited to an overlapping battery cell packaging configuration and a vertical stack battery cell packaging configuration used in an automotive vehicle. The battery module has a plurality of battery heatsink assemblies with the cells disposed therebetween. A plurality of rods extend through the each heatsink assemblies to secure the heatsink assemblies and the cell with one another to form the battery module.

Owner:ENERDEL

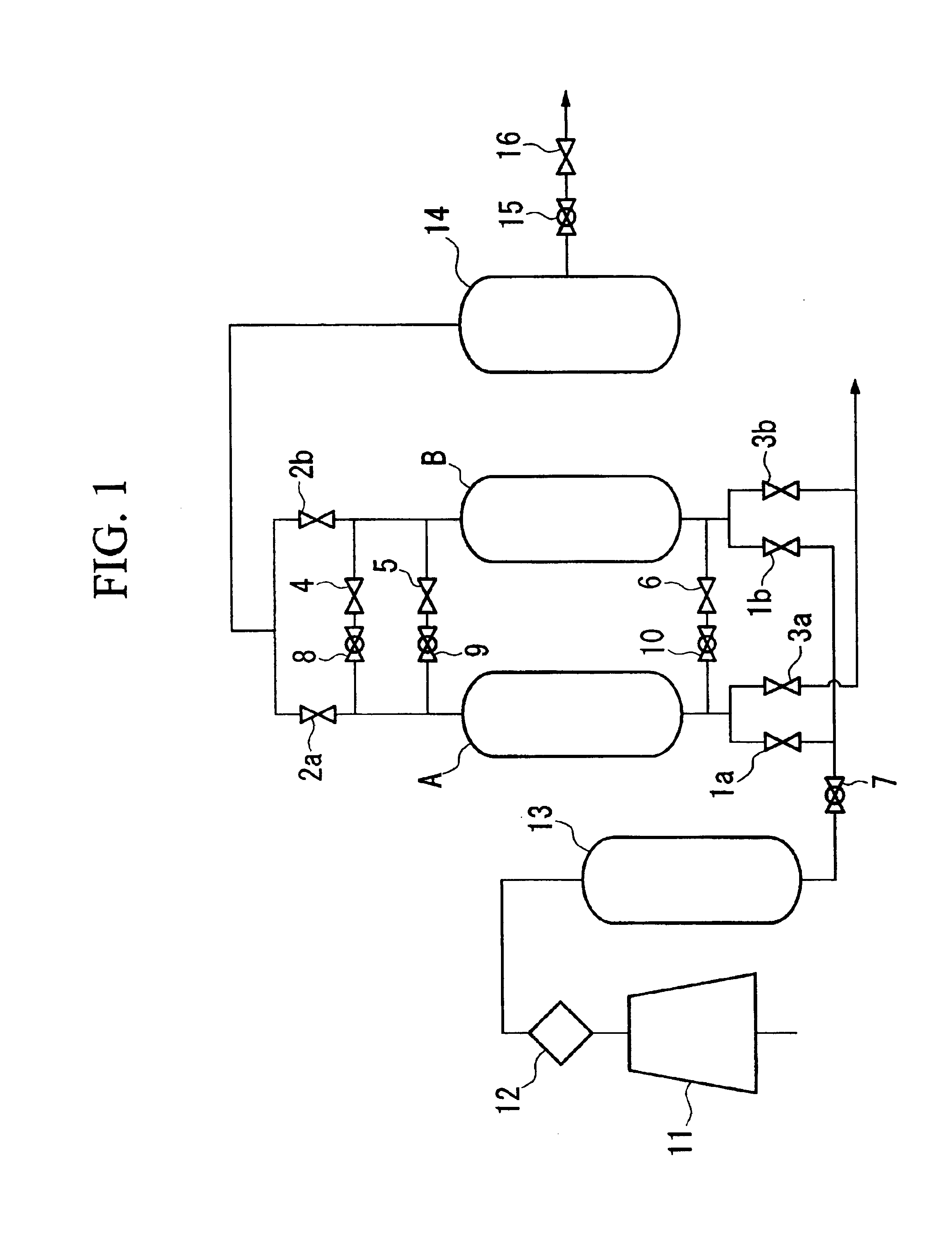

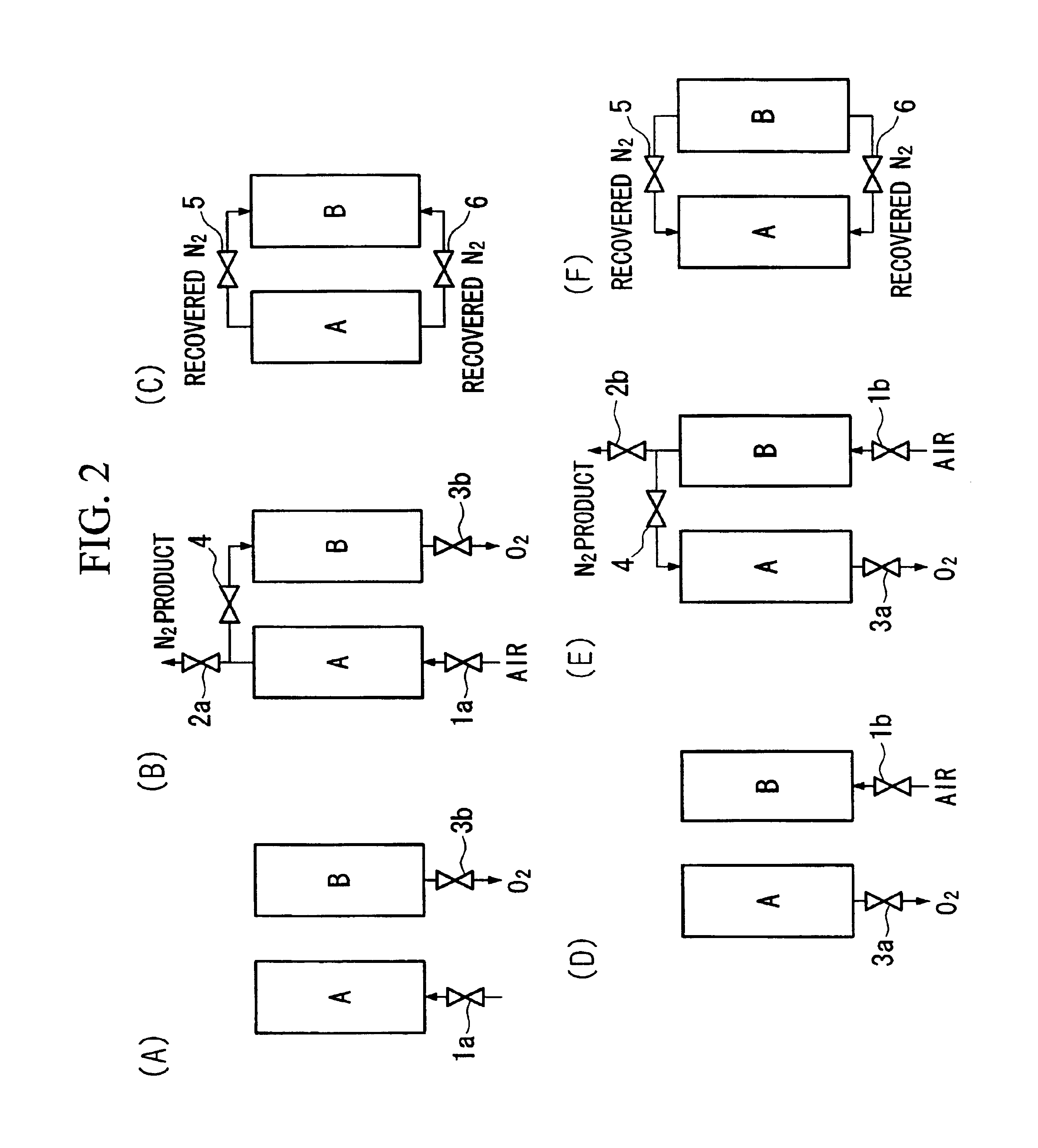

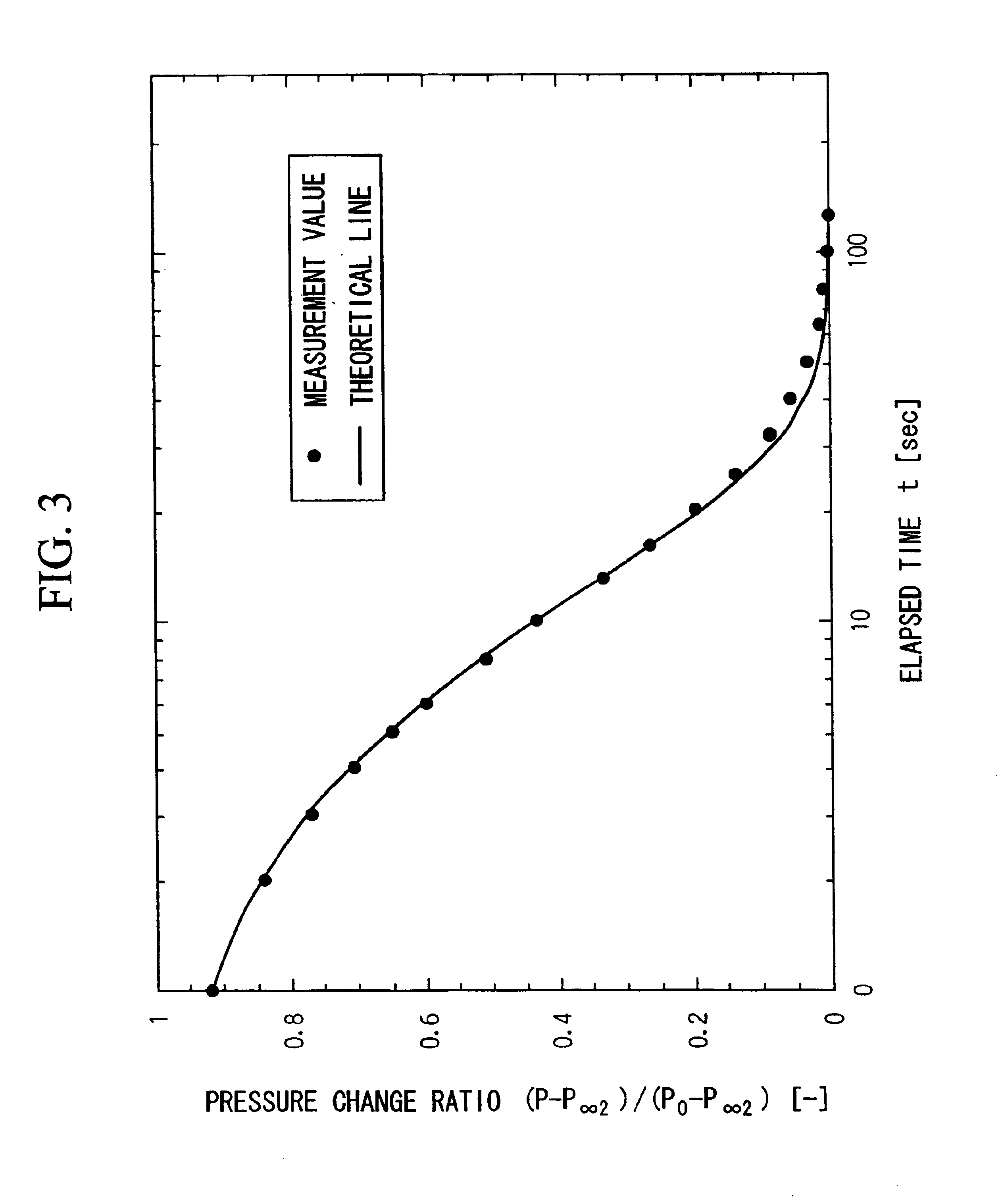

Adsorbent for separating nitrogen from mixed gas of oxygen and nitrogen

InactiveUS6916358B2Minimal operating costMore productiveNitrogen purification/separationGas treatmentSorbentNitrogen

An adsorbent for separating nitrogen from a mixed gas of oxygen and nitrogen is MSC wherein an oxygen and nitrogen separation ratio α and a ratio (t95 / t50) of a time t50 required for adsorbing 50% of the oxygen equilibrium adsorption amount and a time t95 required for adsorbing 95% of the oxygen equilibrium adsorption amount satisfy the inequality(t95 / t50)<0.4×(α−24)α≧35.The amount of adsorbent used with respect to a predetermined amount of nitrogen generated can be reduced since a method is carried out which uses this adsorbent to produce nitrogen by separating nitrogen from the mixed gas of oxygen and nitrogen by means of a PSA method. By this method, it is possible to reduce the cost of the apparatus and reduce and miniaturize the scale of the apparatus, and the power consumption amount can be reduced.

Owner:NIPPON SANSO CORP

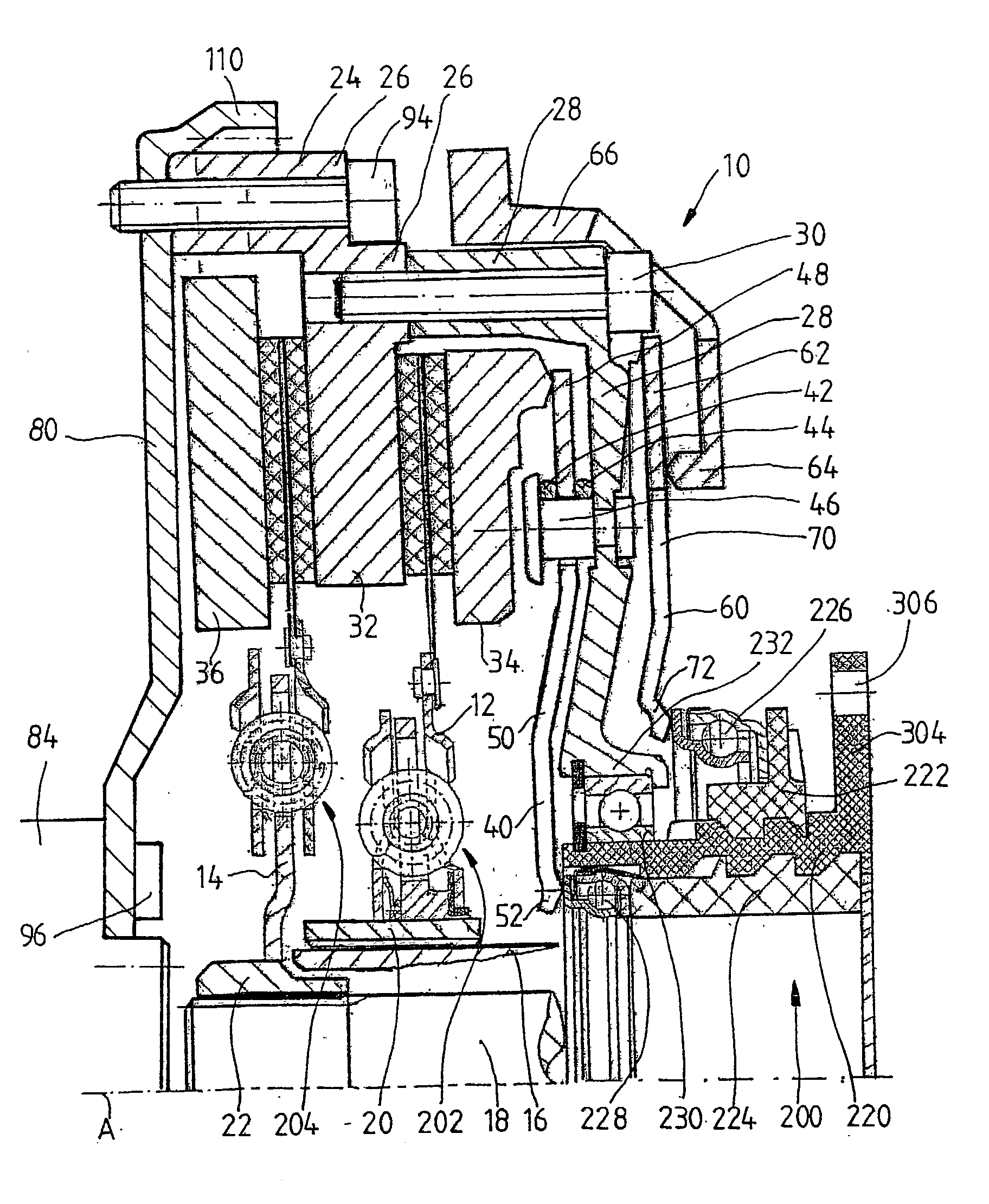

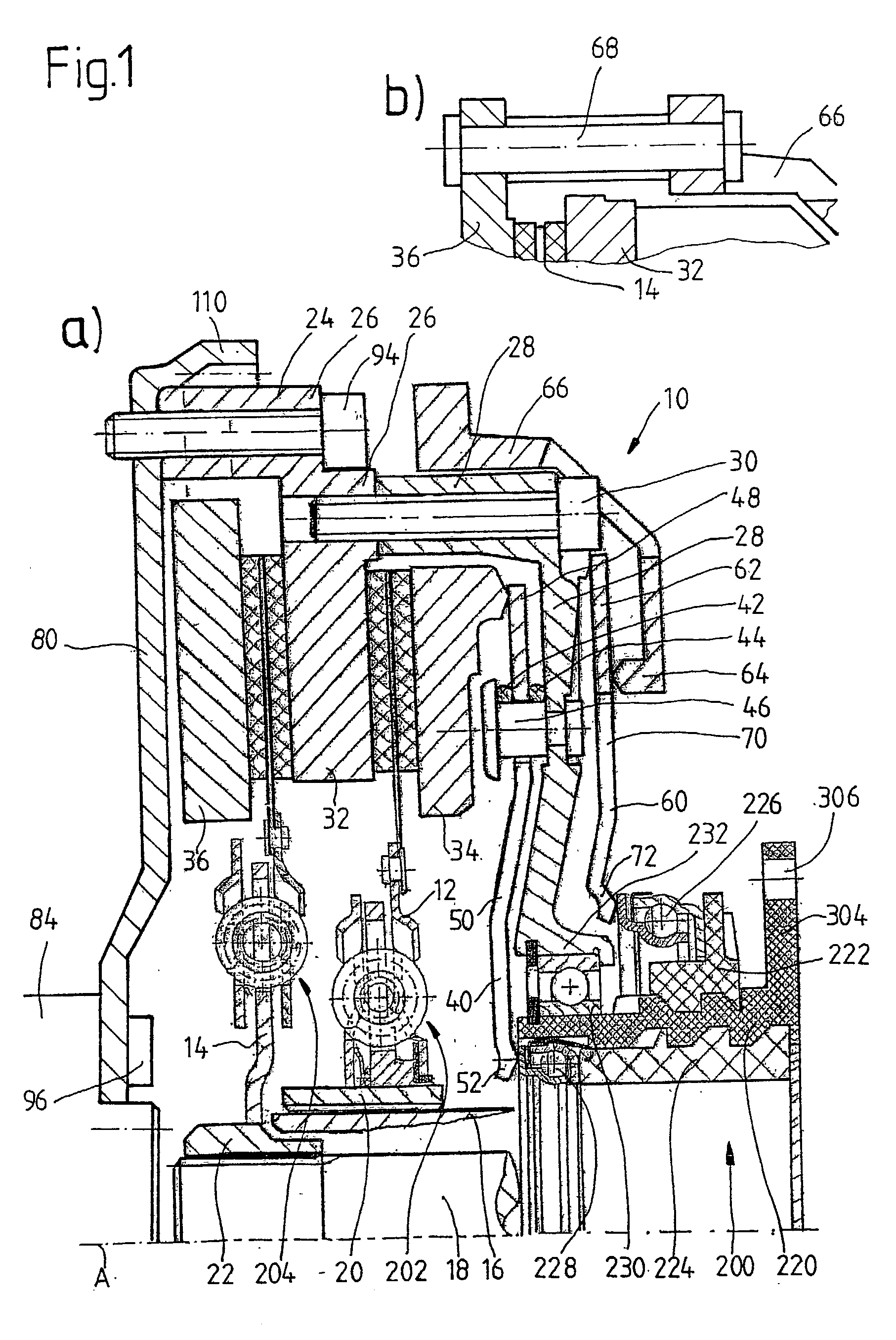

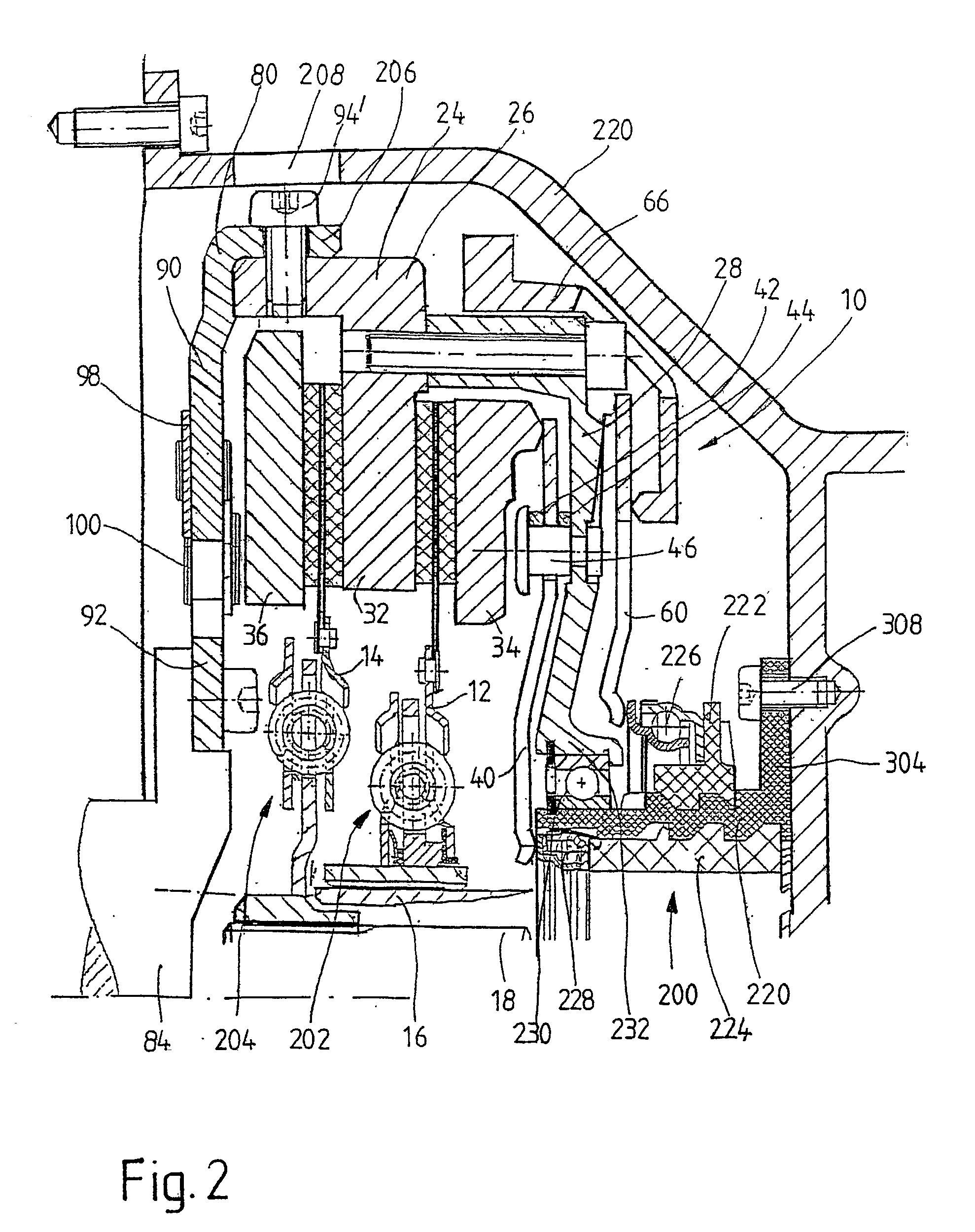

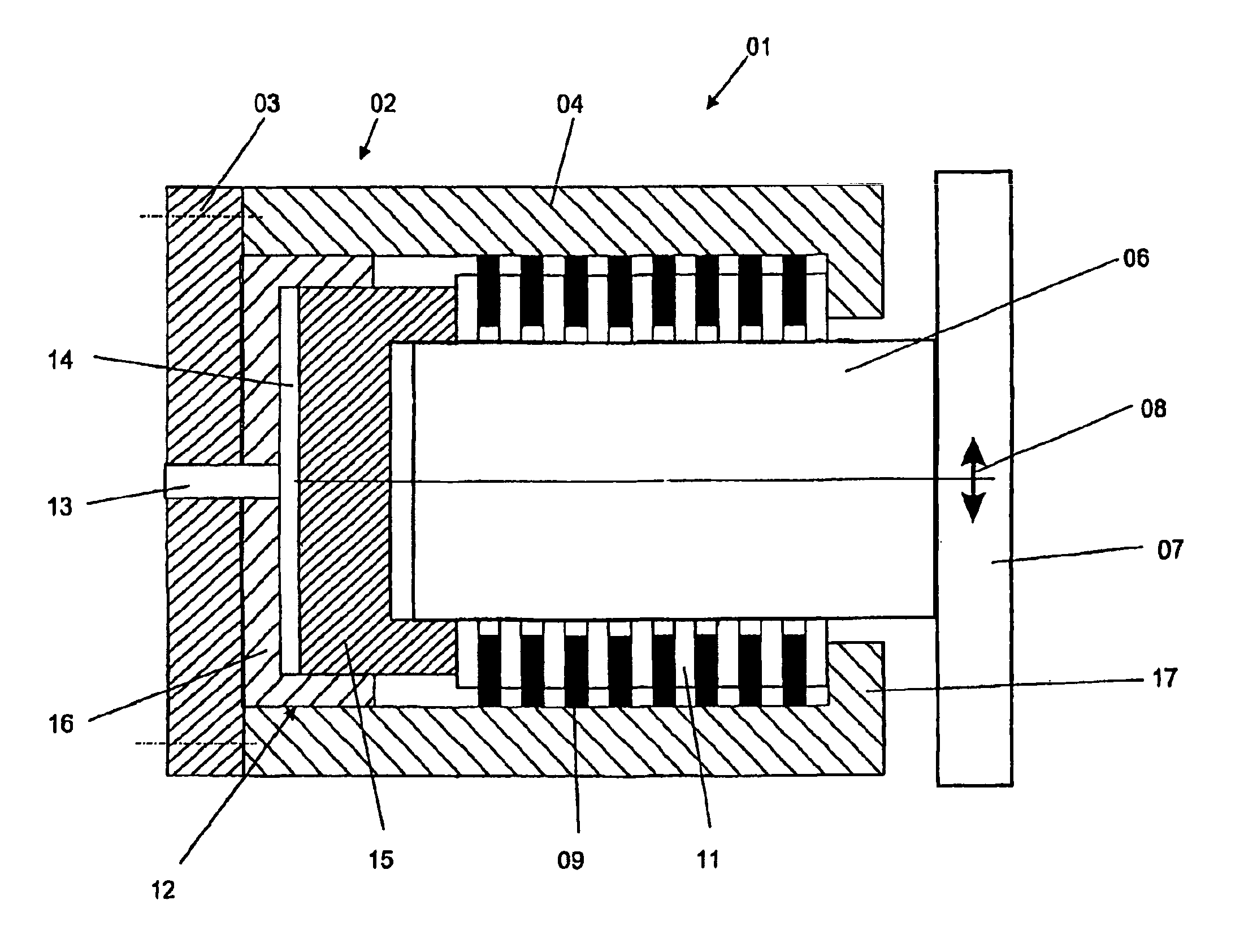

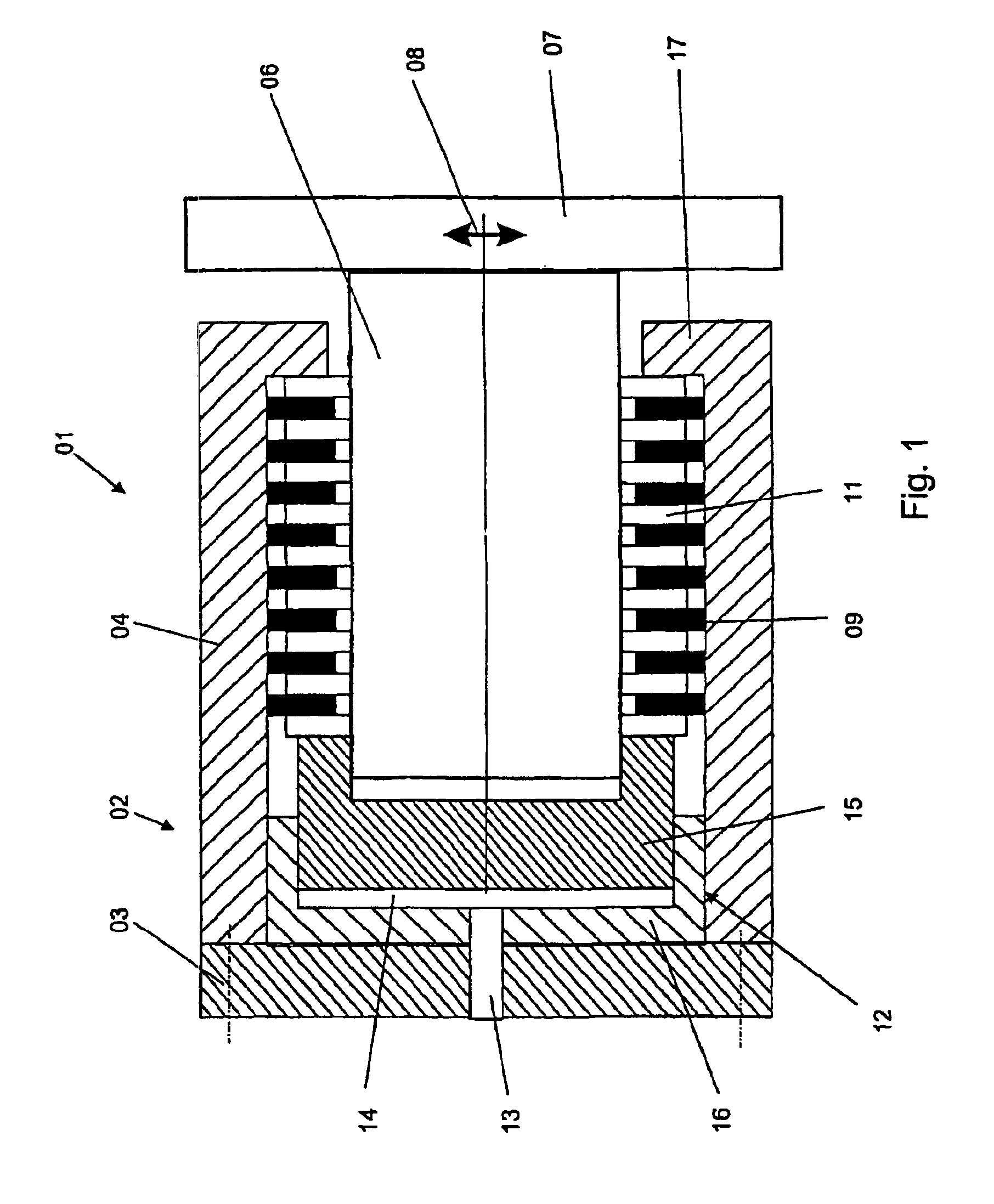

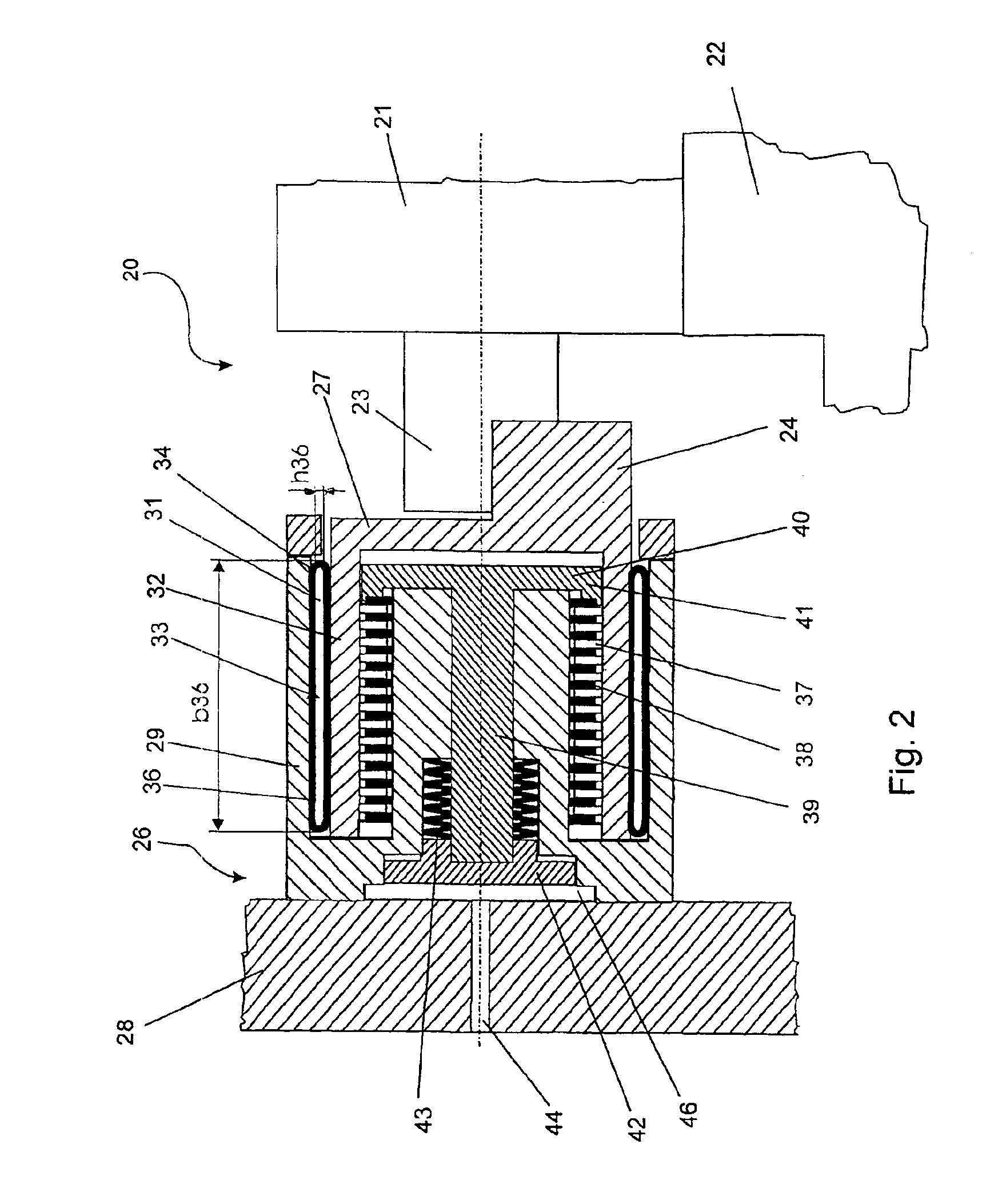

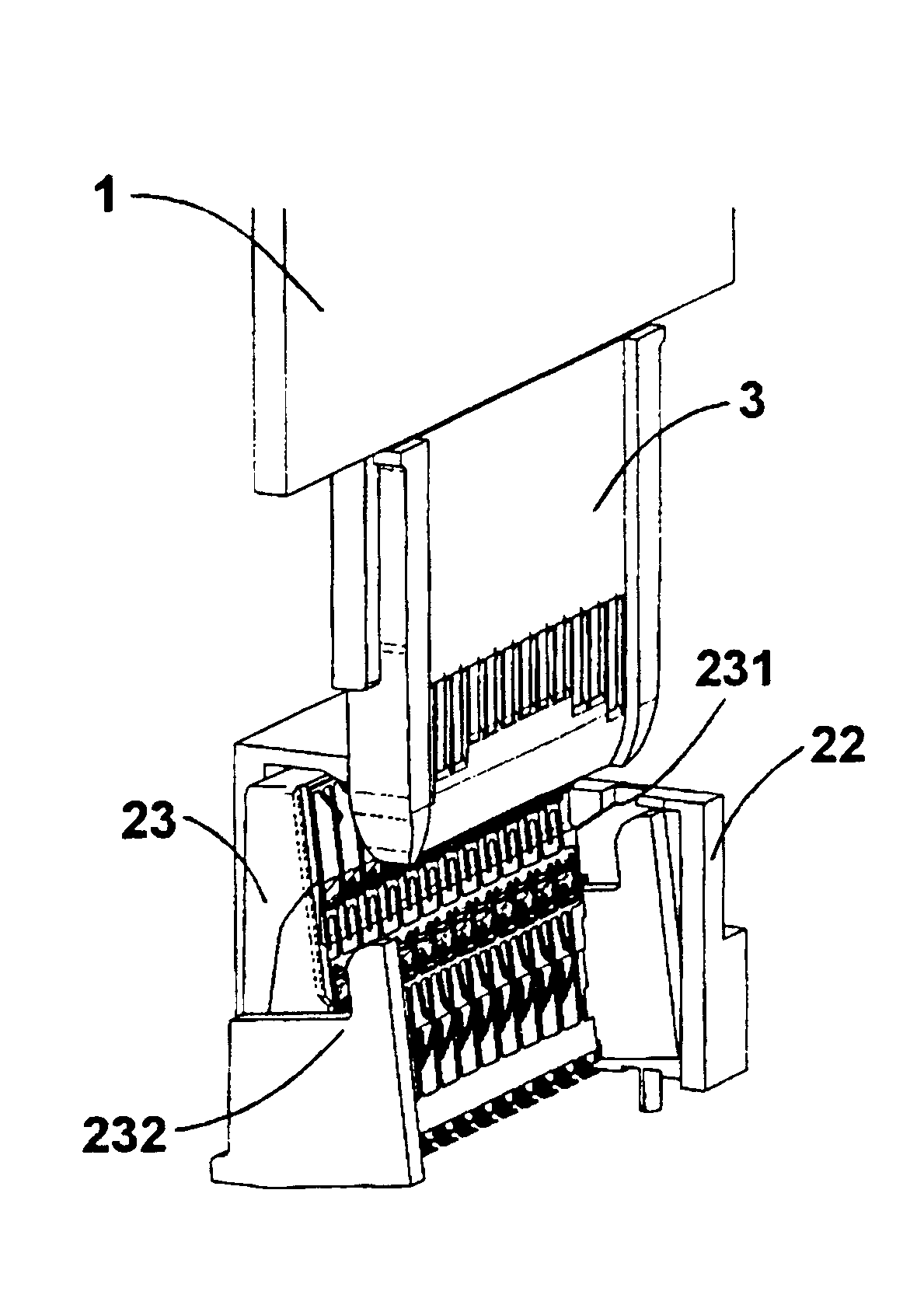

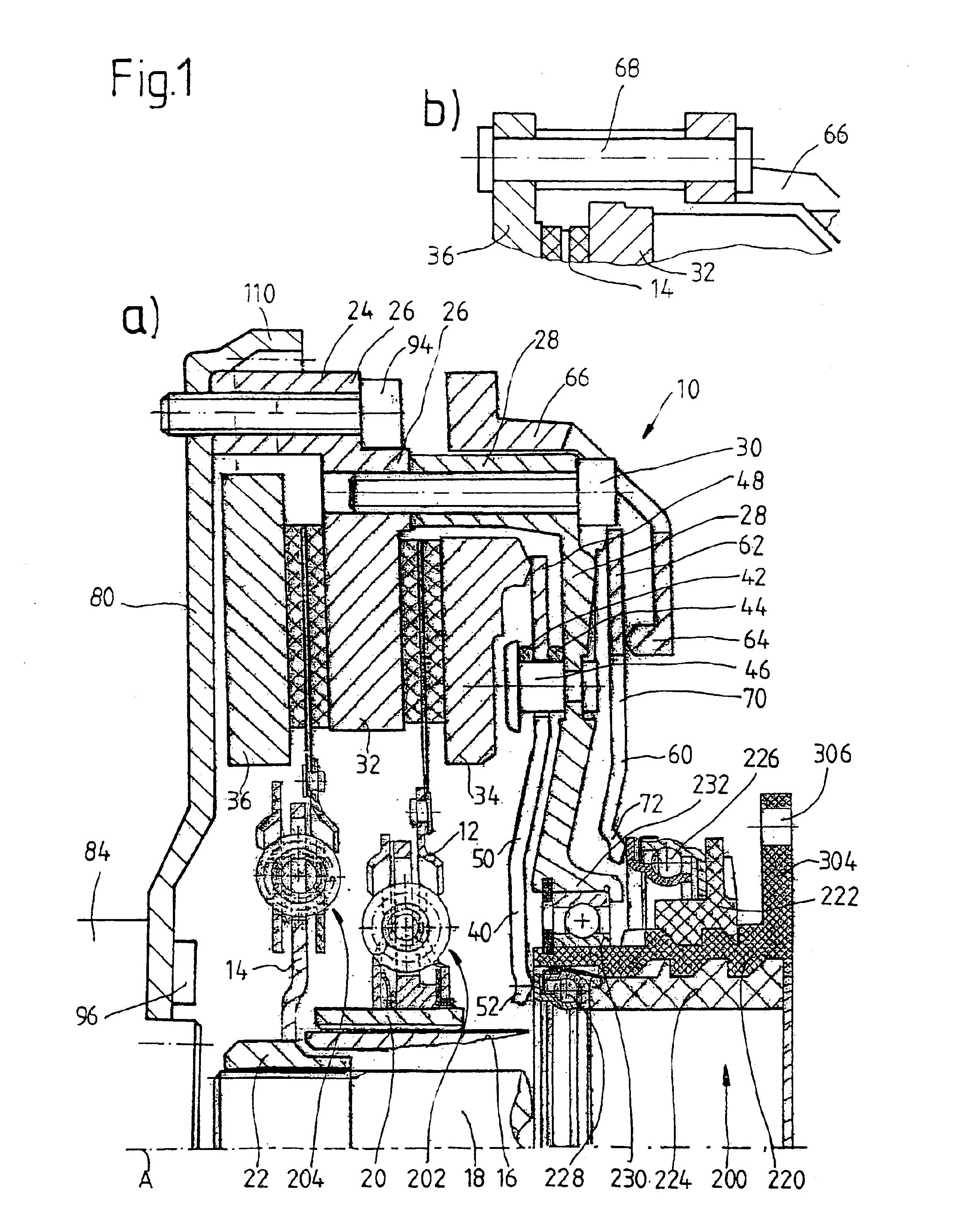

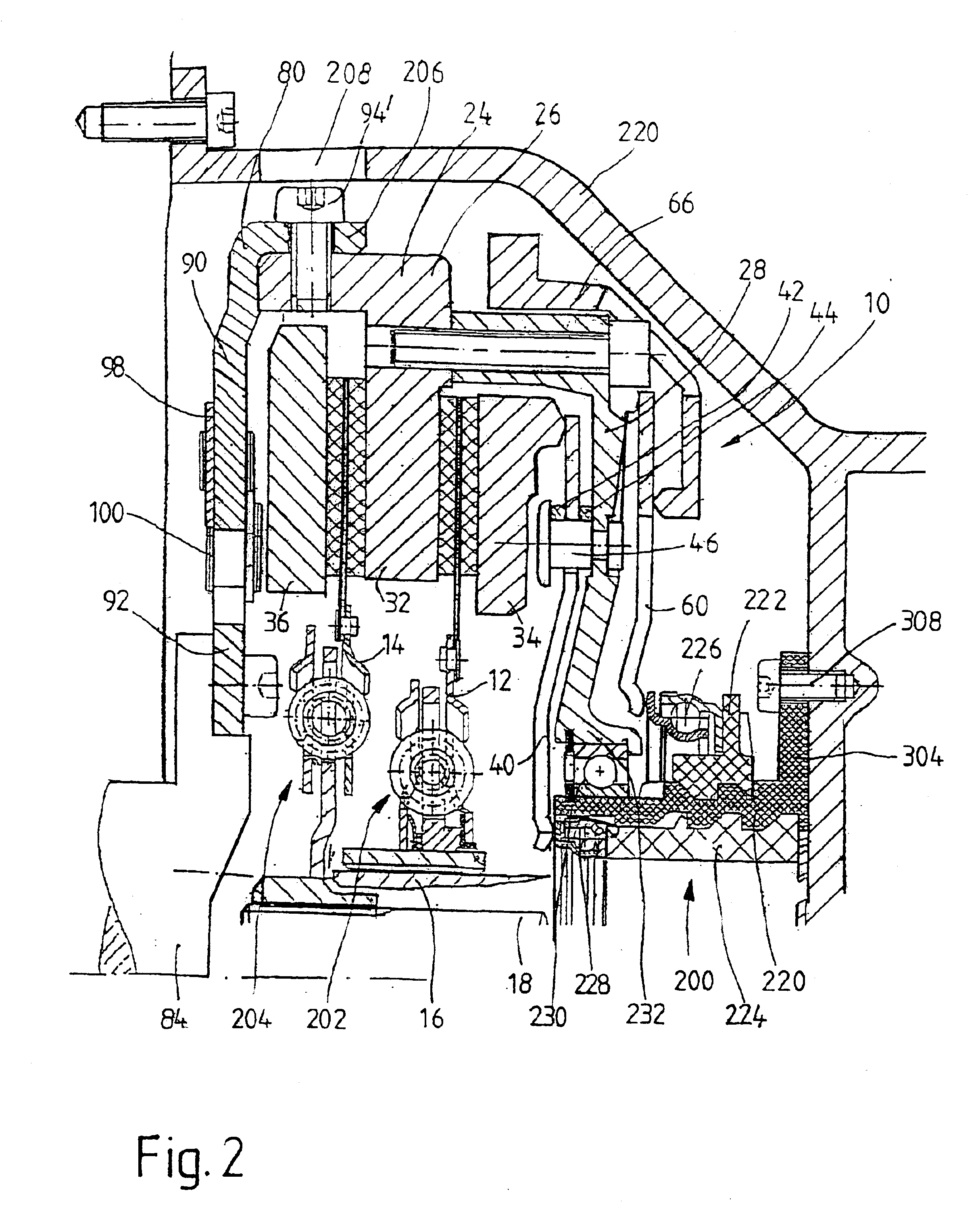

Actuating device for a friction clutch device, possibly a dual or multiple friction clutch device

An actuating device for a friction clutch device installed in the drive train of a motor vehicle introduces actuating forces, especially clutch-engaging or clutch-releasing forces, to the friction clutch device to actuate at least one friction clutch of the friction clutch device in the engaging or releasing direction. At least one actuating element assigned to a friction clutch can be shifted axially relative to at least one support element, which is essentially fixed in the axial direction, to exert the actuating forces. The actuating element belongs to an actuator assigned to the clutch or can be shifted axially relative to the support element by the intermediate action of an actuator assigned to the clutch. The actuating element and the support element engage with each other in such a way that a rotational movement of the actuating element relative to the nonrotatably supported support element, this movement being imparted by the intermediate action of the actuator, is converted to an axial translational movement of the actuating element relative to the axially supported support element.

Owner:ZF SACHS AG

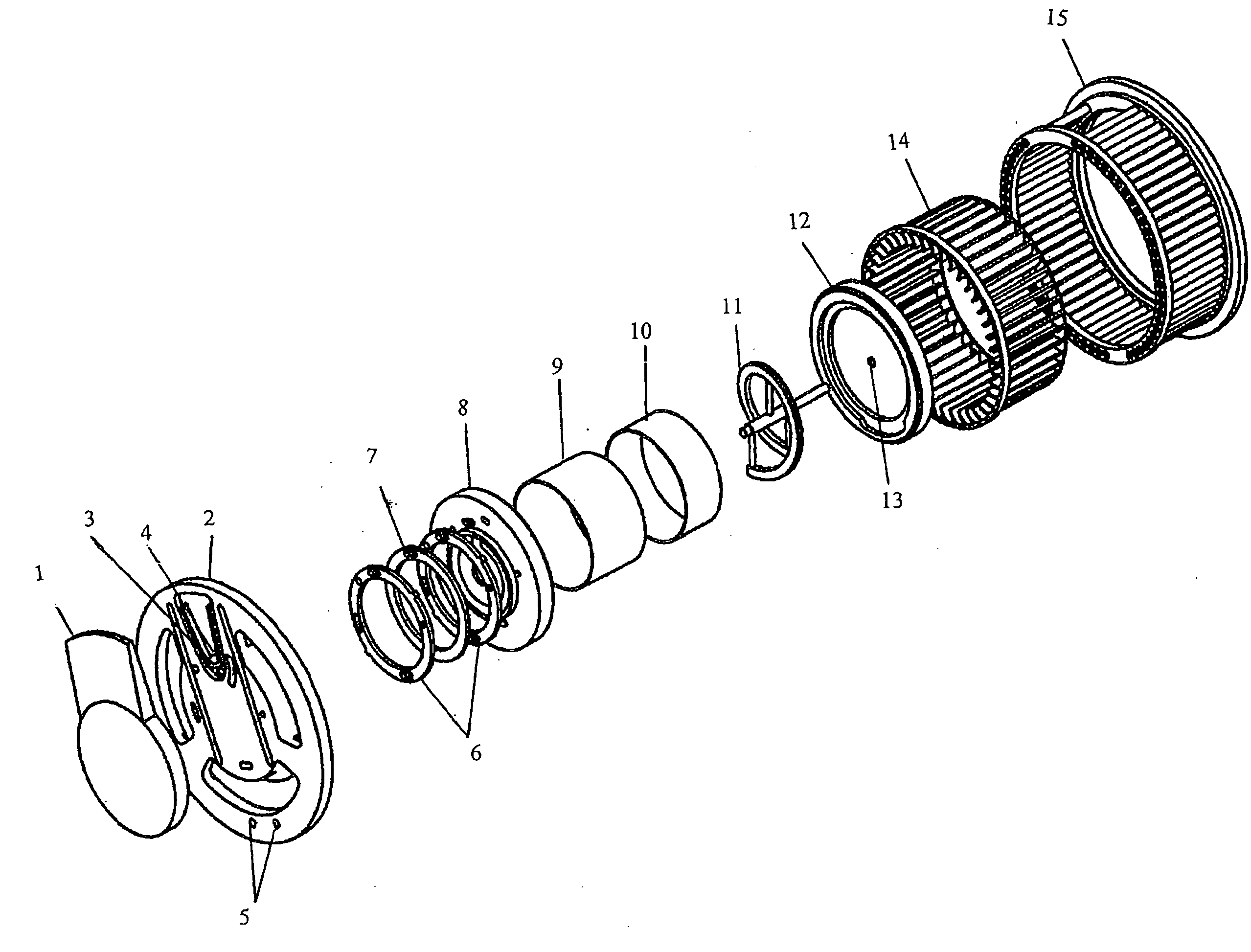

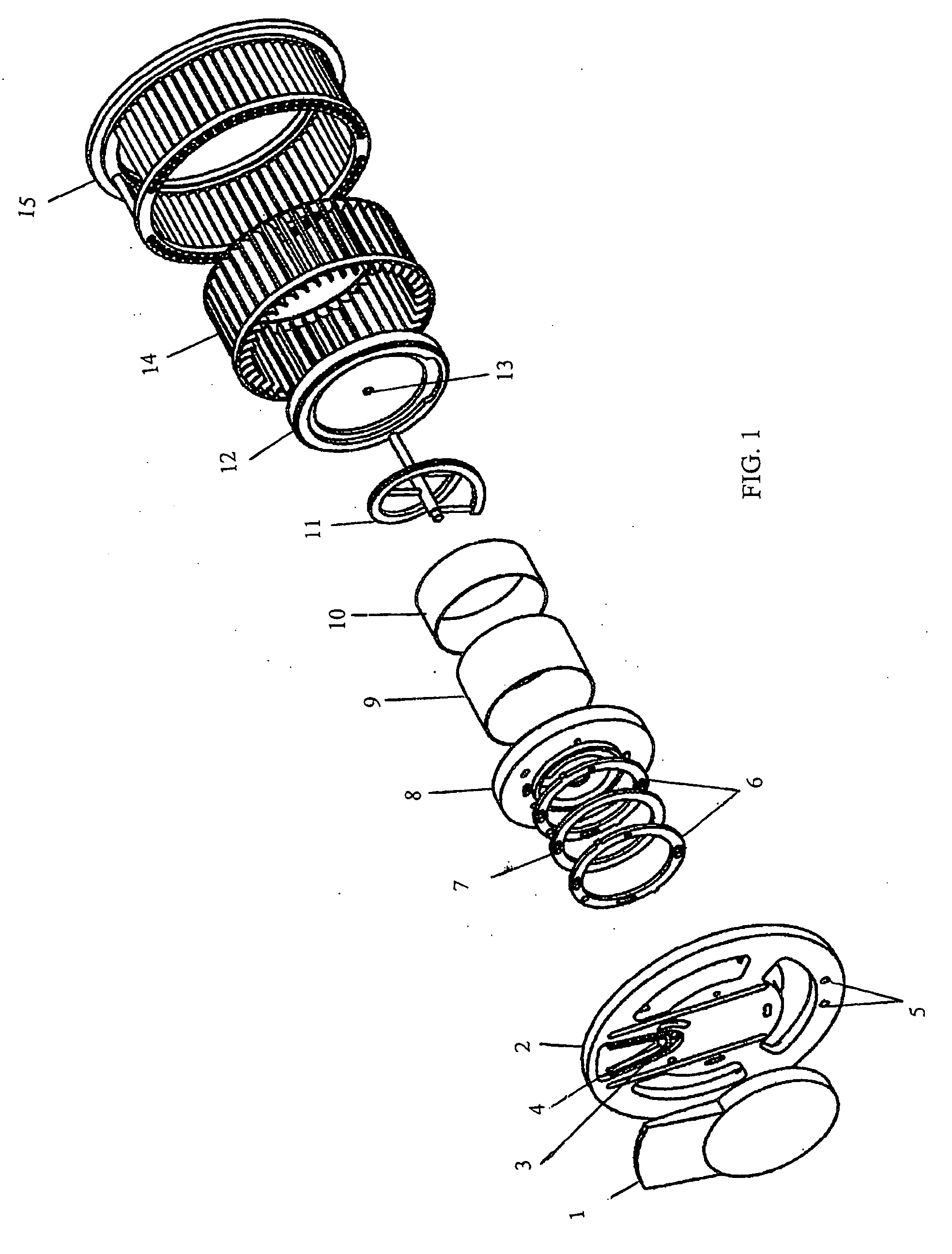

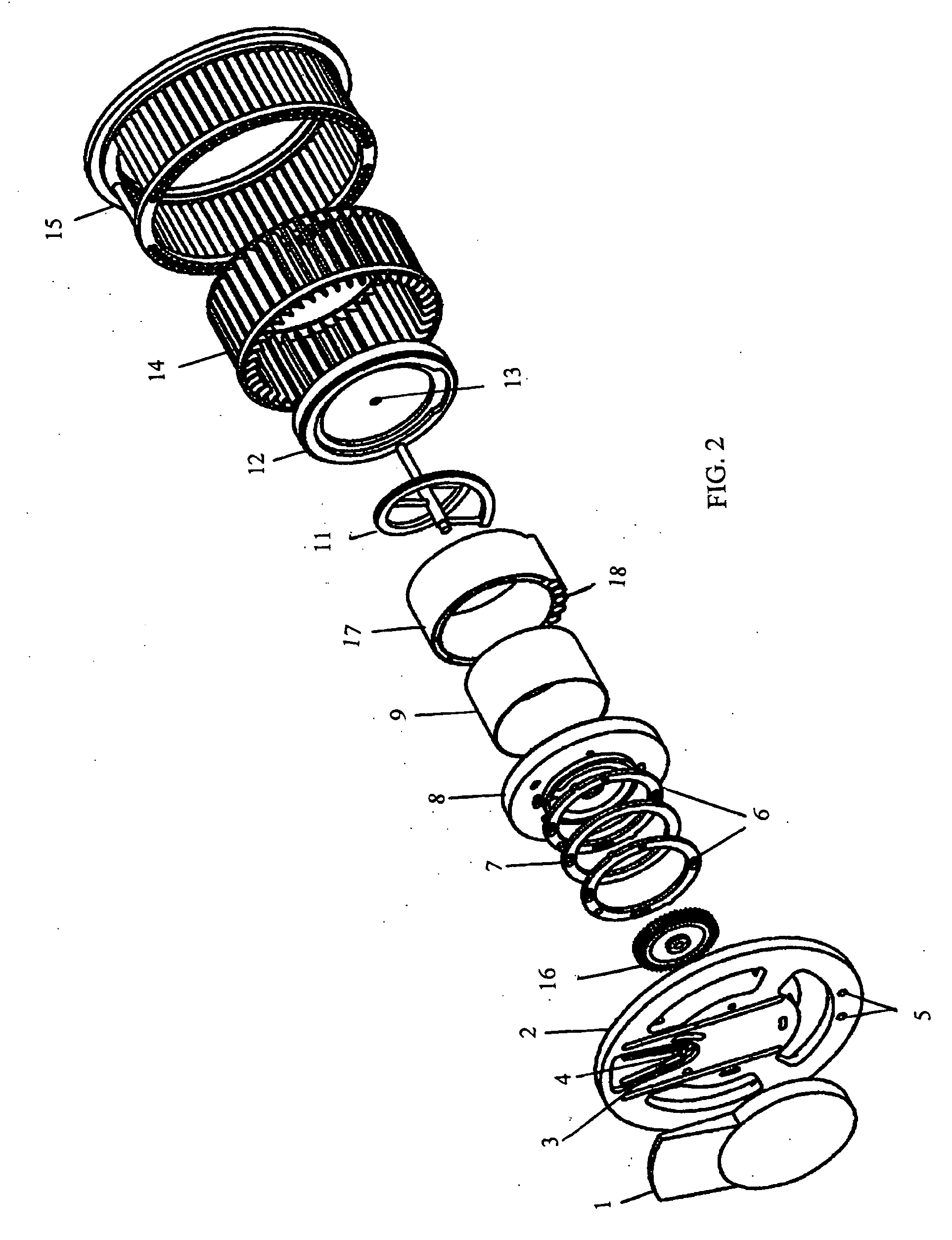

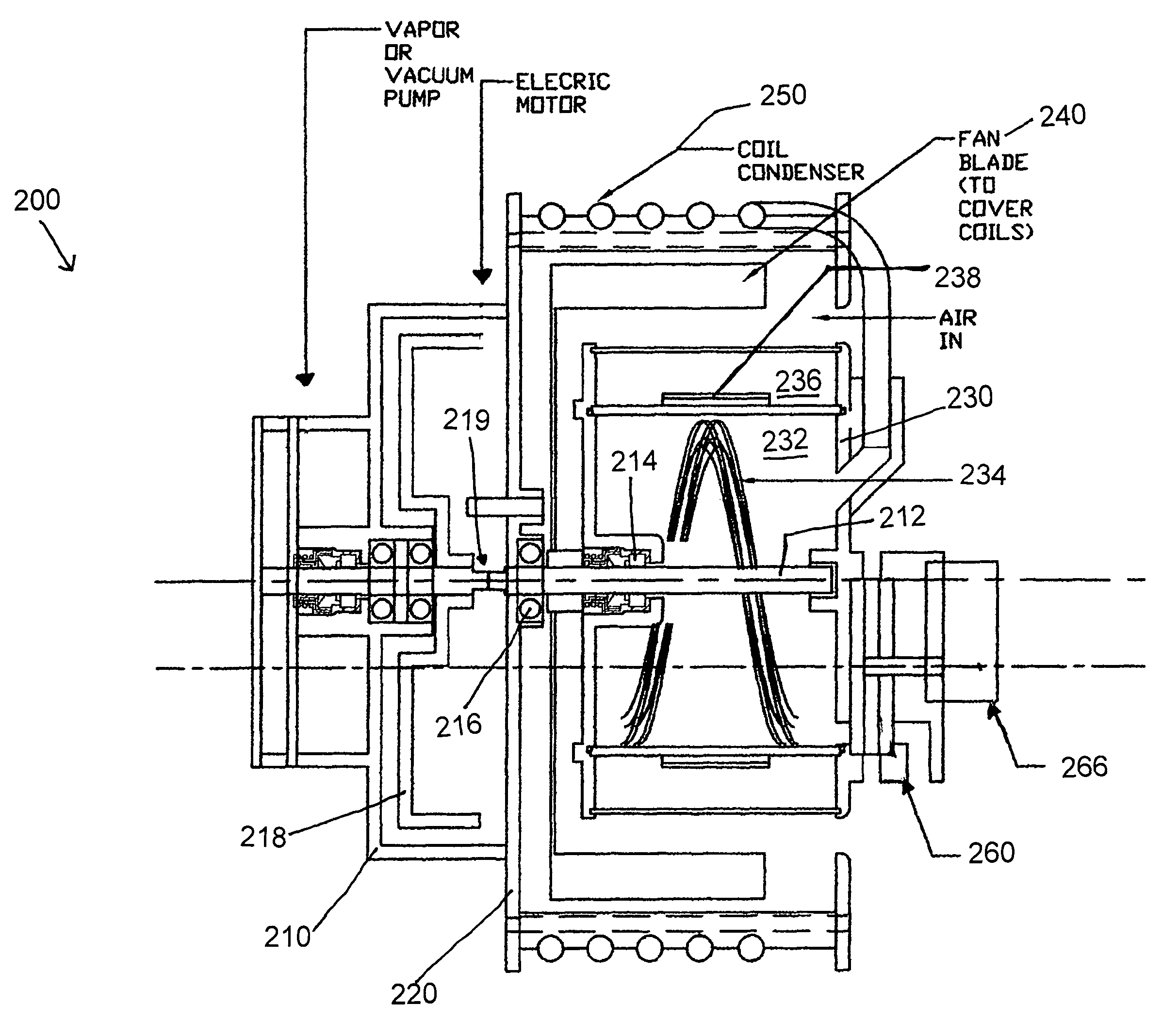

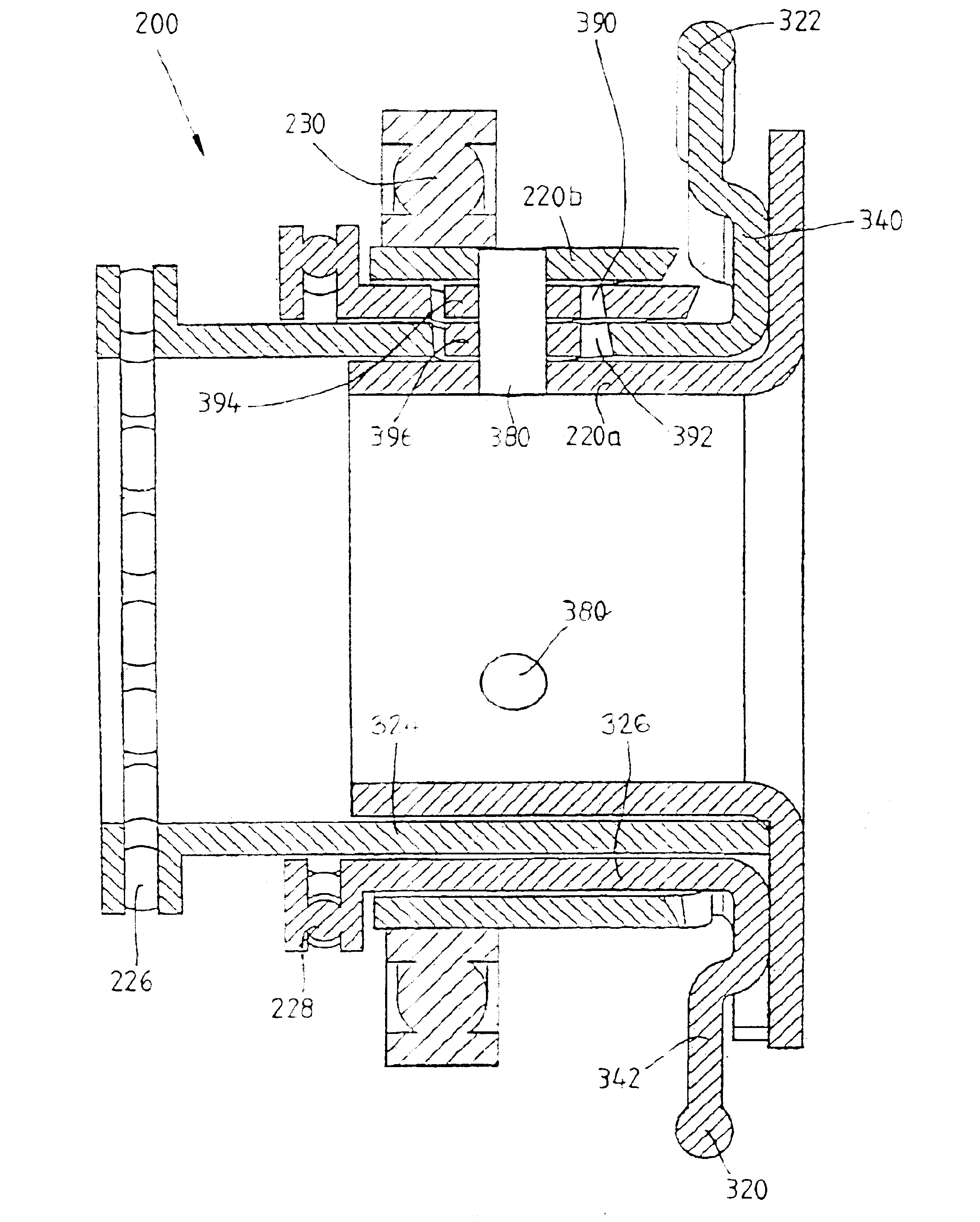

Multiple application purification and recycling device

InactiveUS20070170049A1Easy constructionFlexible operationDistillation regulation/controlEvaporation with vapour compressionDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

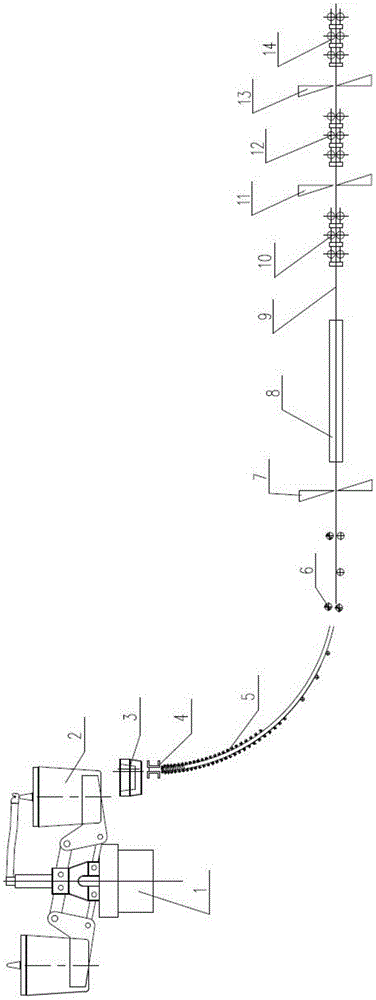

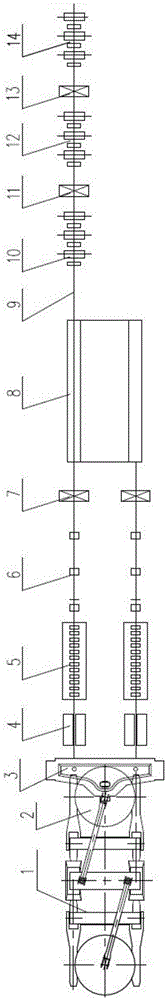

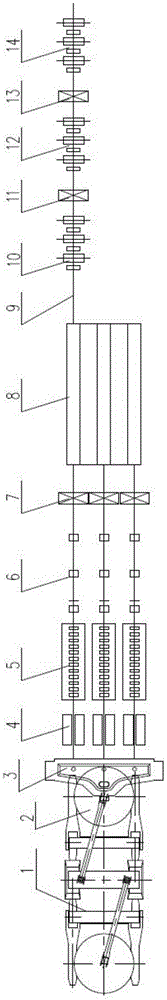

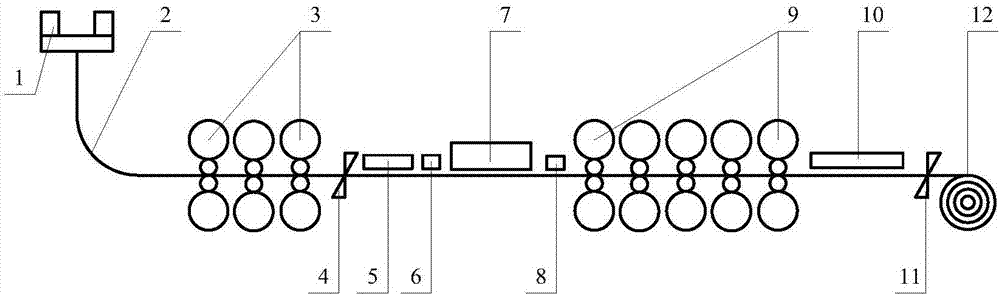

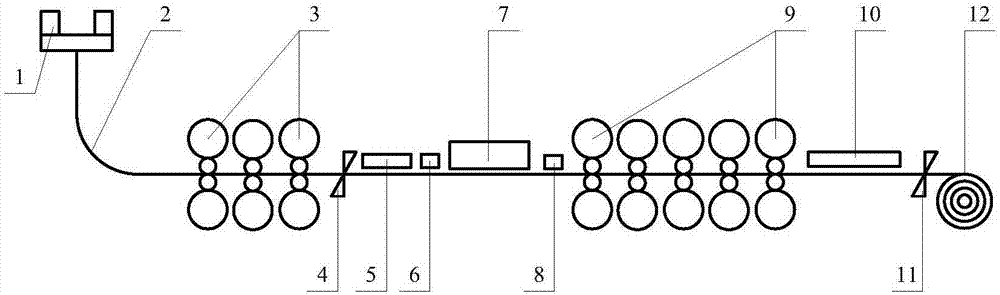

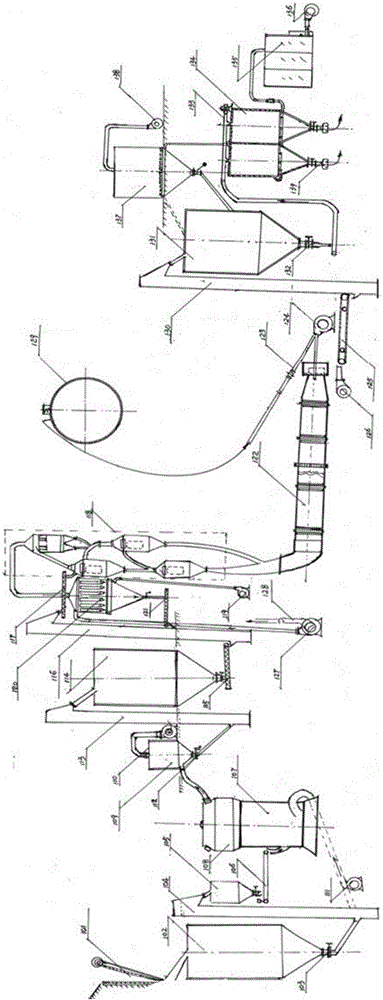

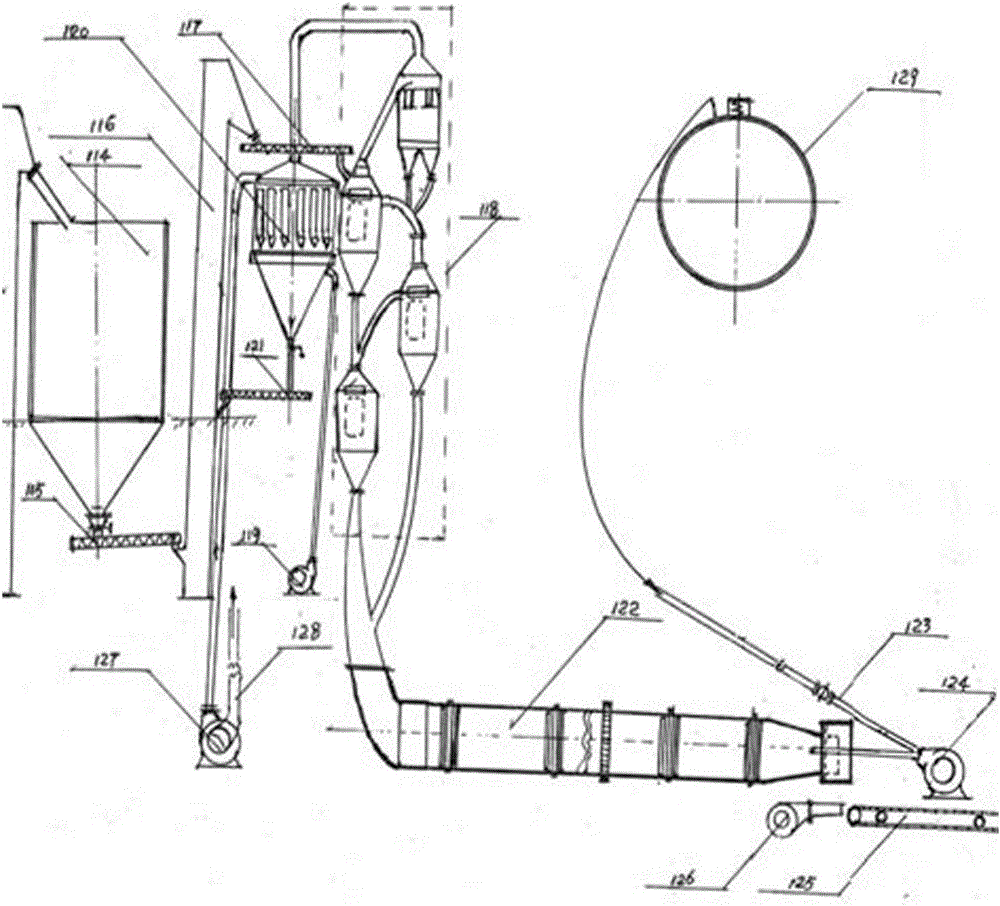

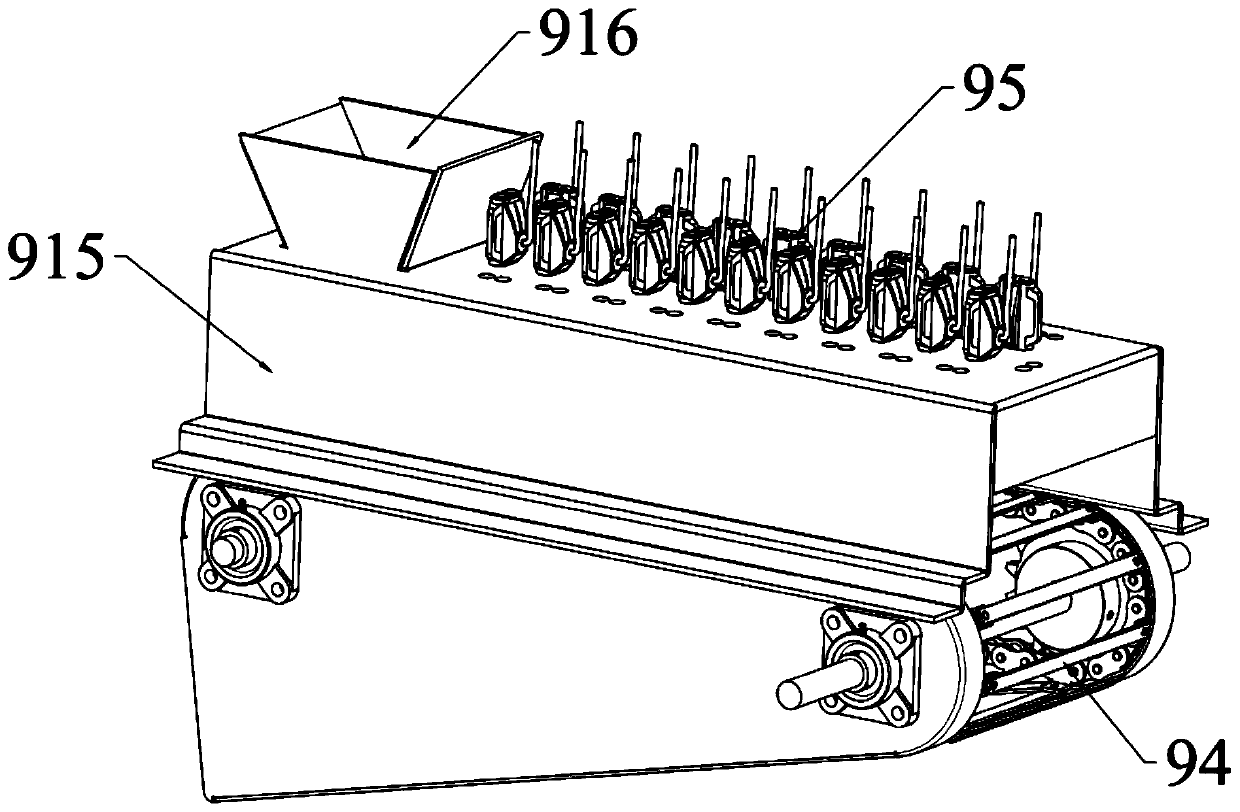

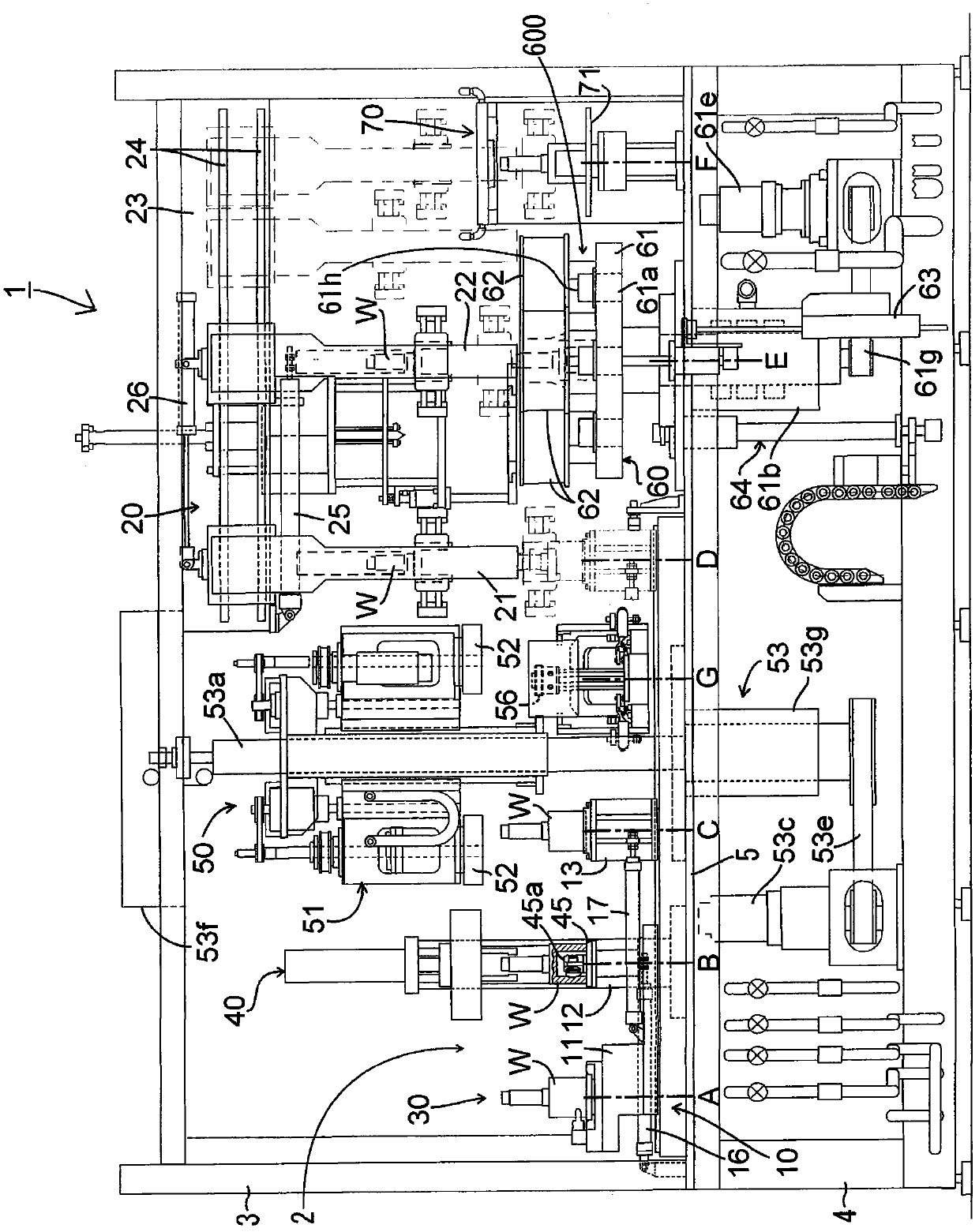

Continuous casting and rolling production line of wire rods and production method of production line

InactiveCN105414185AAchieve seamless connectionRealize construction costMetal rolling arrangementsWire rodProduction line

The invention discloses a continuous casting and rolling production line of wire rods and a production method of the production line. The continuous casting and rolling production line of the wire rods comprises a continuous casting machine, a parallel-flow device and a rolling mill unit. The method comprises the steps that a square casting blank or a circular casting blank is produced by means of the continuous casting machine firstly, the produced square casting blank or circular blank is cut through a cutting machine, parallel flowing is conducted through the parallel-flow device, the parallel flowed square casting blank bodies or circular casting blank bodies are conveyed to an inlet of the rolling mill unit through a conveyor roller way finally, and the rods are prepared by rolling through a rough mill, an intermediate mill and a finishing mill in sequence. According to the continuous casting and rolling production line of the wire rods and the production method of the production line, seamless connection of the continuous casting machine and rolling mills is achieved, the casting blank can be directly hot-delivered into the rolling mill unit to be rolled into the rods, secondary heating through a heating furnace is not needed, and the continuous casting and rolling production line of the wire rods and the production method of the production line have the advantages of being high in pouring speed, small in casting machine flow number, compact in production rhythm, high in efficiency, less in energy consumption and low in construction investment and operation maintenance cost.

Owner:CISDI ENG CO LTD

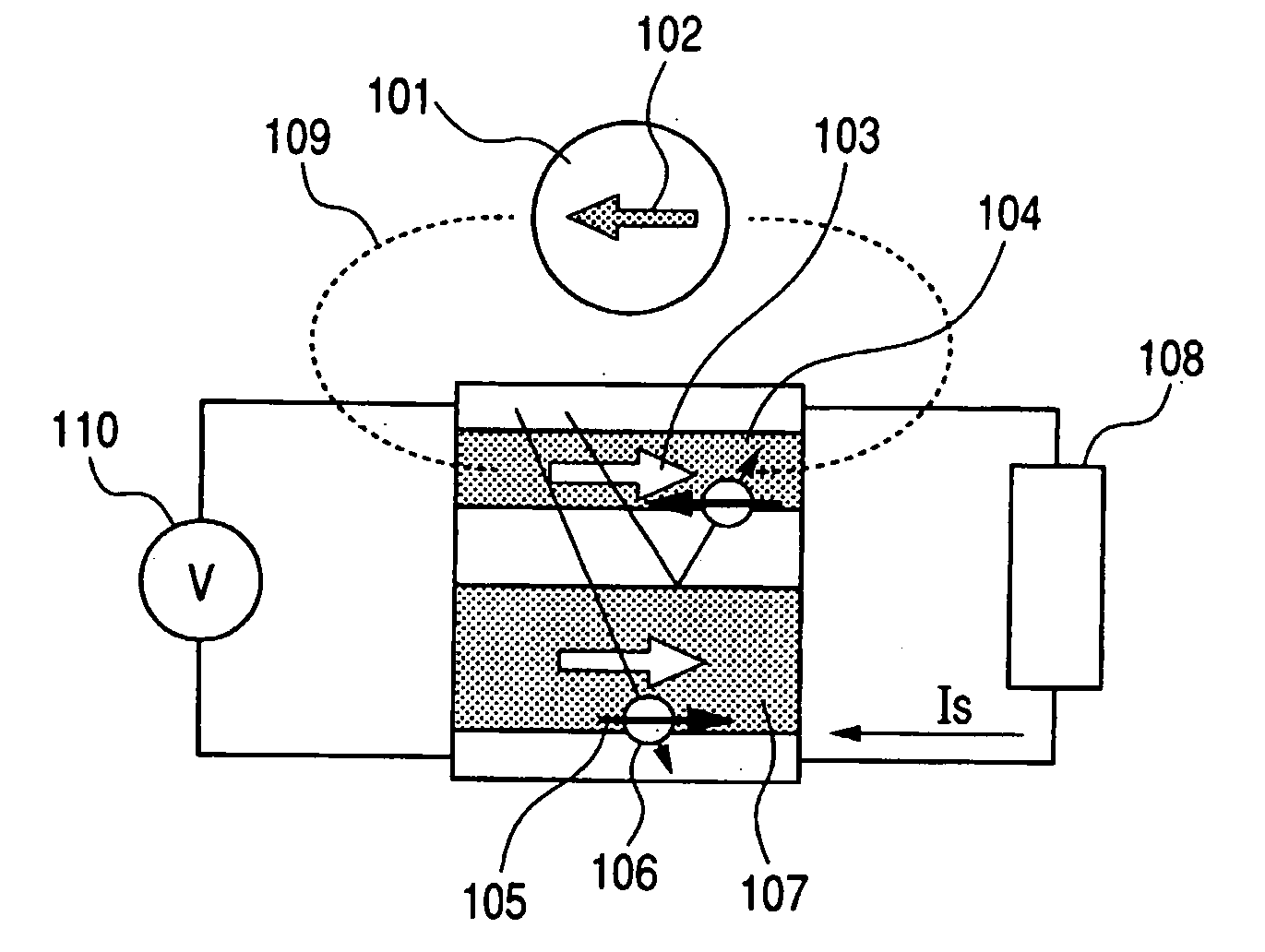

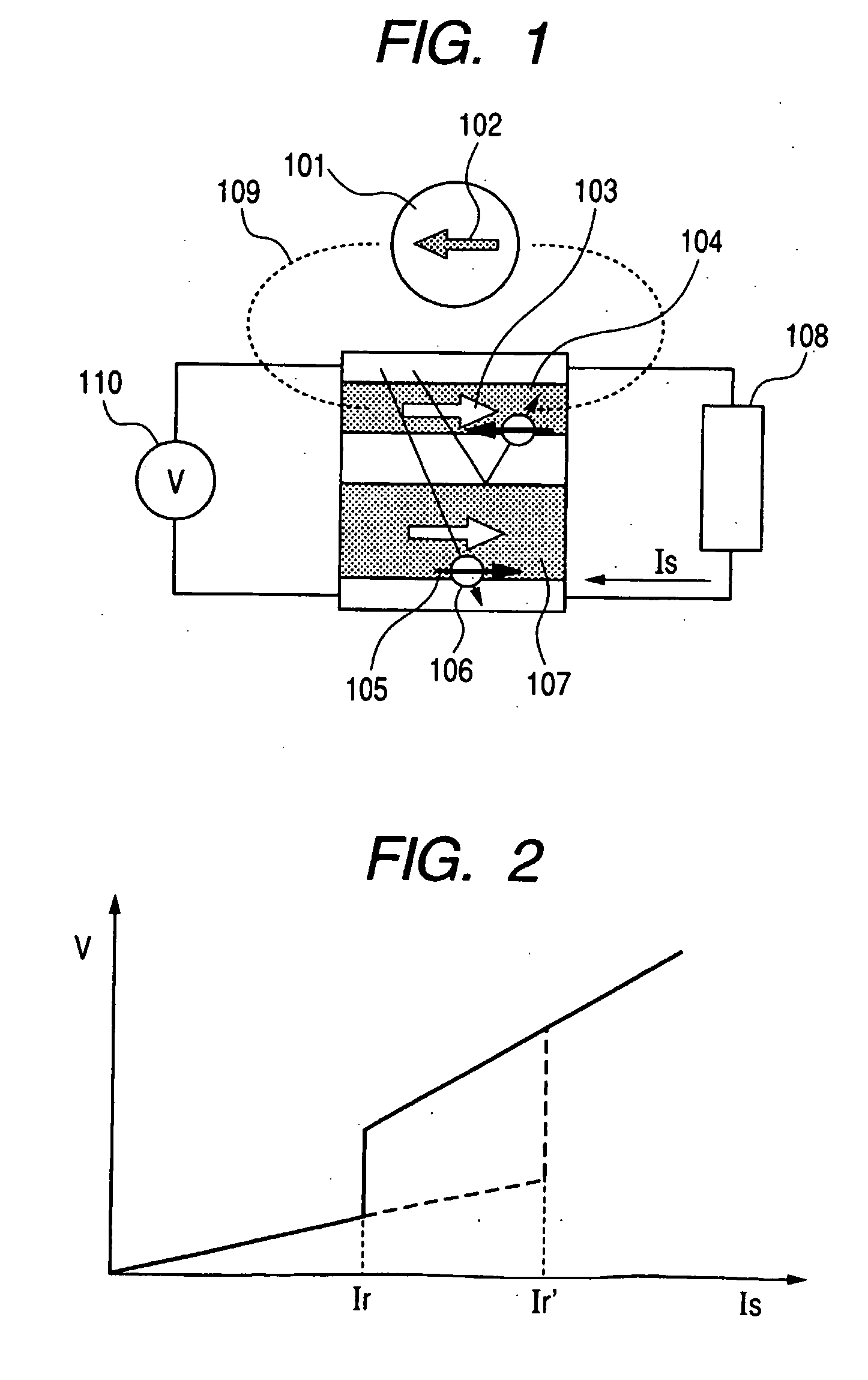

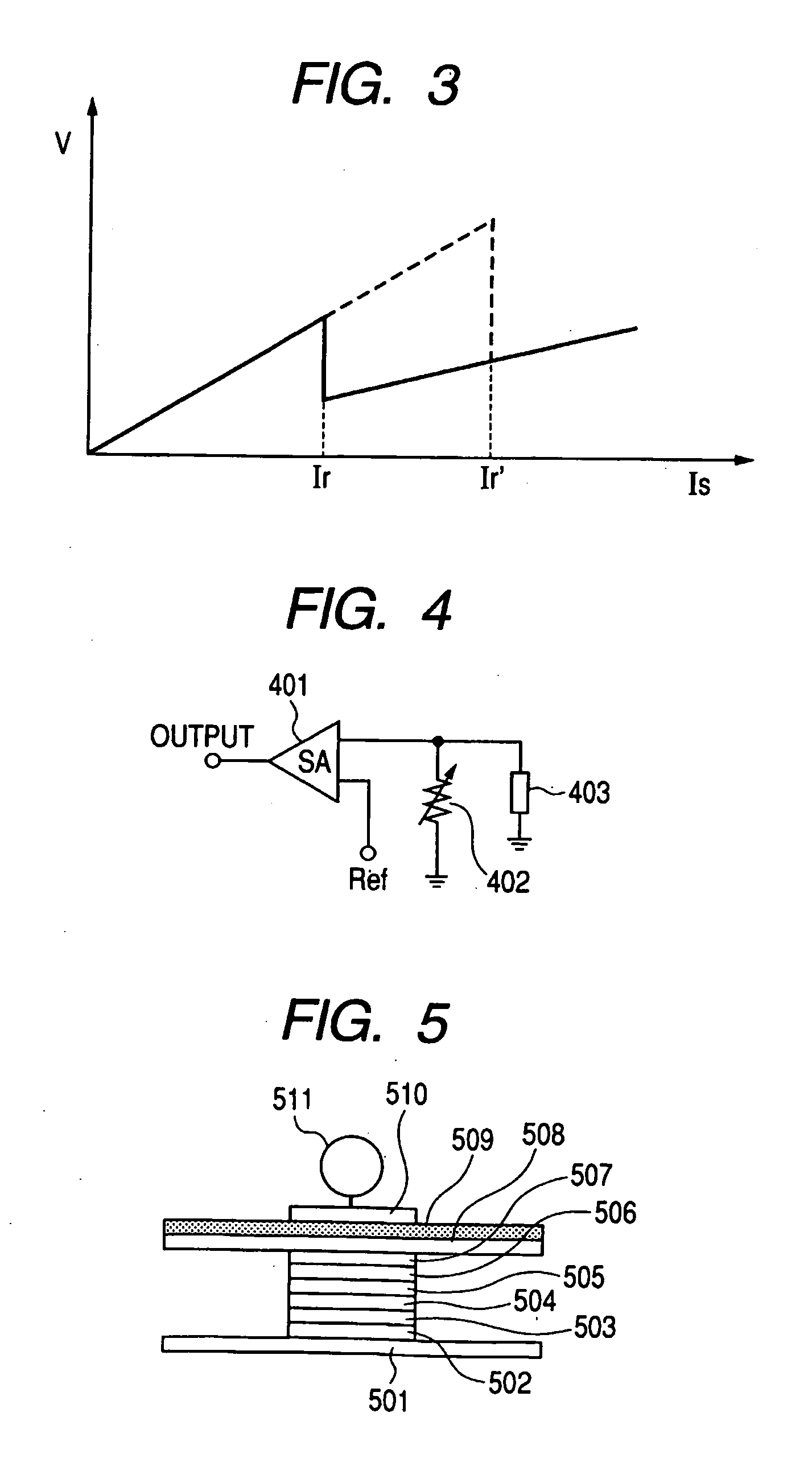

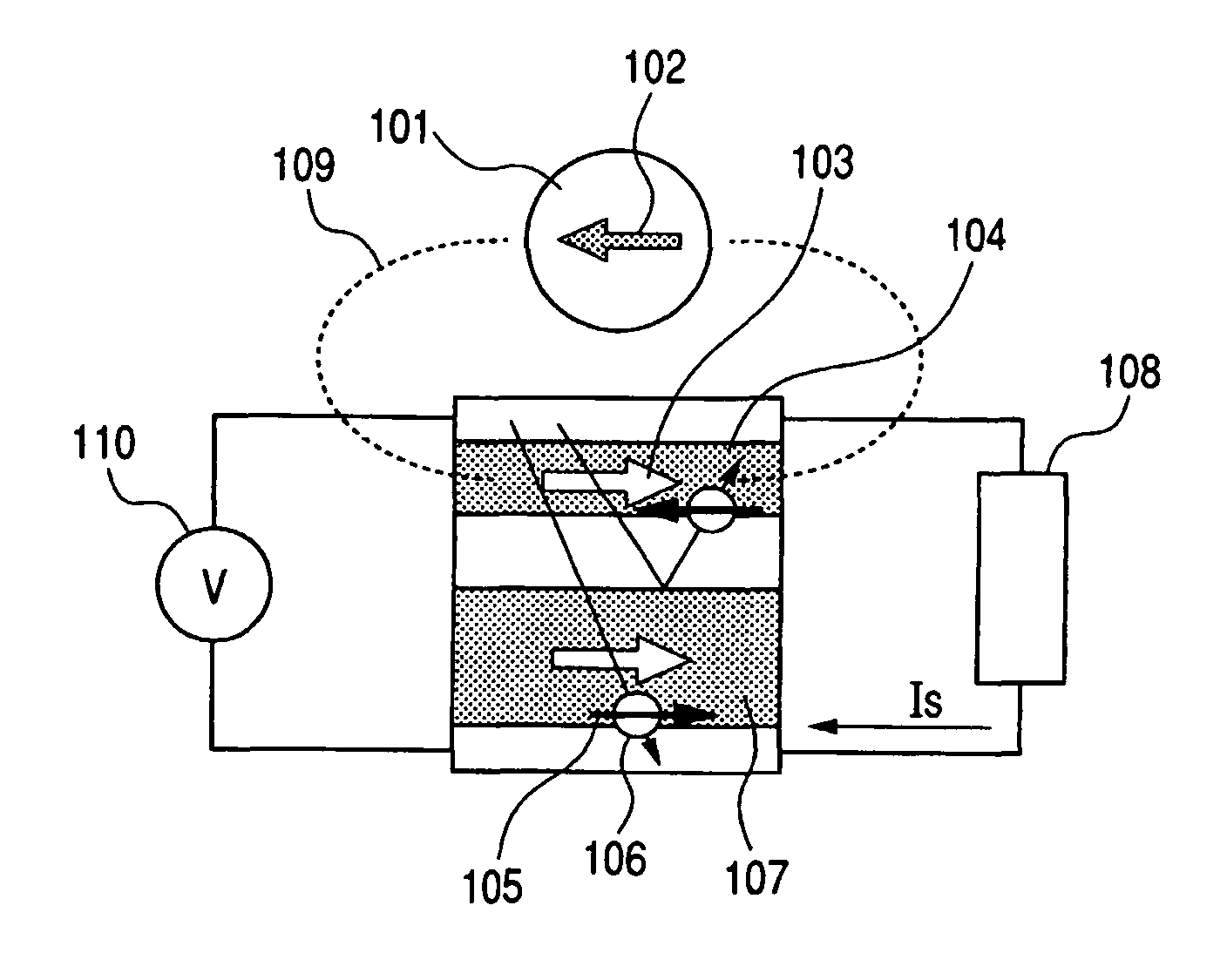

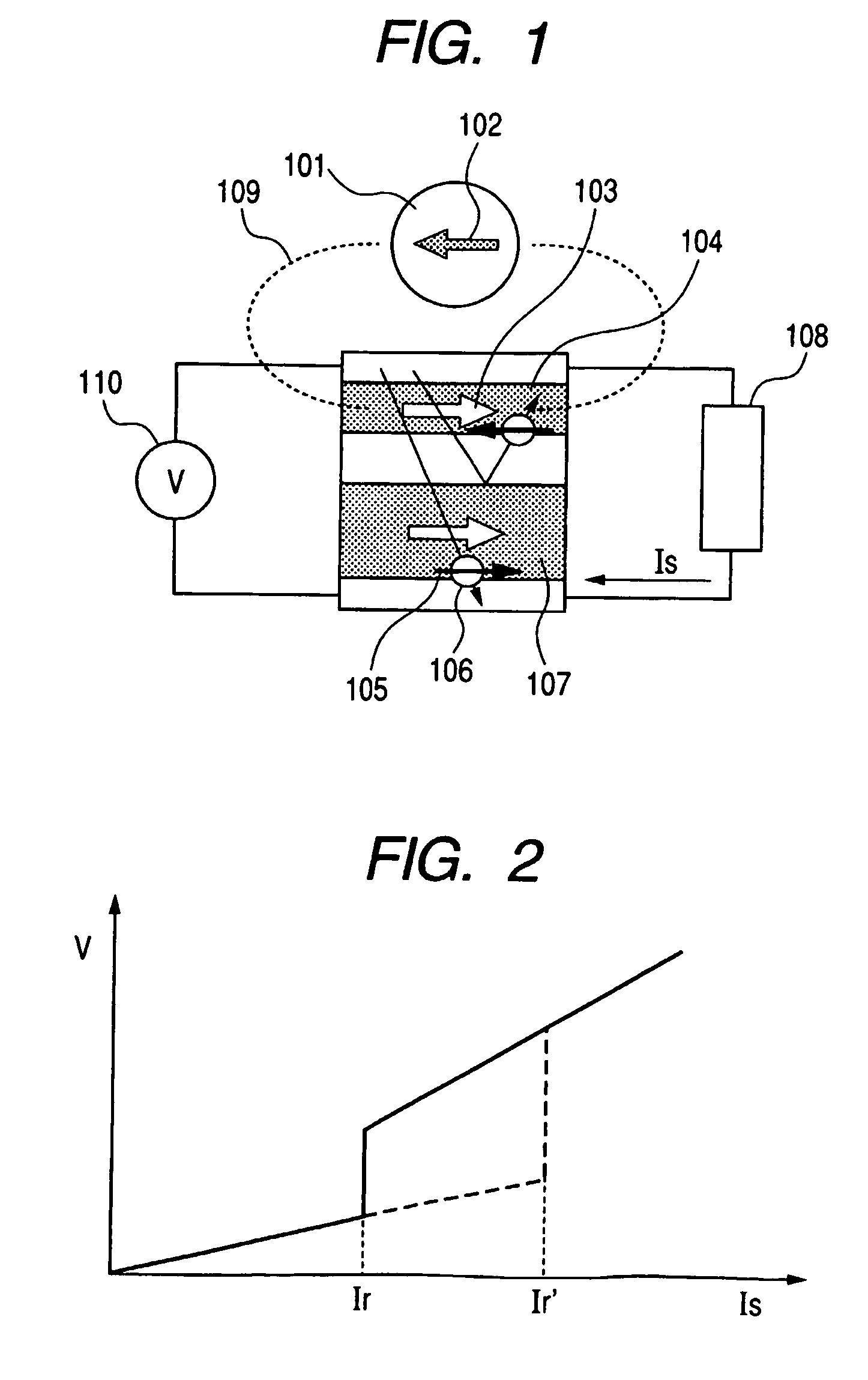

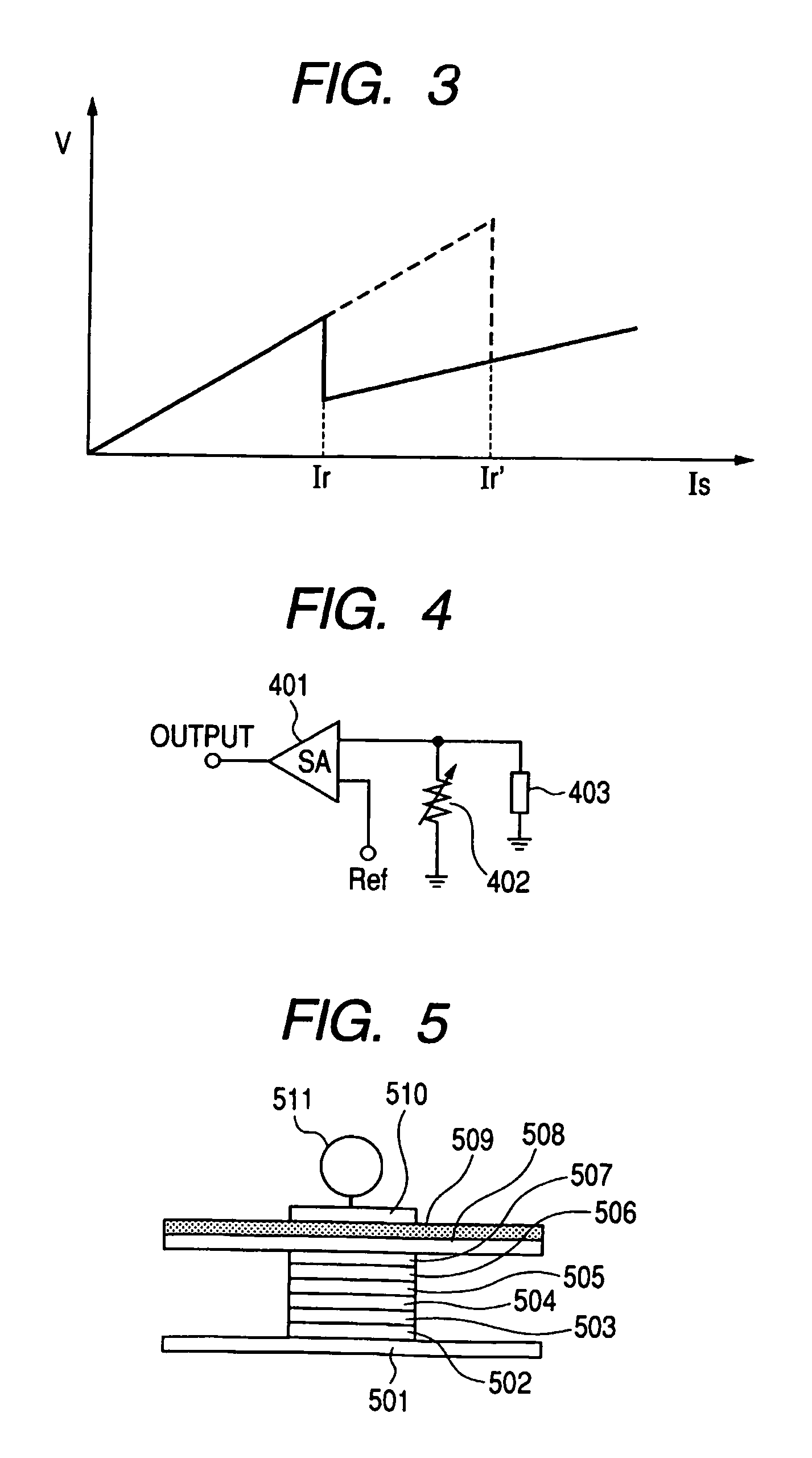

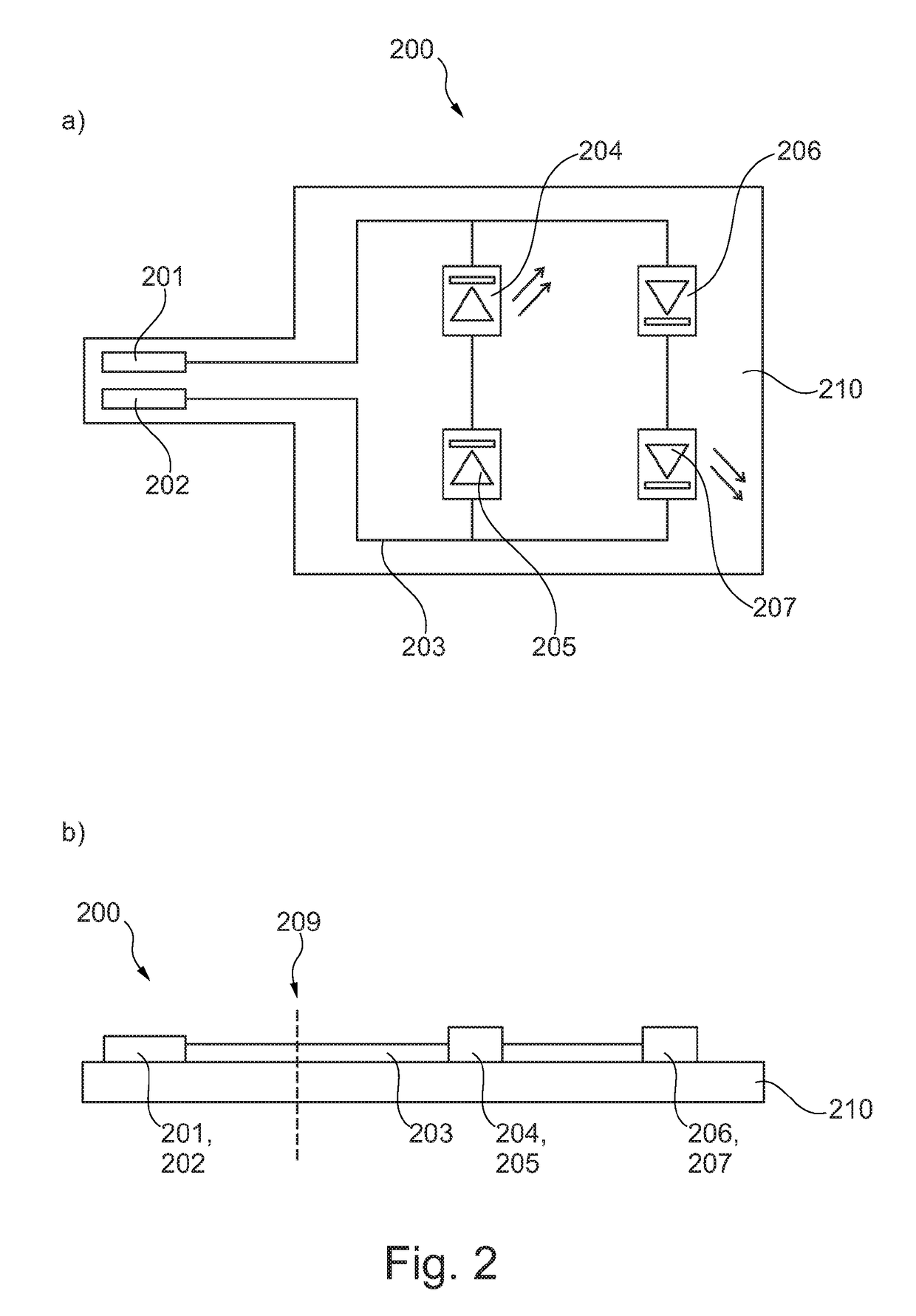

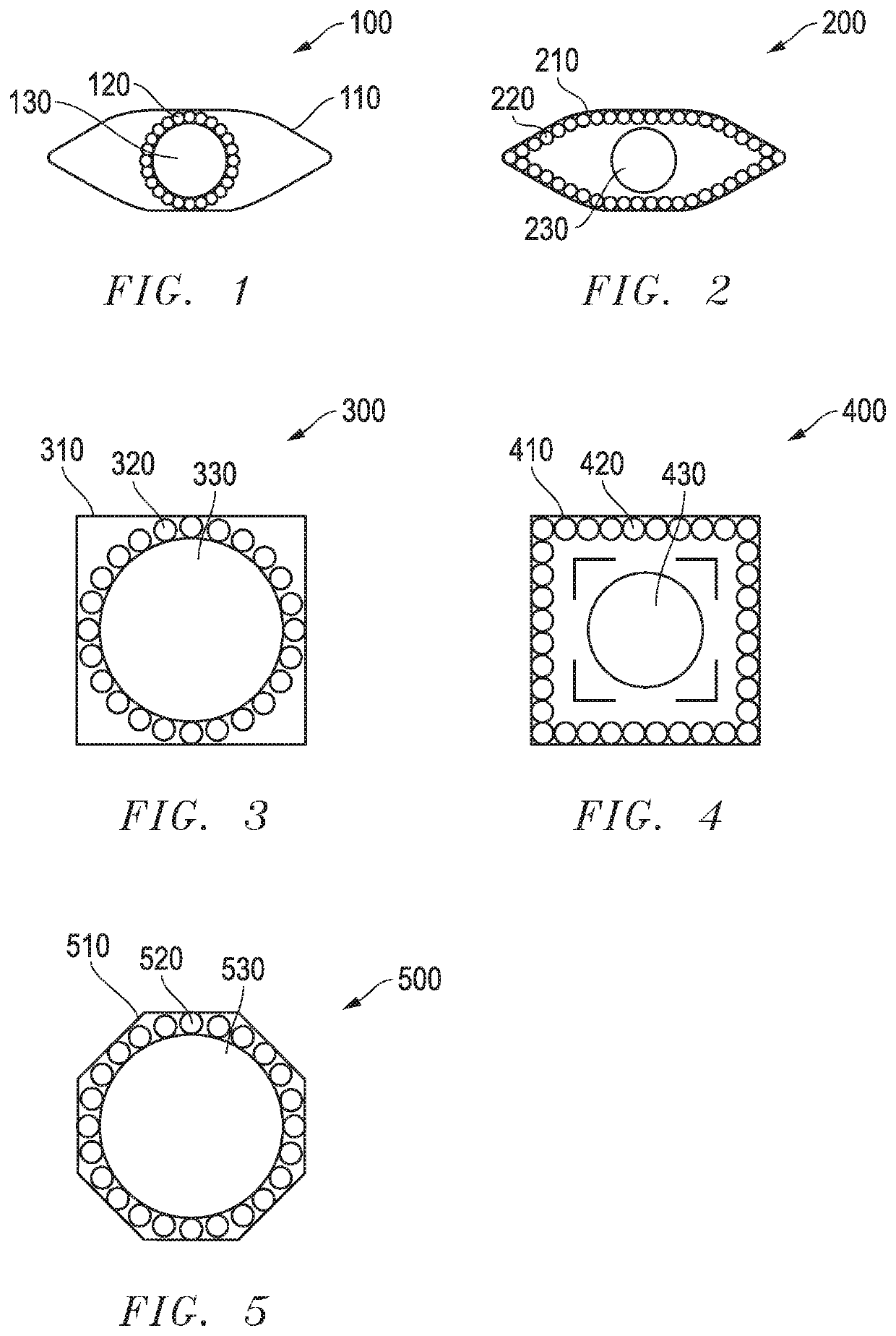

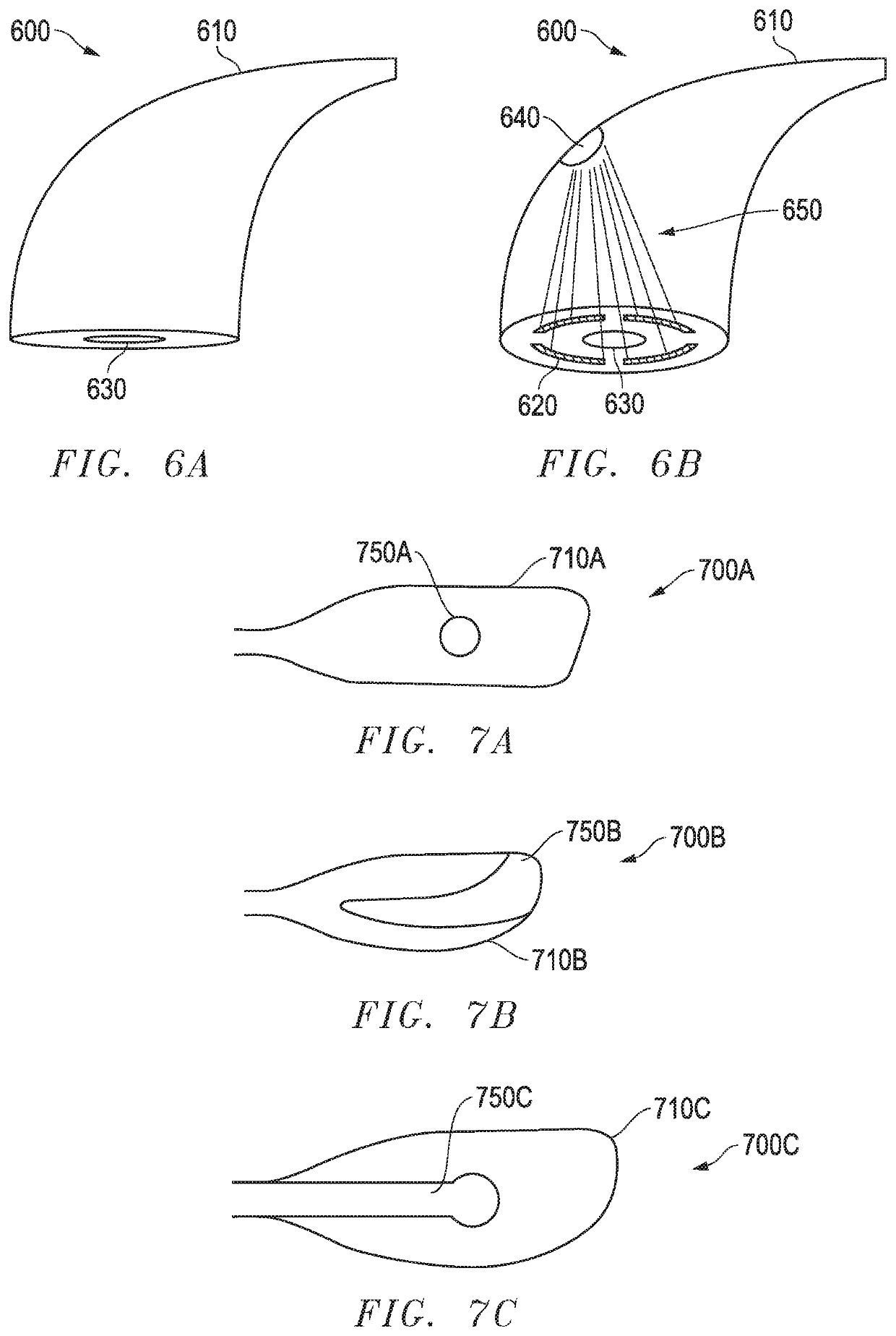

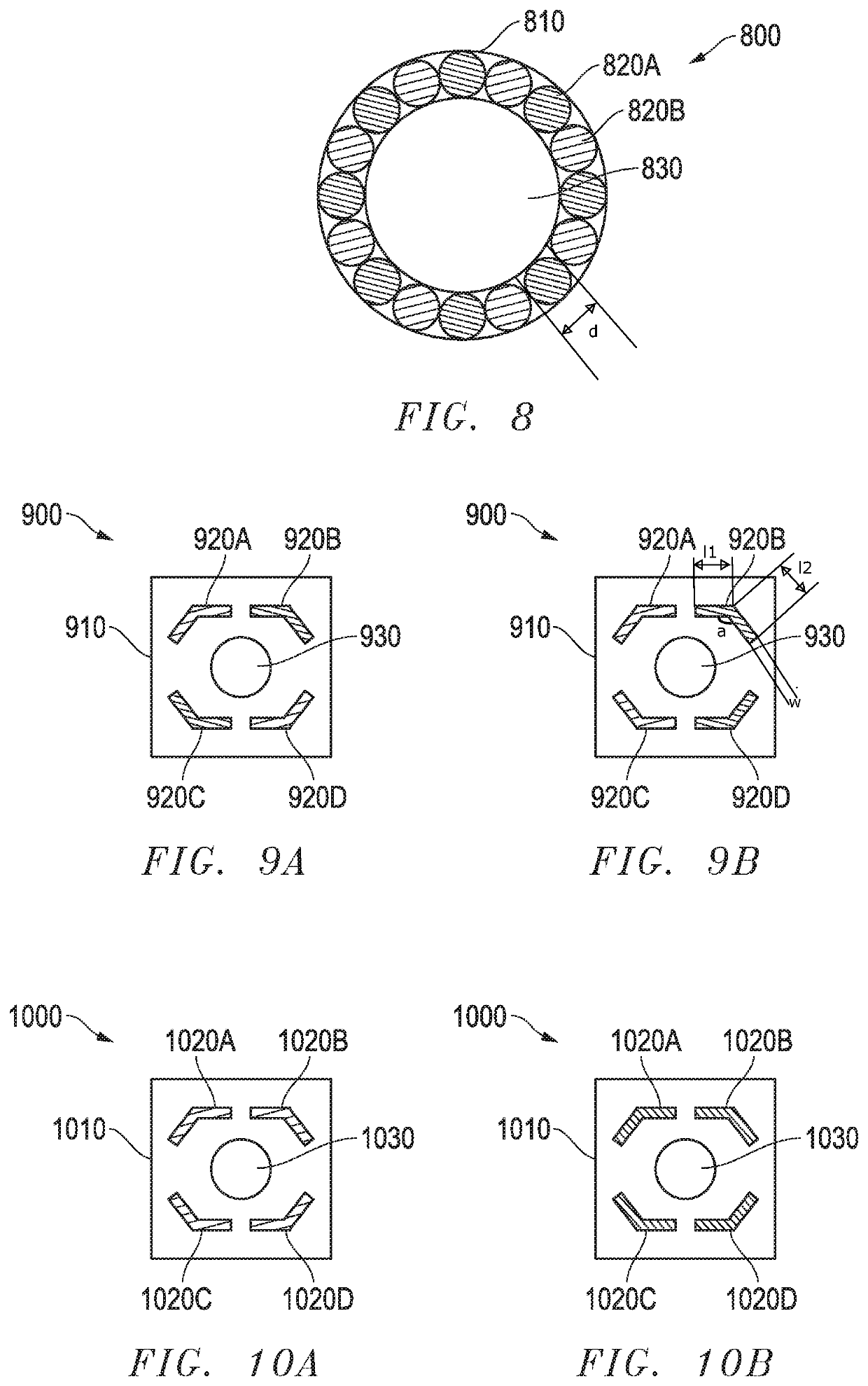

Magnetic Material Sensor and Detection Method Employing this Sensor, and Target Material Detection Sensor and Target Material Detection Kit

InactiveUS20080284419A1Production compactVoltage changeNanomagnetismMagnetic-field-controlled resistorsMagnetizationElectrical current

The present invention provides an appropriately produced magnetic material sensor having a small size.The magnetic material sensor of this invention includes: a magnetoresistive effect film, formed using magnetic films; a current source, for supplying to the magnetoresistive effect film a current having a magnitude and a direction that can change the magnetization directions of the magnetic films; and a detector, for detecting the resistance of the magnetoresistive effect film.

Owner:CANON KK

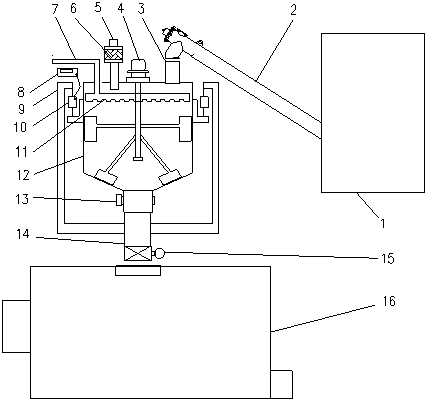

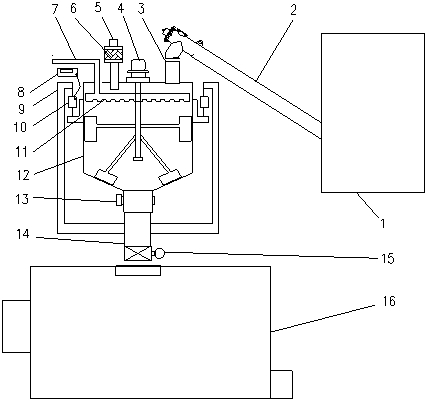

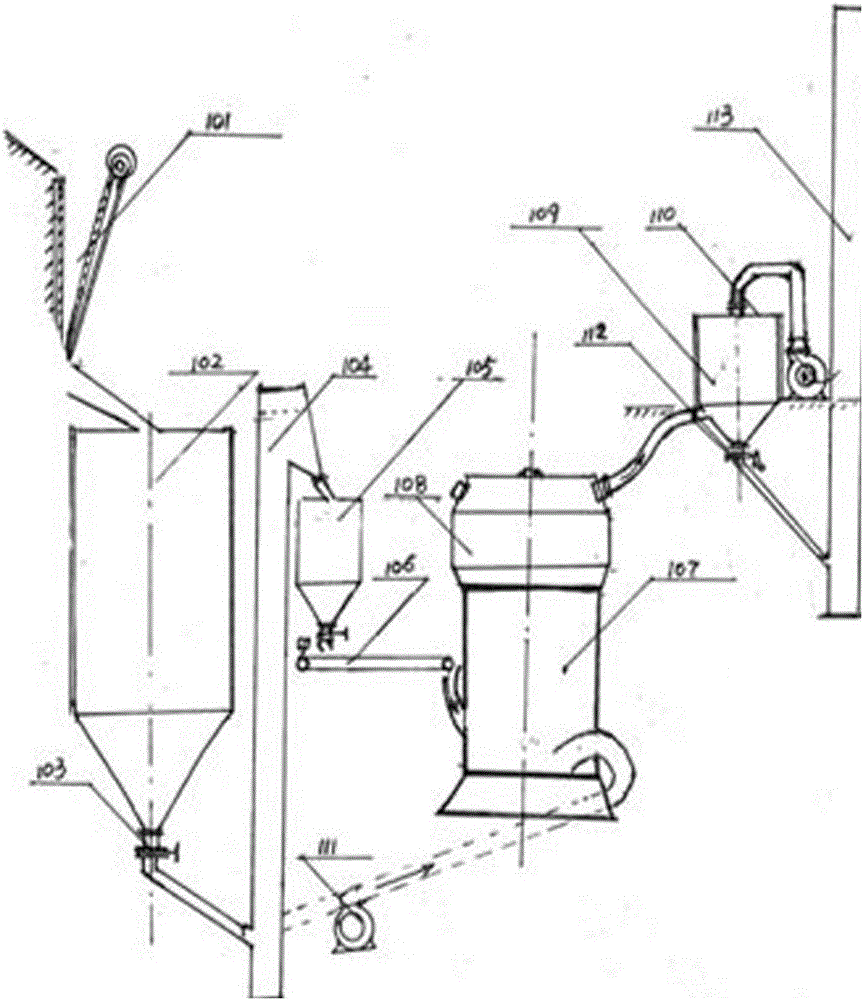

Dust-free concrete production device and production process of dust-free concrete

The invention provides a dust-free concrete production device which comprises a water supply system, a slurry blender, a concrete blender, a weight sensor and a blender bracket, wherein a blending mechanism, a dust filtering device, an air outlet, a powder material input opening, a water inlet and a material discharge opening are arranged on the slurry blender; the dust filtering device covers at the air outlet of the slurry blender; a dust absorbing material is arranged in the dust filtering device; a weight display device is connected with the weight sensor; the slurry blender is hung on the blender bracket through the weight sensor; the concrete blender is arranged below or at the remote end of the slurry blender; after being blended, the slurry is conveyed to the concrete blender from the material discharge opening to be blended into concrete continuously. The slurry blender is provided with the dust filtering device, so that the phenomenon of dust over-flow during the production process is solved thoroughly, and the environment in the machining field is improved; the ingredients of the slurry are weighed and measured accurately; the working efficiency in concrete blending is improved; and the slurry blender blends the slurry more uniformly, thereby being beneficial for the improvement of the quality of the concrete.

Owner:徐州永腾建材有限公司

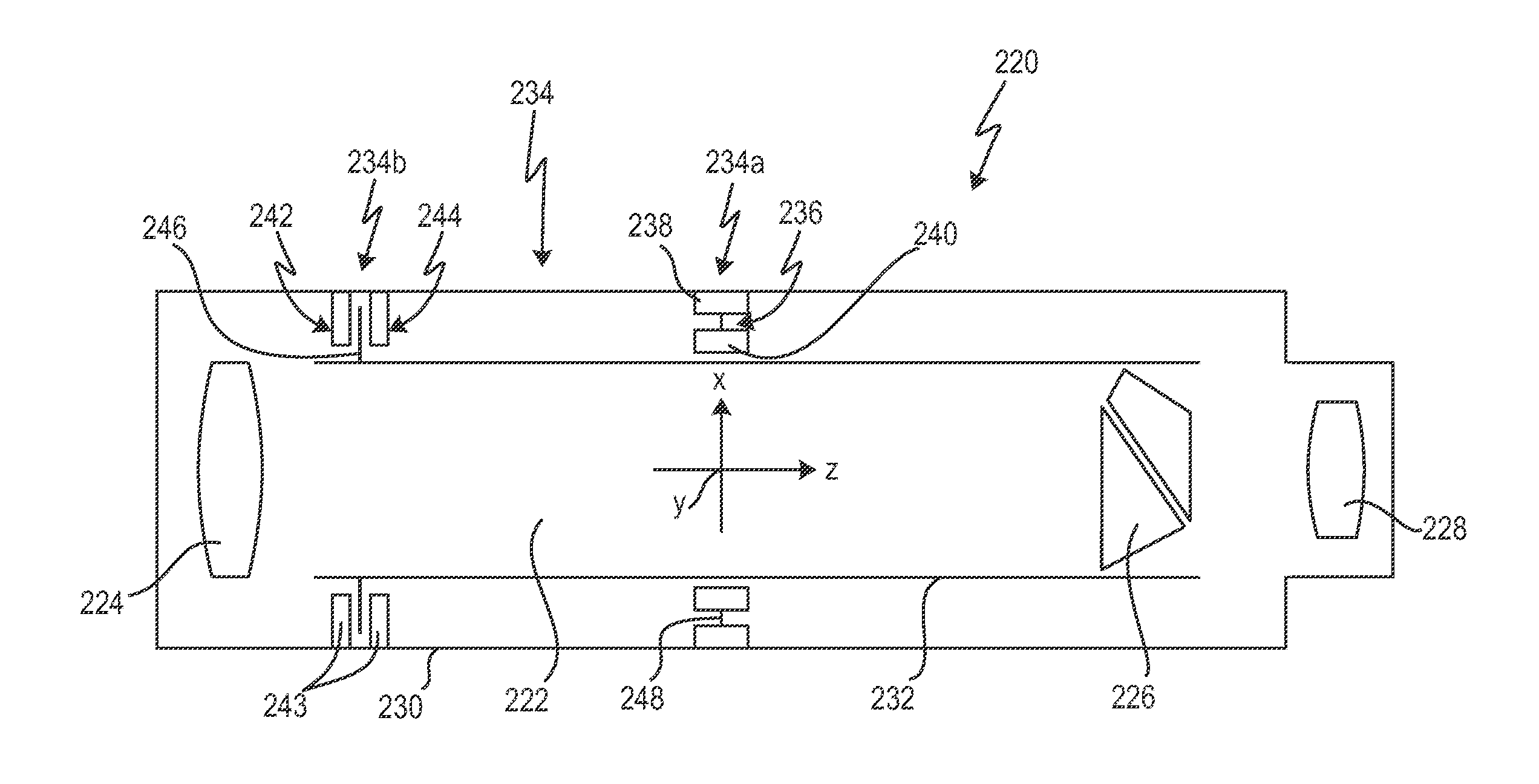

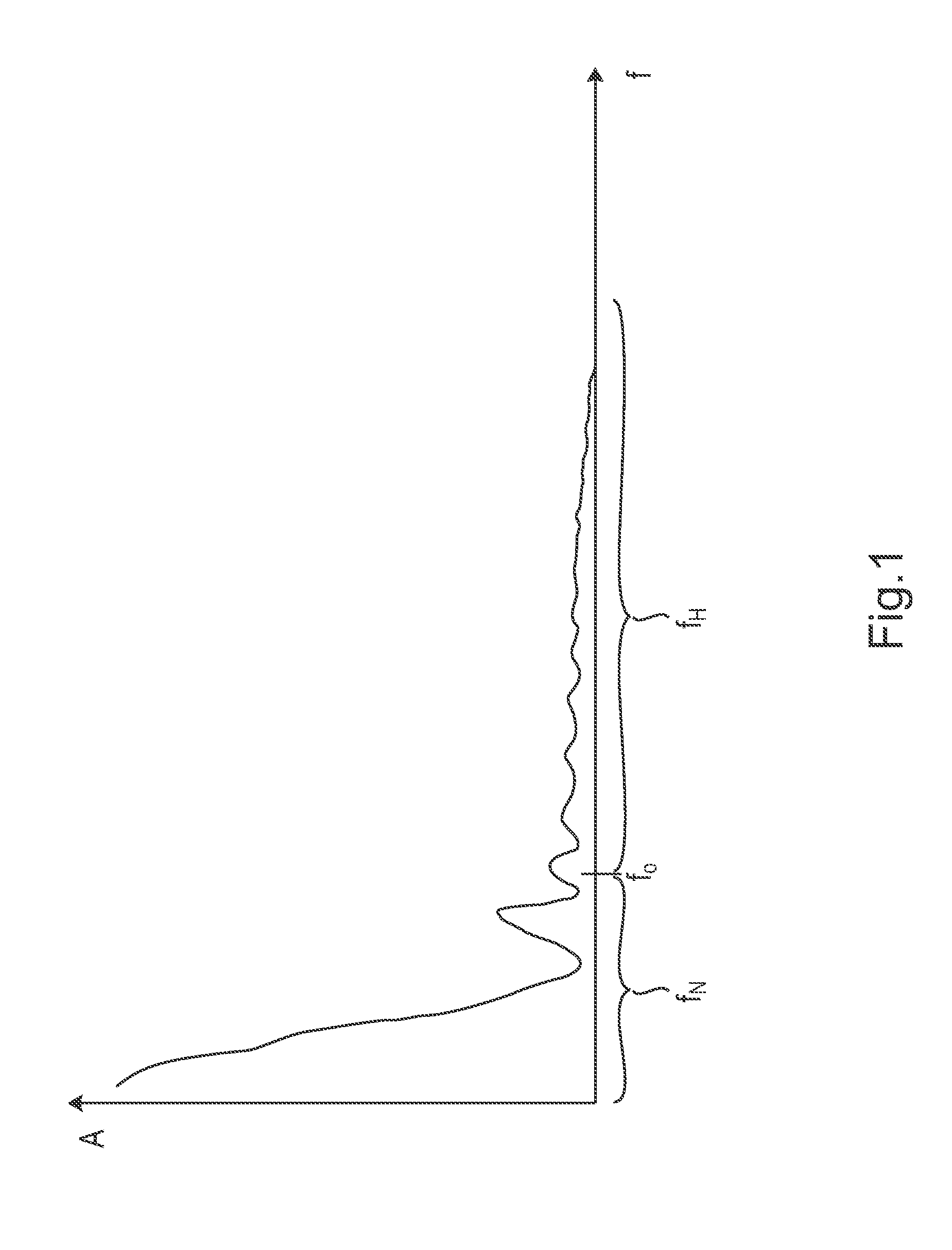

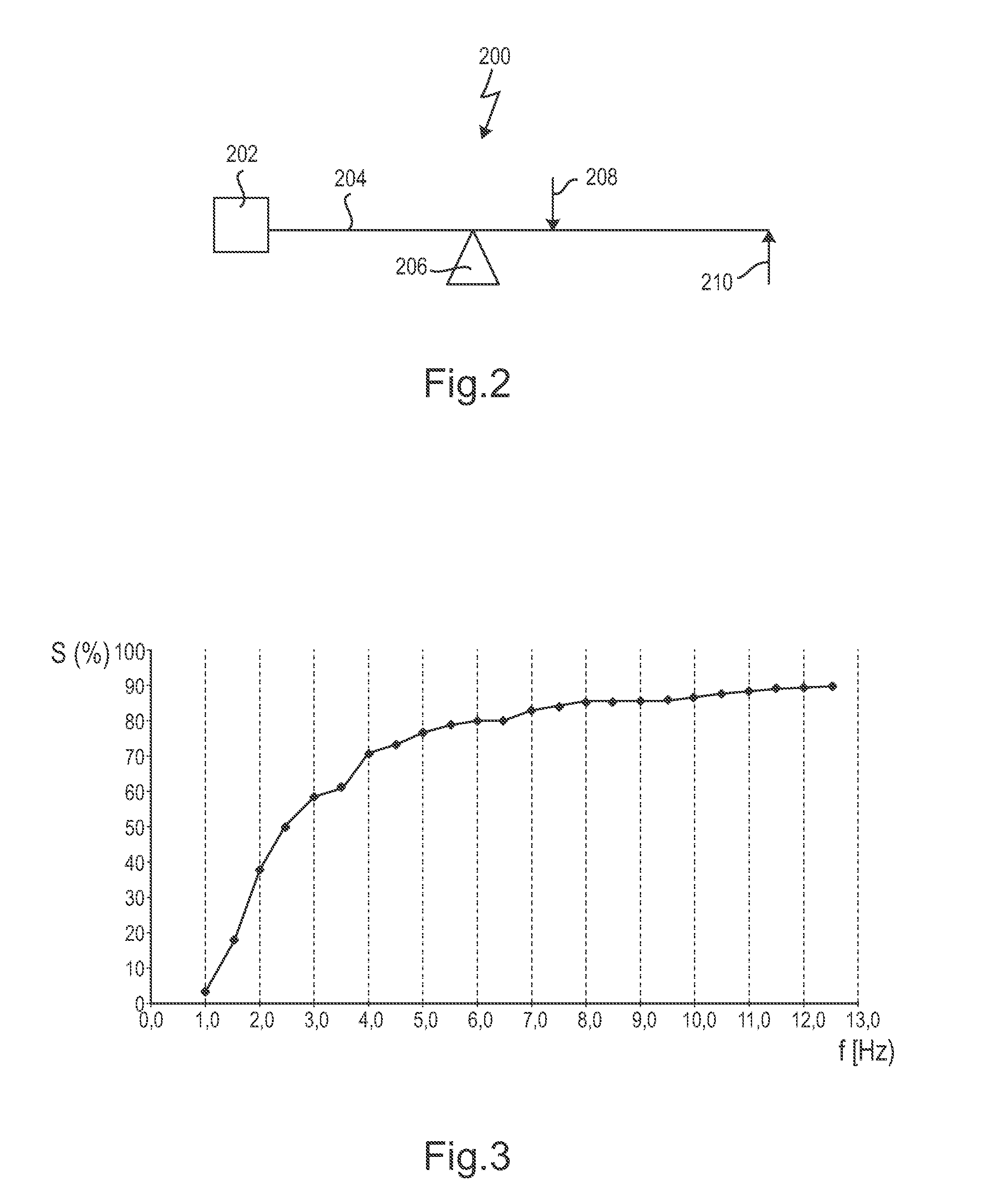

Long-range optical device having image stabilization

A long-range optical device has at least one optical channel, which has a housing and an arrangement of optical elements, wherein at least one of the optical elements is movable relative to the housing for image stabilization in the event of perturbing movements of the housing. The device further has a first passive stabilization system based on mass inertia for the at least one movable optical element, which, in the event of displacement of the at least one optical element relative to the housing, generates a first restoring force proportional to the displacement and a second restoring force proportional to the displacement velocity. The first stabilization system is designed for image stabilization in the event of perturbing movements in a first frequency range. The long-range optical device has at least one second stabilization system, which is coupled to the first stabilization system and is designed for image stabilization against perturbing movements in at least one second frequency range, wherein the first and the at least one second frequency ranges are at least partially different.

Owner:CARL ZEISS SMT GMBH

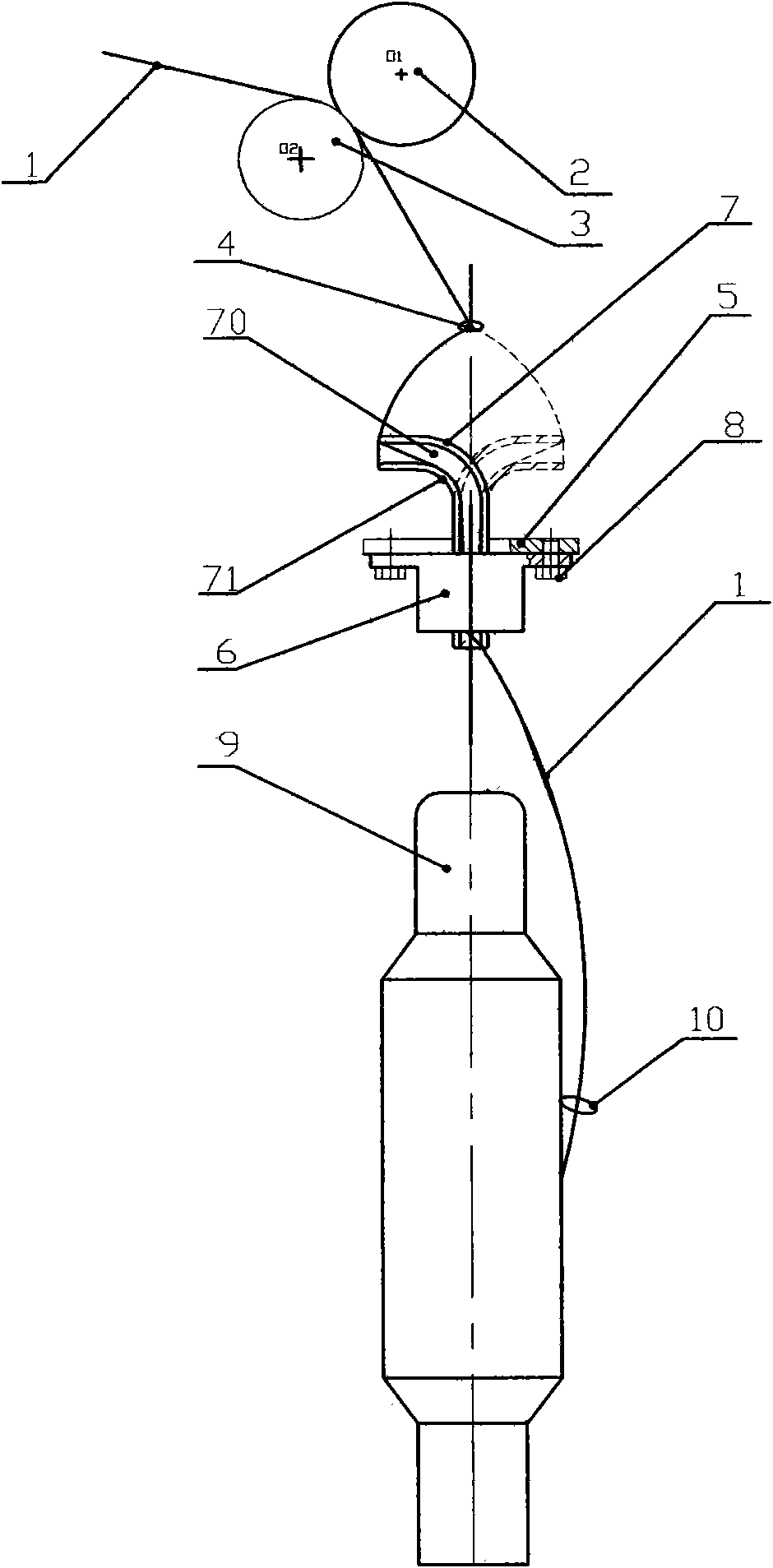

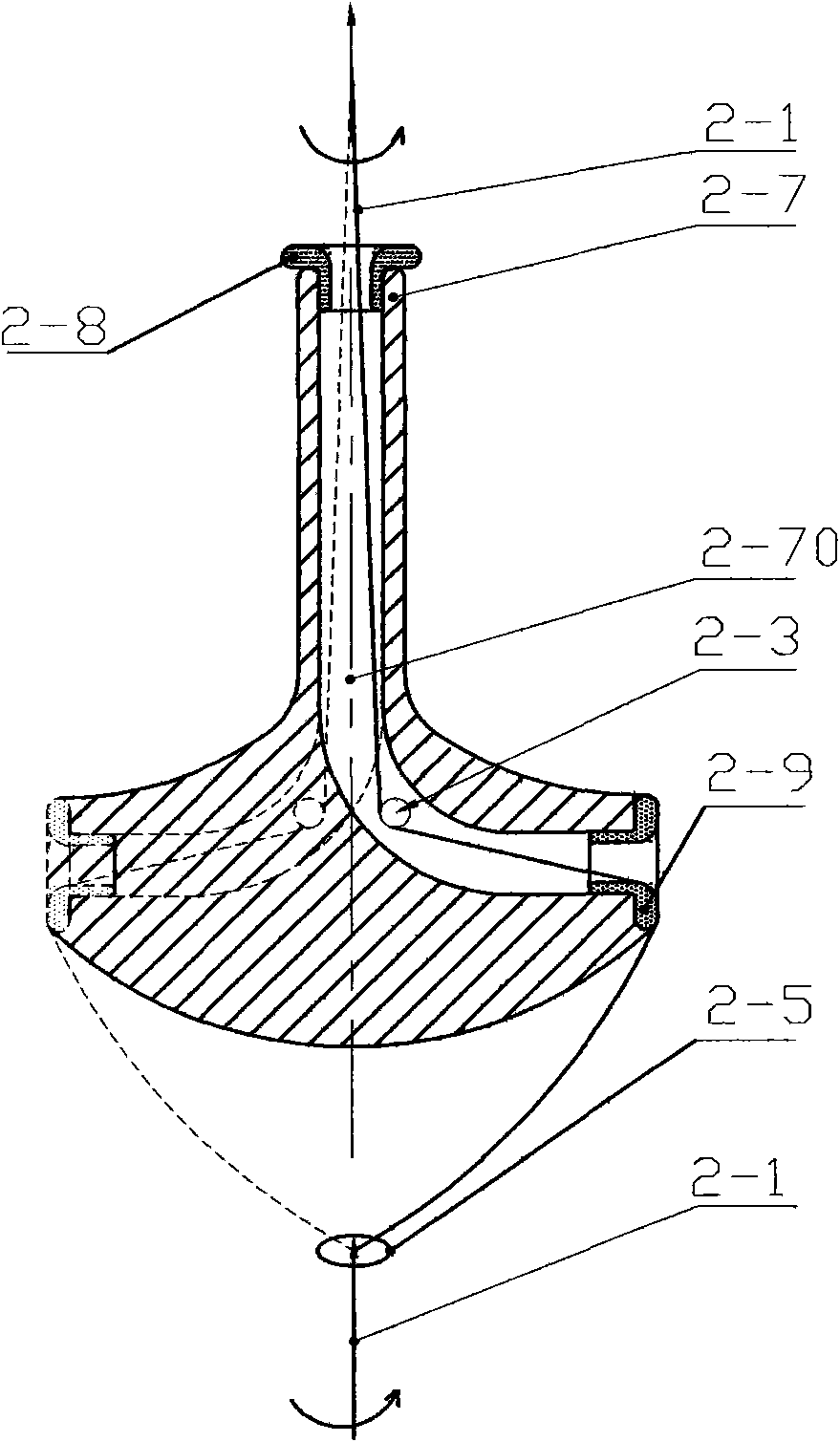

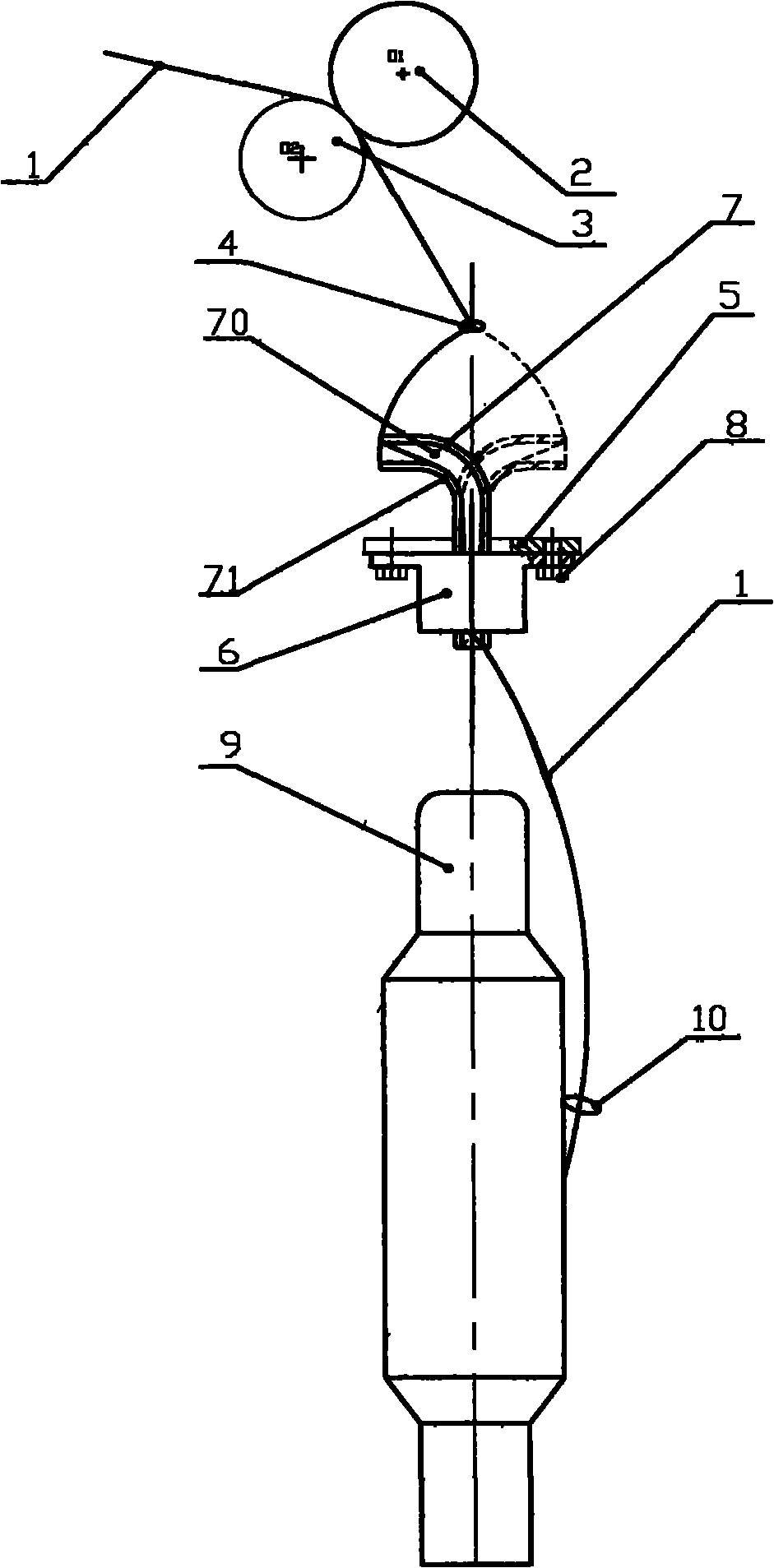

Production method of low torque yarns and device thereof

InactiveCN101967706ASimple production processReduce energy consumptionTextiles and paperYarnEngineering

The invention discloses a production method of low torque yarns and a device thereof, which are used for producing the low torque yarns and belong to the technical field of yarns production in textile machinery. A newly invented yarn false twisting device is mainly adopted and installed at the position above a spinning spindle. The yarn false twisting device ensures that the produced yarns are twisted according to the set number of turns and the degree of twist of a direction of twist opposite to that generated by the spinning spindle after the yarns are drafted by a front roller and a front leather roller, and two degrees of twist are generated for the yarns between the yarn false twisting device and a spinning spindle steel traveler: in one degree of twist, the number of turns formed by the yarn false twisting device is equal to the set number of turns, and the direction of twist is the same as that generated by the spinning spindle; and the other degree of twist is generated by the spinning spindle steel traveler. The three degrees of twist are superposed, the degree of twist generated by the spinning spindle steel traveler is finally formed inside the yarns, and the yarns are wound on a tube of the spinning spindle to complete the whole production process of the low torque yarns.

Owner:绍兴华裕纺机有限公司

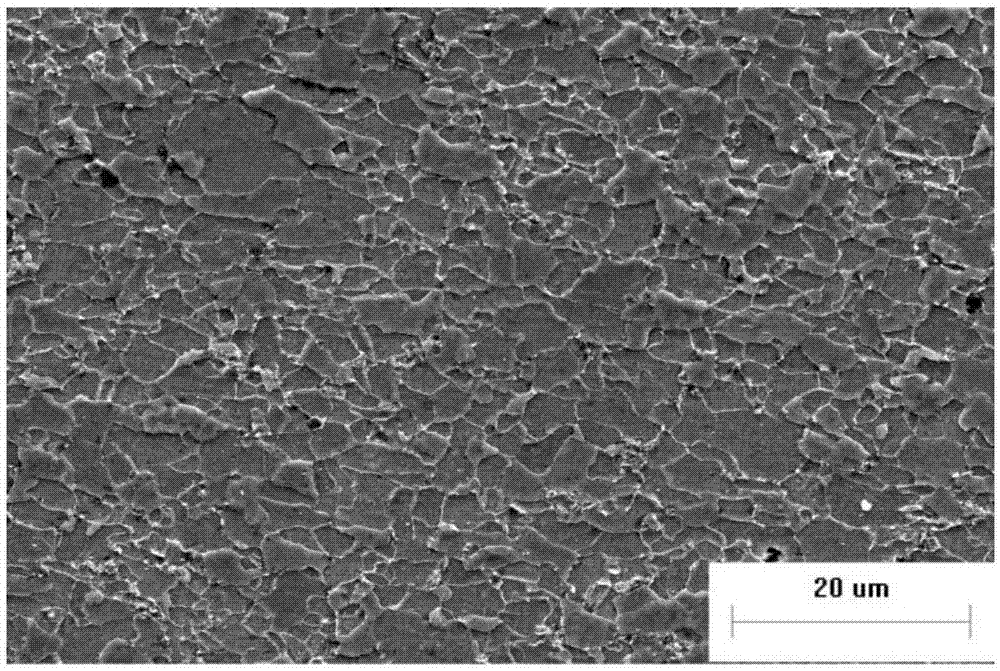

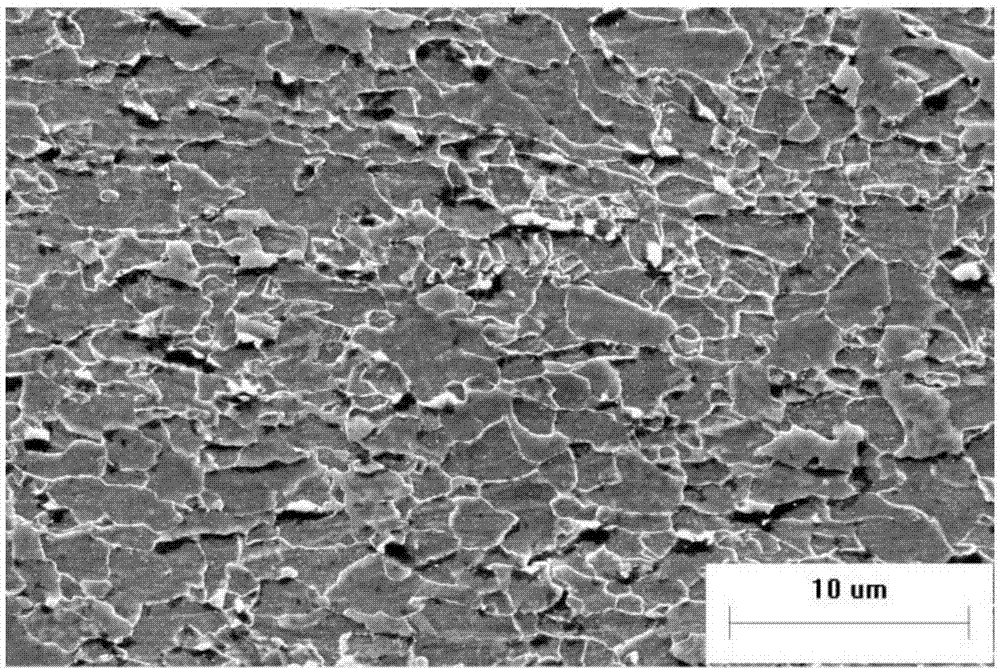

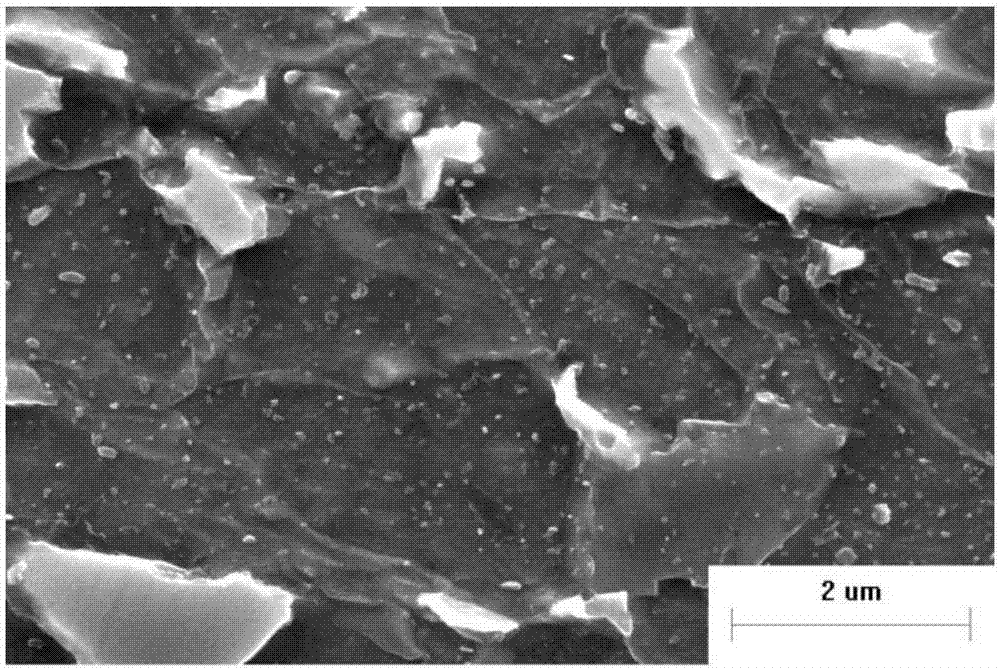

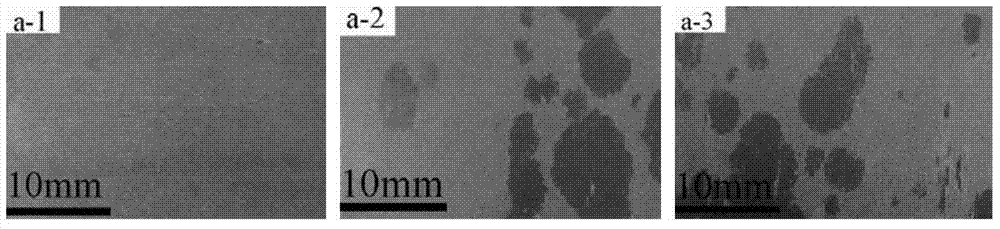

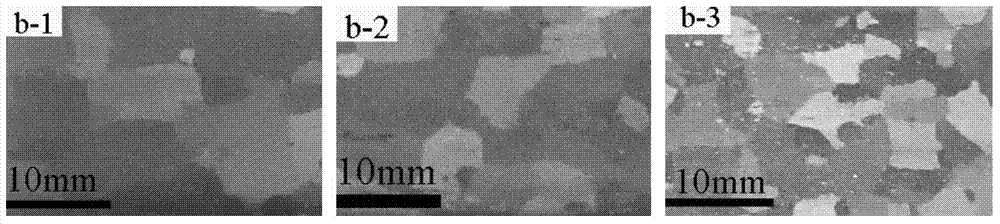

Preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel

InactiveCN107460413AImprove mechanical propertiesGood atmospheric corrosion resistanceWeather resistanceAustenite grain

The invention relates to a preparation method and application of 550 MPa-grade ultra-fine grain high-strength weather-resistant steel and belongs to the technical field of metallurgy. The preparation method comprises the steps that continuous casting blanks directly enter an M rack rough rolling unit under the high pulling speed and are subjected to M-pass continuous heavy reduction (50-60%) rough rolling, and austenite grains are greatly refined; after rough rolling, middle blanks are rapidly heated through an induction heating furnace to the temperature needed for a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then sequentially through a finish rolling set, laminar flow cooling and a reeling machine, finally the organization characteristics that the surface and the core part are coarse, and the portion of the 1 / 4 thickness position is fine are formed. In the production process, finish rolling and rough rolling are both full-headless rolling. An ultra-fine grain high-strength weather-resistant hot-rolling steel belt with the weather resistance being equivalent to corten-A is obtained, and the effects that the thin effect replaces the thick effect and the hot effect replaces the cold effect are achieved; while the weight of a car body is small, the service life of a car plate is prolonged, the production efficiency is improved, and the production cost is reduced; and meanwhile energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

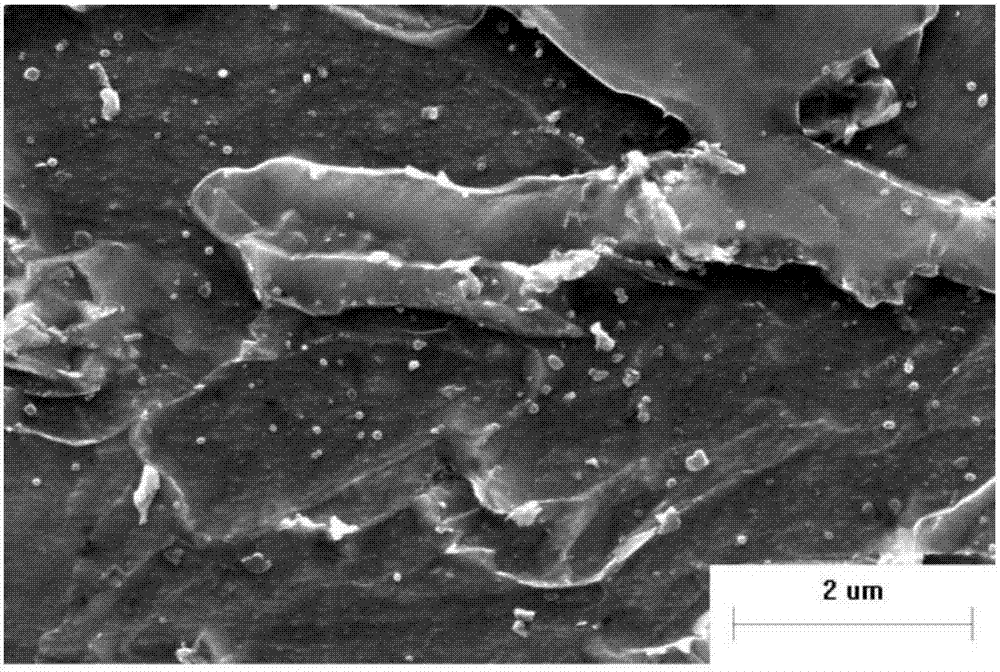

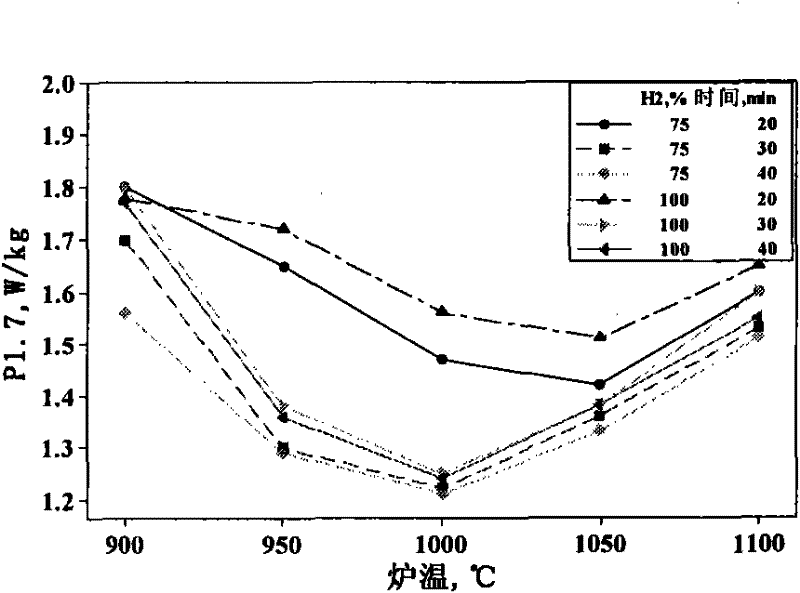

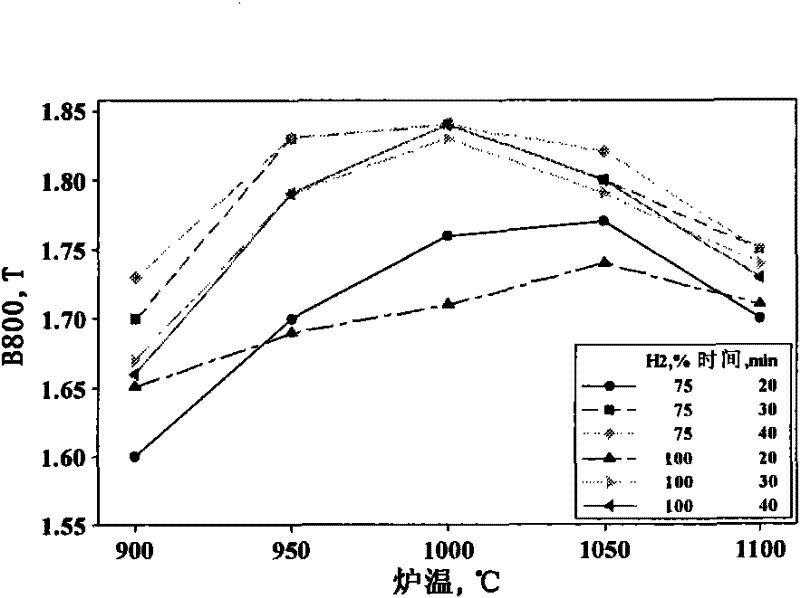

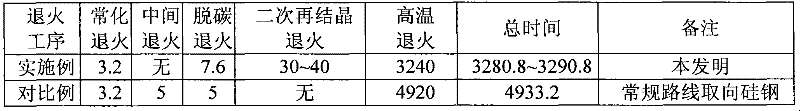

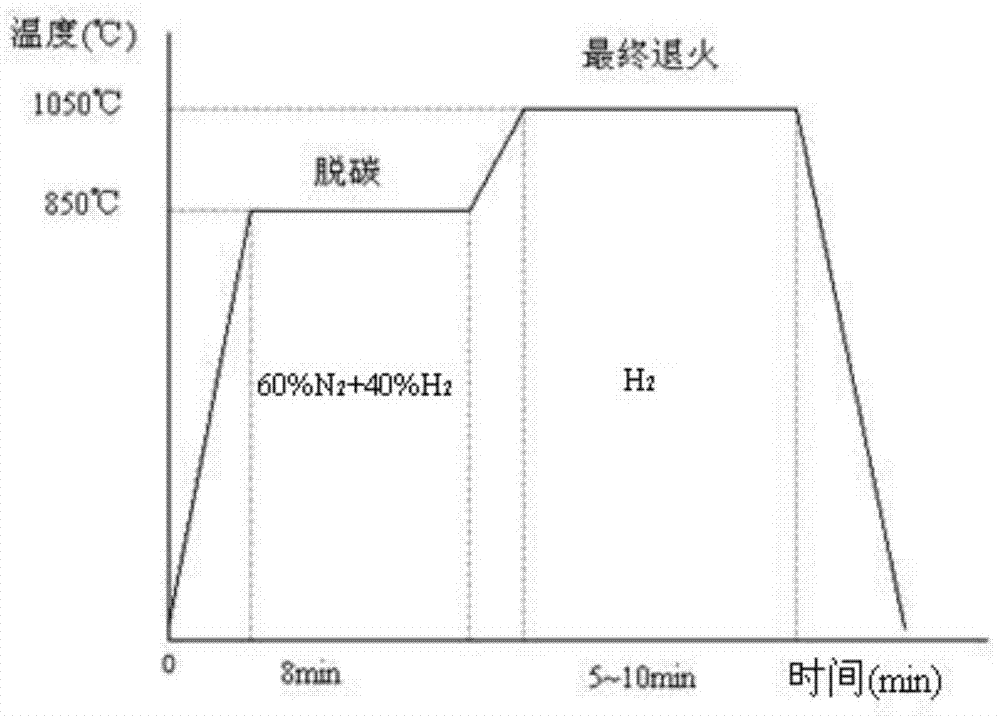

Energy-saving and high-production-efficiency method for preparing common grain-oriented silicon steel

ActiveCN102534363ARealize energy saving and consumption reductionEliminate the intermediate annealing processAcid washingSteel casting

The invention discloses an energy-saving and high-production-efficiency method for preparing common grain-oriented silicon steel. The process comprises the following steps of: smelting and continuously casting, hot-rolling, normalizing and acid-washing, performing primary cold rolling, decarbonizing and annealing, performing secondary cold rolling, performing secondary recrystallization annealing, coating Mgo, performing high-temperature purification annealing, and performing flat annealing and coating an insulation film. On the premise of low-temperature heating of grain-oriented silicon steel casting blank, decarbonizing and annealing is performed between two times of cold rolling, an intermediate annealing process is eliminated, the high-temperature annealing of the grain-oriented silicon steel is divided into secondary recrystallization annealing and high-temperature purification annealing which are implemented separately, and the aims of saving energy and reducing consumption, and improving production rhythm and efficiency can be fulfilled.

Owner:ANGANG STEEL CO LTD

Devices for adjusting the contact pressure of an adjustably mounted cylinder

InactiveUS7021209B2Production compactSuitable performanceRotary letterpress machinesPrinting press partsContact pressureActuator

The contact pressure between an adjustably mounted first cylinder and a second cylinder in a printing machine, and particularly in a web-fed printing machine can be adjusted. An actuator is usable to force the first cylinder toward the second cylinder with an adjustable force. A fixing device is usable to fix the first cylinder in a desired position relative to the second cylinder.

Owner:KOENIG & BAUER AG

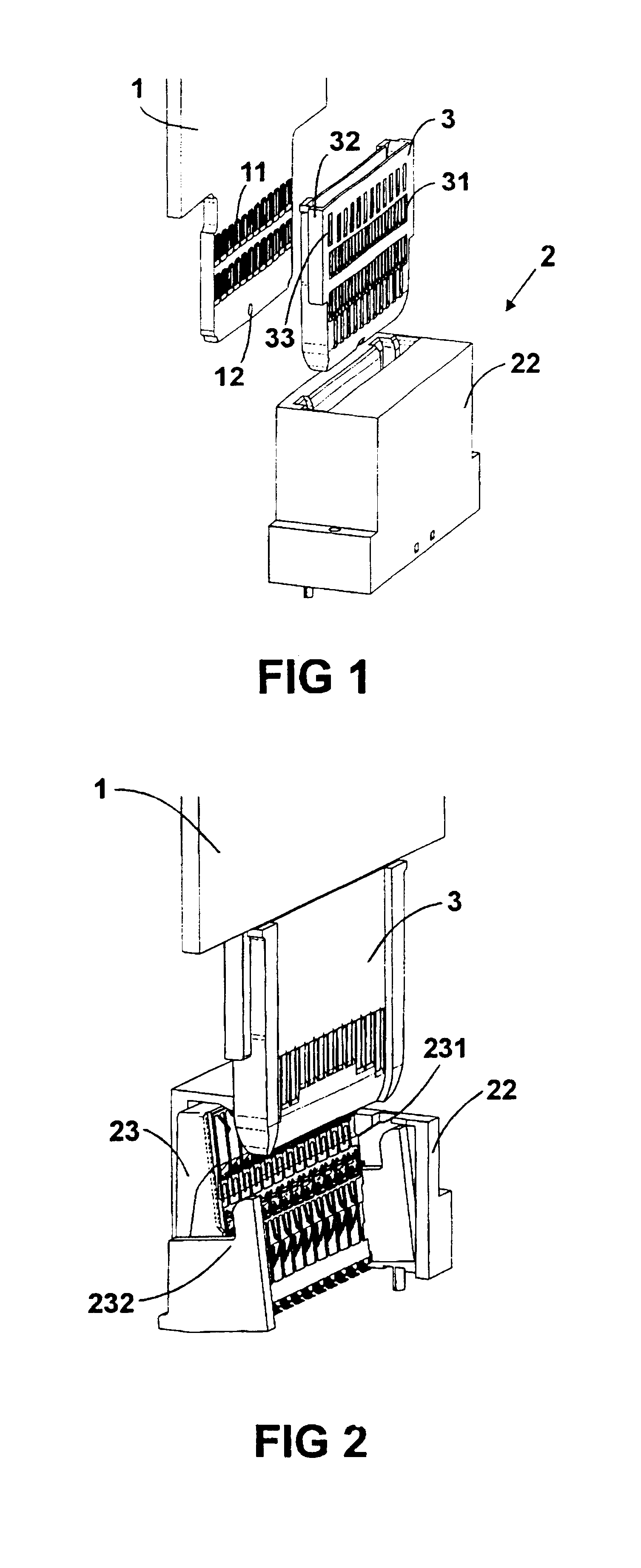

Printed circuit board and connector assembly

InactiveUS6695633B2Produced compactly and easilyBig spaceEngagement/disengagement of coupling partsPrinted circuit aspectsEngineeringPrinted circuit board

A printed circuit board and a printed circuit board zero force connector are configured such that the printed circuit board zero force connector is properly actuated automatically by an attachment provided on the printed circuit board when the printed circuit board is plugged into and removed from the printed circuit board zero force connector.

Owner:TYCO ELECTRONICS BELGIUM EC

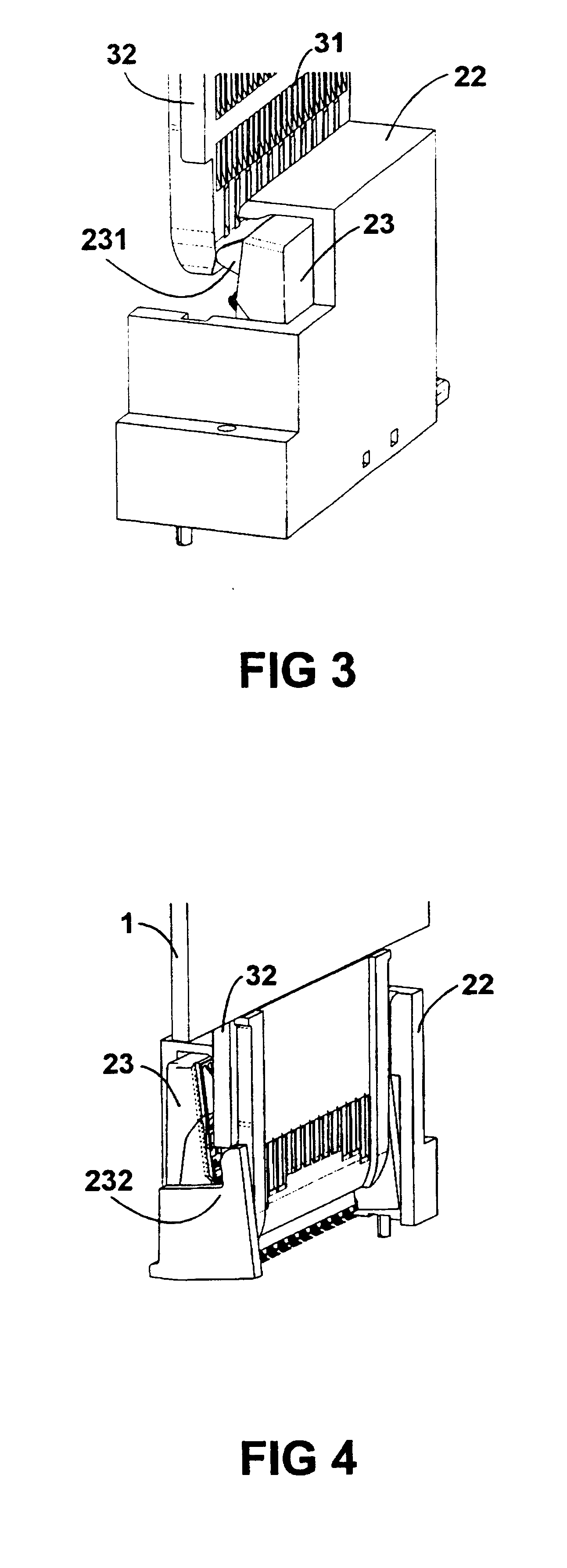

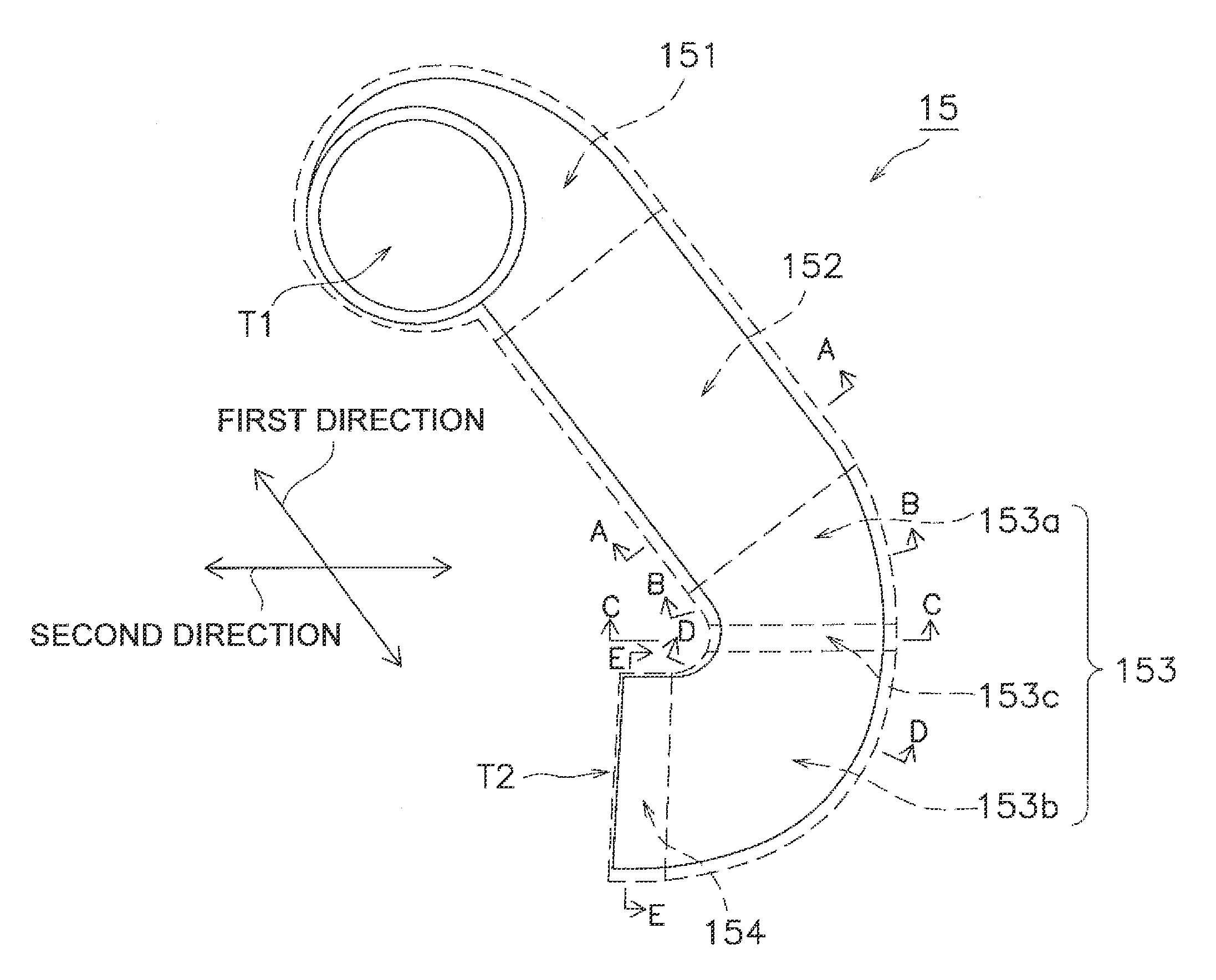

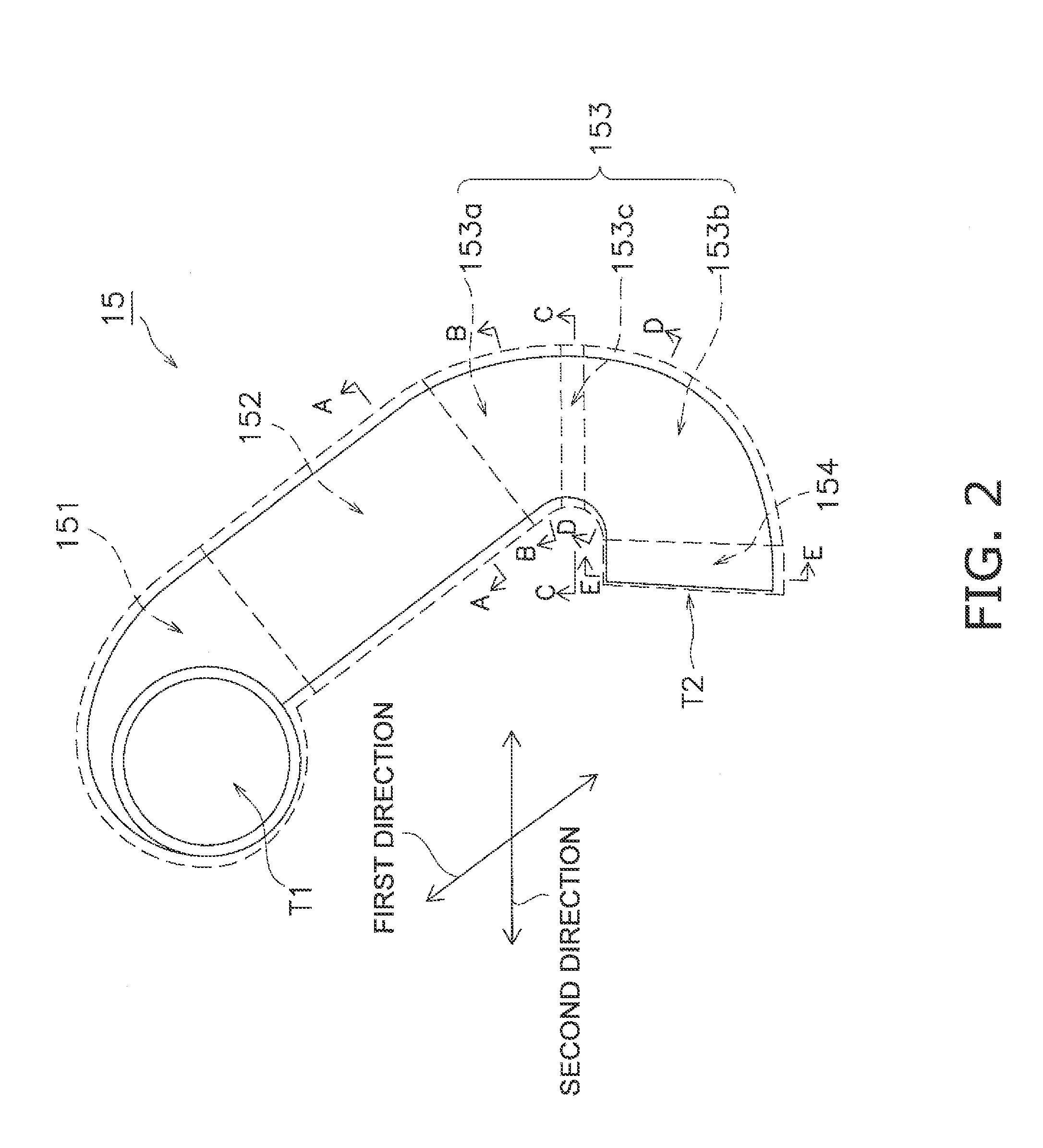

Air supply pipe and forced induction compressor

InactiveUS8555637B2Compactly bentCompact spaceInternal combustion piston enginesFluid dynamicsStraight tubeEngineering

An air supply pipe includes a curved pipe portion having a first end and a second end, a first straight pipe portion extended along a first direction and a second straight pipe portion extended along a second direction. The cross-sectional shape of the curved pipe portion is a rectangular shape having longer sides in a third direction.

Owner:KOMATSU LTD

Preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel

InactiveCN107365940AIncrease surface temperatureReduce the temperatureAustenite grainResource saving

The invention relates to a preparation method and application of 700 MPa grade ultra-fine grain high-strength weathering steel. The preparation method includes the steps that a continuous casting blank directly enters an M rack rough rolling unit at a high pulling speed and is subject to M-gate continuous high reduction (50%-60%) rough rolling, austenite grains are greatly refined, after rough rolling is carried out, an intermediate billet is quickly heated by an induction heating furnace to the temperature needed by a finish rolling inlet, and meanwhile a reverse temperature field is formed; and then the blank sequentially passes through a finish rolling unit, a laminar cooling part and a reeling machine, and the microstructure characteristics that the surfaces and core parts are thick and 1 / 4 thickness parts are thin are finally formed. In the production process, finish rolling and rough rolling are both full-endless rolling. By means of the preparation method, an ultra-fine grain high-strength weathering steel strip with the weather fastness equal to that of corten-A can be obtained, the effects of replacing thick parts with thin parts and replacing cold with heat are achieved, and the automotive body weight is small; and meanwhile, the service life of an automotive sheet is prolonged, the production efficiency is improved, the production cost is reduced, energy consumption is reduced, emission is reduced, and resource-saving and environment-friendly production is achieved. The preparation method and application belong to the technical field of metallurgy.

Owner:UNIV OF SCI & TECH BEIJING +1

Multiple application purification and recycling device

InactiveUS7955476B2Flexible operationEasy constructionEvaporation with vapour compressionDistillation regulation/controlDistillationMultiple applications

A multiple application recycling and purification device has a coaxial core that is horizontally oriented, non-rotating, cylindrical distillation chamber. The enhanced, completely coaxial configuration continuously cleans the entire distillation chamber and spreads a thin film of liquid to enhance distillation and positively aid in the removal of remaining contaminants. Through a timed and positioned valve, the device removes and purges lower-temperature contaminants. Timed valves and sensors control all phases of the distillation to provide a coaxially integrated, stand-alone, adaptable, scalable and maintenance free distillation unit that self-monitors, self-cleans and economically functions to produce the pure distilled liquid, e.g., water. This device can be modified to purify any numerous array of liquids and can be scaled to produce any amount of purified liquids for either household, commercial, or industrial applications.

Owner:MANSUR CORP

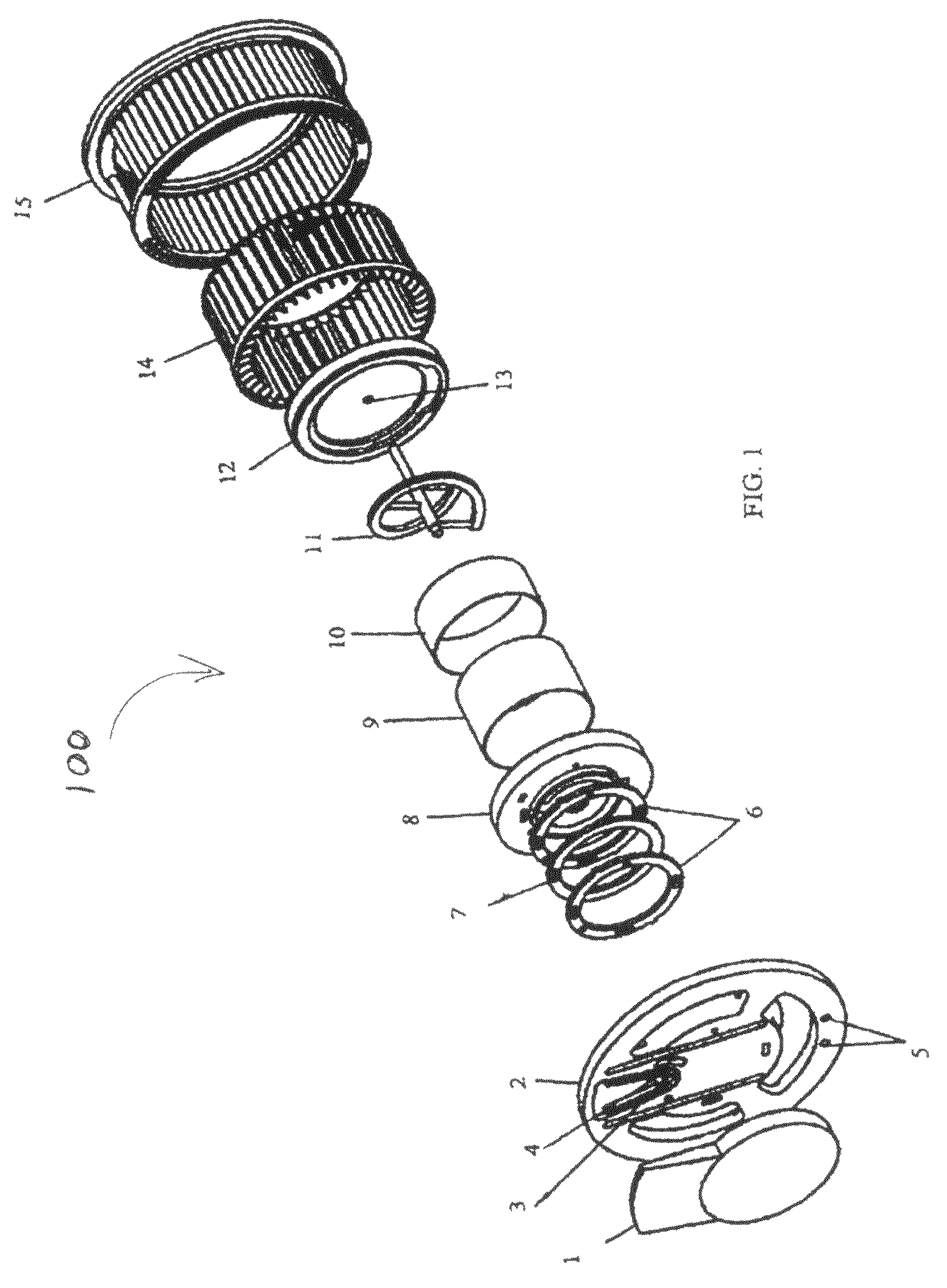

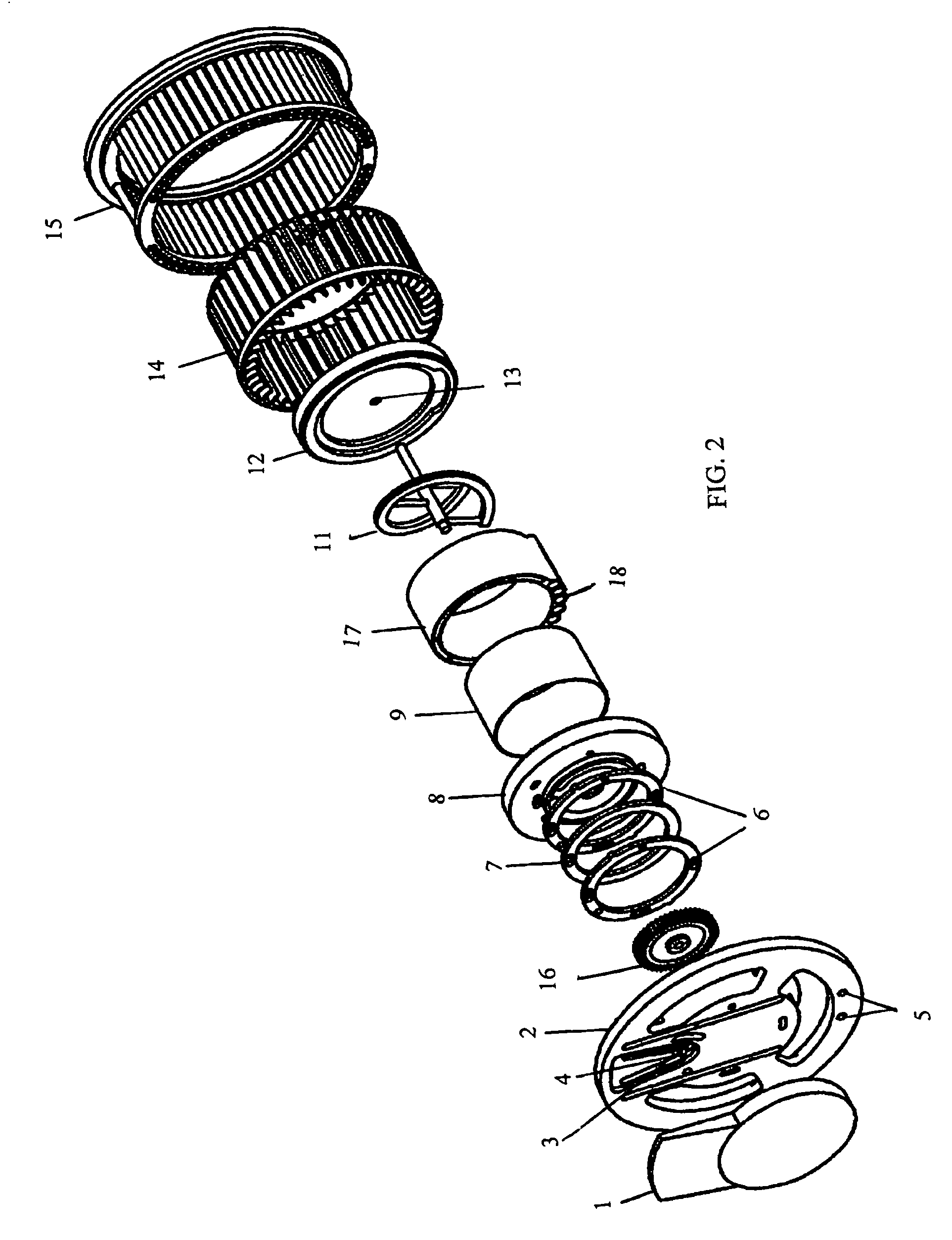

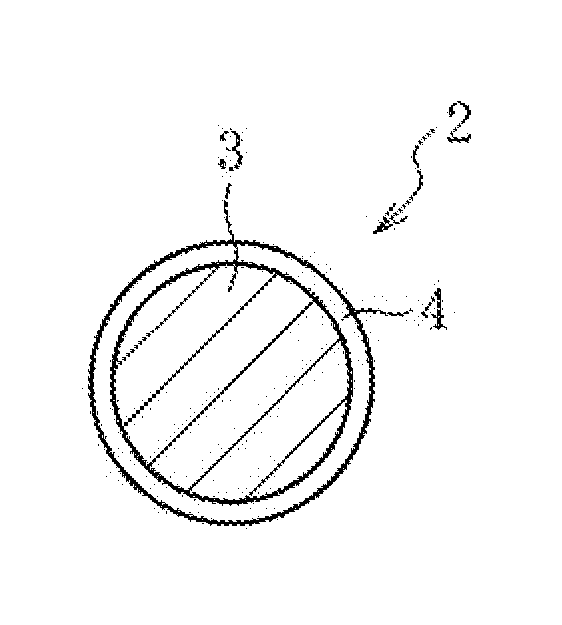

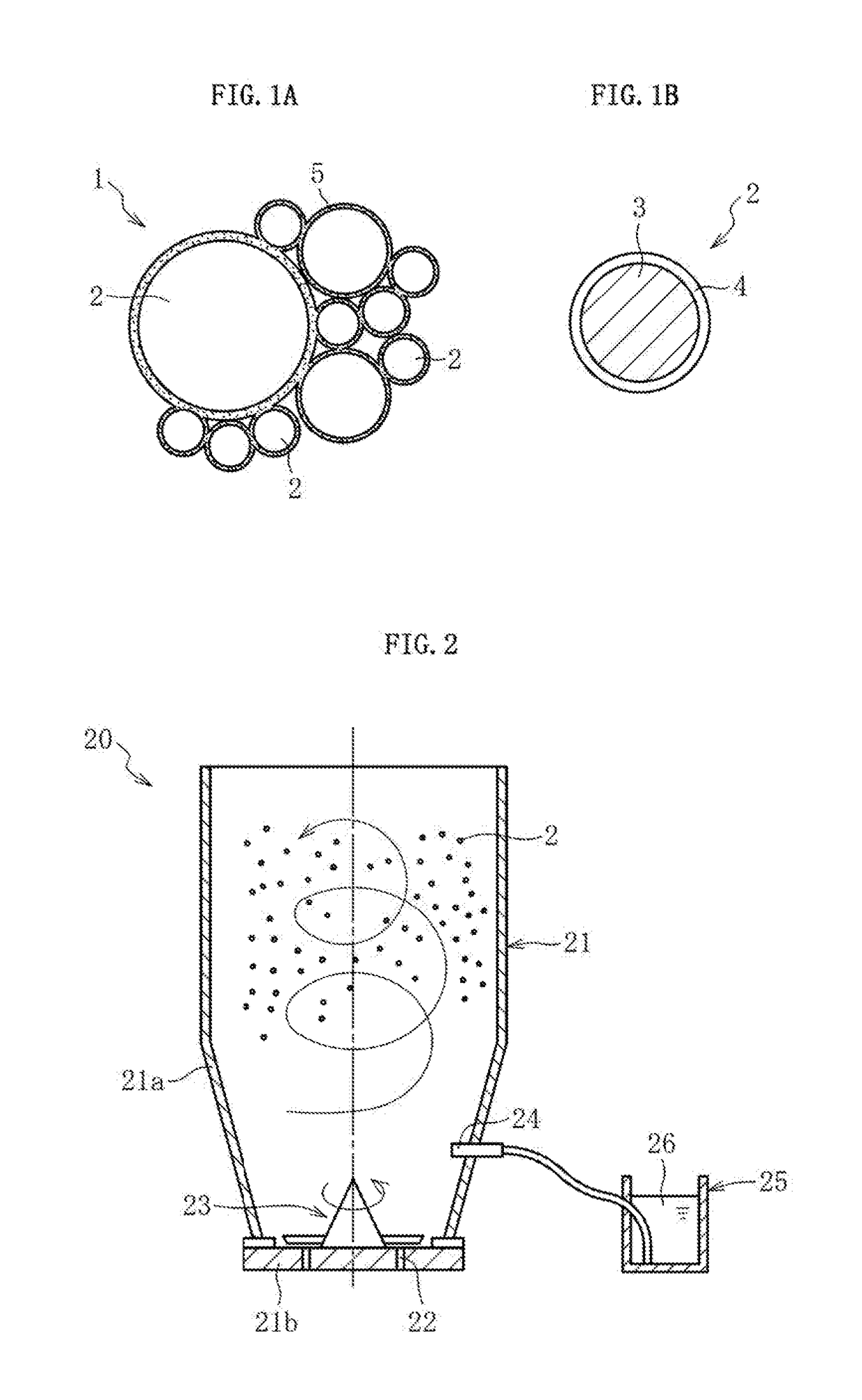

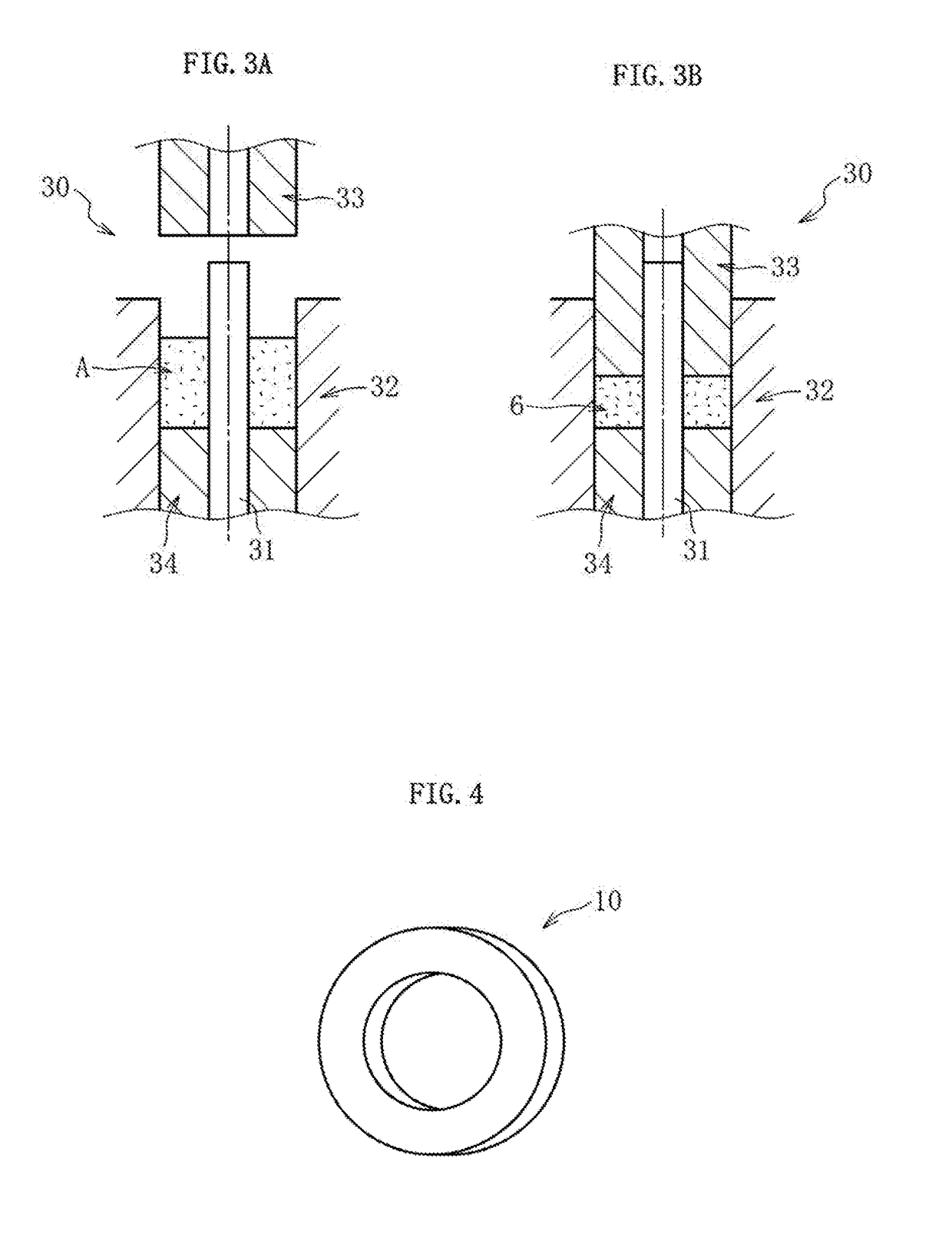

Magnetic core powder, dust core, and method for producing magnetic core powder

InactiveUS20180043431A1High densityEasy to operateTransportation and packagingMetal-working apparatusAqueous solutionViscosity

Provided is a powder (A) for a magnetic core for producing a powder magnetic core, the powder (A) for a magnetic core including: as a main component a granulated powder (1) obtained by granulating iron-based amorphous powder having been subjected to insulation treatment and having a particle size distribution falling within a range of from 1 μm to 200 μm; and glass powder having a softening point lower than a temperature of the annealing treatment. The granulated powder (1) is obtained by binding particles (2) of magnetic powder each formed of a particle (3) of the iron-based amorphous powder and an insulating coating (4) configured to coat the surface of the particle (3) to each other through use of a PVA aqueous solution having a viscosity of from 3 mPa·s to 25 mPa·s.

Owner:NTN CORP

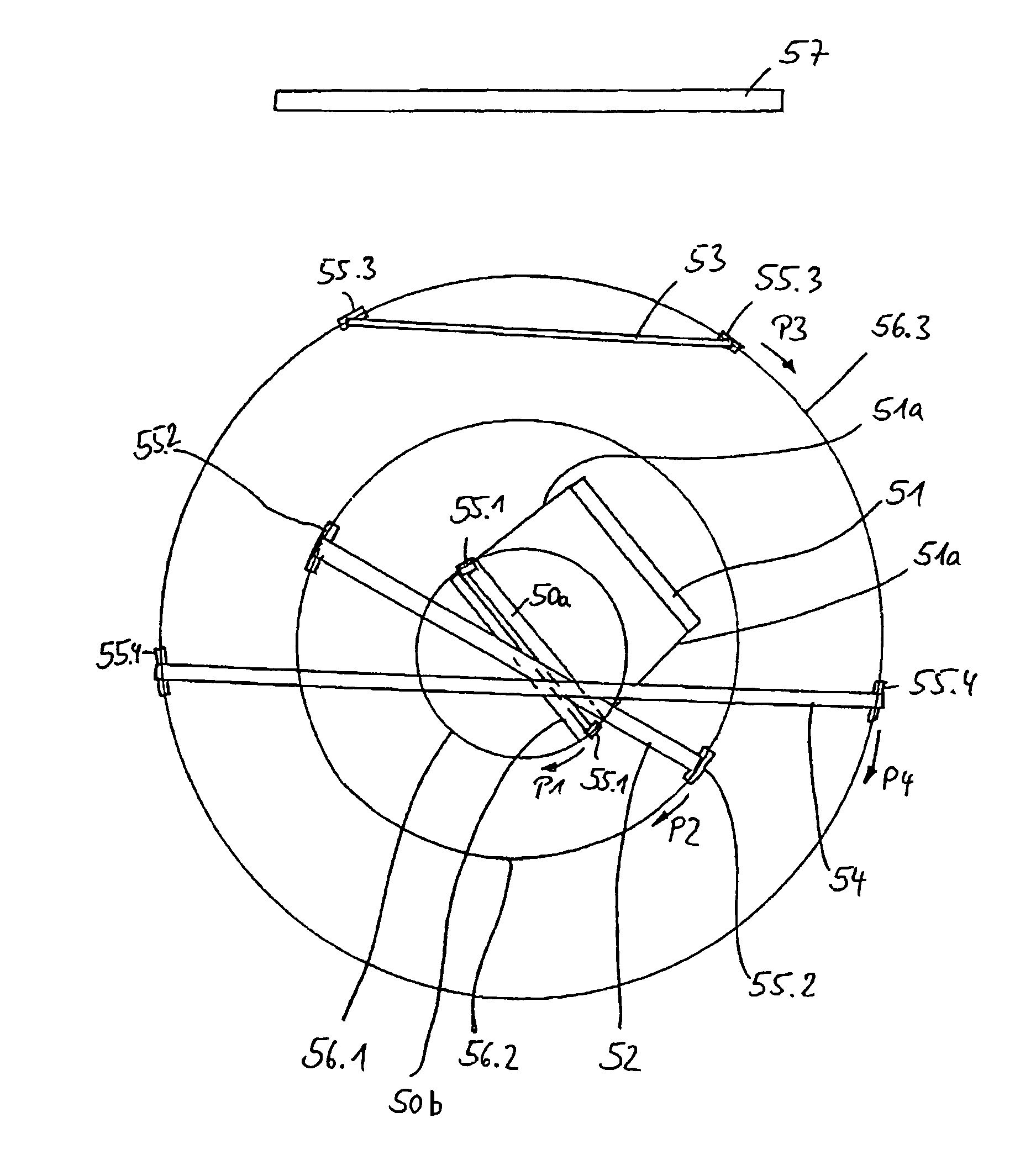

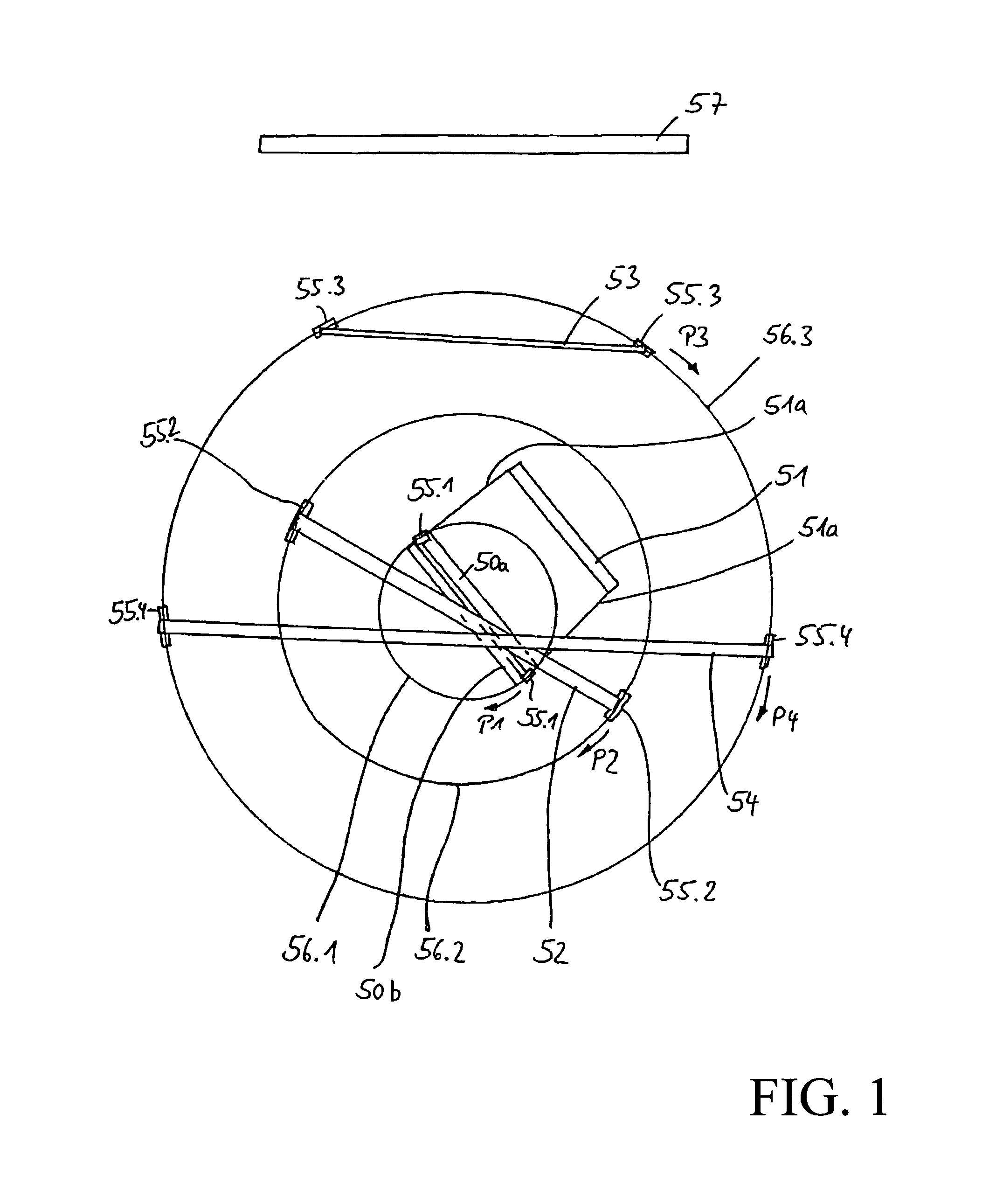

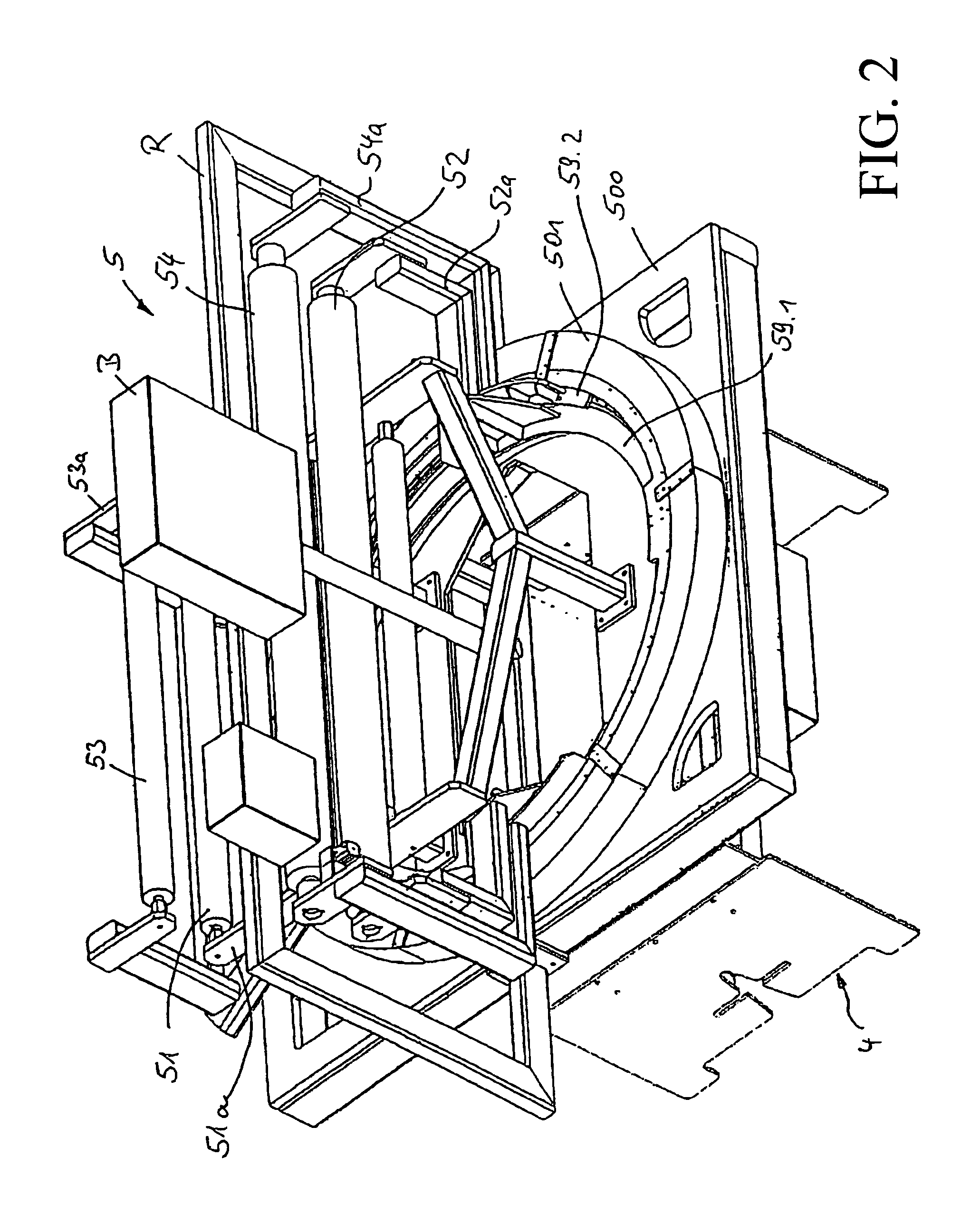

Turning bar draw-off device for a tubular film extrusion installation

InactiveUS7445443B2Easy constructionProduced moreConfectioneryCamera film strip handlingEngineeringMechanical engineering

A turning bar draw-off device for a tubular film extrusion installation, with a plurality of turning bars which can be rotatingly driven around a common axis of rotation or in reverse by rotary drive mechanisms. For the rotating or reversing guidance of the turning bars around the axis of rotation, the ends of each turning bar are connected with guide carriages, which are guided on guide rails arranged in a circle.

Owner:REIFENHAUSER GMBH & CO MASCHFAB

Actuating device for a friction clutch device, possibly a dual or multiple friction clutch device

An actuating device for a friction clutch device installed in the drive train of a motor vehicle introduces actuating forces, especially clutch-engaging or clutch-releasing forces, to the friction clutch device to actuate at least one friction clutch of the friction clutch device in the engaging or releasing direction. At least one actuating element assigned to a friction clutch can be shifted axially relative to at least one support element, which is essentially fixed in the axial direction, to exert the actuating forces. The actuating element belongs to an actuator assigned to the clutch or can be shifted axially relative to the support element by the intermediate action of an actuator assigned to the clutch. The actuating element and the support element engage with each other in such a way that a rotational movement of the actuating element relative to the nonrotatably supported support element, this movement being imparted by the intermediate action of the actuator, is converted to an axial translational movement of the actuating element relative to the axially supported support element.

Owner:ZF SACHS AG

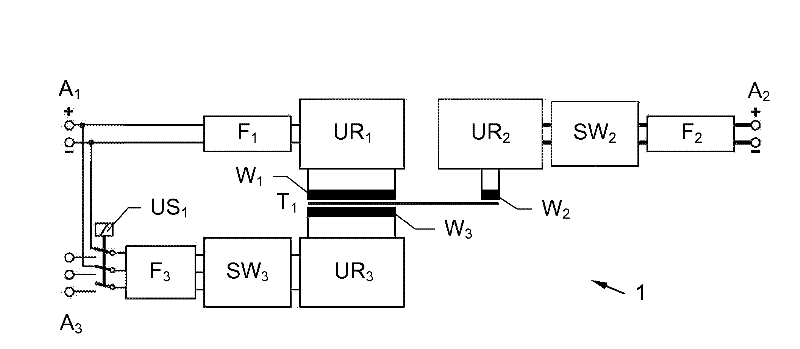

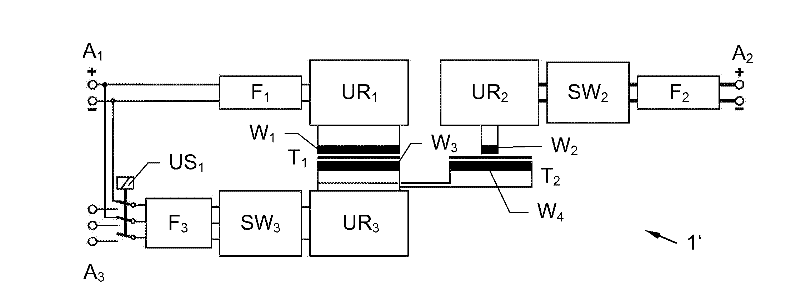

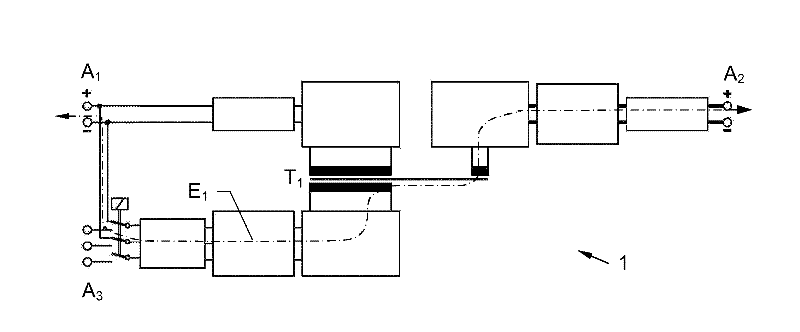

Circuit arrangement for power distribution in a motor vehicle

InactiveCN102458912AReduce lossAchieve adaptationCharging stationsRailway vehiclesConductor CoilElectrical and Electronics engineering

Owner:BRUSA ELECTRONICS AG

Electric arc furnace vacuum magnesium smelting system and magnesium smelting method thereof

The invention discloses an electric arc furnace vacuum magnesium smelting system. The electric arc furnace vacuum magnesium smelting system is characterized by comprising a grinding system, a preheating-decomposition system, a calcination system, a secondary heating system, a vacuum reaction system and a condensate collection system which are sequentially connected with one another. A magnesium smelting method of the electric arc furnace vacuum magnesium smelting system comprises the following stages: preliminary preparation; electric arc furnace vacuum magnesium smelting; and startup and shutdown after reaction completion. The electric arc furnace vacuum magnesium smelting system and the magnesium smelting method disclosed by the invention have the advantages that magnesium-containing powder obtained after grinding, decomposition and heating is subjected to vacuum treatment in a molten pool where iron is molten into liquid iron, and then argon gas is injected and high-temperature magnesium powder is sprayed, so that magnesium steam is generated after reduction; after collection and condensation, the magnesium steam turns into liquid magnesium to form rough magnesium; then, a magnesium ingot is cast through refining; the production process is reasonable, compact, matching in equipment, complete in technology, rapid in reaction process, short in time and high in production efficiency; and the production cost is reduced by 1 / 3 or above.

Owner:狄保法

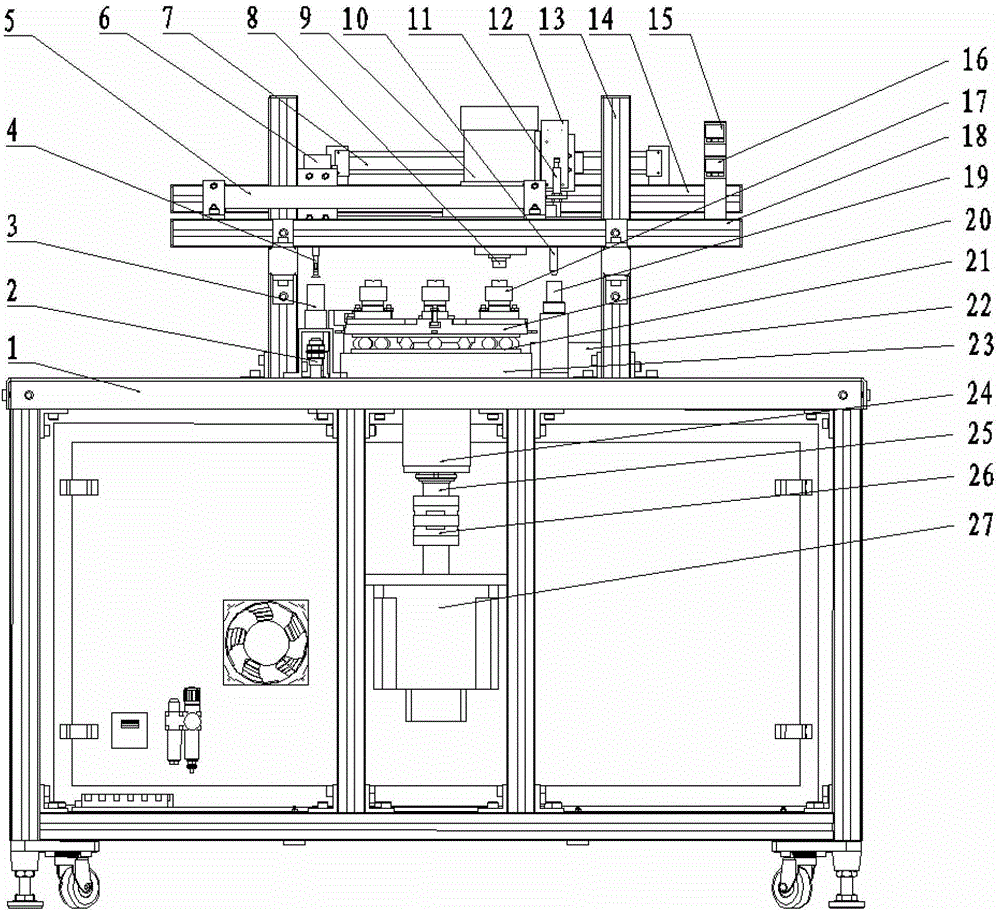

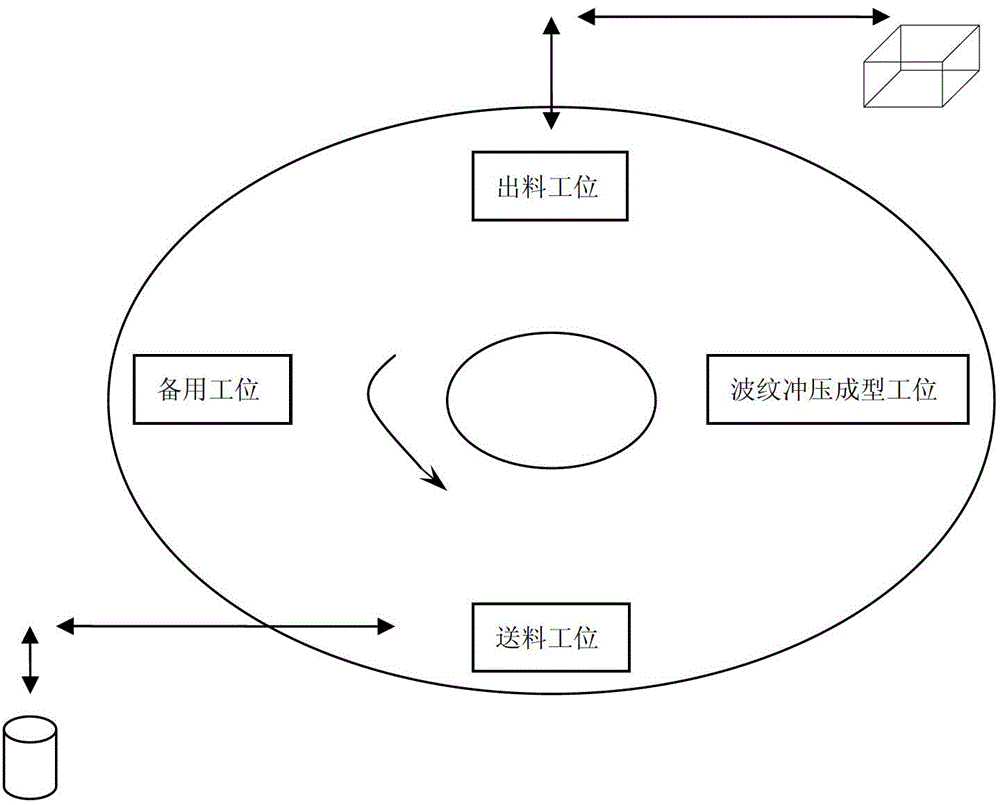

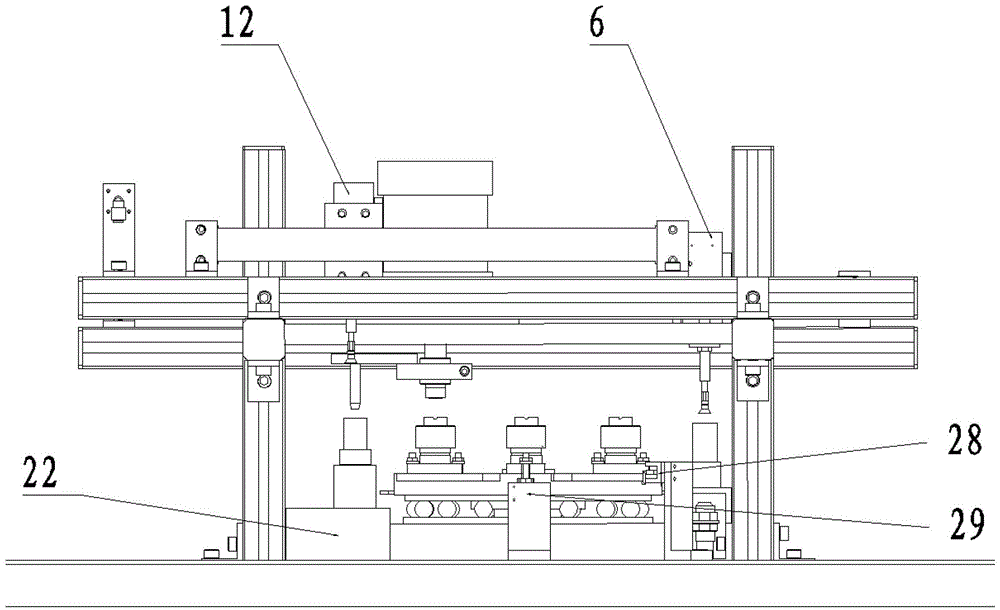

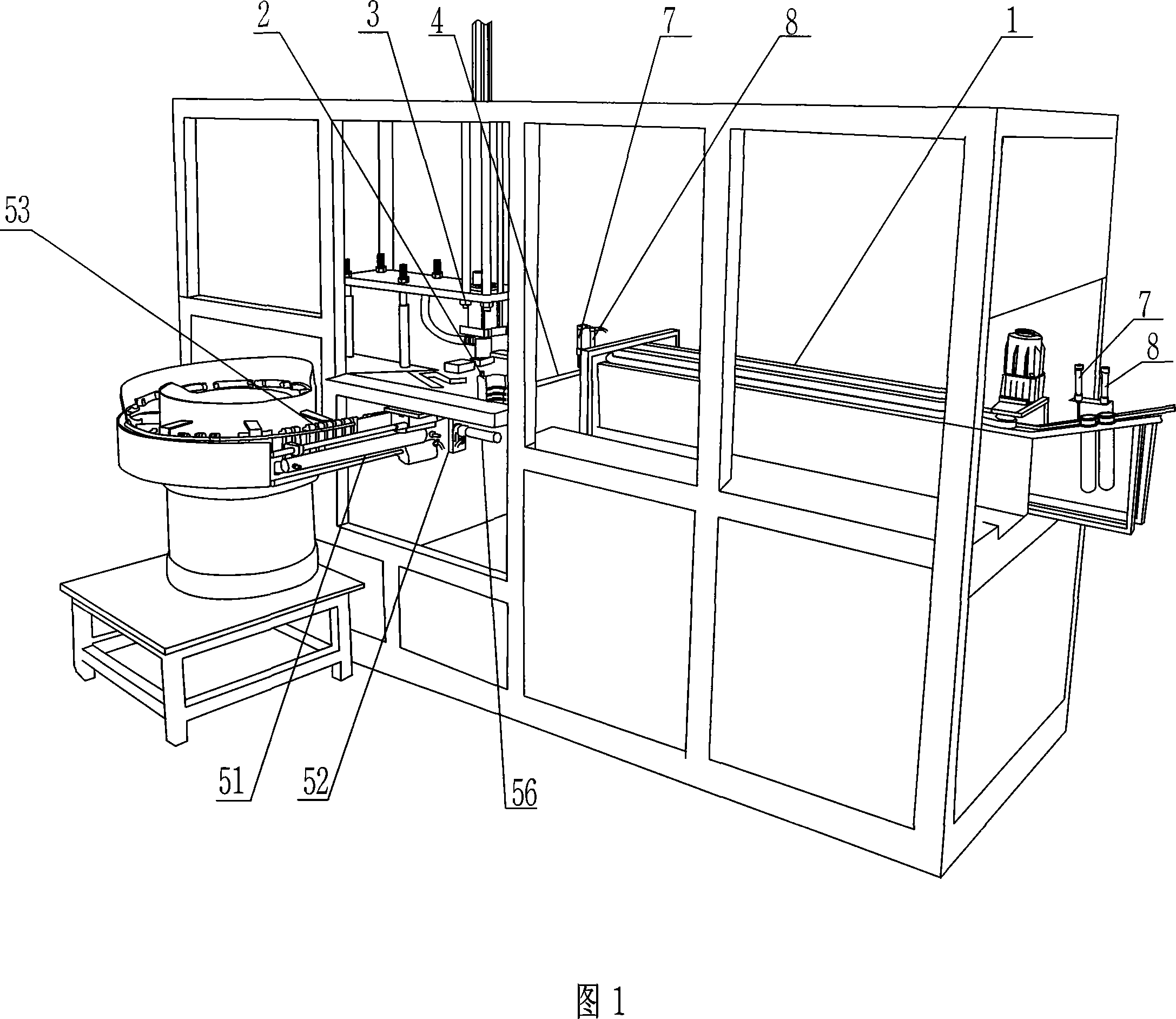

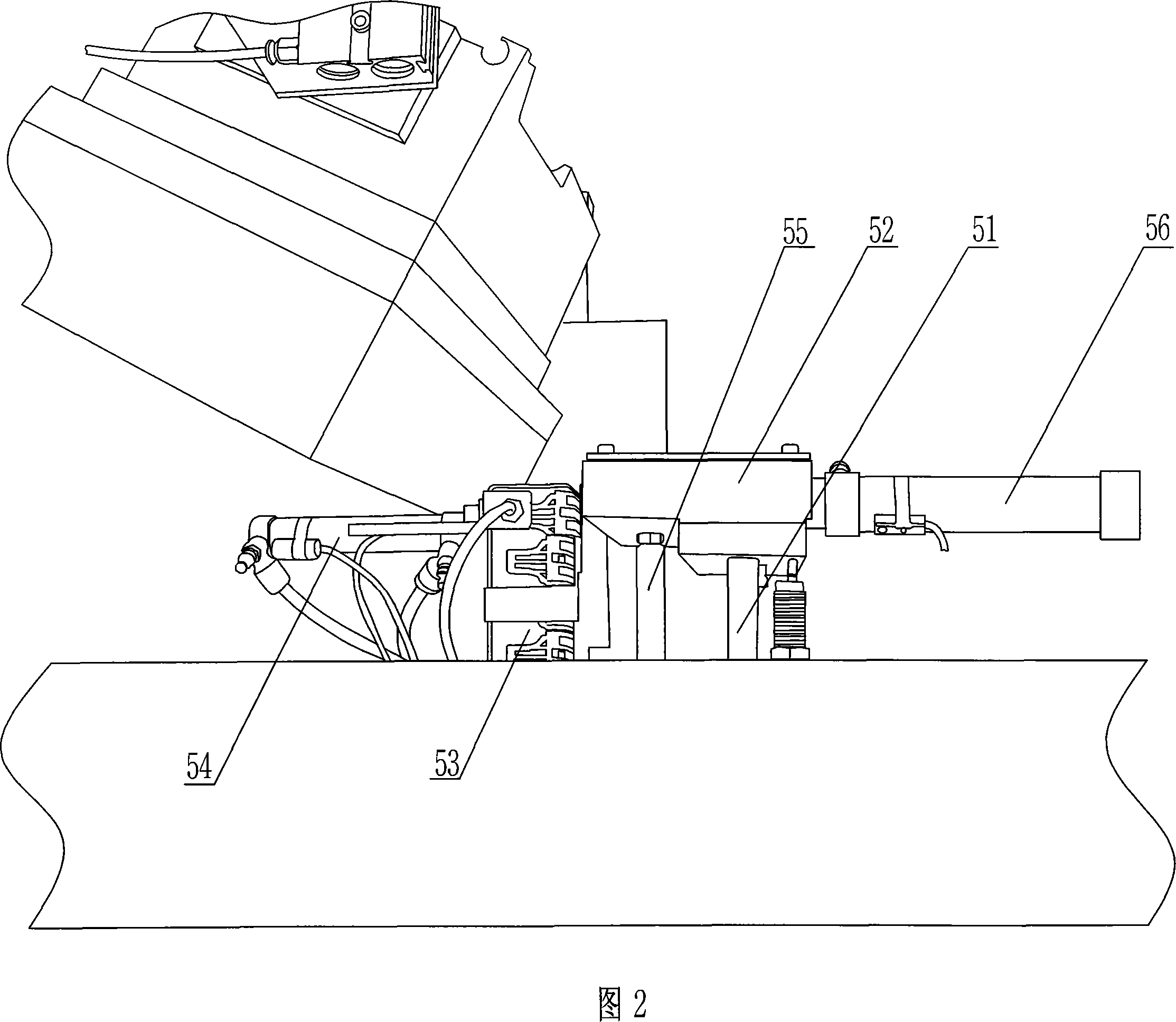

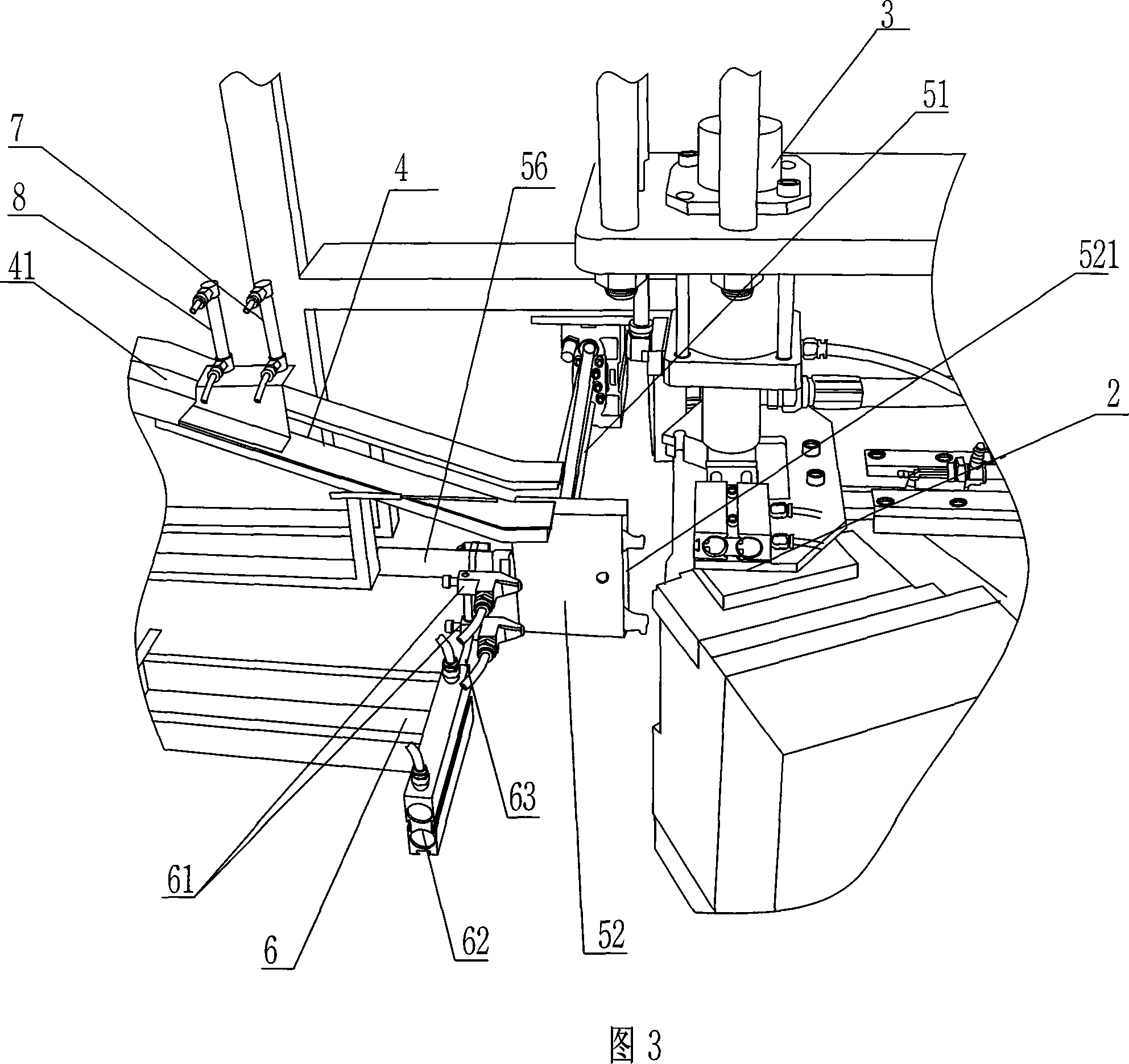

Full-automatic corrugated forming press for isolation diaphragm

InactiveCN102862288AMeet the positioning requirements of handlingSimple structureProgrammable logic controllerEngineering

The invention discloses a full-automatic corrugated forming press for an isolation diaphragm. The full-automatic corrugated forming press for the isolation diaphragm comprises an automatic feed mechanism, a corrugated forming press mechanism, a rotary index table mechanism, an automatic discharge mechanism, an overhead bracket and a control mechanism. According to the full-automatic corrugated forming press for the isolation diaphragm provided by the invention, a PLC (Programmable Logic Controller) is used as a control core, a touch screen is combined to control and operate the whole mechanism, so that the system is stable and simple and convenient to operate. Diaphragms are automatically fed and discharged through a two-dimensional mechanical arm combined with a vacuum chuck, synchronous coordinated operation of three steps: diaphragm feeding, corrugation and discharging is realized by the characteristic of a quarter index rotary table which is precisely positioned through a servo motor adequately, so that the production period of products is shortened, and meanwhile the yield of the products is improved. The full-automatic corrugated forming press for the isolation diaphragm is particularly suitable for automatic production in plants.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing plastic bottle and equipment thereof

The invention relates to a manufacturing method of plastic bottles. Firstly, preforms are arranged inside a preheating device for preheating. Pre-heated preforms are conveyed into matched molds through a conveyance rack. A blow molding device is arranged on the matched molds. The blow molding device is injected into the preforms by using high pressure gas to make plastic bottles. A handle conveyor is arranged beside the conveyance rack, which feeds handles into corresponding clamping positions on the fringe of the cavity of the matched molds automatically. During blowing, the wall of the preforms expands and is bonded to the handles arranged at the fringe of the cavity of the molds. The invention also discloses an equipment to achieve the manufacturing method, which comprises a preheating device, a clamp device and a blow molding device. A preform conveyance rack is arranged between the clamp device and the preheating device. A handle conveyance device is arranged beside the conveyance rack. The invention improves the production efficiency of plastic bottles and is used safely and reliably.

Owner:ZHONGSHAN HUIWEI PLASTIC METAL IND

Magnetic material sensor and detection method employing this sensor, and target material detection sensor and target material detection kit

InactiveUS8852957B2Production compactBioreactor/fermenter combinationsNanomagnetismElectrical resistance and conductancePower flow

The present invention provides an appropriately produced magnetic material sensor having a small size.The magnetic material sensor of this invention includes: a magnetoresistive effect film, formed using magnetic films; a current source, for supplying to the magnetoresistive effect film a current having a magnitude and a direction that can change the magnetization directions of the magnetic films; and a detector, for detecting the resistance of the magnetoresistive effect film.

Owner:CANON KK

Electronic circuit for a blind-spot monitoring display

InactiveUS20170113620A1Solve the lack of spaceFlexible useElectrical apparatusElectroluminescent light sourcesDisplay deviceEngineering

The invention relates to an electronic circuit for a blind-spot monitoring display, having a circuit carrier; a first light source and a second light source mounted to the circuit carrier. A circuit connection is mounted to the circuit carrier, which circuit connection is coupled to the first light source and the second light source. The electronic circuit comprises circuit means which are designed, on the basis of a polarity of a voltage applied to the circuit connection to supply current either to the first light source or to the second light source.

Owner:SMR PATENTS S A R L

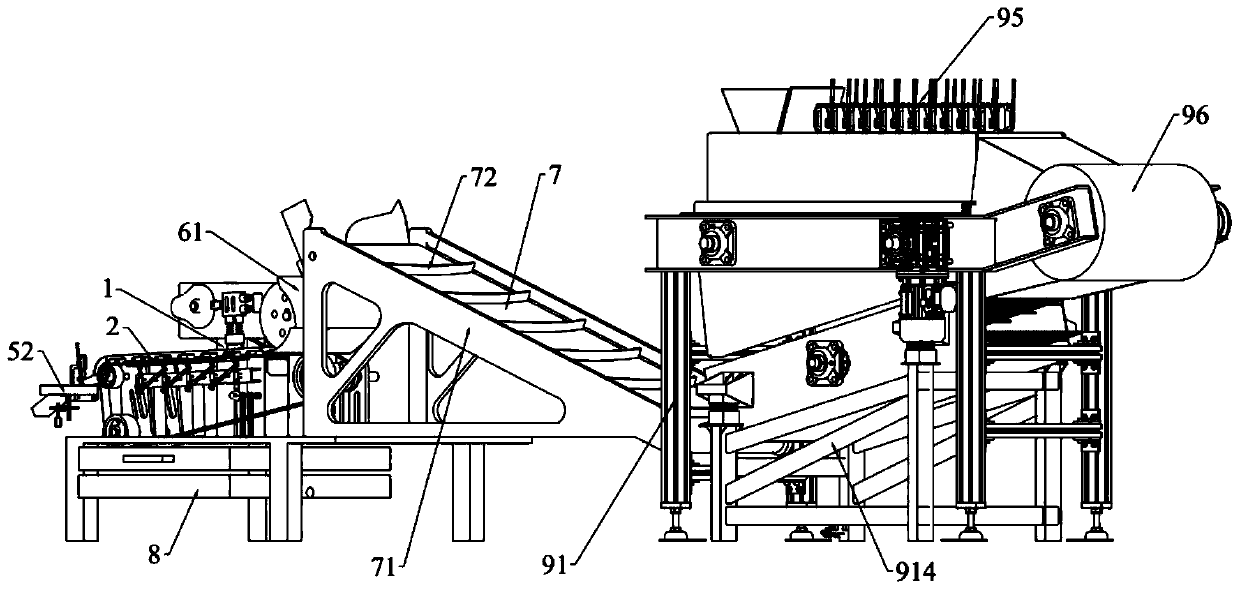

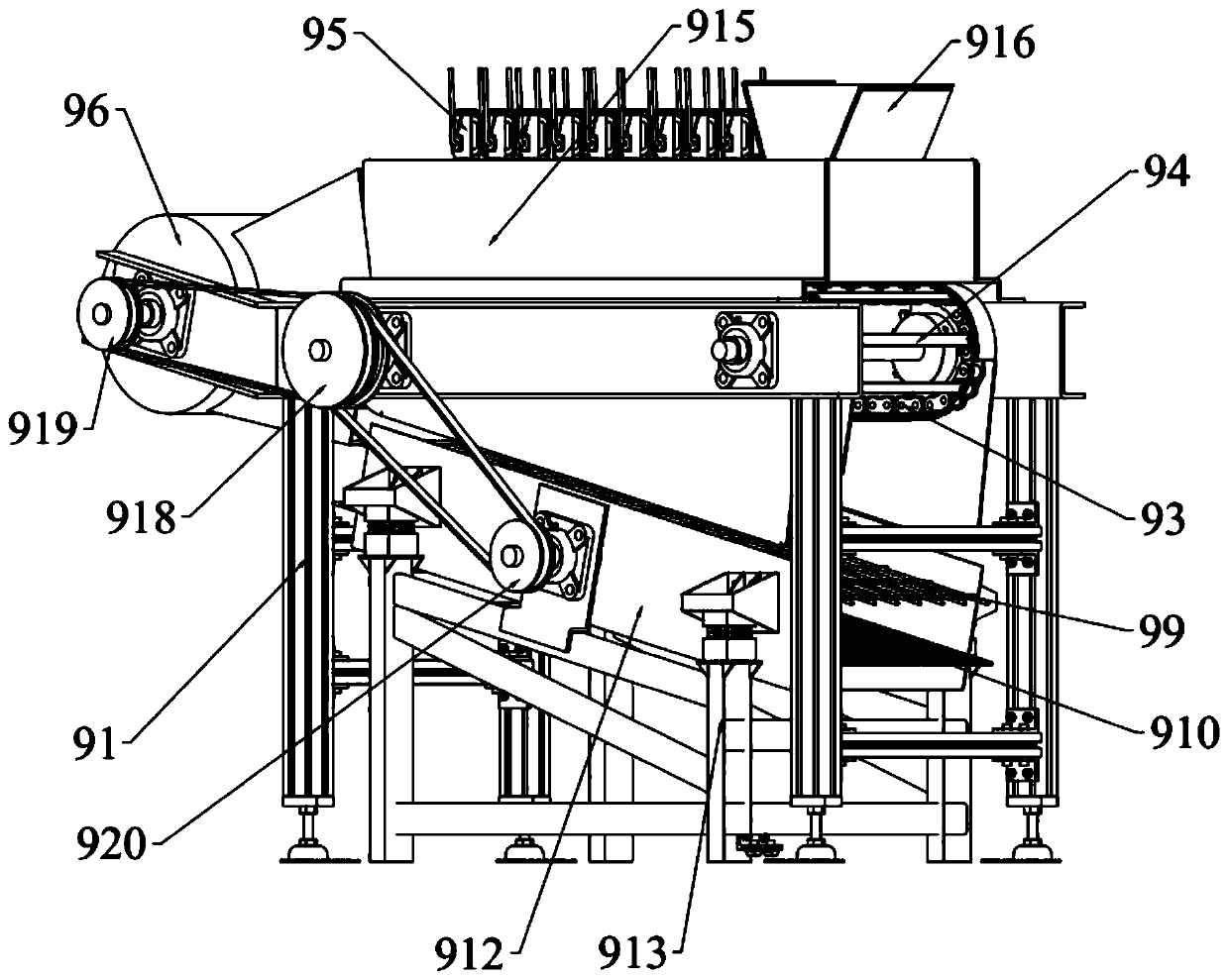

Threshing and husking integrated machine for fresh lotus seeds

The invention discloses a threshing and husking integrated machine for fresh lotus seeds, and relates to the technical field of agricultural machinery, solving the problems that it is difficult to thresh and husk the fresh lotus seeds and to integrate these two steps. The threshing and husking integrated machine is provided with a fresh-lotus-seed threshing device. The fresh-lotus-seed threshing device mainly comprises a fresh-lotus-seedpod fiber breaking mechanism, a lotus seed and lotus seedpod separating mechanism and a lotus seed and debris separating mechanism, and is used to thresh the fresh lotus seeds. The threshing and husking integrated machine is provided with a lotus seed husking device. The lotus seed husking device mainly comprises a lotus seed husking conveyor belt, a lotusseed husk cutting mechanism and a lotus seed husk squeezing mechanism, and is used to husk the lotus seeds. The threshing and husking integrated machine for the fresh lotus seeds has the advantages that the lotus seeds are threshed and husked through the fresh-lotus-seed threshing device and the lotus seed husking device; the whole process can well protect the lotus seeds without damage to the lotus seeds; the machine can adapt to the lotus seeds different in size during husking, the efficiency is high, and the effect is good.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Rear view device assemblies and circuits

ActiveUS10806002B2Production compactElectrical apparatusElectroluminescent light sourcesInformation controlSoftware engineering

Owner:SMR PATENTS S A R L

Method for preparing low-cost oriented silicon steel by utilization of continuous annealing

The invention provides a method for preparing low-cost oriented silicon steel by utilization of continuous annealing, wherein the technological line comprises the following steps of smelting and casting, hot rolling, primary cold rolling, intermediate annealing, secondary cold rolling and continuous annealing. According to the method provided by the invention, a normalizing working procedure is eliminated on the premise of heating the oriented silicon steel at low temperature, and meanwhile the slow heating and high-temperature long-time annealing in the traditional technology is replaced by the continuous annealing, so that the production period is greatly reduced, and the purposes of reducing cost and improving efficiency are achieved. The magnetic performance of a finally prepared product is much higher than that of traditional non-oriented silicon steel, and is slightly lower than that of commercial oriented silicon steel. In some fields that the oriented silicon steel and the non-oriented silicon steel can be used in common, a better effect can be realized.

Owner:UNIV OF SCI & TECH BEIJING

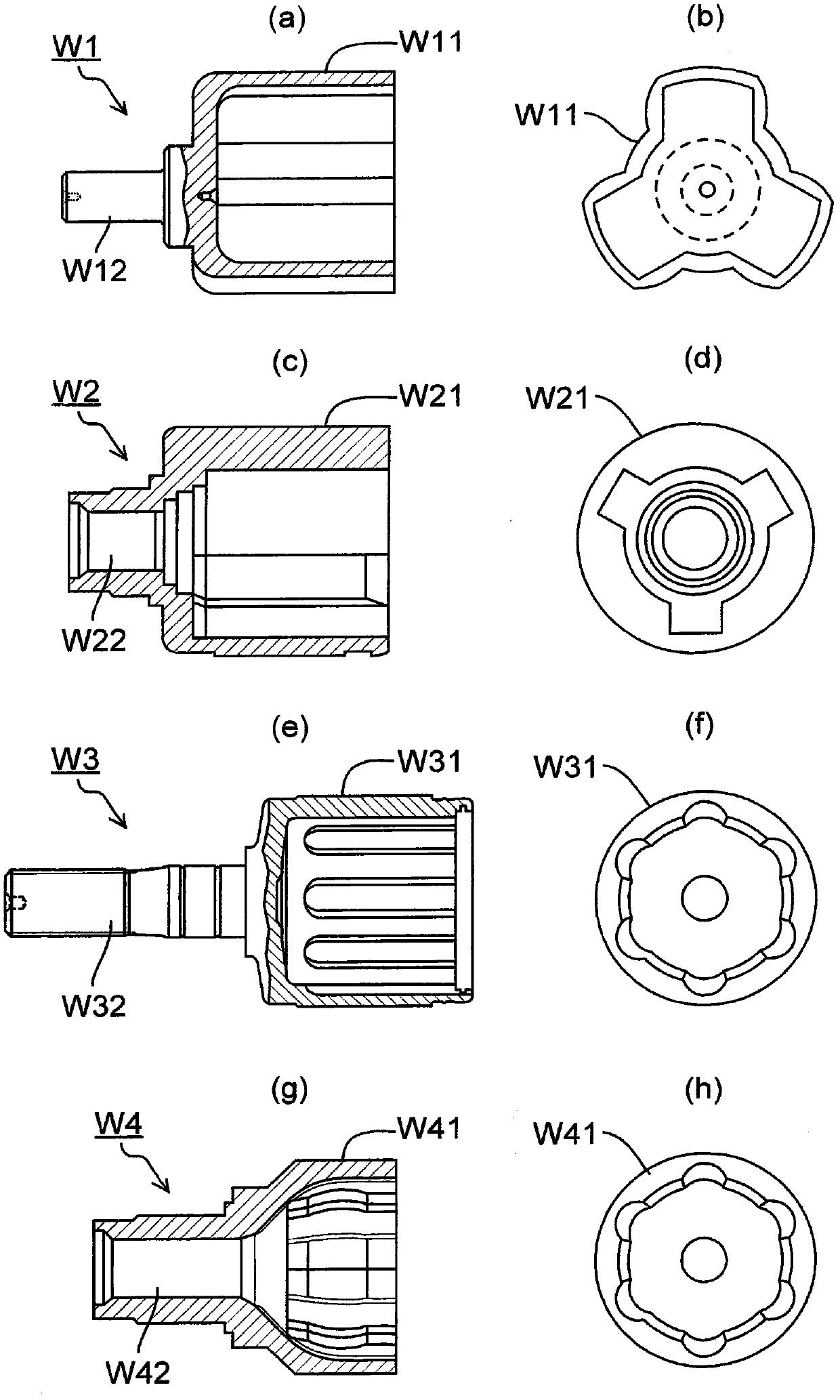

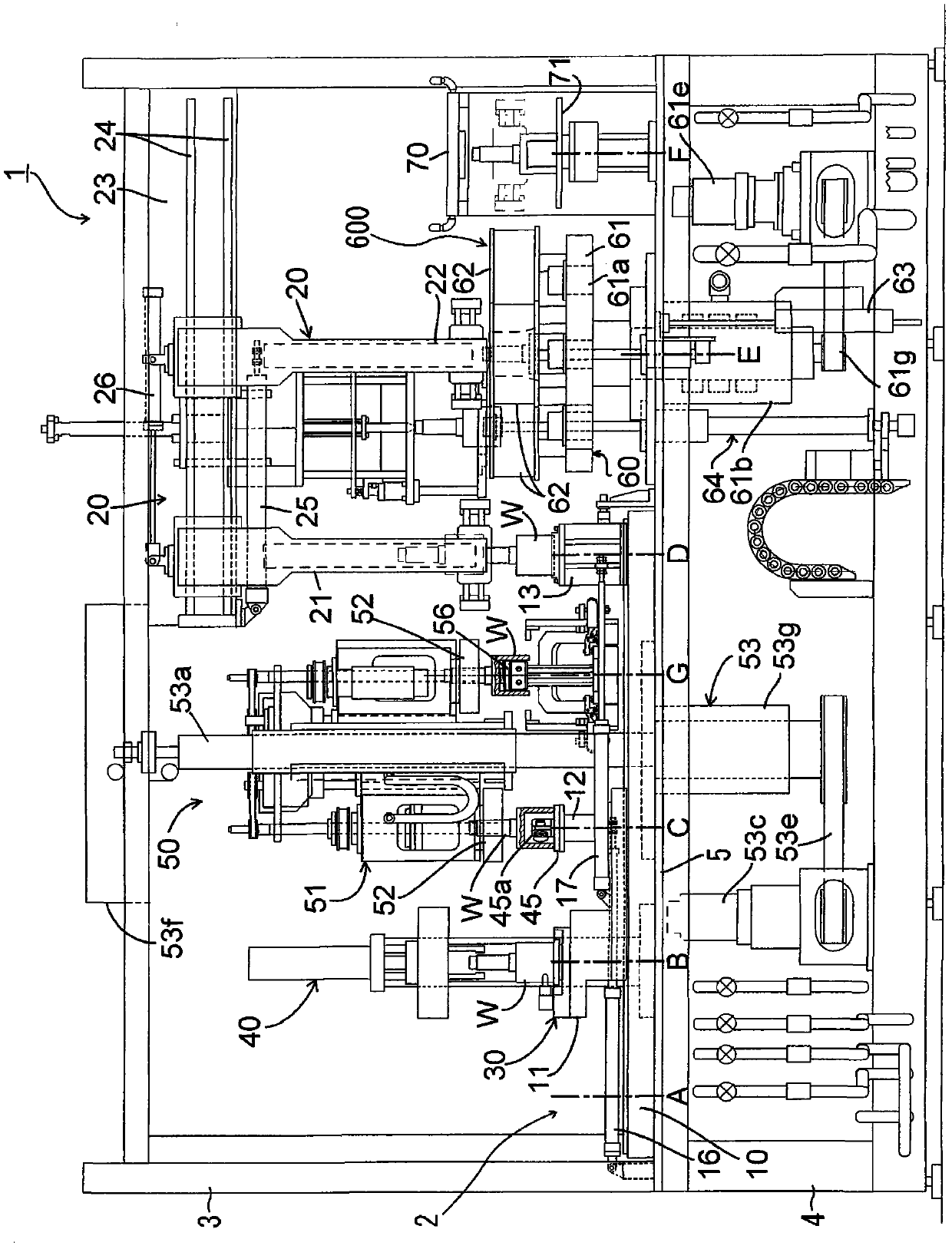

Heat processing apparatus for workpiece

ActiveCN102345004AProduction compactRapid productionIncreasing energy efficiencyFurnace typesProduction lineMaterials science

The invention provides a heat processing apparatus used for the heat treatment of a workpiece, wherein the rod shaft part of the upper portion of a workpiece or the cup-shaped body of the lower portion of the workpiece is subjected to heat treatment by the heat processing apparatus. The heat processing apparatus comprises a temporary phase determination mechanism, a formal phase determination mechanism, a workpiece lower portion heat treatment part and a workpiece upper portion heat treatment part. The heat processing apparatus also comprises one ore more than two of the following members: a desk type conveying mechanism and a suspension bracket type conveying mechanism used for confirming the position of a workpiece or a centering abutting member; a processing component symmetrically equipped with rotary clamping mechanisms with respect to a rotary shaft; a heat treatment head for fixing a fixed base at a predetermined position and connected with a workpiece cooling water pathway; a heating coil for connecting a powered terminal and a power supply terminal and connected with the workpiece cooling water pathway; a workpiece upper portion heating unit for fixing the heating coil of the rod shaft part and the heating coil of the cylinder shaft part at different layers; a rotary cooling device for cooling a workpiece during rotation; and a locking construction for preventing the driving of a heat treatment production line when the locking of an open-close door is unlocked.

Owner:NETUREN CO LTD

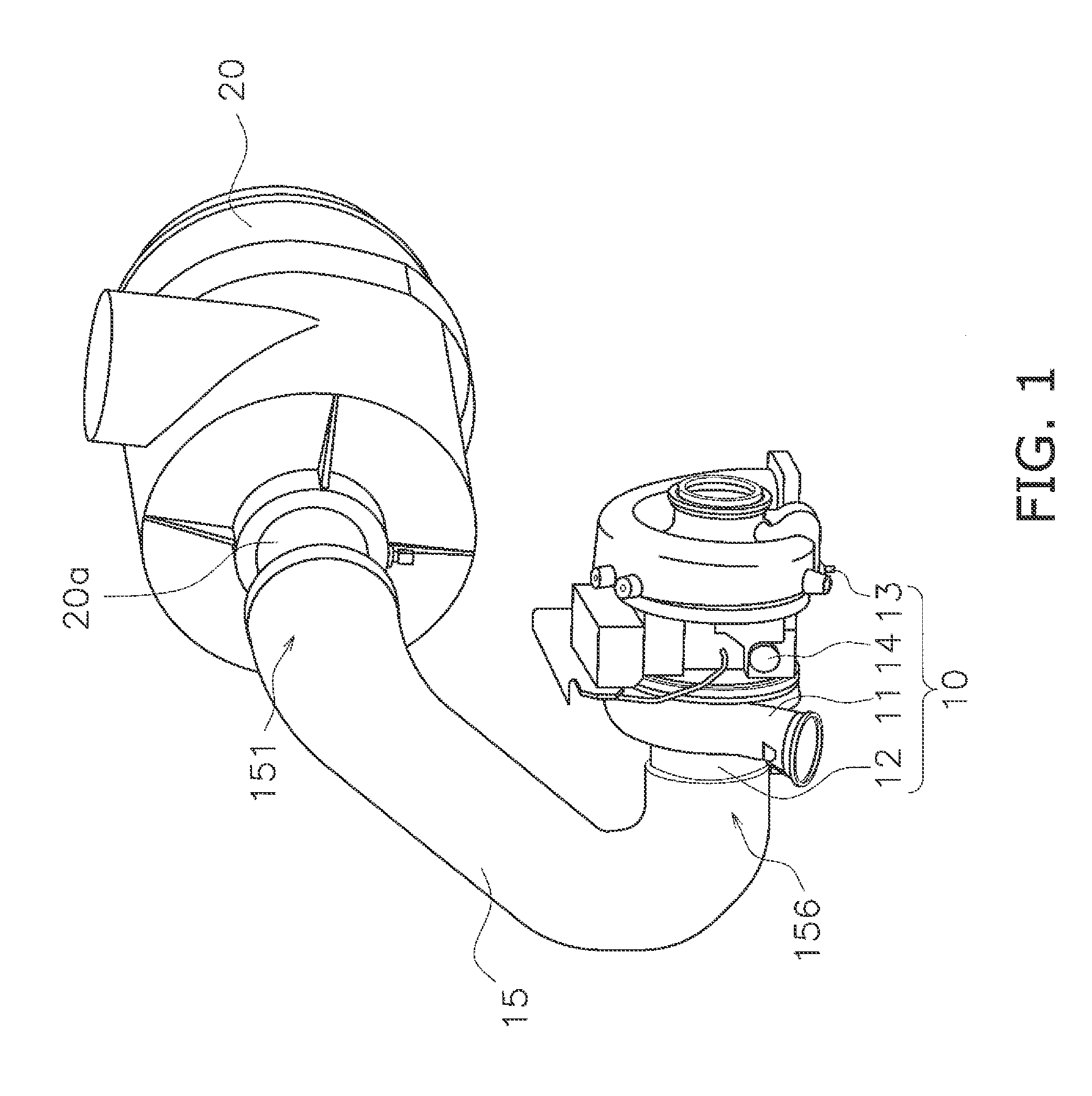

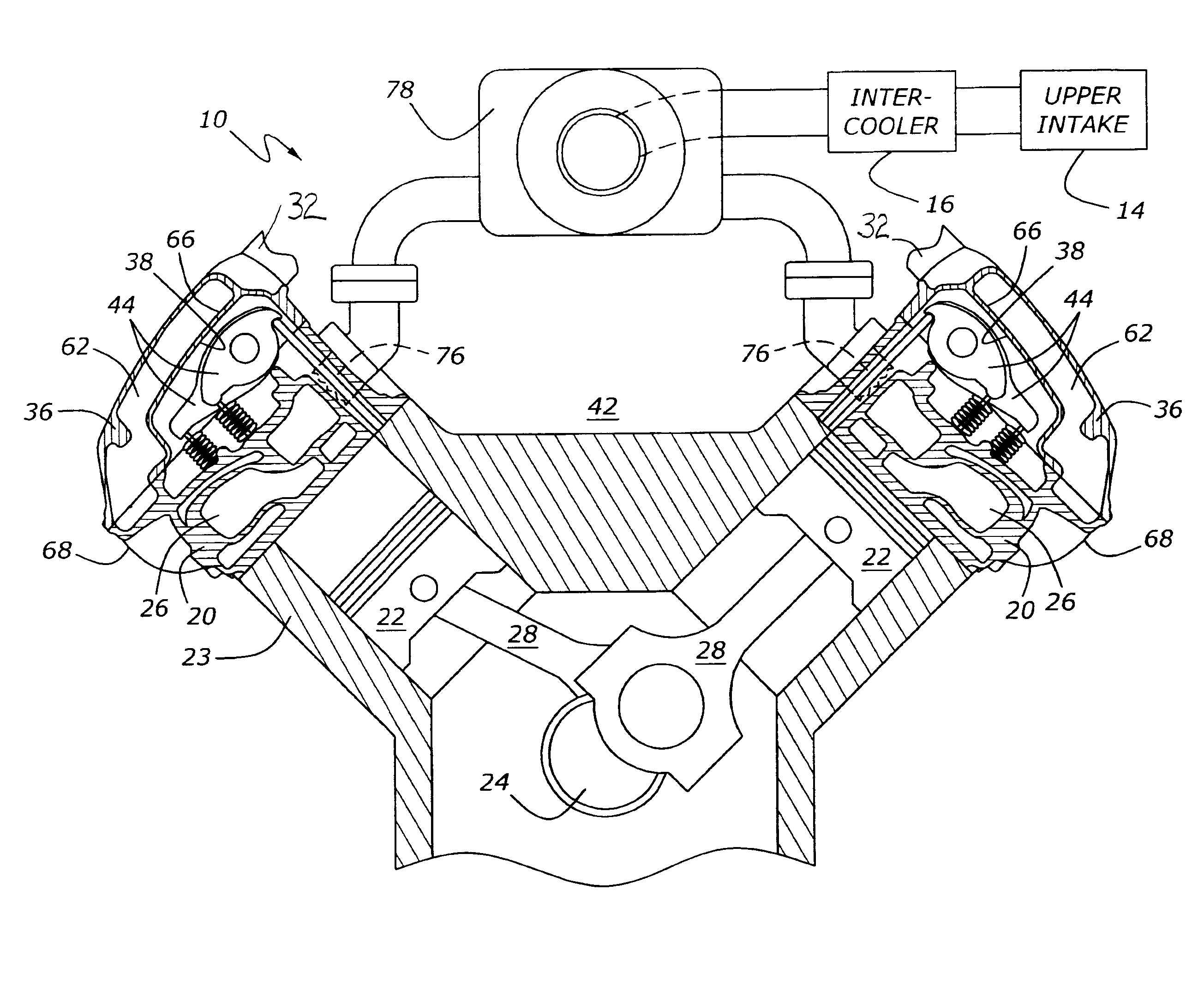

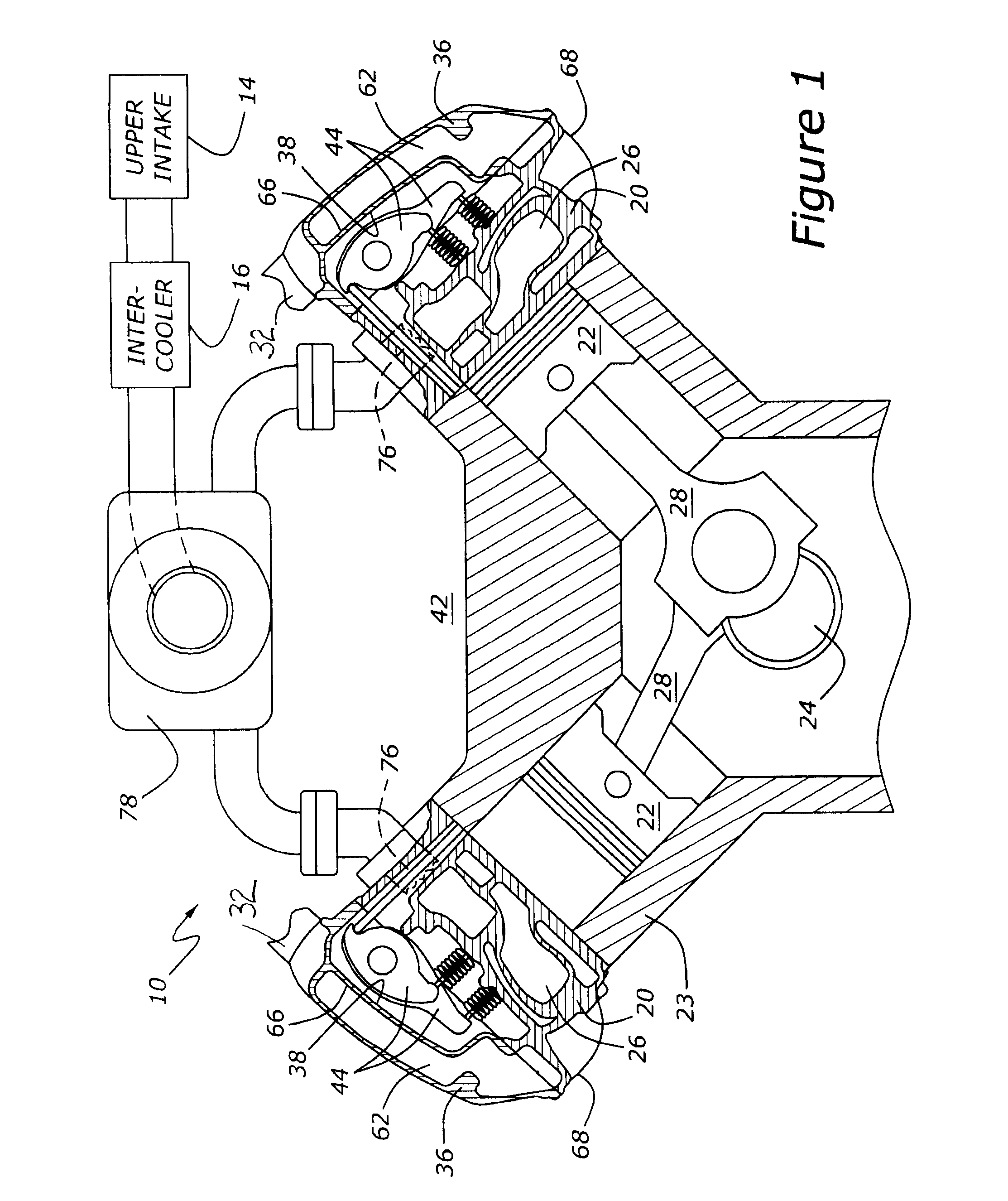

Induction system for internal combustion engine

ActiveUS20100065003A1Improve efficiencyProduction compactInternal combustion piston enginesCylinder headsCylinder headTurbocharger

An induction system for an internal combustion engine includes an upper intake for receiving air from a supply, such as a turbocharger, and a lower intake which combines a cylinder valve actuator cover, a plenum for receiving air from the upper intake, and a number of intake runners which extend across, an integrally with, the cylinder valve actuator cover to cylinder head intake ports which are configured at outboard sides of the engine cylinder head.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com